By Matt Smith

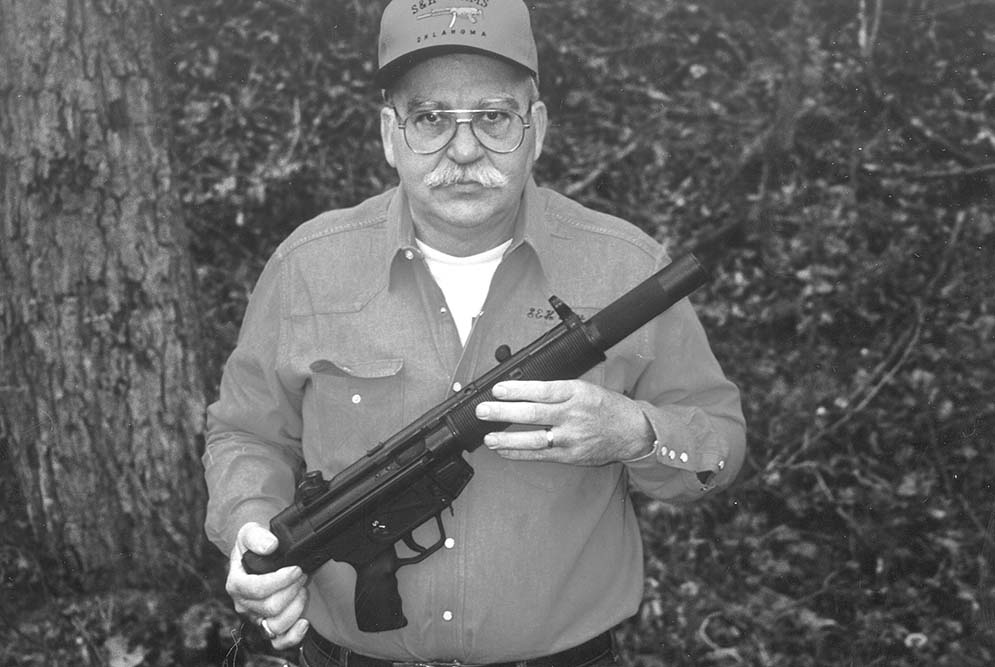

Above: Curtis Higgins holding an S&H factory clone of an MP-5SD SMG.

SAR: Curtis, tell us about your background.

CURTIS: I grew up in Kansas on a farm. I’ve always liked guns, but never knew much about them as I grew up. I went to Vocational College in Pittsburg, Kansas, and took machine shop and welding. I’ve been a machinist for the last thirty-seven years and in the tool and dye business for the last twenty years.

SAR: When did you get into the firearms industry?

CURTIS: In 1986, I formed a partnership with Tom Seslar, who had the idea to build autosears. Tom had limited funding at the time, so I put up some money and we became partners. Tom had a previous partner, Ed Hyde, with whom he formed S & H Manufacturing. Ed was no longer in business with Tom when he and I formed our partnership. Tom and I also had worked together at American Airlines before he quit there to open a pawn shop. Initially, we operated under Tom’s Class III license at the pawn shop, and eventually we got a license together. We worked together until 1989, when Tom moved to Arkansas. He kept the name S & H Manufacturing, while I began S & H Arms of Oklahoma, Incorporated. In addition to the gun business, which I work during the day, I have continued to work the night shift for American Airlines.

SAR: How did the idea for the H & K autosear come about?

CURTIS: Back when Tom and Ed were in business together, they use to work a lot of gun shows selling suppressor parts and drop in AR autosears. After the ruling in 1981, the AR autosears were considered machine guns. Tom had the idea to manufacture HK autosears, register them, and sell them as machine guns.

SAR: Who actually came up with the design?

CURTIS: We basically copied the HK design with some minor alterations. The sears we made went into a different place in the lower and would not fit in a factory full auto gun. Bill Fleming was also converting HK’s on registered receivers with a similar conversion sear made out of heat-treated tool steel. Our sears were investment cast in order to speed up the manufacturing process.

SAR: Did you have any problems registering the autosears?

CURTIS: Yes, because up to this point we had not been manufacturing anything in volume. Just before the machine gun ban went into effect, we manufactured and registered hundreds of sears. Two days after the law changed, we had an ATF inspection to see if we physically had the autosears on hand. Once the sears had been cast, there was still some machine work to be done to complete the manufacturing. The ATF even made a visit to our casting contractor to make sure that they were not giving us a finished product as they were not a licensed manufacturer. Another problem we had was trying to get the casting contractor to cast our sears during the five weeks we had before the law took effect. We kept asking them to run them, but they kept putting us off. We finally went up to talk to them and I took a silver dollar out of my pocket and gave it to the shop foreman. I told him to put it in his pocket and every time he felt or saw it, he was to think about running our parts. It took seven days from start to finish for the investment casting process. They made a wax master part and dipped it in a ceramic slurry, like they’re making a candle. It took seven days for that to set up, and then they poured our parts. They could put up to 50 or 100 on a tree, and several trees on a pour. So, seven days after I gave him the silver dollar, we had our parts. We made close to 2000 sears, before the ban, using the casting method. Fleming and Qualified Shooter Supply were making their stamped sheet metal HK sears at the same time, although we didn’t know it until later.

SAR: How about the FNC sears?

CURTIS: The FNC sears were machined out of sheet metal and then heat- treated. We were the only ones to manufacture and register these sears, and I still have some of these available. If a customer wants to have his FNC converted with one of my sears, it costs $1600 plus $35 for shipping and handling. This includes the installation and remarking of the trigger housing. I won’t sell the sears by themselves. We also manufactured 10/22 sears before the ban. These were made similarly to the HK sears as castings, which we later machined.

SAR: When did you start to manufacturing silencers?

CURTIS: At about the same time, but we weren’t able to do many of them because of the time factor. That’s when I encouraged John Tibbetts to get started in the suppressor business. I even sent him my design on the .22 suppressors, as he was a good friend. John set up his own business, did his own advertising, and now has a full line of his own excellent suppressors. I continue to manufacture the suppressed Rugers including the .22 Mark II pistol, 10/22 rifle, and 77/22 rifle. I also do an MP-5 9mm silencer.

SAR: Are your MP-5 silencers integral or muzzle cans?

CURTIS: Actually, I do both. Both cans have the same diameter, but the muzzle can is shorter at 8 and 3/4 inches with the integral SD can at twelve inches long. My SD suppressor is very close to the factory suppressor. I put the same amount of holes in the barrel, which is the same length as the factory barrel. I also build the rubber hand guards and metal hand guard cages for the SD. I don’t pull the barrels out of the receiver when I work on the guns, unless I absolutely have to for some other reason. I have built fixtures that go onto the receivers, which allow me to chuck up the whole assembly in the mill or lathe for required machine work. Pulling a barrel is time consuming, requires re-head spacing the firearm, and some barrels are screwed in so tight you run the risk of torquing the receiver when attempting to remove them.

SAR: Can you tell us about your machine shop?

CURTIS: With my recent addition, it is now 4000 square feet. As far as equipment, I have two Bridgeport mills, three lathes, a heli-arc welder and a lot of supporting equipment to go with it.

SAR: What kind of welding do you do?

CURTIS: I weld up the HK’s to re-identify them, put on the paddle mag release, and change the model numbers as needed. I have special tooling for all this, to make sure I don’t melt through the sheet metal on the top of the HK’s. I fill in the old model numbers with weld, machine them down, and steel stamp the receivers in a fixture with a new designation. I have different stamps for the MP-5, MP-5K, MP-5 SD, and the HK-33 and -53. For the paddle mag release, the ATF won’t allow you to put the hole all the way through on these guns, so once you put the hole in for the paddle, you have to weld it back up. The hole can’t go all the way through the receiver, so it ends up just being a partial hole through one side.

SAR: What other services do you provide?

CURTIS: I do restoration and refinishing work on guns, as well as gunsmithing to fix HK’s that aren’t running right. I don’t do HK 51’s or 53K’s. I only work on models that the H & K factory makes. I will also rebuild suppressors, including those made by other manufacturers.

SAR: Do you have any new products that you can tell us about?

CURTIS: Yes, I am getting ready to build a run of suppressed .44 Magnum rifles based on the very successful suppressor I used previously on the Marlin Camp Carbine .45 rifle. This run will include some of the lever action 96/44 Ruger rifles and eventually some bolt-action 77/44’s.

SAR: Curtis, thanks for taking time to share your history with our readers.

CURTIS: You’re welcome.

S & H Arms of OK, Inc.

P. O. Box 121

Owasso, OK 74055

PH (918) 272-9894

FAX (918) 272-9898

| This article first appeared in Small Arms Review V5N11 (August 2002) |