By Alton Chiu

Melvin Johnson’s unconventional alternative to the M1 Garand did not see widespread use, but its innovative features were incorporated into Eugene Stoner’s AR-10/15 series rifle.

The Model 1941 Johnson Rifle is unique in many ways. It utilizes a short recoil mechanism whilst contemporaries are gas operated (short-stroke piston of the SVT-40, long-stroke piston of the M1 Garand, or direct impingement of the Ag m/42 Ljungman). It also uses a multi-lug rotating bolt that is part of the bolt group. Unlike other rifles which disassemble into the proverbial lock, stock, and barrel, it disassembles into upper and lower halves. This article delves into the technical details of the rifle, and how the innovations were adapted into Eugene Stoner’s AR-10/15, which will henceforth be treat as the same design for brevity.

History

The gestation period for the M1 Garand was not swift and smooth. John Garand started development with his Model 1921, with his T1E1 being ordered for tests in 1929 and production first delivered in 1937. These early “gas-trap” rifles have a chamber in front of the barrel to trap some of the pressure for use by the operating rod, similar to the muzzle booster of the MG42 and Vickers machine gun. Deficiencies in this system led to changes where gas pressure is tapped via a hole drilled in the barrel. In the midst of these challenges, Melvin Johnson set about to design an alternative with the prototype being completed in August 1936.

The Army Ordnance Board trials in December 1939 found the Johnson rifle unsuitable for service as it would not reliably function with the bayonet attached and the magazine too delicate. In contrast, the Marine Corp trials of May 1940 concluded the Johnson rifle to be superior to the M1 Garand in accuracy and potential efficiency; however, further tests in November 1940 found the Garand to only just edge out the Johnson. The Johnson rifle was officially turned down in favor of the M1 Garand which was already in full production by then.

Despite the setback, Melvin Johnson captured a contract with the Netherlands Purchasing Commission for use in the Dutch East Indies. These rifles were fortuitously chambered in 30-06 instead of the Dutch standard 7.92x57mm. As the Japanese invasion prevented the rifles from seeing service with their Dutch owners, the US Marine Corp procured them for use throughout the Pacific campaign. Notably, USMC Captain Robert Dunlap was awarded the Medal of Honor while thus armed.

Post WW2, Argentina expressed interest but the resulting M1947 auto carbine never went into production and Johnson’s company was absorbed into Winchester Repeating Arms Company. Around the time of the AR-10/15 development, Johnson worked at ArmaLite as a consultant.

Action

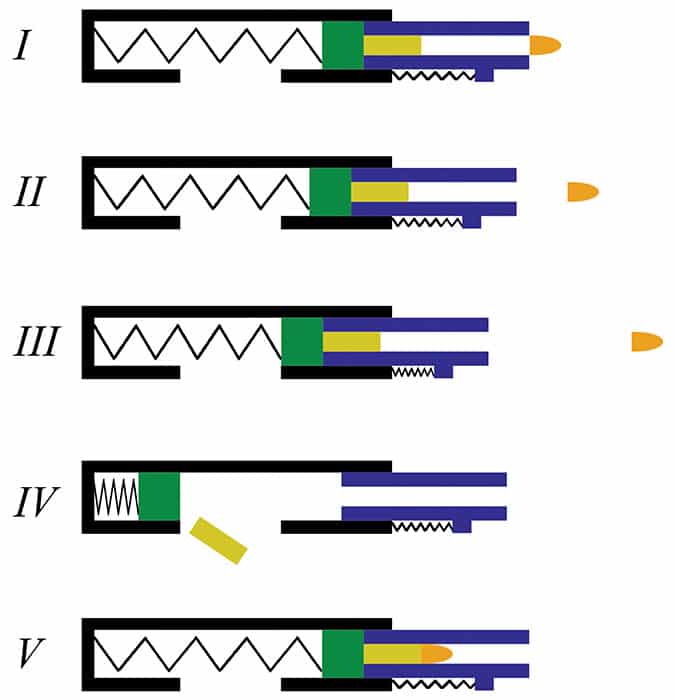

The Johnson rifle utilizes a short recoil action like that in the Browning A5 shotgun where the recoil force, instead of the expanding gas, is harnessed to cycle the action. As the projectile travels down the barrel, the recoil pushes the bolt group and the barrel rearward, compressing the barrel recoil spring and the main spring. The operation is illustrated below. From the Military Handbook of the Johnson Semi-Automatic Rifle published by the Johnson Automatic Trust, when the projectile is at the muzzle, the barrel recoils about 0.0156-inch (Step 1). As the projectile leaves the muzzle, the muzzle blast becomes “the primary operating force of the action”. With the projectile 2-feet from the muzzle, the pressure inside the barrel drops significantly while the barrel recoils about 0.125-inch. Here, the cam on top of the bolt engages the cam on the receiver to unlock the barrel from the bolt carrier group (Step 2). With the projectile 5-feet from the muzzle, the barrel reaches full 0.375-inch travel and the bolt fully unlocked (Step 3). As the bolt group continues further into the receiver to eject the spent case and pick up a new cartridge, the barrel returns forward under the barrel recoil spring (Step 4). Finally, the bolt chambers a new cartridge and returns to battery, ready for the cycle to start again (Step 5).

The barrel latch assembly, at the bottom of the handguard near the front sling swivel, keeps the barrel in place via the collar about half way along the 22-inch barrel. The barrel recoil spring is found in the barrel latch assembly. As with other reciprocating barrel designs such as the MG42, the Johnson rifle handguard, a perforated metal shroud integral to the receiver, is free-floated from the barrel. In contrast, fixed barrel designs such as the 1898 Mauser series feature a handguard that attaches directly onto the barrel.

As a consequence of the short recoil operation, reliability necessitates a calibrated reciprocating mass. Too little mass (e.g. from a short barrel) could lead to excessive bolt speed; too much mass (e.g. from fixing bayonet) could cause short stroking. To avoid that, a 0.5-lb triangular bayonet is utilized in contrast to the standard 2-lb M1 bayonet. Reliable cycling also requires little rifle movement under recoil. From an unconventional position where the user is unable to properly shoulder the rifle, short stroking can occur. When the rifle moves too much, there could be insufficient energy to cycle the action, similar to “limp wrist-ing” a handgun. While the author did not explicitly test for such behavior, the sample rifle did not fail when shot horizontally or when not properly shouldered. The lack of tapped gas means no fouling would accumulate at the piston (e.g. M1 Garand) or receiver (e.g. AR-15).

The actions of both the Johnson and AR-15 rifles are noteworthy in that they do not impart an off-bore-axis torque. When a gas piston actuates the bolt, the line of thrust is by necessity offset from the barrel as seen in the “carrier tilt” encountered by some gas piston AR-15s. This additional component adds to muzzle climb and wear. Both Johnson and AR-15 rifles feature reciprocating mass directly in line with the barrel. Indeed, Stoner further reduces muzzle climb in the AR-15 by placing the barrel in line with the user’s shoulder (similar to the FG42).

Bolt

Both Johnson and AR-15 rifles feature a bolt group with a multi-lug bolt. Unlike a one-piece rotating bolt (e.g. 1898 Mauser), the Johnson rifle bolt group can be split into the bolt and locking cam. The rollers guide the group to rotate the bolt and lock the breech. The same idea is seen on the AR-15 bolt carrier group.

The multi-lug bolt means that less rotation is necessary to open the bolt in comparison to the prototypical two lugged design. The bolt rotates about 90-degrees in an 1898 Mauser, about 45-degrees in an M1 Garand, and only about 20-degrees in the Johnson rifle. This theoretically promotes faster cyclic time and reliability because less energy devoted to rotation means more can be devoted to reciprocation. While the Johnson has eight lugs around the bolt head with the space for the ninth taken by the extractor, the AR-15 has seven lugs around the bolt head with the eighth on the extractor. As such, the AR-15 bolt rotates approximately 22.5-degress to

unlock the breech.

In keeping with most other military arms such as the M1 Garand and SKS, the Johnson rifle has a free floating firing pin. This means that the firing pin is free to move back and forth along the channel inside the bolt. As the bolt slams into battery, the forward momentum of the pin would slightly dimple the primer.

The Johnson rifle employs a control feed whereby that the rim of the cartridge slips under the extractor while the bolt is moving forward. The contrasting push feed method pushes cartridge into the chamber and ride the extractor over the rim as the bolt goes into battery. Both methods are successful. In bolt action, the Mauser 1898 uses a control feed while the Mosin Nagant uses a push feed; in semiautomatic, the FN-49 utilizes a control feed while the AR-15 utilizes a push feed. The control feed of the Johnson rifle is paired with a fixed ejector at the rear of the receiver like the Mauser 1898.

The Johnson rifle extractor is attached to the bolt via the bolt handle. The center stem of the bolt handle can be lifted out under spring pressure and the handle slid toward the bolt face. With the bolt handle removed, the extractor can then be separated

from the bolt.

Recoil Buffer

Unlike traditional designs where the recoil spring resides in the receiver, the Johnson rifle recoil spring and buffer is in the stock. As the stock is not directly in line behind the receiver, a link connects the bolt carrier to the buffer in the same manner as the Benelli inertia system in the M1 shotguns. In the M1941 Johnson Light Machine Gun, the buffer is put in line with the receiver above the stock, eliminating the angled link. The AR-15 also employs this arrangement, but puts the sights higher in order to bring the bore axis into the stock and further reduce muzzle rise.

The Johnson rifle stock has three cylindrical cavities with the bottom one holding the buffer tube. The top one can hold cleaning rod segments while the middle one is shallow and can only hold small items like brushes. The lack of a trap door forces one to remove the butt plate in order to access the storage cavities.

Magazine

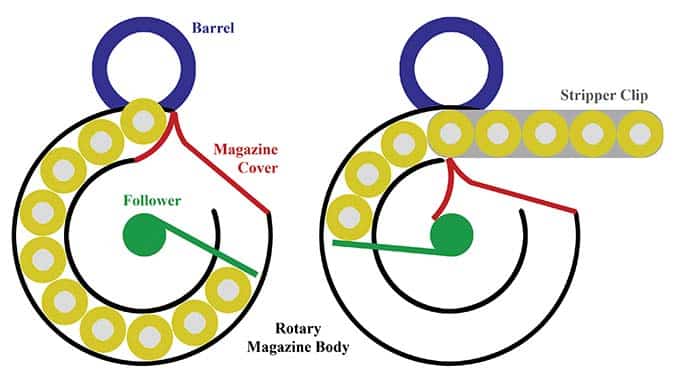

The Johnson Rifle is equipped with an unconventional ten round rotary magazine that gives it a “pot belly” look. The traditional magazines are top loaded and feed vertically. The Johnson magazine is side loaded with each cartridge placed on the circumference, similar to the Ruger 10/22 rotary magazine.

Despite the prima facie similarity between the Johnson and Krag-Jørgensen magazines, they differ in the follower. The Krag user opens the loading gate which disables the follower and relieves spring tension; loose cartridges can be dropped into the magazine without effort. In contrast, the Johnson user must push the cartridge past the magazine cover, against follower spring pressure, into the magazine. After the magazine is emptied, the follower raises the bolt catch and holds the bolt open. To close the chamber on an empty magazine, one must hold the bolt back, push past the cover to depress the follower and allow the bolt to ride over it.

The Johnson rifle is distinctive in that, despite sporting a fixed magazine, it can be loaded and unloaded without locking the bolt back. The Johnson rifle utilizes stripper clips designed for the Springfield Model 1903 rifle and requires two to fully charge the magazine. The author found M14 stripper clips to work equally well. It can also be loaded singly with loose cartridges. To unload the magazine, the cover is fully depressed and the follower then forces the cartridges out.

The Johnson design does not allow the user to easily disable the follower spring pressure in order to clear a feed jam. If a magazine related malfunction occurs, the floor-plate of an 1898 Mauser or the detachable magazine of an AR-15 can be removed to eliminate the spring pressure. In contrast, the author experienced a double-feed with the Johnson rifle that took some effort to clear because of the need to fight the follower pressure.

Trigger Group

The trigger group is attached to the stock via two action screws like the 1898 Mauser. Unlike the Mauser, the action screws do not have smaller locking screws and the author found that they could walk loose under recoil on his sample. A notable feature of the Johnson rifle is that the hammer is placed farther forward of the trigger (about 1.5-inch) than other designs.

The Johnson trigger face is narrower (0.185-inch) in comparison to the Garand (0.2-inch). In addition, it feels more like a single-stage while the Garand is a two-stage trigger. The Johnson safety is a lever in front of the trigger guard that pivots around the vertical axis. The rifle is on safe with the lever pointing to the right (i.e., direction of case ejection), and on fire when the lever is pointing to the left. While both the Garand and Johnson safeties lack markings, the Johnson safety is less intuitive and lacks tactile feedback. In addition, it is difficult to manipulate from the firing grip. The author found these characteristics combine to give the Johnson rifle a less favorable impression in the fire control department.

Sights

The Johnson rifle features an aperture rear sight with a blade front sight protected by strong wings, combining to give a sight radius of 31.75-inches. While the front sight is non-adjustable, the rear sight uses a tangent adjustment for elevation. Each notch corresponds to two minutes of angle. The knob on the right side adjusts windage where a click every 180-degrees of rotation representing two minutes of angle. The rear aperture of the Johnson rifle is larger than that of the Garand, while the front posts of both are of similar thickness. The author found the Johnson sights quick and easy to both use and adjust.

Field Strip

Using only the tip of a cartridge, the rifle breaks down into two major components: upper and lower. The barrel is first removed, then the bolt group. Finally, the hammer block pin is removed to disassemble the rifle into the two halves.

To remove the barrel, the tip of a cartridge is pushed through a hole on the right hand side of the stock to depress the barrel latch plunger. After the barrel is unlocked from the bolt and the barrel latch assembly swung downward, the barrel can be withdrawn.

To decompress the mainspring, several components must first be removed. The bolt stop plate at the rear of the receiver is lifted vertically upward after the plunger is depressed; the author found this step troublesome and a second pair of hands immensely useful. The bolt stop is then removed from the receiver. Next, the plunger in the recoil buffer is compressed and the link between the bolt and recoil buffer removed. The bolt handle is detached from the bolt by lifting the central plunger and pushing the handle forward. With no more forward pressure on the bolt group, it can be moved rearward and withdrawn from the receiver.

The hammer block pin is located just aft of the stripper clip guide. Rotating the pin 45-degs back from the barrel using the tip of a cartridge allows the pin to be withdrawn. The author experienced some difficulty in removing the pin. The rear stock and trigger group, analogous to the lower of an AR-15, is removed by pulling the assembly to the rear. The group of receiver, magazine, and front handguard is analogous to the upper of an AR-15. The two halves mate via a rail between the trigger group and the lower edge of the receiver. Notably however, the Johnson rifle utilizes a number of screws while the Garand and the AR-15 do not.

Shooting Impressions

The Johnson rifle the author tested reliably cycled both Korean and Greek HPX surplus ball ammunition. Mildly unconventional shooting position without the stock fully planted in the shoulder did not produce any malfunctions. The recoil was notably softer than that of the M1 Garand because there is less mass to be stopped at both end of the bolt travel. However, the author felt that the short-stroke gas piston operated FN-49, also chambered in 30-06, has softer recoil.

After some frustrating moments with a number of users experiencing widely varying points of impact, the problem was traced to a loose rear sight. Despite a positive lock on the elevation ladder and the windage knob, the rear sight still wiggled. At 600-yard target, the disruption was about 10-feet. At the 100-yard target, the rifle managed to consistently hit a 12-inch diameter steel target. Unfortunately, this problem prevented a proper accuracy test.

Concluding Thoughts

Melvin Johnson designed a rifle with many innovative features. Although it did not see widespread adoption, it should not be consigned to the footnotes as an “also-ran”. The concentric recoil and bore axes, multi-lug bolt, usage of the bolt group to rotate the lug instead of an operating rod, and the disassembly into upper and lower halves are all features that were utilized on the AR-15. The most popular modern sporting rifle of America owes much to Johnson.

Due to the comparatively small number of Johnson rifles manufactured, they command a high price. The sample from this article costs around $4000. More pristine samples can cost double or more. Despite the price tag, it is an important piece of history worthy of a good home. However, like the BM-13 Rocket Launcher with the soubriquet of “Stalin’s Organ”, Johnson rifle owners should expect puns about the name.

| This article first appeared in Small Arms Review V20N4 (May 2016) |