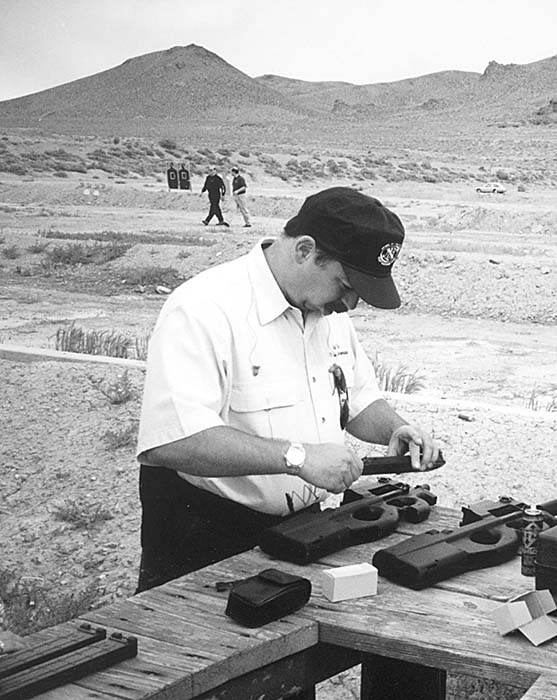

The author (right) receives instruction on the P90 submachine gun from Bill Forsen.

By Matt Smith

This interview was conducted with Jeff Rankin, Director of Contracts, Sales and Marketing; Sal Fanelli, Technical Sales Manager; and Bill Forsen, Director of Law Enforcement for FNMI of Columbia, SC.

SAR: Tell us about how your company is structured.

Jeff: FNMI is a wholly owned subsidiary of FN Herstal in Leige, Belgium. FNMI was incorporated in 1978 in Delaware, and is located in Columbia, South Carolina. The family in the United States, under the FN Herstal name, includes Browning USA and US Repeating Arms, also known as Winchester Rifles and Shotguns.

SAR: Why did you locate your plant in Columbia, South Carolina?

Sal: In 1981, the plant was put there to manufacture the M240 coaxial machinegun for the M1 tank. The initial contract was for 16,417 weapons, plus a 100% add-on option for a total of over 32,000 weapons. Although the initial contract has expired, we are still building the basic version of the M240 today.

Jeff: The Army has been the primary customer, along with some Marine Corp sales over the twenty year M240 production history.

SAR: What came next?

Jeff: In 1987, we began making other US Military products, including bomb racks for the Navy, M16A1 and A2 barrels, and M61A1 entrance hardware.

Sal: In 1988, we submitted proposals for the M249 machinegun, the M16A2 rifle, and the MK19 40mm grenade launcher.

SAR: Who was manufacturing the M16 at that time?

Sal: The M16A2’s were being made by Colt. The Army needed an additional 320,000 and decided to competitively procure them. We bid on it, and in 1988 we were awarded the contract. We are still manufacturing the M16A2’s, with the three round burst selector. From time to time, we also manufacture the M16A3, which is the full auto version of the M16.

SAR: Who was manufacturing the M249?

Sal: Our parent company, FN Herstal in Belgium, had a contract for 10,000 M249’s for the Army. The rest of the production, after the initial 10,000, had to be produced in the United States by law. We produced over 30,000 on that contract.

SAR: What happened with the MK19?

Jeff: This was before my time, but I am told that we had won all three of the contracts we bid on, including the Mark 19, within twenty-four hours. At that time, the company had to make a decision, because in reality, the company couldn’t perform all the work with the facility that it had. The company elected to select the M249 and the M16A2 for production. FN asked to have their name withdrawn from the MK19 competition. This allowed Saco Defense to win the contract. Up to this point, the MK19 had been produced in limited numbers by the Navy in Louisville, KY.

SAR: What impact did the new contracts have on your facility?

Sal: Once we had both of those contracts, we added on office space to the existing building and more range capability. We also leased another 30,000 square foot building nearby that became FNMI-2. All of the raw materials and vender parts came in through this building. Only after the parts were inspected and approved by our quality assurance personnel and then by the Government, were they sent to the main factory. This prevented nonconforming material from entering our production lines.

SAR: Tell us about your range facilities.

Sal: Originally, the factory had one 100 meter range for accuracy testing and one short range for reliability and function testing. Once the new contracts were received, we put in two more 100 meter ranges plus another range for function testing. Each of the long ranges had two distinct shooting positions and the short range had three bays inside of it. All the ranges are inside. We have no external ranges.

SAR: What is a typical test firing sequence?

Jeff: It varies from product to product. As an example, the M249 will go through a function check, rate of fire check, targeting and accuracy, then it’s shot for belt pull to insure the working components are strong enough to pull the belt through the gun. The final check on the M249 is a check with the 30 round magazine. For the M240, it goes through accuracy, targeting, rate of fire, and belt pull. Weapons will see anywhere from a minimum of approximately 126 rounds to a maximum of 156 rounds. Everything is fired from a hard stand mount where an operator pulls the trigger and required data is recorded by computers and gauges.

SAR: What happens if you have a problem with a weapon during test firing?

Sal: If a gun fails one of the performance criteria, that gun is set aside, and is allowed to be repaired. Once a month, a Government representative will come in and randomly select ten guns from the lot. Those ten guns are subject to interchange, where they will completely disassemble the guns, the components are mixed up, and the guns have to be put back together. FNMI personnel perform the work under Government supervision. The guns are disassembled down to depot level. If a part is not interchangeable, we have to discover why and the lot is subject to rejection. If, during the reassembly, we find out that it’s due to a defective part, we have to go back through the entire lot to determine if there are any more defective parts in the lot. If we find out that it won’t go back together due to an operator damaging a part, this will not affect the lot.

SAR: Are all parts manufactured in house?

Jeff: It varies from product to product. We make the key components for each of our products. For example, on the M16, we definitely make the lower receiver and have made the upper as well. We also make the bolt, barrel, front sight, extractor, and other parts, depending on production and delivery schedules. Smaller parts like springs, pins, and plastic components are purchased from venders who we have qualified. We make all the receivers from scratch for the M240 and the M249. More parts are made for the M240 than for the M249. We make more parts for the M249 than we do for the M16 which is a true combination of purchase and manufacturing.

SAR: What ammunition do you use when you test fire?

Sal: All of the ammunition is government furnished and we have to show that our guns function with this ammunition. We typically receive lots of about 100,000 rounds, which will last for a couple months of test firing. The Government then sends another lot and this turnover assures our guns work with a variety of lots of ammunition.

SAR: What weapons are currently in production?

Jeff: The M16A2 is currently in production at a rate of 1500 per month, under contract until May of 2002. We have the M240B in production at a rate of 175 weapons per month through June of 2002. The M249 is in production on a yearly basis at a rate of 250 per month. That contract will be complete in March of 2001.

Sal: The M240B is the new machinegun for the U. S. Army. The basic M240 tank version has a minimum number of parts and is designed to shoot inside a tank. The new M240B is designed as an infantry gun, with a bipod, buttstock, a full-length trigger, and barrel-changing handle.

SAR: Is the M240 being built to replace the M60?

Sal: Yes, within the Army, in every place that we know of, the M240 has replaced the M60. In the Navy, M60s are still being used on some boats, but they are trying to get funding to replace all of the M60s. Within the Air Force helicopter community, their M60s have been replaced with the M240D, the spade-grip version. The Air Force ground forces are scheduled to receive the M240s to replace the M60s within the next two years.

SAR: Are you exporting any of these weapons?

Jeff: We have a few foreign military sales (FMS) cases every now and then. Currently, in the year 2000, we will build one FMS case for the M240 coax version for a foreign customer through the US Army. The customer of the final product is blind to us right now. All of our other weapons are built for and shipped to the US military.

SAR: Has the military had many problems with your products?

Jeff: No, as a matter of fact in 1998 FNMI was awarded the U. S. Army Materiel Command CP Squared Award in the Contractor Performance Certification Program. To my knowledge, we are the only one in the small arms industry that has this award. There have only been seventeen recipients in the entire defense industry. Records from the military testing of our weapons are excellent. For example, on the M240B, 83,000 rounds were fired without a mission failure. The reason they stopped at 83,000 was that their test was done. We don’t know how much more the gun could have operated and these numbers are hard to believe, but they are U. S. numbers.

SAR: Do you make any products for the Special Operations Command?

Sal: SOCOM is looking for a lightweight 5.56 machinegun. Testing started recently on our lightweight version of the M249, and it will probably be a couple months before we will know the outcome of the Navy’s testing.

Jeff: We call our version the M249 SPW (Special Purpose Weapon). It includes characteristics which lighten the weapon while maintaining the reliability and durability of the weapon.

SAR: Tell us about your facility.

Jeff: The facility itself is 140,000 square feet. This includes the manufacturing area with state of the art CNC machining equipment as well as conventional equipment. We do our own in-house heat treating and surface finishes. The finishes include hard chroming of components and black phosphate on exterior surfaces. We have our own tool room to maintain tools and cutters, which can also be used as a model shop to manufacture a new bracket or item that we need to install either a weapon or a mount on a vehicle. We have an external bunker that is divided into two sections that house the government-furnished ammo. The commercial ammo for non-government testing is in a separate bunker. We currently have about 350 employees with the manufacturing areas working ten-hour shifts Monday through Thursday and the administrative staff and offices working five days a week. FNMI is a full house shop with our own engineering department where we do independent research and development on our products.

SAR: What role does the BATF play at your facility?

Sal: The BATF has a role with the various machineguns that we have in the sales and marketing group that we use for demonstrations. We are not allowed to use Government guns with Government serial numbers on them for demonstrations. We manufacture special machineguns with commercial serial numbers for demonstrations, and BATF controls those. Weapons that go to non-DOD customers such as the Coast Guard, the Department of Energy and police agencies have registration through the BATF.

SAR: What weapons do the Coast Guard and Department of Energy purchase?

Jeff: The DOE has selected the M249 and the M240B as their weapons of choice for machineguns for security at nuclear sites and purchase these from us. The Coast Guard uses the M240 family of weapons including the ground version and the airframe version for their boats and helicopters.

SAR: Do you sell many military weapons to law enforcement?

Jeff: Police departments can own military weapons. Some departments have purchased M249’s or at least had demonstrations of the weapons for evaluation. As far as the M16’s, we are restricted by the license between Colt and the U. S. Government and our contract to manufacturing these weapons solely for the U. S. military. We do not sell any M16’s or M16 related parts to anyone unless they are on the contract.

SAR: Tell us about your law enforcement division.

Sal: FNMI, with guidance from FN Herstal, started up the law enforcement division. There are certain products within the company that fit into law enforcement needs. For example, since FN owns Browning and Winchester, they tapped the resources from those two organizations for rifles and shotguns. Browning USA is headquartered in Morgan, Utah. Winchester/U.S. Repeating Arms is located in New Haven, Connecticut. Bill Forsen heads up our law enforcement division. (At this point, Bill Forsen joins in the interview).

SAR: Tell us about your law enforcement products.

Bill: The flagships of our division are the P90 machinegun and the Five-Seven polymer pistol for the law enforcement market. In addition is the polymer framed Model Forty-Nine Pistol. The reason it is named Forty-Nine is because it is available in both .40 caliber and 9 mm. As you can see, the “FN” is prominent in the names of each pistol. The Forty-Nine is available to both law enforcement and commercial sales and is made here in South Carolina. This pistol has two unique features. First, there is no spring tension on the striker until you pull the trigger so it is very safe. It is a true double action. Second, the patented rail system is extended and modular instead of molded in. Worn or cracked rails can be replaced without scrapping the frame. FN Herstal produces a double action version of the Browning High Power pistol which we will be bringing into the country to sell under the FN brand. There is also a possibility that we may begin marketing the single action version of the High Power in the future.

We are planning on introducing a new shotgun and precision rifle, in conjunction with U. S. Repeating Arms, for sale to law enforcement under the FN banner. The shotgun will be pump action, available in 18 or 14-inch versions, with screw-in chokes with improved cylinder and modified tubes. The interchangeable chokes will allow a department to fine-tune the shotgun for use with full power or reduced recoil shells. All steel components on the guns will be phosphate treated instead of the normal bluing. The receivers will come drilled and tapped for optics or ghost ring sights. The stock has been shortened to a thirteen and a half inches to compensate for body armor. The FN Special Police Rifle will be similar to the pre-64 Model 70 and will include the controlled round feed extractor and three-position safety which will allow the bolt to be opened in the safe condition. A detachable box magazine will be used and the chamber and bore will be chrome plated to extend barrel life and reduce cleaning intervals. An HS Precision bedded stock will support the barreled action.

SAR: How did the P90 submachinegun come to be?

Sal: FN did a survey of military services in several countries. The survey revealed that only 10% of the military personnel were actually out there fighting, while the rest were support troops. These others include the truck drivers, cooks, radio operators, and logistics types. If these soldiers got involved in military action, the fighting would be very close, at ranges of less than 50 meters. For them, having a long assault rifle or complicated weapon didn’t make sense. At the same time, NATO was predicting all enemy infantry would soon be wearing some level of soft body armor. NATO was considering replacing 9mm weapons because they were no longer lethal on the battlefield. FN took these two concepts, put them together, and then developed the ammunition and the weapon at the same time. The result was the P90 with the 5.7mm X 28mm round called the SS190. This round can penetrate body armor out to 200 meters in the P90 and 150 meters in the Five-Seven pistol. The purpose of this system was to replace aging handguns and submachineguns shooting 9mm and other handgun calibers. The P90 has been adopted by 19 countries around the world. This means they have evaluated them and purchased a significant quantity, which are in use today either in the military, law enforcement, dignitary protection, or presidential security and protection role.

SAR: Who are some of the countries that have adopted the P90?

Sal: It is in service with several units in France, Belgium and Portugal. There are many more countries that are still evaluating the P90 for potential use.

SAR: What is involved in transferring a P90 to a law enforcement agency?

Bill: First of all, the guns and ammunition must be imported on a BATF Form 6 and placed in a customs bonded warehouse. We are currently using a warehouse in Atlanta, but we plan to locate our own bonded warehouse here in the near future. The second step of this process is to have the items released from the bonded warehouse on another Form 6 when a department wants to make a purchase. Both of these steps require dealing with the BATF Imports Branch. Next, the weapon must be registered with the NFA Branch and later transferred to the agency. These two branches of the BATF do not have a whole lot to do with each other routinely as they have different responsibilities.

SAR: Tell us about your involvement with the National Defense Industrial Association.

Sal: Within FN, we feel that NDIA, in particular the small arms division, is very important to us. It allows us contact with government, academia, and other small arms companies. It provides an avenue for us to get out to many people at one time to talk about new products, what we’re developing, what we’re looking at, and whatever information we want to release that we think others need to know. The NDIA also allows for great teaming. For example, with the P90, when we knew we needed to have a suppressor, it gave us the opportunity to meet some people who did suppressor work. It also gives us the opportunity to work closely with government folks so that we really understand exactly what they are looking for. What’s on paper in black and white can easily be misunderstood, so that’s why it’s important for us to have face-to-face contact and meetings with them at NDIA events.

Years ago, NDIA was looking for corporate sponsorship to help the organization to grow. I checked with the FN executive staff for my participation, and they agreed. FNMI agreed to send me once or twice a year to steering committee meetings. At one of these meetings several years ago, I was asked to be the session chairman for the firepower division. Again, I checked with management, told them this would mean more involvement, and they agreed. This means that as session chairman, I have the task every year to locate a small arms firing range that can be used for demonstrations. I work with the local range people to make sure that we have everything we need, pass information back and forth to the various companies that want to demonstrate their products, organize it, choreograph it to ensure that it goes off as smoothly as possible. These demonstrations give the participants great exposure to other companies, the media, and all DOD personnel for their products.

SAR: Where’s the small arms symposium being held this year?

Sal: It’s going to be held in Indianapolis, Indiana with the firepower demo at Camp Atterbury, which is one half hour away. The meeting is scheduled for August 28-31, 2000.

SAR: What are some of the memorable moments from the past few demos?

Sal: The most memorable part from Reno three years ago was when the Navy showed up with their GAU-18 on the platform and shot at that vehicle. Two years ago, at Fort Benning, the most memorable moment there was the deer coming across the range along with the Navy showing off their Fast Attack Vehicle with all the various weapons and the quick conversion from one configuration to another. Last year, in New Jersey, the highlight was when J.D. Jones shot his .50 caliber pistol at a tank 800 meters away and hit it. There have been a lot of memorable things that have happened, and I could go on for hours with these stories. Someone always goes above and beyond the call of duty to have a great demo. HK, Knight’s Armament, the U. S. Navy and many others put on fantastic demonstrations. I am sure that this year will be exciting as well.

SAR: Thanks for sharing your time and thought with our readers.

Jeff/Sal/Bill: You’re welcome.

FN Manufacturing, Inc.

797 Clemson Road

P.O. Box 24257

Columbia, SC 29224

PH (803) 736-0522

Fax (803) 736-9949

Website: www.fnmfg.com

National Defense Industrial Association

2111 Wilson Boulevard, Suite 400

Arlington, VA 22201-3061

PH (703)522-1820

FAX (703)522-1885

Website: www.ndia.org

| This article first appeared in Small Arms Review V3N9 (June 2000) |