By Dan Shea

The desert at Yuma Proving Grounds was hot- 116 degrees F hot, and no shade. The engineers from HK in Oberndorf Germany were here to torture test a number of their new weapon designs- They had one week to burn up 10,000 rounds of 40mm through the 40mm GMG, and tens of thousands more 5.56 NATO ammunition through the new G36 rifle and carbine. The G36 had been under development for years, kind of a secret project that had been resurrected from the early 1970’s. Their ambition was to see what kind of punishment it would take to cause failures in the new designs, in order to correct any problems before these new HK weapons were sold to end users. This was a bit of a torture test on the shooters as well. I was there for the work, and fired several thousand rounds from the new G36 in all three variations. Your faithful correspondent got a pretty good feel for this interesting new system…

The days of “This is my rifle, this is my bayonet, these are my bullets” disappeared about 35 years ago- the modern soldier needs to be somewhat of a technician as well. Weapon “systems” are now the in thing- each time I go to a show, there are more complex weapons than you can shake an ’03 Springfield at. The men (And women) who use these rifles have a lot of things to worry about besides what fancy features their weapon has. Sometimes hitting a target under stress is impossible due to the brainlock that sets in from multiple button overload. (Ever shoot the aptly named “Spas-12”? Ever consider what figuring out all those controls in a pucker factor 10 situation might be like?). I sometimes wonder if the designers are getting too far ahead of what the users need. My first look at the G36 rifle with it’s space age technology and appearance, and it was “Here we go again…”; until I spent about 15 minutes with a G36 in hand.

Where’s the selector? Right here at the thumb position- simple S-E-F lower. Two scopes? They were there for a reason, they are simple to use, and target acquisition was swift and comfortable. Lot’s of buttons and confusing features? Not on this rifle- easy to figure out, and easy to remember where the few controls are. Disassembly? Here we go, I thought, you need a Master’s in engineering for this. Nope- modular parts, quick to access for disassembly and inspection. This is really a marvelous design. It’s lightweight, ergonomically engineered (That’s “Comfy to shoot” for all you grunts out there), and it has one feature that we all can appreciate- it keeps on shooting.

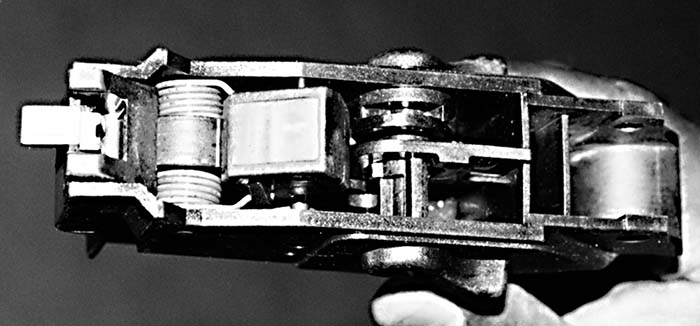

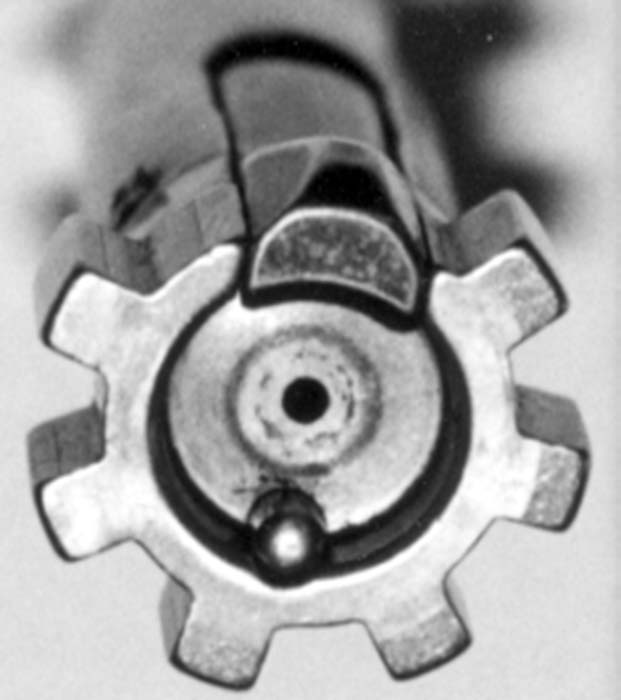

Before I wax too poetic about this rifle system, and call it the “Energizer Bunny” of assault rifles, I need to get a little more technical on this. HK has taken two steps backwards, one step sideways, and ended up moving four steps forward. The gas take off system never exhausts into the receiver. HK uses an M16 style locking bolt head that needs to rotate out of the barrel extension before it can go into recoil. The driving force for this camming action is the backward motion of the bolt carrier, which is driven by a piston and drive rod that takes the energy of the expanding propellant gases (Taken from a barrel gas port) and drives it to the rear. At no time does any of the propellant gas enter the receiver, other than a small amount following the cartridge on ejection. Some existing, proven technologies combined with modern carbon reinforced polymer construction have yielded a very interesting rifle.

The beauty of Gene Stoner’s multiple locking bolt lug design is combined with the cleanliness of the gas piston unlocking system.

Translation: The receiver stays very clean.

And this means: No fouling of the moving parts.

Which accomplishes: Sort of an “Energizer Bunny” assault rifle. You can shoot all day without cleaning, which is what we did out in the desert.

Of course, this is not recommended procedure, and HK may take exception to SAR saying this. That’s alright- because we look at the things from a lot of different angles, and many of us used M16’s back when you had to strip them and clean them every 300 rounds or so, no matter WHAT obligations the social secretary had on the calendar. Many times an “End user” does not have time to clean out the gas fouling, and rifles that are not subject to this problem have always been popular with the troops. HK USA has one rifle with no malfunctions so far, and one carbine had 24,000 rounds put through it at the Yuma test alone. That’s pretty good performance from anyone’s point of view!

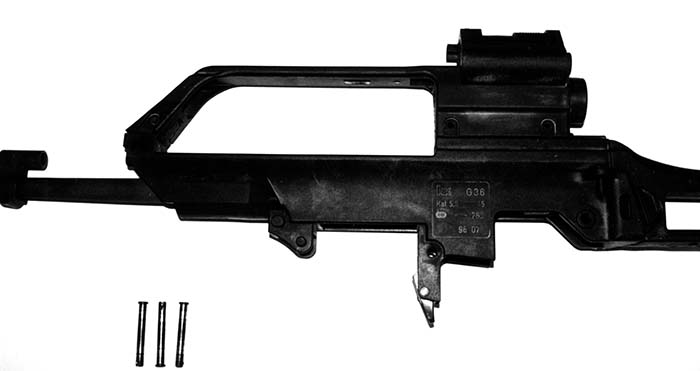

The German Army has purchased the G36 in two different styles- the regular rifle (G36), and a shorter barreled carbine (G36K). A light support version called the MG36 has also been evaluated for possible adoption. The MG36 has a heavy barrel and bipod, and is intended to utilize either the box magazines or a Beta C-mag with a 100 round capacity (These C-mags are in production now for LE and Military customers only). Orders for the G36 filled with the German Army are around 18,000 units to date.

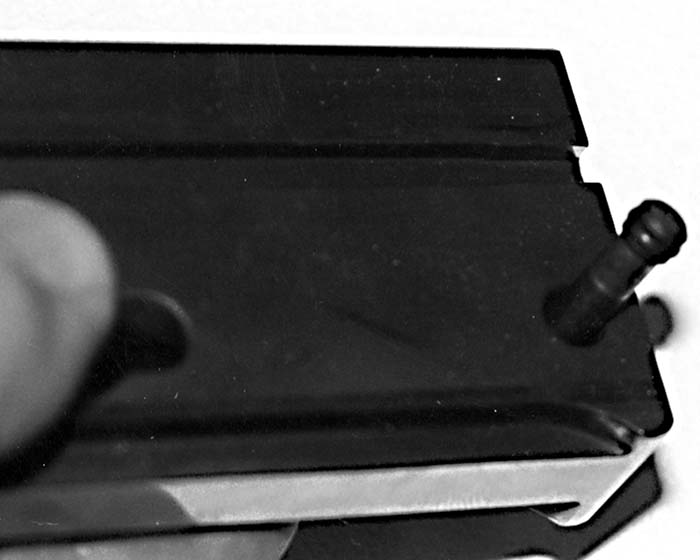

The dual scopes shown in these photos are what the German Army has ordered from HK. Export models (“E”) to the United States will have the single 1.5x scope built into the handle, unless specially ordered. The top scope is an electronic Red Dot type sight that can be utilized with either a battery for low light, or with a shade opened to operate with ambient light during the day. The bottom scope is a 3x optical sight with reticle. It is possible for each sight to be set for a different point of aim. You could conceivably set the red dot for 100 yards, and the scope for 250 yards.

The well thought out ambidextrous controls include the extended selector lever (Safety), magazine release, cocking handle, bolt catch and sling attachments. The cocking handle can also be utilized as a forward assist in quietly closing the bolt with a round in the chamber for special situations.

So, to the big question; “How did it shoot”? Extremely well. The G36 was very smooth and controllable in all of its variations. The straight line relationship of the line of fire of the barrel with the recoiling system and the buttstock has made for a very controllable firearm. There was little evident rise on full automatic, and the bursts were dead on target. I believe that the rate of fire at 750 rpm might be a little bit above the natural harmonic of this cartridge, but it was not really evident from the performance. I did not see a single malfunction in the thousands of rounds that were fired while I was there at Yuma. This does not mean that in the week of testing HK did not have any malfunctions, just that I did not witness any at all in any of the 3 variants we fired. The MG36 on its bipod with the 100 rounds of the Beta C-mag was a regular sewing machine, and it was very controllable.

HK has a winner here. Not much question about it. I do not have any pricing yet, but the rumor is that it will be in line with existing 5.56 caliber HK rifles, and possibly a little more economical. It might be time for you dealers to start thinking about a new line to offer to the departments you service!

For Military or Law Enforcement information please contact:

Heckler & Koch, Inc

21480 Pacific Blvd

Sterling, VA 20166

Phone: 703-450-1900

THE ORIGINAL “HK36”

In the early 1970’s, HK had an experimental rifle called the “HK36” (Not to be confused with the new issue “G36” in this article), building on the new work with synthetic materials that HK was pioneering in the VP70 series which were later used in the caseless ammunition firing G11.

The caliber was a new 4.6-mm x 36 cartridge that HK had developed. The terminal ballistics of the 54.0-grain projectile were devastating in the gelatin tests. The light weight of the new cartridge allowed the soldier to carry double the load of cartridges in magazines (480 rds as opposed to 240) as the 5.56mm NATO allowed.

The new synthetic materials allowed for this recoil operated, delayed roller-locked bolt system to be very light. The HK 36 with one magazine weighed 6.3 pounds. Firing at a rate between 1100 and 1200 rounds per minute, the high cyclic rate was focused on increased hit probability. The line of recoil was straight with the barrel, which in a delayed blowback, straight recoil system, adds a lot of controllability.

The HK36 project was dropped from the “Active files” in the early 1970’s but parts of the project were resurrected for the new G36 series.

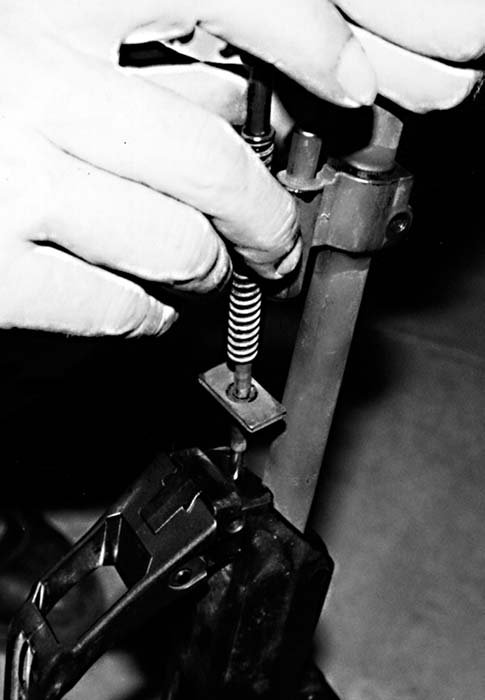

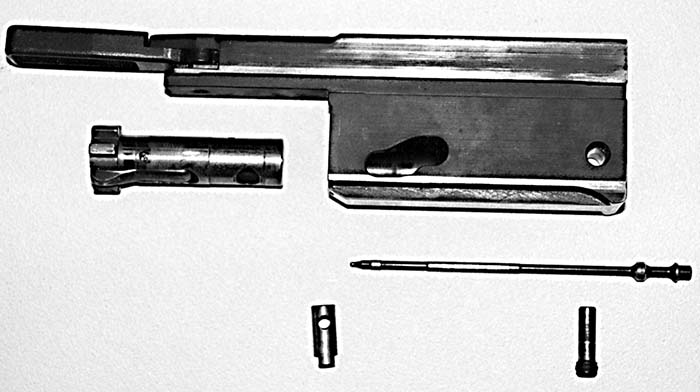

Disassembly sequence

After pointing the G36 in a safe direction, remove the magazine, and inspecting the chamber for “Clear”.

BIRTH OF PROJECT 50

I had always imagined that the designers and engineers at HK GmbH in Oberndorf, Germany, were a very serious crew. Sitting around a drawing table until all hours of the night, never smiling, never joking. In the course of meeting these men, I found that any pre-conceived notion like that was wrong- these guys have a lot of fun with what they do. “Engineer humor” abounds. When I asked what the “Project 50” designation came from, I expected it to be part of a sequential process, or some other forward looking plan. In fact, the “Project 50” refers to the fact that the naming of the project occurred on Mr. Moeller’s (the former head of Design at R & D Department at HK GmbH) fiftieth birthday. Thus, “Project 50” was born.

BAYONET

There were an enormous quantity of AK-74 bayonets left over in the warehouses of East Germany after the Berlin Wall fell. With the re-unification of the East and the West, these have gone into the Federal Republic of Germany’s inventory. The new G36 rifle has been designed to utilize this existing bayonet. The AK-74 bayonet has wire cutting and other proven field capabilities, so the decision was made to use the existing inventory.

| This article first appeared in Small Arms Review V1N2 (November 1997) |