By Matt Smith

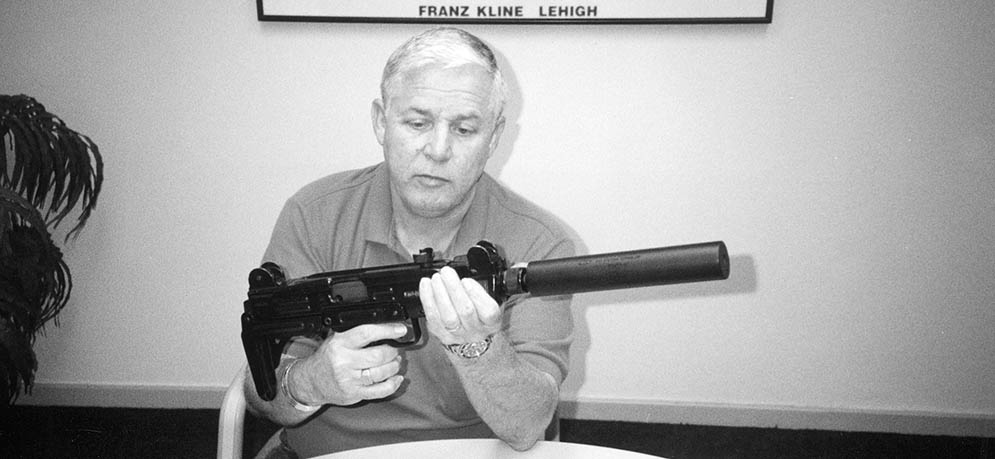

Above: Lynn McWilliams with his favorite SMG, an AWC suppressed Uzi.

SAR: What was your first exposure to firearms?

LYNN: Following high school, I did six years in the Marine Corps. I initially served in a reconnaissance unit. I then ended up being a demolition specialist and assisted in setting up a school in Viet Nam. I spent time operating in the field with the unit gathering Intel on the booby traps that line companies might encounter in certain areas. We would bring in the Infantry Companies and brief them on the latest and nastiest gear that Charlie had in store for them in the field. After leaving the Marine Corps, I had an interest in firearms that led me into the business. We started in Houston, Texas, and eventually moved to Phoenix because of our involvement with McMillan on the Navy sniper rifle project, which was done in conjunction with Qual-A-Tec. During this project in 1988-1989, I worked with Mickey Finn and Doug Olson and had the opportunity to show them a rifle silencer I had been manufacturing. They had a new baffle that was very interesting, and I had a mount and entrance chamber design that worked real well to minimize first round ignition. We ended up combining these features in the Navy contract suppressors. I had to build the machine that would form the baffles for that silencer, because they were too expensive to machine. The stainless baffles were formed under high pressure to a useful configuration, welded, and then machined. The sniper team Honcho for SEAL Team 6, came out and tested the system on the Ben Avery NRA range near Phoenix. His opinion was that the recoil reduction of the silencer made the .300 Win Mag something that could be shot all day. Dick Brown from NAVSEA Systems agreed after firing it to change the mix ratio and procure more of the .300 Win Mag’s than the .308 rifles.

SAR: Tell us about your work with Doug Olson on this project.

LYNN: Doug was domiciled in Chino Valley, Arizona working out of a small building. He had a little Lagun CNC mill, a long bed lathe, and other shop equipment, doing mostly R&D and working on unsolicited proposals. Qual-A-Tec and Phrobus were going through some business restructuring. Following some discussions, Doug thought it to be a good idea to come to work for us. This was during the same time frame that the Navy had issued a requirement for a test quantity of beefed up Beretta 9MM pistol slides. We did the R&D and AutoCAD drawings and prototyping for this slide in our old facility. The production machining went to McMillan Machine for a limited run of the slides. Doug was with us for several years, and while he was with us he continued to work on a pet project of his own, on his own time. It was a caseless cartridge concept, based on a Ruger Security Six pistol testbed. Doug has a very fertile mind, and we reached a point where we had exhausted our requirement for his talents. We did extensive R&D in the years he was with us including building prototypes and function testing. Because of my manpower requirements, I began using Doug more as a machinist than as an engineer at the end. I did not see the caseless ammo project as part of AWC, so I suggested that he call Reed Knight. He did and they decided to get together.

SAR: Where did Tim Bixler fit into AWC?

LYNN: Back when we were in Houston, we didn’t have a sizeable production effort of our own. Tim was a very talented machinist who had converted his garage into a workshop and built parts for us. He had a lathe and a Bridgeport and could machine just about any part we needed. We would give him drawings and pay him to make parts for us. This lasted until he decided he wanted to make silencers on his own.

SAR: How would you define your current customer base?

LYNN: It’s highly diversified. I don’t truly know who all the end users are. I get lots of calls from agencies that have our products, knowing full well that I didn’t sell these to them. We mainly sell to dealers who are free to sell as they see fit. As far as the military, we have never pursued the government or military as a customer. They have found us. The products that they use from us are mostly from off the shelf. Occasionally, we have developed items for Aberdeen Proving Grounds, Picatinny Arsenal, Crane, and recently the Air Force for .50 cal suppressors.

SAR: What’s the best selling caliber of the suppressors you sell?

LYNN: The .22 caliber has always been our best seller. Due to the decline in availability of the machineguns, following the 1986 machinegun ban and the newer legislation limiting flashiders, we are seeing fewer requirements commercially for M16 suppressors and sub-machinegun suppressors. Our commercial pistol and rifle suppressor market however, has grown each year.

SAR: Would you explain the history of the Archangel?

LYNN: This is a good example of something evolutionary. It began with a .22 muzzle suppressor that Phil Dater built for me in about 1980. I sent Phil a Beretta model 70S pistol and had him add his muzzle snuffer to it. It was a good suppressor, but the first shot sounded like a bloody cannon, while the second and third round were fine. I started to play with this thing and ended up trying close to forty different configurations of rearranging and modifying parts. I ended up with something that was very quiet even on the first round. There have actually been five different baffle stacks used in the Archangel series, although a couple were used in such limited custom numbers that they didn’t justify a nomenclature change.

SAR: How about the different configurations with the Amphibian .22 pistol?

LYNN: Looking at the concept of the pistol and its size, it’s actually the barrel construction that makes the Amphibian what it is. It is the length of the barrel that always comes into question. Typically, barrel length affects velocity, but has nothing to do with accuracy. One of the main considerations is the type of ammunition that will be shot out of the weapon. Quality control in .22 ammunition is all over the board. Different lots of the same ammunition can vary greatly. Most people will shoot the cheap K Mart or Wal Mart bulk supersonic ammunition. What we look for on an integral .22 is something that will take that velocity and pull it down to subsonic. Our choices are to use a short barrel or a long barrel with a lot of holes in it. I prefer the shorter barrel route with small ports because it means less machining inside the bore. Big holes in barrels trap big quantities of lead, and at some point in time the chamber around the barrel becomes full of it. The current Amphibian has a short barrel with small ports.

SAR: When did the wet environment cans come on the scene?

LYNN: In the early days, Qual-A-Tec did most of the work with artificial environments. The Navy, at the time, was using the Hushpuppy suppressor with its multiple urethane wipe assemblies. The first shot was extremely quiet and the most accurate compared to subsequent shots. The best accuracy that could be expected using a Hushpuppy on a Beretta was 4 inches at 25 yards with a locked slide. The concept of this silencer was to trap the gas inside the wipes and the slide lock prevented much of the gas from escaping and allowing a high frequency pop out of the ejection port. A negative side effect of shooting the Hushpuppy without the slide lock is the propellant and wipe particles coming back into your face. The big barrier on improving the sound level on the Hushpuppy is the noise of the bullet impacting the urethane wipes. The maximum noise reduction with this system will be 32 dB reduction because of the wipes. This system originated during the Viet Nam time frame, along with other suppressors made by HEL Labs, Sionics, and Frankford Arsenal. It continued to be used following Viet Nam until wipeless systems started to take its place. Artificial environment baffles have to be designed and machined to take advantage of this concept. All we’re trying to do is absorb heat and cause a transfer of energy. Over the years we’ve used condensed copper, screen, and all sorts of things to absorb heat and cause the fireball to lose it’s energy. You have to get rid of the fireball at the muzzle. Artificial environments can be water, gelatin, oil, or grease to quench the fireball. We supply our 9mm, .40 caliber, and .45 ACP suppressors with a tube of product made by AGS. It has excellent longevity no matter how long it sits on the shelf before it’s used. In a Beretta 92, for example, you can shoot a full magazine without much degradation in the sound reduction. Artificial environments allow you to make pistol suppressors that are very small and extinguish a lot of heat and flame at the muzzle.

SAR: What do you think of subsonic ammunition?

LYNN: I understand it has its place today in certain tactical environments but it amounts to carrying a twelve pound .38 pistol out with you if you are shooting a .308 rifle with subsonic ammunition. I consider it a last ditch effort because of the excessive flight time of the slow bullet. You can just about order lunch between the time you fire and when the bullet impacts, depending on the range. I personally prefer full house ammunition where I know a shot on center mass will be more effective with less chance of the target moving out of the bullet’s path. When it comes to subsonic .223, I believe you can probably be just as effective shooting a suppressed .22 LR if you can place the bullet where it belongs.

SAR: Have you got anything new on the drawing board you can tell us about?

LYNN: I have some ideas, but to tell you the truth the problem I have is the time to do it. I continue to have a several month backlog on Amphibians. I will probably go to my grave, building Amphibians, as there is no way I can build enough of them. As a company, we’re about as big as I want to be.

SAR: Lynn, thank you for sharing your story with us.

LYNN: You’re welcome.

AWC Systems Technology

P. O. Box 41938

Phoenix, AZ 85080-1938

PH (623) 780-1050

FAX (623) 780-2967

www.awcsystech.com

| This article first appeared in Small Arms Review V5N11 (August 2002) |