Text & Photos by Jeff W. Zimba

The masters of the miniature machine guns have just unveiled their latest creation. In just over a year, from concept to production, Lakeside Machine of Pound, Wisconsin has announced the addition of the LM-7 to their rimfire lineup. The LM-7 is a belt-fed upper receiver chambered in .22 long rifle for an M16 or AR-15 type rifle.

During the ten year period of the Clinton Assault Weapons ban (1994-2004), common firearms that were deemed “assault weapons” were prohibited from manufacture for sale to individuals. Also prohibited were magazines and feeding devices with a capacity greater than ten rounds. This resulted in a cessation of many innovative projects and caused a sharp increase in price for existing supplies of weapons and magazines. There were many new weapon concepts and pioneering ideas during this time, but with a market limited to the military and law enforcement, economically, there was little point in proceeding. With the expiration of the Clinton Assault Weapons ban in 2004, firearm design and ingenuity has reemerged after being stifled for ten years and new designs and products are hitting the market at an amazing pace.

Lakeside Machine has been in the business of manufacturing high capacity rimfire guns since their purchase of Tippmann Arms from F.J. Vollmer and Company in September, 2001. They initially specialized in the manufacture and sales of the one-half scale miniature Tippmann machine guns (Small Arms Review – Vol. 7 No. 6, March 2004). As the 2004 sunset of the ban got closer, their focus switched to a line of newly designed, shoulder-fired variants. Although the firearms could be manufactured in compliance with the ban, the limited availability of belts for feeding them was very poor. With the ban terminated, more belt material was able to be manufactured and a new generation of belt-fed rimfire rifles was born.

The first shoulder fired, belt fed rifle system designed by Lakeside Machine was the BF1 Vindicator (Small Arms Review – Vol. 8 No. 4, January 2005). Introduced in 2004, these rifles were manufactured in .22 Long Rifle with a few chambered in the relatively new .17 Mach II. These rifles used the same cloth belts originally designed for the Tippmann miniature machine guns and can also use the newly designed disintegrating links; another one of Lakeside Machines’ recent innovations. The disintegrating links are made of a Nylon material and function with .22LR, .22 Magnum, .17 HMR and .22 Mach II. These links have been upgraded by impregnating them with enough metal content to allow them to be picked up with a magnet.

In October of 2004, Eric Graetz, CEO of Lakeside Machine was approached by a customer and asked if he thought he could design an AR-15/M16 upper receiver that would accept his belts and links. Graetz accepted the challenge. After some months of research and development, the machine shop was retooled to manufacture the latest creation: the LM-7 .22LR (and .17 Mach II) belt-fed upper receiver. The prototype was unveiled in December of 2004 at the SAR Show in Phoenix, Arizona.

The LM-7 (the 7th model firearm developed by Lakeside Machine) is a complete upper receiver assembly that will fit on any standard AR-15 or M16 lower receiver and function with the trigger internals as intended. While offered in a semiautomatic configuration, an upgrade is available so the upper will function in full automatic when used on a registered full automatic lower receiver. To the delight of the NFA community, it will also work in conjunction with a drop-in auto sear.

Mounting the LM-7

Before replacing the stock upper receiver with an LM-7, the factory buffer and spring must be removed from the lower receiver and replaced with the new buffer assembly supplied with the LM-7. The factory hammer spring should also be replaced with a much lighter hammer spring that is also supplied with the LM-7. That is the extent of the modifications to the lower receiver when used on a semiautomatic rifle. When used on a full automatic rifle there are a few timing adjustments that may be necessary and will be discussed later in this article.

Installing the LM-7 upper receiver is as simple as pulling the two takedown pins, removing the factory upper and replacing it with the LM-7 upper receiver. Once pinned on the lower receiver, the factory magazine-well now functions as a brass ejection port. In order to catch the ejected casings, Lakeside Machine supplies a brass catcher that locks into the magazine-well in the same manner as a factory magazine. As it fills to capacity it can simply be “ejected” like a standard magazine, the contents dumped out, and quickly reinserted. The bottom of the brass catcher also has a swing-down floor plate to allow empty brass to flow through when the shooter does not want to retain the ejected casings. The brass catcher doubles as an attachment platform for the optional belt box and link catcher. Shooting long belts without the assistance of an A-Gunner can easily be accomplished with the use of the belt feed box. It holds a little more than 200 belted or linked rounds. Since the links are ejected directly across from the feed tray, another identical box mounted on the opposite side of the feed box catches all the used links.

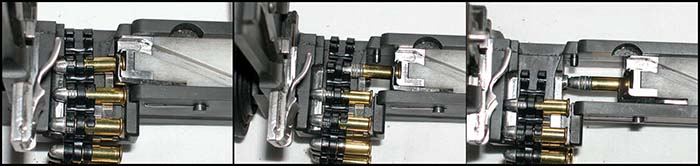

The LM-7 functions in a similar fashion to a Browning Model 1919 machine gun. It utilizes a shuttle feed mechanism that feeds the belt, extracts each round from the rear of the belt, chambers the round and extracts the empty case after firing. This mechanism does not utilize a locked action. The rifle is loaded by lifting the top cover and inserting the belt with the first round placed below the extractor. The top cover is closed and the gun is charged by pulling the bolt handle back and released one time. As a new round is pulled from the belt and loaded in the chamber the fired case is pushed out of the T-slot in the bolt and dropped into the brass box or directly on the ground.

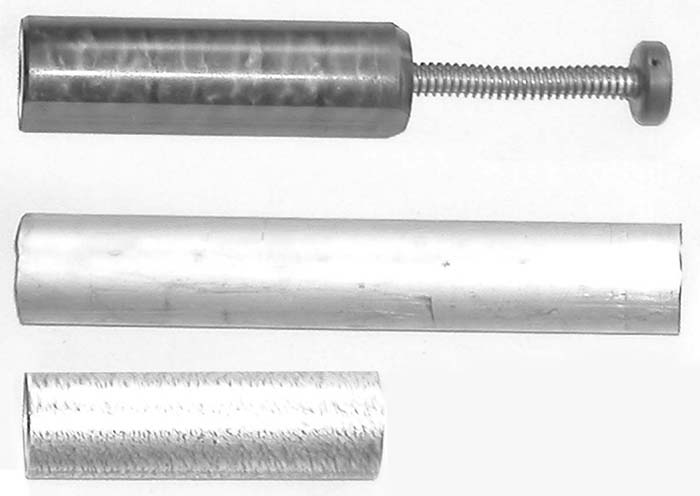

The LM-7 utilizes an exclusive quick-change barrel (QCB) that can be replaced in seconds. Changing or installing a barrel is as simple as depressing the barrel release button, pulling the barrel strait out, replacing the barrel and releasing the button. It is a direct action that requires no twisting, turning, adjusting or head spacing. Barrels are currently available in two lengths and three styles. Barrel lengths are 16.25 inches and 7.5 inches. The 16.25-inch barrels are contoured just like a standard M4 barrel and can utilize any of the M4 mounting options. Where the barrels are secured in the receiver by the QCB mechanism, they are completely free-floating and will work fine with any free-floating style handguard. If you wish to use standard M4 handguards you can utilize an adapter that secures them at the front and also doubles as a front sight block. Where it is unnecessary for the front of the barrel to be supported by any handguard mounting hardware, it lends itself well to the use of shorter barrels with sound suppressors. The 7.5-inch barrel we were shooting with was often fitted with an AWC MKII suppressor that protruded less than 4 inches past the standard carbine handguards. If this system were going to be set up in this configuration for regular use, the handguard would certainly be replaced with a free-floating type or any of the rail systems allowing the use of various accessories.

On the rear of the top cover is a 4.25-inch M1913 Picatinny rail to accept short optics or a removable rear sight. The front block installed with a 16-inch barrel includes a 1.75-inch rail that can host standard removable front sights and accessories. The LM-7 we tested was equipped with an EO Tech Model 552 Holographic Sight. While the version using AA batteries was a little long on this mount, it was certainly still usable. While using the sight with multiple quick-change barrels, we noticed very little point of impact change. Each LM-7 system is shipped with the LM-7 Buffer System, a 16.25-inch barrel, front sight block, brass catcher, two feed boxes, two 100-round belts and 200 links.

Rimfire Ammo Reliability

When the LM-7 was designed, it was built to function with the inexpensive CCI Blazer ammunition. This is fantastic news for shooters who are conscientious about their ammo budget. We tested the LM-7 with several types of .22LR ammunition and have included a chart indicating performance, muzzle velocity and rate of fire when utilized in full automatic. The ammunition we tested included CCI Blazer, CCI Mini-Mag, CCI Stinger, Remington Thunderbolt, Federal Lightning, Federal Bulk Pack, Federal Champion, and Winchester Wildcat. It ran fine with most but the Federal Champion was the least reliable. The absolute best was the CCI Stinger due to the increased power over standard .22LR ammo but the additional cost (almost $4.00 for a box of 50) may be enough to discourage many people. The Winchester Wildcat, Federal Lightning and CCI Blazer all worked great. The Federal Bulk Pack and Remington Thunderbolt also worked quite reliably. For some reason it was a little finicky with the CCI Mini-Mags. The author has found after years of shooting select-fire rimfire rifles and pistols, that when determining which .22LR ammo will work the best, it is usually a good idea to just try several brands in your own firearm. Some seem to run great with one particular brand while other firearms like something completely different. Factors that may be important in the LM-7 that would not necessarily be an issue in other .22LR guns include the thickness of the rim. After extraction from the belt, the round is channeled down a T-slot to the chamber, and captured in the T-Slot again as it is channeled down to the point of ejection. If a particular brand or batch of ammo has a thicker than usual rim, it could interfere with, or stop, the operation of the gun altogether.

The greatest obstacle in reliable functioning is the lack of energy in the little .22LR cartridge. It takes a lot of energy to run these machines in full automatic and when you start adding factors like pulling belts and links, the challenge gets even greater. Light parts and springs, necessary because of the low amount of energy created by the rimfire round, only add to bolt bounce problems and pose additional hurdles in the development of select-fire, Rimfire guns. Unlike many other select-fire .22 LR firearms, bolt bounce is not a problem in the LM-7 due to the function of the extractor pulling the new round from the belt at the same time the chambered round is fired. This action dampens the rearward travel of the bolt and eliminates the bolt bounce issue.

Timing and Function in Full Automatic

With the weak .22LR ammo in mind, we can get into some of the timing issues when shooting the LM-7 in full automatic. Subtle inconsistencies that are not critical dimensions with higher-powered rounds can often be the determining factor in creating problems when shooting rimfire rifles. In the case of the LM-7, some of the loose tolerances of standard 5.56mm guns combined with the fact there are several manufacturers of rifles, receivers and parts to fill them, create an enormous number of potential combinations.

When shooting the LM-7, the trigger function is identical to that of the original 5.56mm rifle. While shooting in semiautomatic mode, when the bolt carrier recoils from shooting the chambered round, the hammer is cocked and held captive by the disconnector. When the shooter lets off the trigger the hammer releases from the disconnector and engages the front of the trigger. When the shooter squeezes the trigger the hammer is released and the process starts all over again. When shooting in full automatic mode, the hammer bypasses the disconnector and does not contact it at all. A spur on the back of the hammer is caught and held captive by the auto sear and it is only released when the bolt carrier trips that sear when the gun has chambered the new round and it is in battery. The timing aspect comes into play with the relationship between the bolt carrier sear trip and the sear releasing the hammer.

The part of the LM-7 that has to be altered for full automatic fire is the bolt carrier. Just like the standard AR-15 and M16, all that is necessary for the upper receiver to accommodate a legally owned full automatic lower receiver, is the addition of a sear trip on the carrier. Lakeside Machine will be happy to provide owners of registered receivers or drop in auto sears with the piece needed to engage the auto sear. That is where the timing comes into play. The sear trip on the carrier needs to contact the auto sear at the precise time the new round is fully chambered. Due to the large number of parts and receivers on the market, one gun may need a specific thickness on the sear trip to engage the sear at the correct time while another gun needs one much thicker. This timing can be accomplished by simply removing an Allen-head screw, removing the sear trip, adding a piece of shim material (an old feeler gauge set works great for shimming) and replacing the trip and screw. When the hammer drops at the same time the bolt completely closes it is ready to go.

Early in the testing we realized the tolerance difference in some hammers also created a problem where the guns would not cock the hammer far enough to catch it under the auto sear. This would cause the hammer to follow the carrier back into battery without firing it. Some of the hammer spurs were much thicker and/or longer than others. The cause of the problem was the lower power of the .22LR ammo was sending the much lighter bolt carrier back much slower than a standard 5.56mm carrier and not getting the hammer to fall back far enough. The reason this is not usually a problem with the 5.56mm round is because the mass of the carrier and the speed it is recoiling at is much greater than that of the LM-7. Lowering the internals of the entire LM-7 system so the hammer would drop much lower and not rely on speed, but simply movement, solved this issue.

Loading Belts

If there is any downfall to shooting belt fed firearms it is the simple fact that we have to load belts before we can shoot them. Lakeside Machine has helped us out a little in this area with the introduction of their new belt-loading device. A box of ammo, or small handful if you have bulk ammo, is dumped into the sorting hopper. A few shakes of the wrist and several are all lined up protruding from a small slot in the bottom of the device. A transfer bar is pushed up through the slot, catching the already lined up ammo, and slid out the front of the hopper. The transfer bar is then inserted into a loading block and the result is 10 rounds, all perfectly spaced and ready to be belted. When the belt is pushed over the rounds in the loading block they are all perfectly spaced and seated to the correct depth when the belt is removed. Several loading blocks can even be connected in unison to speed up the process. The author uses 3 blocks mounted together and has found that to be fast and comfortable. Since new belts are very tight the first time they are loaded, there is a spike that acts as a belt spreader included with the loading tool that can be mounted with the loading blocks. A simple pass through each pocket prior to loading each first round and it is no longer a struggle. No more blistered fingers from loading new belts and more time shooting instead of loading. As previously mentioned, you can also use disintegrating links instead of the cloth belts. These are much easier to load but don’t tend to hold the linked ammo quite as secure as the cloth belts do. Some people have found that given a slight pinch while loading them creates a little tighter hold. Both belts and links provide excellent results at the range. The 8-piece belt loading system is available for $40 and should be mandatory equipment for anyone who owns one of the Tippmann miniatures, a Vindicator Carbine or an LM-7.

BATFE Technology Branch Ruling

Unlike many other manufacturing projects, there was still something necessary even when the majority of the in-house troubleshooting had been completed. The Technology Branch of the Bureau of Alcohol, Tobacco Firearms and Explosives makes legal determinations on new firearms and related accessories based on samples submitted. They examine these new designs and based on the item submitted they will issue a determination in writing. There have been other designs submitted for determination changing the caliber and/or feed mechanism of specific firearms, where the devices were ruled firearms of themselves. There have been other designs where Technology Branch has determined the new device was too easily convertible to full automatic fire and ruled as machine guns, themselves. For obvious legal reasons a sample LM-7 was submitted to ATF and on December 6, 2005 it was determined that the LM-7 does NOT meet the definition of a firearm or a machine gun, and is simply an upper receiver, like countless other replacement upper receivers on the market.

Range Performance

Most of the range time was during sub-freezing temperatures at our production office in Maine. The LM-7 ran perfect in semiautomatic mode right from the box. In order to achieve reliable performance in full automatic, it had to be timed. This can be accomplished in less than an hour with the right materials and depending on the firearm you have, it may not involve any adjustments at all. As explained above, during preliminary testing we discovered several variables in most lower receiver fire control groups that had to be tweaked, and at this point Lakeside Machine has already addressed them in their new production models. Once we had everything adjusted and timed it ran excellent. We successfully ran several long belts just for function testing (ok, and a little fun) and fired several strings collecting data on muzzle velocity and rate of fire with several types of ammo in different configurations. The data from those tests are provided in the accompanying charts.

Conclusion

Lakeside Machine has hit a home run with this design. As an accessory for a military style firearm that has been the USA primary service weapon for over 40 years, there are a lot of host guns out there as potential customers. It is a reasonably priced way for a shooter to “upgrade” to a belt-fed firearm and it is a great way to shoot on a budget with the cheap price of most .22LR ammunition. It is fun to shoot and works excellent right out of the box in semiautomatic mode and, with a minimal amount of timing and fine-tuning, in full automatic. The conversion to LM-7 from a factory upper receiver is simple and can be completed in less than a minute. The vast number of accessories available for the LM-7, both from Lakeside Machine and current ones already on the market create an infinite number of configurations to suit any shooter. Where the LM-7 works in conjunction with previously owned, registered M16s and drop-in auto sears, it is about as close to having a “new” machine gun as we can get since May 19, 1986. There will always be room in this writer’s reference collection for an LM-7.

Sources

LM-7 Upper Receiver

Lakeside Machine

N5391 County Road. S.

Pound, WI 54161

Phone: (920) 897-4682

Fax: (920) 897-4688

www.lakesideguns.com

PACT Timers

PACT Inc.

Dept. SAR

P.O. Box 535025

Grand Prairie, TX 75053

(800) 722-8462

www.PACT.com

LM-7 Specifications Chart

Caliber: .22 Long Rifle

Overall Length: 24.5 inches w/16.25 inch barrel

Barrel Length: 16.25 inches & 7.5 inches

Weight: 5.05 pounds w/16.25-inch barrel

Barrel Rifling: 6-groove, right hand, 1 in 12 inches

Firing Mode: Semiautomatic and select fire

Method of Operation: Closed bolt, blowback action

Finish: Manganese phosphate

Rear Sights: M1913 Picatinny rail

Price: $1,750 suggested retail

.22 Long Rifle Muzzle Velocity Barrel Length

Ammunition

7.5-inches

w/flash hider

7.5-inches

w/sound suppressor

16.25-inches

w/flash

hider

16.25-inches

w/sound suppressor

Remington Thunderbolt

997fps

1,032fps

1,095fps

1,088fps

CCI Mini Mag

975fps

1,027fps

1,069fps

1,055fps

CCI Stinger

1,334fps

1,345fps

1,450fps

1,474fps

Federal Bulk Pack

1,064fps

1,054fps

1,139fps

1,148fps

Federal Champion

1,111fps 1,141fps 1,179fps 1,206fps

Measurements recorded 8 feet in front of the muzzle with a PACT MKIV Timer & Chronograph

.22LR Rate of Fire

Barrel Length

Ammunition

16.12-inches

w/flash hider

16.25-inches

w/sound suppressor

Remington Thunderbolt

970rpm

1,025rpm

CCI Mini Mag

1,046rpm

1,036rpm

CCI Stinger

1,076rpm

1,085rpm

Federal Bulk Pack

975rpm

N/A

Federal Champion

857rpm

857rpm

Measurements recorded with a PACT MKIV Timer & Chronograph.

| This article first appeared in Small Arms Review V9N7 (April 2006) |