By Edward T. McLean

Identifying all magazines, for all AK variants, would be of such a large magnitude that it would be completely impractical to attempt. As such, this effort is limited to 7.62x39mm magazines with a capacity of 30 rounds or less, and which don’t need to be modified to work in a standard AK-47. Even with this seemingly narrow scope the project proved dauntingly large, and continued to grow as new variations showed up.

Soviet Union

When the Soviet Union started production of the AK-47 in late 1948 at the Izhevsk Machine Plant, also known as Izhmash, it came with a 30-round magazine that has come to be called the “Russian Slab-Side.” It gets its name from its smooth stamped sides and was produced only by the Izhmash factory. They are relatively rare as the design was replaced before AK production was started at another factory.

The Russian Slab-Side magazines are generally covered in inspector stamps, but the Izhmash factory mark (feathered arrow in triangle) will be found stamped low on the back of the mag’s body. Made from thick 1 mm steel, it is without doubt extremely durable, but heavy. They originally had a blued finish, but many appear to have been later refinished with a black enamel coating.

About the time that the Type III AK-47 was adopted in 1954, a new lighter 30-round steel magazine was introduced. Stamped from thinner steel (.75 mm) this design featured ribs in the body for added strength. The body, as with the earlier Slab-Side version, was formed from two stamped metal halves that are spot welded together along the front and along the rear flanges (referred to as the mag spine). The body features three outward and one inward facing longitudinal ribs, as well as five outward facing horizontal ribs along the bottom of the magazine. Three of these horizontal ribs are noticeably short, and basically just wrap around the bottom rear of the mag. The first ribbed mags had the inward facing rib at the rear of the mag’s body going strait up and under the plates that reinforce the feed lips. This type of mag was produced by many other countries, and I will refer to it in the future as the “First European Ribbed Type.”

The earliest Soviet ribbed mag, the “Izhmash Back-Stamped Ribbed Mag”, has the Ishmash factory mark stamped on the bottom-back of the mag like the Russian Slab-Side mag. At first, these mags were blued, but this was eventually changed to a baked-on black enamel finish. Izhmash reportedly switched to a baked-on enamel finish on its AKs shortly before production of the AKM model began in 1959. The followers on these early Izhmash ribbed mags will have a large pill shaped bulge with a hole through its front left side. This bulge does not extend to the rear of the follower.

Eventually, the Izhmash factory mark was moved to the spine, and this version is generally referred to as the “Early Izhmash Spine-Stamped Mag.” This was followed by a new follower with a longer thinner bulge on it that extends to the back of the follower. The hole through the front left side of the earlier follower’s bulge was also eliminated. The hole’s purpose seems to have been the prevention of a stuck follower from suction in a heavily greased mag, but this had apparently been deemed unnecessary.

At some point the dies used by Izhmash to stamp mag bodies were redesigned. The inward facing rib at the back of the mag now stopped short of the lip reinforcement plates, and turned at a 90 degree angle toward the rear of the mag. This rib resembles an upside down and backward “L”. This type of mag body was also made by many other countries, and I will refer to it in the future as the “Second European Ribbed Type”.

As would be expected; these mags will be found with the Izhmash mark stamped on the spine, and with a baked-on black enamel finish. Collectors generally refer to them as a “Late Izhmash Spine Stamped Mag.”

In 1960, the Soviet’s Tula arsenal started production of the AKM. All Tula rifles, and steel mags, were finished with a baked-on black enamel finish. These mags are of the Second European Ribbed Type, and will usually have a fair number of inspector stamps on both the spine and its lower sides. Tula’s factory mark is a five pointed star that, when found, is always on the spine. Tula steel mags are relatively rare as they were only made for a few years before production was switched to the new AG4 plastic type.

The last steel mag produced by the Soviets is referred to by collectors as the “Izhmash Side-Stamped.” It is basically a Late Izhmash Spine Stamped mag with one very noticeable difference. On the mags left side, the middle outward facing vertical rib stops well before the other two, leaving a blank area at the bottom of the mag where the Izhmash factory mark is prominently stamped. These mags carry a black enamel finish, and as the name implies, were only made by Izhmash.

During the mid to late 1950s the Soviets also produced an aluminum 30-round magazine for the AK generally referred to as the “Aluminum Waffle” by collectors because of its very distinctive ribbed pattern. This mag is made entirely of aluminum, except for its spring, and carries a black enamel finish. They will be found with multiple inspector stamps on both the spine and lower sides. Made by Izhmash, most will show its factory mark on their spine. They were probably discontinued in favor of the steel mag’s greater strength. Soldiers have been known to use their mags as hammers, and even bottle openers.

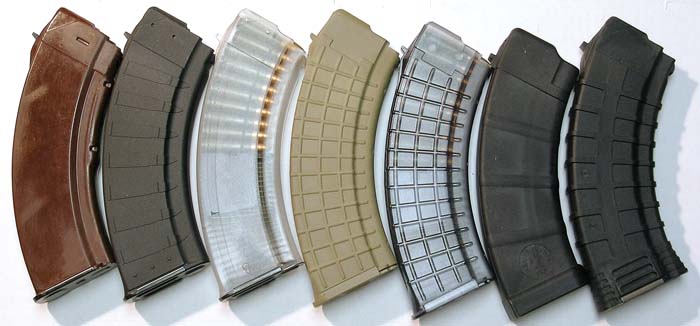

During the early 1960s, the Soviets introduced a new 30-round AK mag made from a glass-fiber reinforced plastic called AG4. This mag was molded in two halves that were then joined with an epoxy adhesive with steel front and rear lugs being molded into the mag’s body. The follower, keeper/takedown plate, and floorplate also remained steel. These “Russian AG4 Plastic Mags” were made by both Tula and Izhmash. The respective arsenal’s mark being molded into the bottom right side of the mag while the mold number is on the bottom left side. Inspector marks were stamped onto the body of the mag with permanent ink. It is interesting to note that these mags never fully replaced the steel mags in Russian service. Reportedly, this was due in no small part to soldiers fears that, if they were injured, shards of a plastic mag would not show up in an x-ray.

Between the two manufacturers; a large number of variations of the Russian AG4 plastic mag exist. Very early mags had a mold line that gave the impression of long top, and were brown in color. The color was quickly changed to a much more common reddish-orange and this was then followed by a mold re-design that moved the mold line higher up on the body. Mags will also be found with, and without, a noticeable ridge running down the back of the mag, and at least four types of floorplates are known to exist. Izhmash also had at least two sizes of its factory mark molded into the body.

During the 1980s, the Soviets experimented with a plum colored polymer AK-47 mag at a time when they were manufacturing a similar mag for use in their 5.45x39mm AK-74 rifles. Like the AK-74 mag, steel lugs were molded into the body and it used a steel floorplate. Criss-crossing ribs, however, were molded into the body for added strength, and possibly for quick identification as to its caliber. These “Russian Plum Waffle Mags” unfortunately lack any markings to indicate the arsenal that made them. Only a handful of these 30-round mags have made their way into the U.S., and it is probably the most sought after AK-47/AKM mag.

At the present time, the Russian Izhmash factory is making a 7.62x39mm black polymer 30-round mag for export sales with its AK103/AK104 rifles. None of these have ever been directly imported into the US, but some have reportedly made their way here through a third country. The mag made for Izhmash’s Siaga version of the AK are often modified to work in a regular AK, and incorrectly represented as one of these.

Bulgaria

In 1958, the Bulgarians began producing the AK-47 at their Factory 10 under Russian license. The earliest Bulgarian steel mags were of the First European Ribbed Type, and are seen stamped with either a “10” or an “E” in a double circle on the spine. The “E” in double circle may have come about in 1964 when the Bulgarian Factory 10 was temporarily re-named as the United Industrial Plant “Friederich Engels,” but more likely represent a different factory. All of these mags appear to have a blued finish, and have the large pill shaped bulge, with hole, on their followers. The follower’s bulge is similar to the earliest Russian ribbed mags, but is not rounded as much.

The next Bulgarian steel mags were of the Second European Ribbed Type. These will be found with both the earlier follower and a new follower featuring an elongated bulge without a hole in it. All the marked ones so far observed carried the “E” in double circle stamp on the spine. They all appear to have a phosphate finish.

The third Bulgarian steel pattern is a unique type. The inward facing rib on the rear top-left side of the mag expands backwards in a slanted concave shape to the feed lip reinforcement plate. On the right side it expands backwards in a slanted convex shape. Early mags appear to have a phosphate finish while the later/majority have a black enamel finish. Most of these “Late Bulgarian Steel Mags” are unmarked, but a few have shown up stamped with either an “E” in double circle or “25” in double circle stamping on the rear spine. The “25” in double circle represents Optico Electron Inc., a well known Bulgarian manufacturer of polymer AK-74 mags. (Author’s note: In the future I will refer only to the number of outward facing ribs on a steel mag. The inward facing rib at the rear will be considered a “given” and covered by its type description.)

Around 2000, a series of experimental 30-round polymer Waffle mags were imported by Magua Industries from Bulgaria. Imported in only small quantities; they were advertised colored either arctic white, blue, clear, gray, hunter green, olive green, plum, or yellow. However; only the arctic white, clear, hunter green, and olive green colored mags appear to have made it here in any quantity. They will carry the “10” in double circle factory mark molded into the left side. These mags were strengthened by having a thin sheet of steel, as well as steel front and rear lugs, embedded within the polymer body. The follower and keeper/takedown plate were made of polymer, but the floorplate remained a steel stamping. The clear polymer mags, for obvious reasons, had the steel sheets left out of the body, and have suffered badly from cracking at the lips due to this fact and the type of polymer used.

A few years later large quantities of these 30-round polymer waffle mags, now black in color, started to be imported into the US. Interestingly, they will sometimes be found with, and without, a mold number on the right side. These mags were designed for military sales, and have shown up in Iraq in large quantities with the new Bulgarian AKs supplied to the post Saddam army.

The 1994 Import Ban of so-called “assault rifles” led to the more politically correct thumbhole stocked AKs without bayonet lugs. The Bulgarians produced the SA93 and SLR95 “sporting” rifles, and exported them with newly developed 5 and 10-round shortened versions of the black Bulgarian Waffle. The bodies of these magazines are the same regardless of whether it has a 5 or 10 round capacity, but capacity is increased to 10 rounds by the use of a shortened follower and keeper. No factory markings will be found molded into these mags. The follower is marked with a “5” or “10” in silver paint to indicate its respective capacity.

KVAR Corp. has recently had the Bulgarian arsenal produce waffle mags for them in special colors to match the US made polymer stocks it sells. OD green mags have been made in 5, 10, 30, and 40-rounds capacities. Plum mags have been made in 30 and 40-rounds capacities.

In early 2007 another type of polymer 30-round mag was imported that is usually referred to as the “Bulgarian Bullet Mag.” The name comes from the rough image of seven 7.62x39mm cartridges molded into each side. The mag also has “Cal. 7.62×39” molded into the bottom of the left side, as well as three small stars molded into the bottom right side. The manufacturer, ISD Bulgaria, Ltd., placed no arsenal marking on these mags to indicate that they made them. The polymer body is reinforced with thin sheets of steel, and the floorplate remains a steel stamping. The follower and keeper are made from polymer but, more importantly, so are the front and rear lugs. Unfortunately, the rocking motion used to insert an AK mag in a rifle will eventually wear out plastic lugs, and one should expect only a fraction of the lifespan of a military steel mag.

One feature of these mags that has caused some consternation with first time users is its so-called self cleaning feature. As the follower rises up it forces the feed lips slightly further apart, and supposedly crud up and out. The increased width of such an empty mag sometimes prevents its insertion into a rifle; particularly those with US made receivers, but problems have been encountered when inserting empty mags into factory built AKs. Inserting three rounds in a mag allows insertion in any AK.

The “bullet” images molded into the mag’s body have never been much of a hit with the shooting community. In late 2007, the Bulgarian factory redesigned the molds to remove the bullet images and replaced the three stars on the bottom right side with an unknown symbol believed to represent the factory. The “CAL. 7.62X39” marking on the bottom left side was also made a little more prominent. Otherwise, the mag remained the same and this new version is generally referred to as the “Bulgarian Slab-Side.” In July 2008, a clear polymer version of this mag was introduced to the US market. The “Bulgarian Clear Slab-Side” lacks the steel reinforcement sheets in its body for obvious reasons.

In mid-2008, the unique Late Bulgarian Steel Mag started showing up in the U.S. with the same black polymer follower and keeper used in the Bulgarian Bullet and Slab-Side mags. It would seem that ISD Bulgaria is manufacturing these new hybrid mags in order to keep the price competitive with military surplus. These mags are finished with a baked-on black enamel finish, show excellent workmanship, and work very well.

East Germany

East Germany received a license from the Soviet Union in 1957 to produce the AK-47, but production didn’t start until 1959. East German 30-round mags are all of the First European Ribbed Type, and are generally known for the excellent quality of their salt blued finish. The follower is of a unique pattern having a bulge that is flattened at its rear, but rounded at the front. Early East German Blued Mags will almost always be found with two to six large thin block style letters stamped on the spine. There is no apparent pattern to the letters stamped on the spines and these are believed to be just inspector stamps. A single small number in an oval, such as “15”, “16”, and “29”, is also sometimes found stamped on the spine.

Much rarer, and largely unknown, is the Late East German 30-round mag. The body and follower remain identical to those of an early East German mag, but have a black phosphate finish. The thing that really makes this mag stand out is its unique floorplate. The floorplate’s normal oval shaped stamping, at its front end, has its rear edge flattened into a slanting straight line. The few of these mags that I have examined were unmarked.

Egypt

Egypt received a license to produce the AKM in 1971 and began production shortly afterwards initially using imported Russian parts. Egyptian 30-round mags, surprisingly, are of the First European Ribbed Type. Early commercial mags imported to the US were stamped “Made in Egypt” near the top of the mag on the left side. The glossy black enamel finish applied to the mag’s body and floorplate is often atrocious, showing obvious paint dripping. The follower, however, retained a blued finish. What really makes this mag stand out from other First European Ribbed Types is their welding patterns. The rear catch has unusual tear-dropped shaped spot welds, while the front lug and front edge of the mag’s body has round spot welds. The welding along the spine is neither round nor oval, and while sometimes indistinct, is best described as a blob.

Later both 30 and 5-round Egyptian mags were imported with a matte black enamel finish on the mag’s body, and with blued followers and floorplates. The follower pattern was slightly different on these mags, and the front lug was enlarged. The welding pattern, however, remained nearly identical. No factory markings have ever been identified on an Egyptian mag.

Finland

Large scale production of Finland’s version of the AK-47, the M62, began at both the Valmet and Sako factories in 1965. The Finnish produced 30-round steel mags are of the First European Ribbed Type, and have a blued finish. While at first glance they may look similar to any number of mags, they have several unique features that make them easy to pick out. First is a folding rectangular steel ring welded to the floorplate. This ring’s purpose has been variously described as a means of securing the mag to the soldier’s web gear or for attaching a lanyard ring; but a Finnish veteran informed me that it is simply to give a soldier something to grab onto when removing it from a magazine pouch. Secondly, they have both a 10-round and a 30-round witness hole in the back. All other European 30-round ribbed mags have just a 30-round witness hole. An examination of the right side of the rear lug will most often show a “T” proof mark, which reportedly comes from the Finnish word “Taisteluväline” or War Material. Much less common are commercial mags marked with an “S” instead – believed to represent either Sako or Sporter.

A unique 15-round steel mag was developed for export sale with the semi-auto 7.62X39mm Valmet M76 rifles. The mag’s body will show only three horizontal ribs on it. The floorplate ring was also left off these mags. The rear of the floorplate is thus left distinctively flat while other European ribbed mags have a round shaped stamping there.

During the early 1990s the Finnish began developing a polymer AK mag for its military. These mags bear a strong resemblance to the Bulgarian Waffle mags in that they have crisscrossing horizontal and vertical ribs on their sides. Likewise; steel front and rear lugs were molded into the body along with thin sheets of metal to strengthen the feed lips. Unlike the Bulgarian Waffle mag, the Finnish Waffle design uses a polymer floorplate.

Finnish Trial Waffle Mags were dark green in color. Shortly after trial production began a polymer loop was molded into the bottom front of the mag and the floorplate was strengthened. When finally adopted, the color was changed to black, and a date code was molded into one side. The few Finnish Black Waffle Mags I have seen were made during the 1994-97 time period. A few of these black mags, made for commercial sale in Europe, were laser engraved “SAKO” on the bottom right side.

Hungary

Hungarian 30-round mags are all of the First European Ribbed Type. Early mags had a blued finish and will often be found with an “02” and a smiley-faced quarter-moon stamping on the spine. These early mags have a very distinctive bulge in the follower that is flattened at both ends. These early follower bulges also have a noticeable large hole in the front left side. The takedown plate’s button also stands out as it is clearly flattened when viewed through the hole in the floorplate. At some point the finish on all the mag’s components was changed to black enamel.

Few changes will be noted in the Hungarian 30-round mag during its long production span. The first design change was apparently to a follower with a more traditionally oval bulge shape. This was followed by a small “M” in circle inspector stamp on the spine, and a new floorplate with a thinner oval shaped stamping at its front. Large quantities of these late mags will also be found with takedown plates having only a gray phosphate finish, and even with no finish.

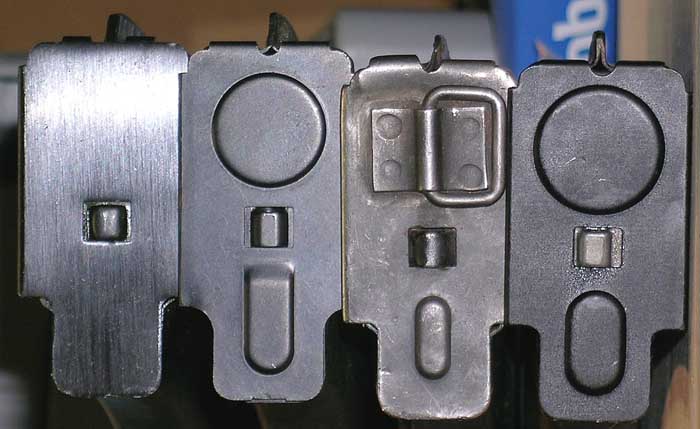

Only a few of the late Hungarian AK mags present a challenge to identify. These mags were generally made for commercial sale in the U.S. and are unmarked. An easy way to identify these mags, as well as any Hungarian mag, is to disassemble the mag and look at its keeper. Hungarian AK mag keepers are unique among the European and Egyptian steel mags in that it lacks a spring guide protruding from it.

In 1965, the Hungarians adopted a compact version of the AK called the AMD-65. It was designed for specialized troops and so that a soldier could easily exit an armored vehicles using it. A 20-round AK mag was developed for use with the AMD-65 and featured three vertical ribs and no horizontal ribs on its side. All of the mags that I have seen were finished in a black enamel finish. Changes in markings, follower shape, takedown plate finish, and floorplate stamping followed the 30-round mag.

The Hungarian FEG plant produced a superb 5-round mag with a dedicated body die for its post ban SA 85M rifles. These mags clearly show superior welding and a near flawless flat black baked-on enamel finish. The mag’s body features three vertical ribs, but no horizontal ribs. The inward facing rib at the rear, as on all Hungarian mags, is of the First European Ribbed Type. The followers and floorplates on these are the same as used on late Hungarian 30-round mags. The keeper, with its button showing through the floorplate, has just a gray phosphate finish.

Poland

Poland received its license to build the AK-47 in 1956 and probably started production shortly afterwards. The earliest Polish 30-round mags are of the First European Ribbed Type and bear a strong resemblance to the earliest Russian and Bulgarian Ribbed mags. The follower’s bulge, however, more closely resembles that of the earliest Bulgarian mag. Unfortunately, no factory mark will be found on these, and inspector stamps vary more than other manufacturers. Large round inspector stamps, with numbers and letters inside, are often found stamped on the spine of the very earliest mags. I have observed “K1” over “S/59”, “PW” over “3”, “K1” over “1/055”, and even large simple numbers such as a “2” or “4” stamped within these circles. A letter, a number, or a combination (such as “S2” or “S7”) will also often be found stamped on the spine or lower sides of the mag. Later examples are commonly seen with an “11” or “12” in a triangle stamped on the spine. Disassembly of one of these mags will often show inspector stamps on the side of the followers; something not found on either Russian or Bulgarian mags. Polish mags also generally show very small weld marks (or none) on the front lug while the Russian and Bulgarian mags have large/obvious weld marks on the front lug.

Late Polish Mags are of the Second European Ribbed Type, and have a black phosphate finish. They feature new followers with an elongated bulge without hole. A few of the earliest mags of this type will be found with an “11” or “12” in triangle stamped on the spine like the earlier Polish mags.

Unfortunately, the vast majority of these Late Polish Mags are unmarked, and bear a strong resemblance to those from Rumania. Polish mags will have less evident weld marks, show generally more care in construction, and have a follower that differs slightly. The front of the oval bulge on the follower, that cuts inward, is shorter, slants less, and generally is less noticeable than on a Rumanian. The cutout on the floorplate’s rear for clearance of the mag’s spine is also noticeably smaller on a Polish mag.

Poland also manufactured a 30-round black polymer mag; apparently during the late 1990s. The body, follower, and takedown plate were made from polymer while the floorplate remained a steel stamping. The front and rear lugs on the mag were steel embedded within the polymer body. “7.62×39” was molded into the mag’s body on the upper left side. All the mags I have observed had a mold number of “1” or “2” on the lower left side. Unfortunately, cracked feed lips have been a serious problem with these Polish Polymer Mags.

Rumania

Rumania appears to have started manufacturing AKs around 1963 with its MD63 variant. All Rumanian AK-47/AKM mags, because of the late start in manufacturing, are of the Second European Ribbed Type. Some of the earliest 30-round blued mags will be found with a Cugir factory mark of an “arrowhead with shaft within a triangle” on their spine that’s often confused with Izhmash’s complete feathered arrow in triangle. Most of these early blued mags just have a couple of letters and numbers stamped on the spine and lower side. After a time, the finish was changed to a black phosphate. Then the factory seems to have adopted an “O” stamped distinctively low on the spine’s side as a standard inspector stamp. Many of these “O’ marked mags will also be found with a large “22” stamped on the rear spine.

Rumanian mags show incredibly little change in their construction over their long production history. New dies were clearly made to mimic earlier ones and welding patterns remained consistent. These mags are sometimes derided for their very visible welds and poor finish. These issues are only cosmetic and they function as well, and sometimes better than, steel mags made by any other country.

Rumanian semi-auto AKs imported into the US generally came with either a 5 or 10-round shortened mag. These mags differ in length, although slightly, according to their capacity. Interestingly, the 5-round mags have a witness hole to show when it is fully loaded, but the 10-round mags do not. Unfortunately, they were made simply by cutting down a regular 30-round mag and forming crude lips for the floorplate to slide onto. Because some of the side ribs still remained on these new lips, removing or installing a floorplate generally requires a little effort. They retain the black phosphate finish found on the larger 30-round military mags. An examination of these mags clearly shows that the Rumanian Cugir factory did not take special care when producing mags for the commercial market.

China

The Chinese started production of the AK-47 in 1956. The earliest Chinese AK-47/Type 56 mag is generally referred to as the “Sino-Soviet Model” by collectors. The body is of the First European Ribbed Type and has a blued floorplate that is very similar to a number of Warsaw Pact types. The biggest difference is the use of a blued stepped-follower instead of the elongated oval bulge pattern follower found on European type mags. The body of the mag carries a black phosphate finish. A check of the bottom rear of the mag will almost always show a “66” in a triangle stamping that represents Factory 626 in the Hei Long Jing Province of China.

The second pattern Chinese mag, the “Spine-Back Transitional,” is a unique design. The mag’s body is similar to the earlier mag but lacks the three short horizontal ribs that wrap around the bottom-back of the mag. The remaining two horizontal ribs along the bottom side of the magazines are much longer than normal and go from almost the very front to the very rear. Like the Sino-Soviet model, the body is phosphated while the follower, floorplate, and keeper are blued. The follower remains the Chinese stepped pattern. All the examples I have examined are unmarked, but its design is so unique that they are easy to pick out.

A third type of Chinese mag was revealed during the Vietnam War that is called the “Chinese Spineless” by collectors. The mags two halves simply interlock, and are then spot welded together – thus eliminating the normal spine. The ribbing pattern stamped into the sides remains the same as the earlier Chinese Spine-Back Transitional. I believe this design is slightly less expensive to make and offers a slight weight savings over previous steel types; both important considerations when you’re planning on making the millions of mags that the Chinese have. Add in that they are actually easier to remove from webbing, grasp, and insert in a rifle, and you have an AK mag that has probably been seen in every post 1970 conflict featuring an AK. These mags, however, are sometimes criticized because it is felt that the lack of a spine running down the back somehow weakens them, but in reality they have proved themselves more than durable. Some of these mags made during the early 1990s, specifically for export to the US, will be found with “Made in China” stamped on the floorplate. Other examples will be found with unique stamped rear lugs instead of the normal milled type.

The Chinese Poly Tech Corporation made special high grade 30-round versions of the Chinese Spineless mag for commercial sale in the US. These “Poly Tech Mags” show superior quality control when it comes to welding and blueing, have “Poly” and “China” stamped on their floorplates, and will have three witness holes in the back to show when 10, 20, and 30 rounds are loaded. At an additional cost they were also available with a chromed follower for easier cleaning and smoother function.

The Chinese continued to seek ways to cut cost while arming its huge and expanding military forces. Sometime, probably during the 1970s, they modified the Chinese Spineless mag to make it even faster and cheaper to produce. Called the “Chinese All-Stamped” by collectors, it eliminated the re-enforcement plates welded to the top of the mag and uses a stamped rear lug. This mag eliminated the need for the feed lip reinforcement plates, usually welded to the top of the mag, by stamping a pattern at the top of the mag that added both strength and tightened its fit in a rifle’s magazine well. Only a few made it in directly from China before President Clinton sent a letter to the BATF in May of 1994 outlawing imports of Chinese ammo and guns. However, large numbers of these once rare mags were imported from the former Yugoslavia in 2007.

The Chinese Norinco Corporation also produced a 30-round brown polymer mag for the US commercial market that was designed to take advantage of the popularity of the Russian AG4 plastic mag that it clearly resembles. These mags were strengthened by having thin sheets of steel, as well as steel front and rear lugs, embedded within the polymer body. The follower, floorplate, and takedown plate remained of steel construction. These “Chinese Phenolic” mags will be found with the Norinco trademark molded into the bottom left side, and the “66” in triangle factory marking on the bottom right side.

The Chinese, always eager to fill a perceived need, developed a 20-round AK mag for the US market. Stamped from special dies, it features three vertical ribs that stop just short of the bottom and no horizontal ribs. Both 10 and 20-round witness holes are drilled into its back. Other than the above changes; the Chinese 20-round AK mag characteristics are the same as the Chinese Spineless 30-round mag.

China produced a special 5-round mag for sale with its post ban AKs meant for the US market. Stamped with special dies, it has two vertical ribs and one horizontal rib at the bottom. The Chinese 5-round AK mag uses the Chinese stepped follower, are blued, lack a witness hole, and have “China” stamped on the floorplate. “China” will be found stamped in two different sizes on the floorplate. Huge numbers of these mags were imported before the ban, and many dealers still have these new-in-wrapper for sale.

The Chinese Norinco Corporation also attempted to make a more politically correct semi-auto AK for the US market called the NHM91. They put a rivet in the rifle’s receiver, just behind the magazine well, that would only allow the insertion of a special 5-round mag with a milled cutout in its rear catch. This rivet was not required by any US import restriction or law, and most rifle owners simply ground it down so any AK mag would fit.

The NHM91 5 Round is an easy mag to pick out. It has just three vertical ribs, has the rectangular milled cutout on top of the rear catch, lacks a spine, is blued, and has the Chinese stepped follower. Interestingly; none of these that I have examined have “China” stamped on the floorplate.

In the early 1960s the Chinese developed a select fire carbine that combined features of both the AK and SKS, and was adopted by their military as the Type 63. Although little known in the West, it was made in large quantities by several factories. It was fed by a detachable 20-round mag clearly developed from the AK’s mag, but featured a special projection at the rear of the follower. This projection travels within a channel built into the rear of the mag, and activates the Type 63’s bolt hold open mechanism when the mag is empty. For some reason, probably due to the BHO mechanism, the stepped follower is reversed on a Type 63 mag – the depression from which the last round is fed is on the left side. Because of this, the witness holes, indicating when 10 and 20-rounds are loaded into a Type 63 mag, are also reversed to the rear left side. These Type 63 mags were not designed for use in full-auto AKs as they lack a milled clearance for the AK’s disconnector on the upper right side feed lip reinforcement plate. However, these mags work just fine in semi-auto AKs, but will block the bolt from closing after the last round is fired.

An impressive little collection can be made up solely of Type 63 mags. At least five steel versions, and one black plastic version have been identified. The steel mags are centered around three basic body stamping types – two vertical ribs with one horizontal rib at bottom (2+1), two vertical ribs with two horizontal ribs at bottom (2+2), and a very large star interrupting two vertical ribs with two horizontal ribs at the bottom. All three body types were made with the normal feed lip re-enforcement plates (as on a traditional AK mag), but the last two types were also made with just ribs stamped to reinforce the feed lips (similar to the Chinese All-Stamped mag).

North Korea

North Korea began manufacturing the AK-47 during the late 1950s as the Type 58. Little is known about their mags as they have never been directly imported to this country. The few 30-round mags that have made it here are clearly copies of the Chinese Sino-Soviet mag right down to the finish applied to them, and I have little doubt that they were manufactured with Chinese tooling and assistance. These can be identified by the North Korean arsenal’s mark of a five-pointed star within a circle stamped on the mags spine.

Yugoslavia

Yugoslavia’s first AK, the M64, had a couple of unique features. They were built with a grenade launcher, and a last shot bolt hold open (BHO) mechanism. A notch cut into the upper left side of the M64 mag activated the rifle’s BHO mechanism with its follower, and a button on the left side of the receiver would release the bolt after a fresh mag was inserted. While the M64 corrected the AKs often criticized lack of a BHO feature; it also created a greater problem in that normal AK mags could not be used in it. This limited foreign sales, and created possible internal supply issues.

The Yugoslavian M70 AK solved these issues in a simple way by making the mag the BHO mechanism by itself. The Yugoslavian’s just omitted two small bumps on the inside of the mag that stops the follower from traveling all the way up. In an empty M70 mag the follower is only stopped by the feed lips. A bolt returning, after the last round has been fired, will be stopped by the specially designed and strengthened follower that now blocks it. Using a Yugoslavian M70 mag in any other AK will also cause the action to remain open after the last round is fired. I believe that earlier M64 mags were upgraded to this latter pattern by simply replacing the follower with the newer type.

The Yugoslavian M64/M70 mag is easily distinguished from all other AK mags. Their blued bodies lacks the short horizontal ribs that wrap around the bottom rear of the magazine, as found on all ribbed mags but some Chinese, and the two remaining long horizontal ribs stop well short of the magazine’s front (unlike on the Chinese mag). The M64 mag will also have its unique notch on the upper left side.

Examination of Yugo M70 mags coming out of the former Yugoslavia shows two distinct variants. The two mags are quickly differentiated by the shape of the witness hole in their back – round or triangular. Very notable differences in the follower and front catch will also be seen as well as less distinctive differences in just about every other part. The general better condition of the Triangular Witness-Hole M70 Mags, along with the fact that the earlier M64 mags have round holes, has led to the probable conclusion that they are of newer manufacture. The lack of any transitional mags, between the two types, would also seem to indicate production at two different factories.

There has been some speculation that the triangular witness-hole M70 mags were made in Iraq, and provided as aid to the Muslim forces of Bosnia. However; I have yet to hear of a triangular witness-hole mag being found in Iraq. Most likely the triangular M70 mags were simply made at a second plant in Yugoslavia set up to meet the demands of the Yugoslavian civil wars.

No short 5-round sporting type mags were produced by the Yugoslavian factory for commercial sales in the US. Post ’89 Ban rifles, sold by Mitchell Arms, came with full size 30-round mags that were simply blocked to accept only 5 rounds.

Bosnia

In 2006, in a large shipment of AK mags from the now dissolved country of Yugoslavia, came two newly discovered, but clearly related, 30-round mags produced in what is now Bosnia. These mags were made so that the bolt would be blocked by the follower after the last round is fired and were probably made under less than desirable conditions for the cutoff Bosnian forces. They are crudely stamped and welded, and poorly finished with what appears to be gray phosphate. Quality control clearly suffered on these as a few of my mags are too wide to insert into my Chinese made AKs. Disassembly of one will also show that the plant making them relied on bent flat-springs instead of the traditional coil spring. These mags show both the ingenuity of the manufacturer, and the desperation to arm the fledgling Bosnian forces.

Both Bosnian mags are essentially the same having only one wide outward facing vertical rib running down the side. The only real difference is the inclusion of a large stamped “fleur-de-lis” symbol on the bottom sides of one of the mags. The fleur-de-lis has special meaning to the Bosnian people, and is included on their national flag. This symbol is also used by the Boyscout organization and this has led to this mag being referred to by collectors as the “Bosnian Boyscout mag.” The mag without the fleur-de-lis symbol is simply called the “Bosnian Single Rib.”

The so called “Bosnian Two-Rib” steel mag was also unknown in the US until the above 2006 shipment. However, there is still some very reasonable speculation that these may actually be of Croatian origin. They appear to be what they are claimed to be: a rushed expedient mag manufactured for an army cutoff from outside supply. Most have a hastily applied blued finish, but a few also appear to have an equally poor phosphate finish. These mags generally have rather poorly made followers, floorplates, and keepers. There are two types of followers, unique to this mag, that are often poorly welded; one of which appears too short in length. The floorplates generally are poorly fitted and will often wobble side-to-side on the magazine. The keepers often are over-sized thus making disassembly of the mag difficult. Many of these also have a letter (W, X, etc.) and a number (2, 3, 5, 6, etc.) stamped on the bottom rear of the mag.

There has been some speculation that the Bosnian Two-Rib was designed as a bolt hold-open mag because it lacks the normal dimples on its inside that prevent a follower from traveling all the way up. Pulling an AK’s bolt backwards and releasing it on an empty mag will usually result in the bolt being stopped by the follower. However, when firing the last round in a mag, the greater returning force of the bolt invariably pushes the follower down so that the action will close. The traditional rounded end of the follower’s bulge allows this to happen and also generally results in damage to the follower over time. The reasons for making a mag in such a way, other than to simplify production, escapes me.

United States

In order to convert an imported rifle to a banned configuration, or build such a rifle from an imported parts kit, a certain number of U.S. made parts must be used. A U.S. made mag is an easy way to provide three such compliance parts – the mag body, the follower, and the floorplate. This fact has spurred the U.S. development and production of AK mags.

A US manufacturer, National Magazine, has been producing metal AK mags since the ban was lifted. Taking the Chinese All-Stamped as a model, they stamp out the tops separately and then weld mag bodies of various lengths to these. Using this production model, they are able to produce mags in an incredible variety of capacities. They produce mags in 10, 20, 30, 40, 50, 75, and even 100-round capacities. As mentioned earlier; the end product strongly resembles a Chinese All-Stamped mag, but the use of a green plastic follower and the welded joining of the upper and lower halves clearly differentiates them. No markings are found on these mags and they carry a glossy black enamel finish. Unfortunately, my experiences with these mags have not been good and I can not recommend them.

When Pro-Mag first introduced its U.S. made polymer AK mags, they only made a 30-round black version. These early mags had thin gauged 19 coil mag springs that were noticeable shorter than a Russian AG4 mag’s 22 coil mag spring. Failure to feed properly was a common problem with these early mags. Pro-Mag increased the gauge and length of latter springs, still with just 19 coil springs, on latter production mags and this has apparently solved feeding problems. These mags are also sometimes found too long to fit in AKs, but the careful removal of a little material from the rear lug will solve this problem. Construction is entirely of polymer except for the steel spring.

Pro-Mag significantly increased their offerings in 2007. They now make Black, Coyote Tan, and O.D. Green mags with capacities of 5, 10, 20, and 30 rounds. They also make clear and smoke colored transparent mags with a 30-round capacity. “PRO MAG” is prominently molded into the bottom left side of the mag as well as the floorplate. In a sign of the times, the company’s internet address is also molded into the floorplate.

An unexpected black synthetic 30-round mag from Thermold Design & Development showed up on the market in 2007. These Thermold Mags are marked “Master Molder” on both the right side and floorplate, and carry the “Law & Gov’t Use Only” warning on the left side from the high capacity mag ban period. They are made from a durable Nylon resin called Zytel and have three large horizontal ribs wrapping around both the sides and front of the mag. A very prominent and strong floorplate sticks out on the bottom. I would not consider them an “attractive” mag. Thermold’s web site shows that it also offers a 10-round version of its Zytel mag, but I have been unable to find any distributors with them.

A quick examination reveals that they lack an anti-tilt follower. Disassembly will show they use a spring not interchangeable with those from military AK mags. On the plus side, the Zytel lugs look better designed, and more substantial, then those of a Pro Mag. I have had no problem inserting these in any of my rifles, and so far functioning has been 100%.

Tapco introduced a U.S. made polymer 30-round mag in the fall of 2008. These mags have a very distinctive ribbed pattern and an unusual flared-out bottom. “Tapco USA” is molded into the top left side of the mag, and the follower. The steel floorplate, the only steel in the mag other than the spring, is also stamped “Tapco USA”. “7.62x39mm” will be found molded into the upper right side. Interestingly; a small date code, and a cage code number, are also molded into the mag. They produce these colored in either black, dark earth, or olive drab.

I had no trouble inserting these Tapco mags into any of my AKs. The lugs, although Polymer, appear strong and the follower is of an anti-tilt design. It uses standard AK type springs, which actually appear to be stronger and longer then those found in many military mags. Limited function testing showed 100% reliability. These mags would appear to be an excellent choice for the shooter needing U.S. made mags.

Conclusion

What is left out there to be discovered? Obviously there are some still unidentified types. Hopefully, we will see some of the distinctive Rumanian 20-round mags carried by the dreaded “Securitate” in their compact AKMs from the 1989 Rumanian revolution. Albania and Iran are reportedly making copies of the Chinese Spineless mag. Iraq probably made a version of the Yugo M70 BHO mag, and some cut down 20-round mags. Cuba is probably making mags that follow Russian patterns. North Korea almost certainly has made changes to its 30-round AK mag over the years and its soldiers have clearly been seen with 20-round mags. There is also no doubt that there are several other countries that are making, or have made, mags as well.

What are the best mags for the shooter? It is hard to go wrong with any of the European Ribbed or Chinese steel types. The Bulgarian Waffle and Soviet AG4 mags are excellent choices for those looking for military quality synthetic mags – but will cost you more. I would also suggest finding some 20-round Hungarian or Chinese mags for shooting from a benchrest. The shooter needing US made mags also has several good choices.

| This article first appeared in Small Arms Review V13N8 (May 2010) |