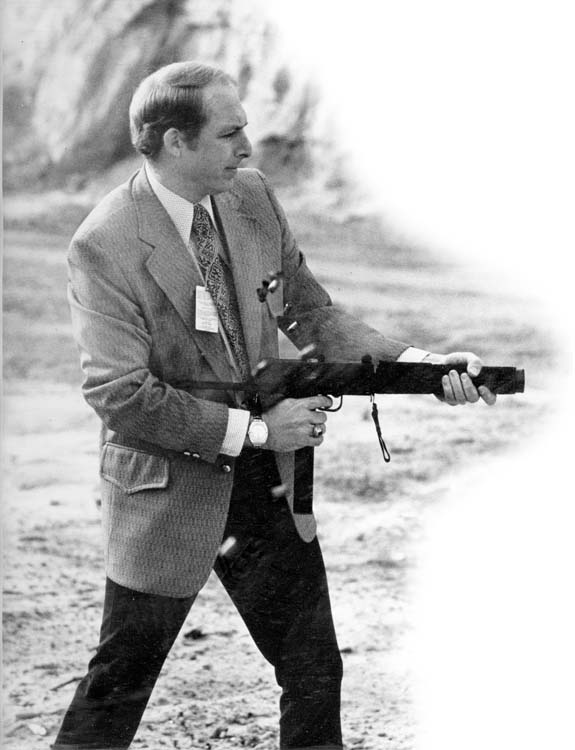

Although the name John Foote may be unfamiliar to most today, he is a very talented engineer and firearms designer. Mr. Foote, like most designers, had a lot of ideas, was awarded a number of patents, and built a number of prototype weapons. However, most of John Foote’s prototypes looked like production firearms, with fine finishes, beautiful wood stocks and foregrips, all done by him.

John P. Foote was born on 23 August 1937 in Lovell, Wyoming. His father designed natural gas plants and after each job was completed John’s family moved. At fourteen years of age, young John and his family were living in Texas where he became interested in firearms and built his first rifle. The stay in Texas only lasted three years before the family moved to Ohio where John graduated from high school. After high school John returned to Texas where he attended Texas A&I University, completing two years of basic engineering studies. He then transferred to the University of Texas at Austin, graduating with a degree in mechanical engineering in 1962.

After graduation one of John’s first jobs was with Pratt and Whitney as a test engineer on the J-58 hybrid engines that were used to power Lockheed’s SR-71 Blackbird, a long range, Mach-3 reconnaissance aircraft.

Having more interest in firearms than jet engines, John moved onto a job at AVCO Ordnance in Richmond, Indiana. AVCO was developing rocket-powered arms similar to the short-lived Gyrojet pistols. Mr. Foote worked on several designs including a 40mm shoulder-fired weapon fed from a drum magazine and a 16mm pistol.

In 1966 John went to work for TRW in Ohio. While there he met and worked with Gene Stoner on the 25mm Bushmaster project, and a 35mm Oerlikon-Buhrle cannon design. Another project, on which Foote worked with Stoner at TRW, was a twin barrel externally powered armor machine gun. A scale model was built in chambered for the 7.62 NATO cartridge. After leaving TRW, John went to work at Colt where he briefly worked on the M16 successor program before being lured back to TRW where he worked until the plant closed in 1970. A true firearms enthusiast, Mr. Foote designed and built many prototype rifles at home in his spare time.

The MP61 Submachine Gun

One of John Foote’s early prototype weapons was a simple .45 caliber full-automatic only submachine gun built in 1961. The MP61 was designed as a rudimentary low-cost weapon. The receiver was fabricated from the steering column of an old Plymouth. The MP61 had a cyclic rate of approximately 500 rounds per minute, and was fed by standard M3 “Grease Gun” 30-round magazines. The weapon had an 8-inch barrel; overall length with stock folded was 15-inches, and a loaded weight of 8.25 lbs. The prototype MP61 was marked: MP 61, EX-003, No. 20. There was only one prototype MP61 built; the weapon was never put into production.

MP63 Submachine Gun

The .45 caliber MP63 submachine gun was designed by John P. Foote and produced in prototype form in 1963. The unique feature of the weapon was its long hollow “forearm” that ran the entire length of the weapon. The trigger and sear linkage were contained inside of the forearm of the MP63 and the sear was located at the rear of the receiver. The gun featured a top-mounted cocking handle that was convenient for left-handed operators of the weapon. The cartridge ejector was permanently fixed to the receiver. The U.S. M3 submachine gun magazine was utilized to feed the weapon. Barrel length was 9 inches and the overall length was 16 inches. Markings on the receiver were MP 63, No. 25 Escondido Arms MFG.

MP32 Submachine Gun

The Foote MP32 closely resembled the Thompson submachine gun, but had an inexpensive seamless steel tubular receiver and barrel. The weapon was chambered for the .32 caliber pistol cartridge. The weapon was meant to be an inexpensive, and very controllable, variation of the Thompson. There was not enough interest generated to justify a production run of the MP32.

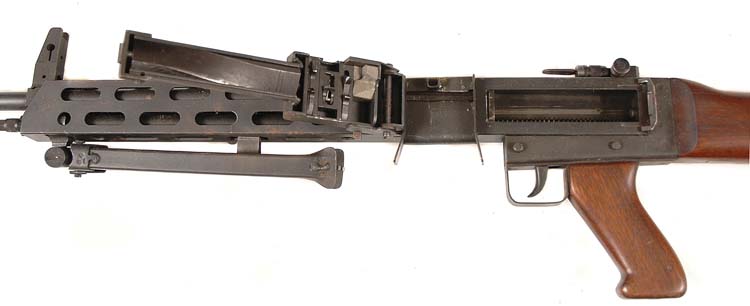

MG69 Light Machine Gun

The Foote prototype MG69 light machine gun was primarily constructed of sheet metal components. The belt-fed weapon used a unique side-mounted hinged cover that held a long semi-hemispherical cylinder that was activated by the movement of the breech bolt to feed the ammunition belt into the receiver. The weapon also featured a fixed, folding bipod and folding rear sight.

MP970 Submachine Gun

Mr. Foote’s next effort was the MP970 submachine gun. The 9 designates 9mm, the number 70 the year the weapon was built. The MP970 featured a rectangular steel receiver with a number of cooling slots around the enclosed barrel. The receiver was fabricated from flat steel plates that were spot welded together. The blowback operated, open bolt MP970 used a telescoping style bolt to keep the overall length of the receiver to a minimum and a detachable wooden buttstock was also planned. The weapon fired full-automatic only, feeding from a German MP40 machine pistol magazine. Barrel length was 8 inches and overall length was 15 inches. There were no markings on the receiver of the prototype.

The Foote Hinged Submachine Gun

This unique Foote weapon had a square sheet metal receiver that was hinged in three separate places. The top plate was hinged at the front and rear. The bottom receiver plate, containing the trigger group, was attached to the rear plate by a third hinge. The weapon was disassembled by manipulating the magazine catch that would first release the bottom receiver plate; that would be followed by the rear plate and then finally the top cover in a clockwise fashion. When unfolded, the three hinged plates remained attached to the gun and allowed for fast and complete access the bolt, barrel and trigger housing group for maintenance or cleaning. Only one prototype was built.

The R-68 5.56mm Rifle

The Foote R-68 (Rifle, 1968) was an experimental assault weapon. The basic goal was to design a simple, easy to manufacture, low-cost weapon. The design was simple having only 68 parts. The receiver was made from uncomplicated steel stampings. For reliability, the proven long-stroke, adjustable gas system was used where the gas piston was attached to the bolt carrier. The same system used in the Soviet AK-47 design. The rotating bolt design was locked using an interrupted buttress thread. The charging handle was centrally located on top of the barrel for accessibility by both right and left hand shooters. The safety lever was located inside the trigger guard for easy operation while keeping the shooter’s finger close to the trigger.

FAC 70 Assault Carbine

The FAC 70 Carbine (Foote Auto Carbine) was a 5.56mm weapon that was a product improved version of the R-68 Rifle, which was considered to be too heavy. The FAC 70 was lighter and easier to manufacture than the R-68. Sterling Armament of England was very interested in the FAC 70 Carbine and the carbine was shipped to England for test and evaluation.

Military Armament Corporation

During 1970, John interviewed for job at the Military Armament Corporation in Marietta, Georgia. He was hired as an assistant to Gordon Ingram in the Research and Development Department of MAC. Later, Mr. Foote was promoted to Head of Engineering, Head of Quality Control and Vice President; holding all three positions at the same time. MAC demonstrated many of John Foote’s designs to potential customers. His FAC 70 Carbine was offered to Sterling Armament of England. Sterling showed considerable interest in the rifle, but a deal could not be made. Mr. Foote left MAC about the same time period they began to experience irreversible financial difficulties.

Foote-Ingram Pistol

After the demise of the Military Armament Corporation, John Foote designed an improved version of the basic Ingram design he designated the M10A2. Simplified for mass production, one of Mr. Foote’s innovations was a modular trigger group. The Foote-Ingram M11A2 was a .380 caliber pistol that was 20-percent smaller in size than the production MAC M11. The barrel threads were much finer than those on production MACs to prevent the suppressor from loosening during firing.

U.S. Armament Corporation

After leaving MAC, Mr. Foote became part owner and President of a new company: the U.S. Armament Corporation. John Foote had designed and built a .22 caliber conversion kit for the AR-15 and M16 rifle. His design competed with many others for adoption by the U.S. Army, including the version designed by MAC co-worker and friend Max Atchisson. After the usual extensive testing and government red tape, Mr. Foote’s conversion unit won the competition and was adopted by the Army as the .22 Caliber Adapter, M261.

The first production run was subcontracted out to Okay Industries, of New Britain, Connecticut. A second contract was awarded to Maremont of Saco, Maine. Mr. Foote eventually sold his U.S. Armament Company and all the patent rights to the M16 .22 caliber conversion kit.

After leaving MAC, John contacted Sterling Armament on his own in another attempt to sell his FAC 70 Carbine. Again, there was considerable interest in the rifle, but even when offered on a royalty basis, well under the $100,000 MAC had proposed, no deal could be made. Sterling felt that too much work remained on the project. The company wanted production drawings and tooling, but since the prototype was hand-made in Foote’s shop, none were available.

Foote-Sterling

The Foote/Sterling was first produced in 1982 as a .22 caliber semiautomatic pistol. The weapon was an accurate 3/4 scale copy of the British Sterling submachine gun. There were two variations offered. One was the standard model and the other had a slightly shorter barrel and receiver. There were approximately one hundred standard models, and only ten of the short version produced. The Foote pistols are treasured collector’s items today. A third select-fire model was planned but never went into production.

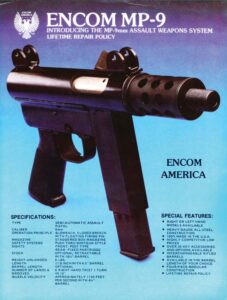

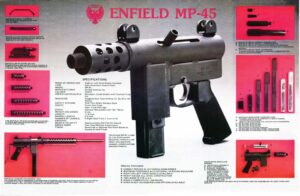

Encom Pistols and Carbines

In the mid-1980s, military-type semiautomatic rifles like the AR-15 were becoming very popular. During this period Mr. Foote designed and manufactured a line of assault carbines and pistols known as the Encom line that included the 9mm Encom MP-9 and .45 caliber MP-45. There were approximately 5,000 firearms manufactured before production ceased. The weapons were sold under the name Encom, Enfield America and Component Metal Products or CMP.

The Terminator

John Foote’s next project was an inexpensive, blow-back operated, single-shot 12 gauge assault style shotgun designed for Wayne Daniel’s SWD company. The shotgun was named the Terminator and a total of 1,452 were manufactured.

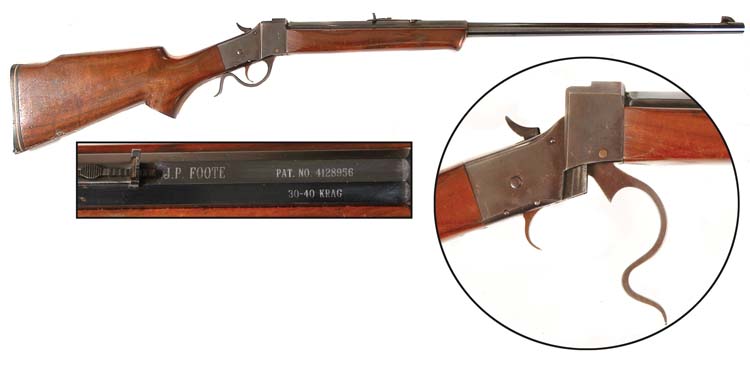

The J.P. Foote Company

At the J.P. Foote Company and sister company Progressive Engineered Products, both located in Marietta, Georgia, John Foote designed and manufactured many non-firearm related products. One of the most successful was the Hydraulic Rail Lubricator, a patented device used for lubrication of the inside of railroad track rails. The J.P. Foote Company also manufactured specialized parts for industrial and medical equipment.

(Special thanks to John Foote and Don Thomas for providing information and photographs for this article.)

| This article first appeared in Small Arms Review V14N11 (August 2011) |