U.S. made M240 Coax with “Spirit” button for meeting the first year production goal.

When I answered the phone, I could sense the frustration in his voice. The caller was a friend of mine who head up small arms procurement in a Scandinavian country. His quick greeting was followed by the description of a small machine screw. As he gave me the dimensions in millimeters, I banged out a few numbers on my calculator, and realized he was describing a 6-40 screw – common in our inch-system. He told me it was for a U.S.-made gun sight. He had checked all of his sources in Scandinavia and even some in Europe, but none of these suppliers had any on hand. He asked if I would buy him some of these screws so he could pick them up when he visited me in Florida during the following week.

This episode started me to thinking about U.S. small arms. Is it time we consider going metric? I know we’ve been at this crossroads before, but it has never happened. Maybe there are good reasons now to reconsider. If you’ll allow me to present some facts, I’ll let you be the judge.

One of the first facts to consider, is that a “decimal-based measurement system” (the metric system) was proposed by Thomas Jefferson in 1790 and the U.S. mint was formed to produce the world’s first decimal currency with the U.S. dollar equal to 100 cents. Our system of measure did not go that way. As I’m sure you know, our inch-system is a carryover from our days as an English colony. The last major holdouts for the inch system were one-time fellow colonies: New Zealand, Australia, and Canada who switched over to metric more than 40 years ago.

Flirtation with a Metric Small Arm-the FN FAL

In 1953, the U.S. military had to decide what they would do if the 7.62mm Belgian FN FAL (U.S. designation T48) were to win the competition against the U.S. T44 (M14.) After beating out the M14 in several trials, the FAL was on the fast track to become the official U.S. service rifle, but the FAL did have one detractor: the design was metric. To assure there would be no U.S. production problems, Harrington and Richardson was awarded a contract to convert the design over to the inch system. H&R built a quantity of 500 inch-system FAL’s of exceptional quality. As this production was ongoing, engineers under the direction of Springfield Arsenal’s Roy Rayle, worked around the clock to correct deficiencies in the M14 design. In 1954 testing, the two rifles – T44 (M14) and the U.S.-made T48 (FAL) tested to a draw, and in subsequent trials the T44 went on to win.

Why the big exercise to make an inch-system rifle? To enable U.S. production of the T48-FAL in the 1953 timeframe, there was almost no choice but to convert the design and the drawings to the inch-system. Factories across America had manual lathes and milling machines that could produce weapon components, but these were all set up with inch-system controls. Screws, roll pins, solid pins, spring wire, and sheet metal stock were readily available in U.S. markets, but only in inch-system sizes. Similarly, measurement tools, like vernier calipers, micrometers, and gage blocks were configured for inch-system only measurements. Producing metric components in the U.S. without converting to the inch system was simply not a reasonable option. Success of the T44-M14 made the issue temporarily go away, with no need for further consideration of the metric system in small arms for a long time afterwards.

U.S. Government Mandates Metric

By 1968, most of the world had become metric so a Federal law authorized a 3-year study to determine the impact of increasing metric use in the U.S. Many of the major companies in the U.S. passed out conversion manuals for the International System of Units (SI) that was being adopted throughout the world and trained their workers to use the metric system. By this time, the newer Computer Numerically Controlled (CNC) lathes and milling machines were capable of easily converting back and forth from inch to metric so there would be no major trauma when metric drawings reached the production floor.

The U.S. Metric Study was completed in 1971 and their published report recommended we should “go metric” on a carefully coordinated national program. Congress passed the Metric Conversion Act of 1975 and established a U.S. Metric Board, but a timeline was never established for metric conversion. U.S. arms producers like the General Electric Armament Systems Department, followed a government directive mandating that new guns should be metric. They complied in the next product they released, making the drawings for the newest Gatling gun totally metric. And what about the ammunition feed system that connected to it? It was produced using inch system dimensions. Why? Because the government directive said the guns had to be metric, but made no mention of the feed system, so it was a half measure at best. This was typical of the resistive mood of the country towards the metric system. After years of public apathy, spending money, and achieving only marginal results, the U.S. Metric Board was disbanded by President Reagan in 1982.

European Small Arm is adopted: It’s a Sweet Baby but it’s Metric.

In the mid 1970s an international shoot-off resulted in the adoption of the first metric weapon in modern U.S. military history, the 7.62mm FN Herstal Belgian MAG-58. The machine gun, U.S. designation M240, was designed totally in metric. The Army bought the manufacturing rights and the drawings with the intent to competitively procure the weapon and spare parts from manufacturers in the U.S. This required that the Army bring these 1950s era drawings up to current standards, meaning the ones outlined in a specification known as ANSI-Y-14.5 managed by the American Society of Mechanical Engineers. The Army converted the drawings themselves but left the metric system in place. They also left the drawings in first angle projection – the European standard – but more about that later.

It is important to note that by the late 1970s, the manufacturing scene in the United States changed dramatically. CNC machine tools were everywhere, with most of them easily capable of switching from inch to metric. Many conventional lathes and milling machines had digital readouts added to them, making them capable of inch/metric conversion with the push of a button.

FN Herstal won the 1979 production contract to make the M240 in the U.S, and built a factory in South Carolina. FN knew they would be faced with a challenge in finding qualified machinists and other factory help, but they had experience in setting up small arms factories in third world counties and reckoned South Carolina would be easy by comparison. They brought in their own manufacturing team to train the workers, hired manufacturing managers who had prior experience setting up manufacturing plants outside the U.S., and went totally metric on the manufacturing process. During the first full production year, a quantity of 4,509 M240’s was the production goal set by the Army. Guns from every production lot that year had to pass an interchangeability test with other M240s made on the same line. At specified intervals, U.S. made M240s were interchanged with FN Herstal-made guns and were required to pass the same acceptance test. In every case, the weapons functioned flawlessly and the production goals were achieved.

Five years later, the FN South Carolina plant submitted the lowest bid and won the manufacturing contract for the M16A4. If there was to be a metric/inch production challenge, this was it. There was no plan to change the M16 drawings to metric. In fact, it was never discussed. Rather, buttons were pushed on the CNC machines and machines that were formerly making metric M240 parts were now making M16 components. Not only were both inch and metric drawings on the shop floor at the same time but the U.S. drawings were in third angle projection and ones of European origin were in first angle projection.

First Angle – Third Angle: What is it and Who Cares?

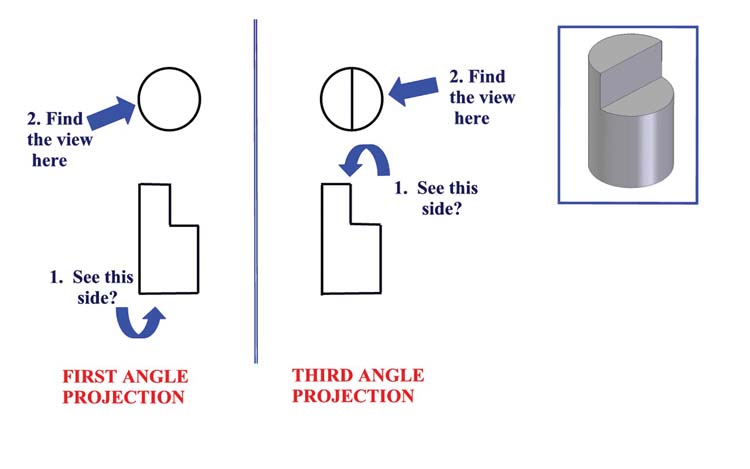

The “projection of a drawing-first or third angle” relates to engineering drawings, or “blueprints” if you prefer that term. Since we must use a two dimensional drawing to define a three dimensional component, rules have been set up for where different views are positioned on the drawing – this is called the “projection.” Europeans set their drawings up in first angle projection while in the U.S. we prefer third angle projection. First angle and third angle drawings have one view in common but the rest of the views are in opposite locations. The differences between these conventions are explained in the illustration, and it all makes more sense if you consider the logic behind them. In the third angle system, the user moves his/her eye around the part 90° at a time to “see” another side of the part and the view is positioned accordingly. In the first angle projection system the part is “rotated” 90° each time for a new view. If you are familiar with one system and not the other, you’ll find the left side view where you expect the right side to be, the top where the bottom should be, and so on.

Textbooks describing these systems make the case that Americans find first angle projection illogical. To avoid confusion, drawing standards specify that a figure with two views of a truncated cone be placed in the title block of every drawing to show the part is depicted in first or third angle projection. There is little danger in confusing metric dimensions for inch dimensions; like making a firing pin 400 inches long instead of 400 millimeters. Not paying attention to whether the part to be made is described in first or third angle projection, however, can easily result in parts being made backwards.

By now you may be wondering how FN Manufacturing made out manufacturing with drawings in first and third angle projection as well as metric and inch. Surprisingly it didn’t cause them any problems. The U.S. Army eventually did convert the M240 drawings to third angle projection, fearing that small businesses making spare parts without understanding the application could mistakenly make the parts backwards.

Where Are We Now?

He we are today, 30 years after the metric M240 was put into U.S. production and where is our manufacturing technology? Essentially with the flip of a switch, practically every modern machine tool will operate in metric or inch. Electronic digital readouts on manual milling machines and lathes give even those machines dual capability and the opportunity for even the smallest machine shop to produce in either system. Even inspection equipment from Coordinate Measuring Machines to hand held vernier calipers and micrometers swap metric units for inch units at the push of a button. And what about first and third angle projection? Most good Computer Aided Design (CAD) systems that we now use to make our drawings can switch from either system by the mere selection of a “radio” button. Our military continues to procure metric weapons including the Beretta M9 pistol and the Heckler & Koch M320 grenade launcher and at the same time inch-system weapons like the M4 and M110.

It is the job of U.S. arsenals and military directorates to specify what small arms will be bought along with the drawing packages that define them. There is a directive in the Federal Acquisition Regulations that specifies metric dimensions should be used. Officially, the metric system is preferred, but there are open ended exceptions to the Metric Conversion Act. This means the military doesn’t really care if your drawings are inch or metric or if your hammer rotates on a 1/8-inch pin or one 3 millimeters in diameter. One of the newest small arms under consideration by the military is the LSAT designed by AAI. This light machine gun, firing cased telescoped ammunition, is designed in inch system and is likely to stay that way unless the military directs otherwise.

Pro – Let’s Do It

Just how difficult would it be to specify totally metric weapons from here on out? There would be changes to threaded fasteners, pins, nuts, spring wire, rollers, ball or roller bearings and other hardware. For the most part, the standard metric sizes are close enough to the standard inch sizes so that nothing is sacrificed in strength or durability. Sheet metal comes in standard metric sizes but this is one where direct substitution that could cause a problem causing the substituted part to be too thick or too thin. This change does require careful study and potentially some dimensional changes to mating parts.

Our NATO and other allies are all using the metric system and sometimes our weapons systems. If our small arms were designed with metric, components like pins, screws, and other hardware, would be available to them in their normal supply chains avoiding situations like the one my Scandinavian friend encountered. In short, metrification would make all U.S. small arms more attractive to the rest of the world.

Likely the best reason is that the metric system is incredibly simple. U.S. schools are teaching the metric system and students are finding it easier than our inch system. One high school teacher told me that when her students are required to make measurements, she gives them metric rulers. She switched from inch rulers because students became so bogged down with fractional inch conversions; they were missing the point of the exercise.

Con – Let’s Don’t

We’ve been making parts in inch system dimensions for a long time, now, and have a ready supply of inch system hardware and components. In many cases, metric components are more expensive. The easiest path forward is to continue to let small arms manufacturers produce weapons using any system they want.

Any change, no matter how small, always has an associated price. Not every machine shop is equipped with the latest machine tools and measuring equipment, and even those that do, will still find a certain percentage of their equipment will become obsolete.

The manufacturing success at FN aside, it cannot be denied, there is always the possibility of making manufacturing mistakes when using both inch and metric drawings in the same factory. Introducing metric drawings in first angle projection will only compound the problem.

Conclusion

It’s decision time. Do we make the change to metric in small arms now, or do we kick the can down the road and hope for the best? After all, we still have some allies who, like us, have not adopted the metric system – Liberia and Myanmar. If we hurry, we might at least say we’re not the last country to “Go Metric.”

| This article first appeared in Small Arms Review V14N6 (March 2011) |