By Pascal Thibert

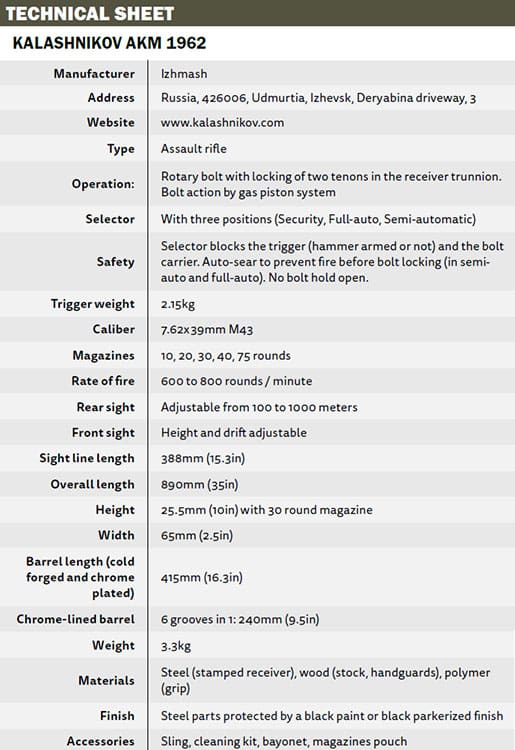

The AKM (Kalashnikov Improved Assault Rifle) is the second version of the AK-47. It was adopted in 1959 by the Russian Army. Built with a receiver stamped on a hydraulic press, it is lighter, more reliable and cheaper to manufacture, but a little less rigid than the AK-47 receiver.

History

The history of the AK-47 is quite well known, and it is inseparable from the birth of the at the time new multi-purpose Soviet cartridge, the 7.62x39mm M43. This caliber was imagined almost at the same time as the German 7.92x33mm ammunition, which the Russians tested after seizing the Sturmgewehr 42 on the battlefield. They also officially tried the USM1 US carbine chambered in .30 carbine (7.62x33mm).

The concept appealed to the Russians, and they set to work as early as 1942 to define their own intermediate rifle caliber adapted to an assault rifle—less power and speed but more capacity and compactness to make the weapon-ammunition package more effective in combat. It took a long time before arriving at the perfect caliber and at the concept of the assault rifle. A 7.92x41mm cartridge was designed and tested in a dozen different weapons. The results were not ideal; the weapons were too heavy so studies resumed. New tests were scheduled for the beginning of 1946 with the appearance of Mikhail Kalashnikov and the presentation of his work. He made a prototype submachine gun which was rejected by the evaluation commission. Then he designed a semi-automatic rifle, inspired by the M1 Garand rifle, called the AK-46 or AK N ° 1. The commission studied three rifles made by Bulkin, Dementiev and Kalashnikov. The latter was evolving his assault rifle, cleverly using the best solutions designed by the weapons engineers of his time. He finally won the official tests with his weapon that offered the best compromise between reliability, lightness, endurance and precision.

Production began in Izhevsk in the Urals during 1947 with press-formed receivers Type I that posed many manufacturing and quality problems. This led to mass producing machined frames Type II before being able to switch to stamped receivers from 1951 on.

The AKM Loses a Kilo

The AKM (Improved Kalashnikov Assault Rifle) was adopted in 1959 after studying numerous evolutions and having multiple tests. Despite the competition from other rifle prototypes, sometimes well designed and cheaper to produce, the Russian Army chose the AKM. The main evolution came from its press-formed receiver—lighter, cheaper to manufacture but a little less rigid. It was stamped from a 1mm-thick steel sheet and reinforced by front and rear blocks riveted to the receiver. The front block supported the barrel held in place by a transverse pin, unlike the AK-47 which had a barrel screwed into its machined frame. The cost and time required for manufacturing were also considerably reduced. Indeed, the machining of the steel blocks of the AK-47 to make receivers required more time, skilled workers and more raw materials.

Kalashnikov’s stock and grip were redrawn and lightened. Stock and handguards were made of birch plywood, which were lightweight and inexpensive. A compensator was added on the thread to reduce muzzle rise in automatic fire. The thread also allowed you to install a suppressor. The rear sight measured 800 to 1000 meters maximum, which was very optimistic. It was adjustable in height while the front sight was adjustable in height with the tool provided in the cleaning kit, but also in drift by a gunsmith with a hammer.

The main improvement concerned the weight, which was reduced by 1kg, being lowered from 4.3kg to 3.3kg by the lighter receiver being manufactured from sheet metal, by the slightly less heavy bolt, and by the modified wood. The AKM was black matte parkerized while the AK-47 was blued. Improvements were also made to the barrel and to the gas ports to increase reliability.

A new bayonet was designed to be attached to its rigid sheath, forming a cutting tool for barbed wire. The AKM could be equipped with many accessories; for example, the PBS silencer and the NSPU night-time scope. The 6G15, an adaptable grenade launcher under the barrel, was also developed for the AKM which launched front-loading 40mm VOG-25 grenades.

Auto-Sear also for Semi-Automatic Fire

The operation of the AKM is well known and often copied, with its bolt that locks in the steel block in front of the receiver, called the trunnion, by two lugs. This steel reinforcement is riveted into the housing and supports the barrel. Some manufacturers prefer the screwed in barrel. The front sight and the gas block are also each fixed on the barrel by two transverse pins.

When the bolt carrier approaches the chamber, the bolt rotates about 30 degrees to the right to lock into the receiver, with its two lateral lugs. The front of the bolt is thus in contact with the end of the barrel, and the cartridge is chambered. When you press the trigger, expanding propellant gases activate the piston / bolt carrier. The carrier moves back a little, which causes the unlocking of the bolt (by the action of the milled rail in the carrier that rotates the bolt to the left) and then the rearward motion of the bolt-carrier assembly ensures case ejection.

The trigger mechanism is equipped with an auto sear. This auto sear locks the hammer in the armed position when the bolt moves back, in addition to the hammer lock by the trigger. When the bolt advances, it hooks the auto sear, which unlocks the hammer. This allows hammer activation of the firing pin once the bolt is in the front most position, against the chamber. This operation is valid for semi-automatic shooting and for automatic shooting. Hence the importance of the presence of this trigger on all Kalashnikovs. This type of system also exists on the military M16 or M4, but in the full-auto mode only.

An Izhmash AKM Dated 1962

The AKM has a three-position selector that has the particularity, like the other rifles derived from the AK, to place the automatic fire position in the middle of its movement, just after the safety position. The safety selector closes the receiver and does not allow dirt to enter. It blocks the carrier from retracting, and the hammer and all the trigger mechanism from operating, cartridge chambered or not. When the magazine is empty, the bolt remains closed; it has no last round locking stop to keep it open. The trigger is well designed with its hook on the top of the hammer, far from its axis, which allows it to obtain a nice and functional release weight, around 2.0kg to 2.2kg, while the military rifles generally have heavier detents.

Disassembling the AKM is very easy for routine maintenance but also for the replacement of the barrel, a stock or a handguard. Pin punches and a gunsmith’s hammer are sufficient to disassemble most of the parts including the trigger, plus a screwdriver for the bakelite grip screw.

We had the opportunity to test a Russian military version of the AKM from l962, in its original configuration with all its parts and old wood. It bears its manufacture date next to its serial number, the EY42xx, and next to the triangle with arrow inside logo of the manufacturer Izhmash. Its sling also has its period markings; it is therefore the sling put into service in the Russian Army with the AKM. A weapon 56 years old still in excellent mechanical form. Its condition was not perfect at the time of purchase so its owner has made the choice to give it a facelift by polishing the wood (stock, handguards), which has removed the protective varnish but has given back the wood their original coloring.

Installation of Anti-Rise Muzzle Brake

After severe use over the years, the metal parts looked like new after a good cleaning, polishing and two coats of black paint (housing, guide rod gas borrowing, top housing cover). Successive cleaning and retouching had made the receiver look very worn; it was necessary to remove the painted fittings to obtain a uniform surface and color.

This AKM is chambered in the original caliber, the 7.62x39mm Kalashnikov, and it has the famous muzzle brake bevel cut intended to thwart the rise during automatic fire. A Russian pouch for AK or AKM for three magazines, a cleaning kit in the stock, plus the maintenance rod in place under the barrel, completed the set. A proper bayonet remains to be found.

We made our tests at 100 and 200 meters, using the metal sights, followed by the Aimpoint M4 sight and then the Aimpoint T2 sight, mounted lower. These two Aimpoints are made with 2 MOA red dot diameters. All our tests took place without any negative shooting incidents, 100% reliable chambering and ejections. We used a Millett brand firing support to stabilize our AKM. For our tests, we fired factory ammunition but also reloaded ammunition in order to be able to use powerful and quality cartridges with powder and non-corrosive primers— a bit aggressive for the barrel and the bolt. We had the opportunity to fire ammunition with brass cases from PPU Serbian FMJ ball 123 grain, then Wolf steel cases, green cartridges of former East Germany and Russian military cartridges also with steel cases.

.311 and .308 Bullets on Lapua Cases

To continue our tests, we proceeded with reloads on this cartridge with the use of Lapua cases using boxer primers, known for their quality. The die sets come with two calibration rods. It is necessary to install the rod for .30 caliber bullets beforehand to remove primers and full sizing. We chose to reload ammunitions so that we could test several types of bullets—123 grains in .311 caliber and 125 grains, 150, 168 and 200 grains in .308 caliber. For the .311, we used Sellier & Bellot bullets n ° 2907 standard Kalashnikov, then the Hornady .308 in 125 grains, IMI .308 in 150 grains FMJ, Lapua Scenar .308 in 167 grains and Sierra HPBT. 308 in 200 grains. All our reloads were made with Vihtavuori N120 powder; the manufacturer gave several loads depending on the bullet weight. As soon as it was decided to increase the bullet weight, it is imperative to lower the powder load to remain in admissible pressures. The capacity of cases does not allow exceeding certain limits for reasons of volume, the bullets above 125 grains coming easily in contact with the powder.

The results were correct with the factory ammunition as with the reloaded ammunition. Even if the AKM was not at the level of that of the M16, they were very accurate with match ammo. We obtained scores on targets with five cartridges at 100 meters from 85 to 97mm (3.34 to 3.81 inches), then from 113 to 158mm (4.44 to 6.22 inches) at a distance of 200 meters. These scores are honest with respect to some with surplus ammunition or with poorly prepared rifles, but they are not really at the level required for NATO assault rifles.

In automatic fire, the rifle is very lively and moves a lot, so it must be properly controlled. The bolt requires a powerful movement backwards to overcome the hammer resistance to put it in a cocked position.

Present-Day Kalashnikov Group

The latest versions of Kalashnikov rifles can be seen on the Kalashnikov Group website, with an interesting 9mm Parabellum model built on an AK receiver, or a Saïga rifle chambered for a new caliber, the 366 TKM, consisting of a 37mm (on the basis of the 7.62×39 M43 case) and a 9.55mm bullet of 168, 201 or 231 grains. This ammunition was introduced by a Russian manufacturer named Techkrim (a company specializing in sports ammunition and non-lethal ammunition). The other models are still produced, such as the AK-74, still in service in the Russian Army, as well as the Saiga civil versions, now very widespread.

All these AKs are produced on the historic site of Izhevsk, capital of Udmurtia, located in the Urals, which is a major industrial, commercial and scientific center. The history of the city dates back to the spring of 1760, when a dam on the Ij River was built simultaneously with the adjacent metallurgical plant. The development of Izhevsk was due to the installation of the armaments factory which began its activity in 1807. The city had developed its specialization in the field of defense, metallurgy, war weapons and hunting rifles. The first production for war was destined for the Napoleonic Wars of 1812. Izhevsk was a major strategic problem at all times, especially during the Russian Revolution. At the time of the First Five-Year Plan, the city grew rapidly thanks to new industries, such as motorcycles, machine tools and chemistry. In December 1934, Izhevsk was proclaimed capital of the Udmurt Republic.

Important Production Capacities

During the Second World War, the importance of the city as a weapons production center was considerable. The Izhevsk factories could equip an aviation division and an artillery division in one day. The post-war period is characterized by the development of the industrial base with a significant production of arms, motorcycles, automobiles and machine tools, renowned worldwide. Mikhail Kalashnikov is one of the architects of these successes, alongside other engineers. Izhevsk has always been a city of mechanical industries, famous for the arms factory established in 1807. It is, of course, in this factory that the Kalashnikov AK-47 assault rifle was developed and manufactured as its later versions. The Izhmash group also produced cars, IJ brand, as well as motorcycles. The concentration of defense factories in Izhevsk made it a very closed city during Soviet times, and foreigners were not allowed to enter it.

The Kalashnikov Armament Group took its name in 2013 in tribute to its engineer Mikhail Kalashnikov, who died that year. The first private investors arrived in the group suffered heavy losses. Kalashnikov was able to rectify its accounts by proposing new models, but especially by diversifying in particular sectors like clothing and knives. The group is developing its equipment and presents many new products: electric motorcycles, observation drones, non-lethal weapons and robotic destructive tanks. This initiative was taken by CEO, Alexeï Krivorouchko, who arrived during this first wave of privatization. In January 2017, Kalashnikov Group announced that it wanted to increase its workforce by 30%, with the creation of 1,700 additional jobs.

| This article first appeared in Small Arms Review V22N4 (April 2018) |