By Jean Huon

At the end of the 19th century, tests had taken place in France in order to equip the Army with a semi- automatic rifle. Several prototypes were constructed and some of them were put in test by military units. In 1905, a special program was defined and in 1913, the Meunier A-6 rifle, which fired a 7mm rimless cartridge, was ready to be adopted. But the imminence of a large scale conflict made the project fall through.

At the beginning of the World War I, some officers expressed their regret to not be able to equip the troops with a semiautomatic rifle. But headquarters estimated that such a realization would be too long and too expensive for a country in a war and that it had other priorities; like the realization of a light machine gun.

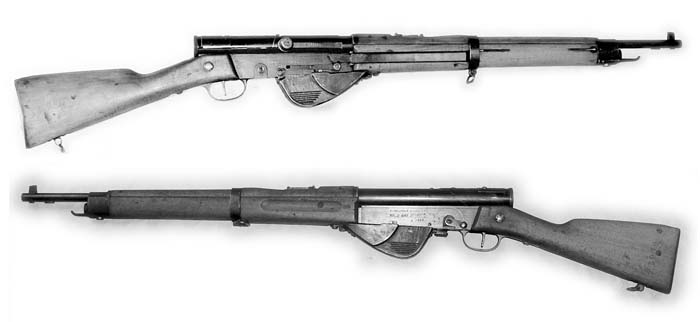

This did not prevent technicians and engineers from carrying out research in this field and to propose a semiautomatic rifle which they presented: like the modification of the rifle Lebel Modèle 1886-93. In fact, this modified rifle only used several parts of the Lebel that included the stock, forearm, tube magazine converted to gas cylinder, sling swivel and butt plate. The barrel was not from the M1886-93 but from the M1916 rifle, as was the rear sight and bayonet.

The rifle worked with gas action and the piston was placed in the tube magazine in the forearm. The breech and store were derived from those of the many prototypes developed before the war.

Developed by Ribeyrolles, Sutter (Weapons Controller) and colonel Chauchat (Chief-Inspector of Small Arms factories) this rifle had, compared to its predecessors, the advantage of firing the 8mm Lebel cartridge. The weapon was ready by 1915, but its development was delayed due to difficulties for adjustment and resistance of several parts.

While waiting for the new rifle to be ready, the plans of the Meunier rifle were revived and the rifle was manufactured in 1916. 1,013 specimens were made and 843 were sent to the Army while waiting for a model in 8mm to be available.

Finally, the R.S.C rifle was adopted in May 1916 and designated Automatic Rifle Model 1917 by a note of December 1916 recorded under No. 27001/3. But its manufacture encountered technical requirements that were not possible to solve in the immediate future. This is why the small number of Meunier A6 rifles had been issued while waiting.

The production of the automatic rifle R.S.C began on April 1, 1917 and was made by several factories specializing in the production of the light weapons:

- Manufacture Nationale d’Armes de Tulle made the receiver, barrel and trigger guard,

- Manufacture Nationale d’Armes de Châtellerault made the trigger housing,

- Manufacture Nationale d’Armes de Saint-Etienne manufactured the bolt, the bolt carrier, the piston, the gas cylinder, stock and also barrels,

- Manufacture d’Armes de Paris (private factory) provided the cocking lever, the rod, feeding mechanism and magazine cover.

The assembly of all these elements was carried out in Saint Etienne (serial number preceded by the letter A). Some weapons – a hundred approximately – were also assembled in Châtellerault (serial number preceded by the letter B). The production series continued for seventeen months, and by September 30, 1918, 85,333 specimens had been manufactured at a rate having reached 5,500 weapons per month.

France was the first country to equip its infantry with a semiautomatic rifle and employ it in combat. In the units equipped with it, the rifle Model 1917 was distributed at a rate of 16 guns per company to platoon leaders and the good shooters. These men were selected for their aptitude for handling the weapons and their knowledge of mechanics because repairs were frequent.

Description

The stock is that of the Model 1886-93 and is assembled to the receiver and trigger housing with two screws. The trigger mechanism includes the trigger guard, trigger-sear and hammer. The spring, made of steel wire, is the same for the trigger and hammer. The receiver is made of a cylindrical element with two lower flat sides and a screwed-plug at the rear. Locking slots are tooled inside the front of the receiver. A bolt catch is screwed on the right side and locks in the lower part of the rod to keep the bolt open in the rear position. This device, rather rustic on the first weapons, was later modified.

The safety lever is located on the left side. Pushed forward (S), it locks the hammer and backwards (F) for firing.

The bolt is made of two pieces. The bolt carrier is assembled with the rod by the cocking lever. The bolt head carries two series of three lugs placed in opposite positions. A helicoid slot tooled at the rear of the breech permits the head to turn for locking. The barrel comes from the Mannlicher-Berthier M1916 rifle, because when manufacturing of the M1917 rifle began, production of the Lebel rifle stopped. The barrel is bored 8mm diameter with four right lands and grooves, one turn in 240 mm (9.5 inches). At 140 mm (5.5 inches) from the muzzle is a gas port with an adjustable screw. The gas cylinder is inside the forearm inside the tube magazine. At the rear, the piston has an external flat rod on the right side. This rod is prolonged by a flap which covers the ejection port.

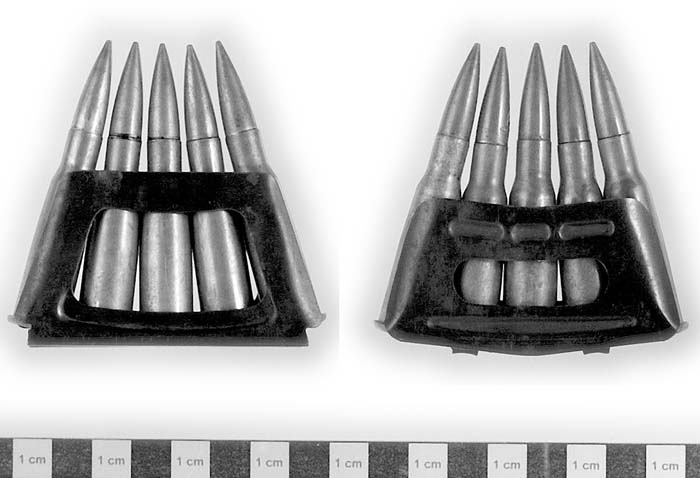

The magazine is fed by a clip of the Mannlicher type. This clip is not interchangeable with that of the Model 1916 rifle because it is flat-bottomed and does not comprise a locking device. The feeding device is made of one follower, two links and one cam. These elements go upward by a tube-push rod which is pressed on the piston. A buckled plate casing protects the charger and the mechanism and the magazine is covered by a sheet metal box.

The sights also came from the rifle Modèle 1916, with a triangular front sight and a rear sight with steps (400 to 800 meters) and leaf (900 to 2400 meters). Some weapons are fitted with phosphorescent pellets on the sights for night shooting.

The forearm is maintained with the barrel by a lower band holding a sling swivel and an upper band with a straight stacking rod. A handguard covers a part of the barrel.

On the left side of the frame it is possible to see the following marks:

MANUFACTURES NATIONALES

MA T MLE 1917

Or:

MANUFACTURES NATIONALES

MA S 1918 MLE 1917

Before Shooting

Place the gun down on its left side, set the safety on S (safe) and open the magazine cover. Pull downward on the follower until the feeding system locks and the cam comes to the main link. Introduce a loaded clip and close the magazine cover. Place the safety on the F (fire) position. Pull the cocking lever to the rear and let go. The hammer is cocked and retained by the sear and a cartridge is pushed in the chamber. The bolt head then turns and locks the bolt. Adjust the rear sight. The gun is now ready to fire.

Operation

As the shooter squeezes the trigger, the sear moves and permits the hammer to push the firing pin. When the bullet passes over the gas port, part of gas is bled into the cylinder and pushes the piston backwards. It moves back by compressing the recoil spring and involves the rod. Under the action of the helicoid slot, the head of the breech carries out a rotation of 90 degrees and the bolt is unlocked. The breech then moves back extracting the empty case. The hammer is retained by a hook of the trigger until the trigger is squeezed. When the shooter releases the trigger, the hammer is retained by the sear. This device, slightly altered, was also used on other semiautomatic or automatic rifles such as the MAS 49 or the U.S. M16. Under the combined action of the cam and rods, the follower pushes the ammunition and presents the next cartridge for chambering. The recoil spring involves the moving parts (piston, rod and bolt). A new cartridge is introduced into the chamber and during closing the bolt head is rotated and locked.

Disassembly/Reassembly

This operation requires a screwdriver:

- inspect the gun and be sure it is not loaded,

- move the bolt to the rear, the hammer has to be retained by the sear,

- take off the handguard (retained by a spring with the barrel),

- take off the cocking lever,

- remove the rod,

- unscrew the receiver plug,

- extract the bolt,

- separate the bolt head.

Other parts such as the trigger mechanism, feeding device and piston have to be disassembled by a gunsmith. Reassembly is in reverse order.

Accessories

Each user of rifle Model 1917 is equipped with:

- A sheath made of impermeable fabric intended to cover the mechanism.

- A muzzle cover.

- A bayonet. It is the sword-bayonet Model 1886/93/15. Overall length is 635 mm (25 in.) with 518 mm blade. The handle is made of brass, cupronickel alloy or blued steel. The cross guard, made of steel, supports the ring and the locking button and has no extension. Cruciform blade is polished steel. Sleeve is of blued sheet steel ending with a ball.

- A cleaning kit containing an oil can, a hook-ejector-screwdriver, pin drift, brush, wooden scraper, cleaning string and a rag. Moreover, it was envisaged to allot a third of rod to each man.

- Tools and replacements. Each company was equipped with a special case containing the necessary tools to ensure the complete disassembly of the weapon; as well as batch of spare parts (ejectors, extractors, strikers, screws, pins, springs) allowing a gunsmith to repair the weapons on the field. We did not find any trace of the possible use of scope with rifle Model 1917.

Evaluation of the Rifle M1917

Trouble during firing were often encountered with the semiautomatic rifle M1917, generally due to the introduction of foreign material such as dirt, mud or sand into the mechanism, excessive fouling or to the failure of certain parts.

Variations

The short rifle Model 1917 is a shorter variation of the rifle described below being more easy the handle in the trenches. The rear sight is the same. The upper band is larger with a curved stacking rod. This model did not proceed beyond the experimental stage and few were manufactured though some of them would have been tested in the field.

Short rifle Model 1918

Tests of short rifle Model 1917 were generally satisfactory and an improved variation was developed: the short rifle Model 1918. It has a rotary sheet cover that moves with the rod to avoid introduction of mud in the mechanism. The driving mechanism now has a telescopic recoil spring and the handguard is longer and covers the barrel. The rear sight is shorter and permits shooting up to 2, 000 m.

After shooting the last shot, an automatic device retains the bolt in an open position. Feeding is now made with the same clip as Berthier M1916 rifles and carbines. The magazine cover lock was modified (that of the Model 1917 tended to open during shooting…).

Testing of the rifle Model 1918 took place at the beginning of the summer of 1918, but its manufacture began only in November from the same year and it was limited to 4,000 specimens because of the suspension of the hostilities. Subsequent testing and development of new guns using more modern materials quickly displaced the Model 1918. Nevertheless, the rifle Model 1918 underwent the test of fire in Morocco during the war in the Rif (1921-1926) where it gave a satisfactory performance.

Rifle M1917

Caliber: 8mm

Ammunition: 8mm Lebel (8x51R)

Overall length: 1.330 m (52.362 in.)

Length w/ bayonet: 1.848 m (72.756 in.)

Barrel length: 0.580 m (22.835 in.)

Weight: 5.225 kg (11.519 lb.)

Capacity: 5 shots

Rifle Model 1918

Caliber: 8 mm

Ammunition: 8 mm Lebel (8 x 51 R)

Overall length: 1.100 m (43.307 inches)

Length with bayonet: 1.628 m (64.095 inches)

Barrel length: 0.580 m (22.835 inches)

Weight: 4.770 kg (10.52 pounds)

Conclusion

The semiautomatic rifle Model 1917 is the first of its type to be used on a large scale. Conceived in haste and served by ammunition whose case profile was inappropriate with the operation of the semiautomatic weapon system, it could not continue a great career. It was, however, the first of a long line of French semiautomatic rifles whose study started in 1921 and was completed in 1940. These rifles were produced in series after WWII: MAS 44, MAS 49 and MAS 49-56. It is also interesting to note that the feeding device of rifle M1917 was later used on the American Garand M1 rifle.

(All French semiautomatic rifles are described in Jean Huon’s book PROUD PROMISE published by Collector Grade Publications.)

| This article first appeared in Small Arms Review V12N3 (December 2008) |