By James L. Ballou

The United States M3, often referred to as the “Grease Gun,” was either loved or hated by its user. In this article we will discuss in detail its design and experimental versions. Also will be told the story of a soldier who actually used an M3A1 in combat and still loves the old warhorse: crude but deadly.

Col. Rene Studler, Chief of R&D U.S. Army Ordnance, put together the design team of George Hyde and Frederick Sampson. Mr. Hyde was a noted arms design engineer and Mr. Sampson was an expert in the field of stamped materials and worked for the Guide Lamp Div. of General Motors. This was the perfect combination for the project. Utilizing readily available and noncritical materials they developed a new design. This design could be subcontracted out to small home machine shops all over the country for rapid manufacturing.

The first model was the T-15, which was to fire the 9mm cartridge. The first mistake they made was to utilize the Sten magazine: its only fault was it fed from a single feed double stacked magazine. The other problem was to make the ejection port size suitable for a 9mm cartridge only. They also included a selector to give semiautomatic fire. On the next model, T-20, they eliminated the selective fire capability and began to concentrate on the .45 ACP cartridge. One excellent design feature was the use of dual operating rods and springs. They could be adjusted so that the bolt never bottomed out. The heavy .45 ACP bolt was carefully engineered so that it never struck the back of the enclosed tubular stamped receiver. At this point there was only one description that stuck, “It looks like a grease gun.” Thus was born the nickname which still remains.

Someone corrected the ejection port and built in a simple but robust safety. Open the cover and it is ready to go and closed it is on safe. Incidentally, the cover cleverly moves the bolt back off of the sear. It is almost fool proof.

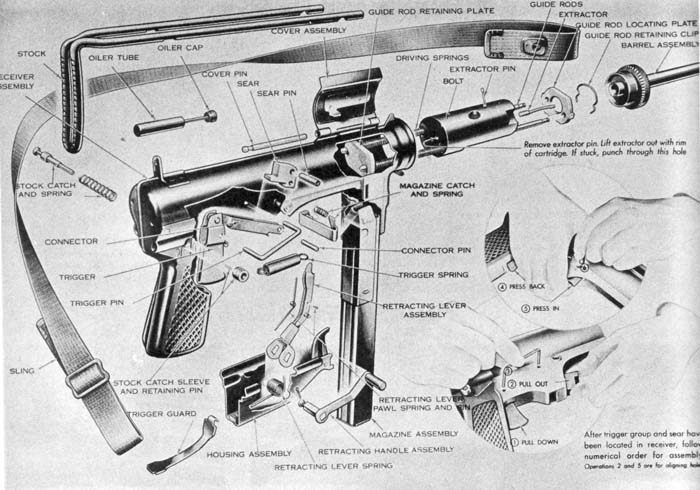

The wire stock, a tubular dual rod device was made even more practical by threading the ends of the rod to take a standard cleaning brush. The stamping for the receiver gave an ample pistol grip with pressed in serrations. The whole receiver is welded together with a sturdy threaded insert for the barrel with had a rugged collar. All in all, the M3 is a robust, reliable and compact submachine gun – all this for the measly sum of $20.94.

The M3 had two flaws that were corrected later. First, the cocking handle was complicated and prone to breakage. Second, disassembly was also complicated in that it had to have the trigger and cocking mechanism removed before the bolt assembly could be removed.

The M3A1 final design was adopted in December 1944, so that not many made it into combat. The improvements were simple. First, eliminate the cocking mechanism and lengthen the ejection port so that the bolt could be retracted by direct digital contact. Second, improve the bolt so that the ejector went through the bolt allowing the whole assembly to drop out in one piece by simply unscrewing the barrel assembly: pure and simple. Another modification was to the wire shoulder stock. They wisely included a magazine loader and bent the stock to allow it to be used as a wrench to loosen the barrel nut assembly.

Inland Division of General Motors produced a total of 646,000 M3 and M3A1s during WWII. Ithaca Gun Co. made 33,227 for the Korean War.

Variations and Experimental M3s

One attempt seldom mentioned, the T 29, submitted in the fall of 1944 was to chamber the SMG for the .30 Carbine cartridge. Though only three were made it was found that the 30 Carbine load was a bit much for the spring action. In addition to that there were already over 6 million carbines in service.

Bell Laboratories developed several suppressed variations of the M3. Bell Laboratories Report on Suppression of M3s from Silencers Patterns and Principles – Frankfort Arsenal Report R-1896 August 1968, reports: “By far the strangest was the “around the corner” gun, developed for use by Tankers. This gun would enable the Tankers to shoot the enemy who were trying to get in and under the tracks. The first combat use was by the Germans who used it against Russian sappers who tried to blow the treads of German tanks. It seemed they could not depress the MGs far enough to take out the Russians. By attaching them to their Stg 43s or MP 44s, they could literally fire on their own treads. The interesting fact is that the Germans went to the U.S. Patent Office to get the design for an “Around the Corner Gun.”

Present Day Use

Three wars and numerous conflicts have proven the old M3 to be a viable weapon. It can take enormous punishment and keep on running. It works in the hottest, coldest and dirtiest of environments. It even works underwater.

There are reports as late as the 1990s that M3s could be found racked up in tanks. After-action photos of the Iranian hostage crisis disaster showed suppressed M3s in the wreckage of the C-130.

The Battle Patrol: Combat Use of the M3

Most people remember the M3 as either an object of ridicule of a “funny old WW II gun” racked up in tanks. One of its greatest assets was its compactness and ability to be disassembled into a package for use behind enemy lines on clandestine operations.

Little is found on the actual use of the gun in combat though we have here an actual story of a man who used the M3A1 to effectively neutralize an enemy patrol and win the Silver Star; an award just below the Medal of Honor. Private First Class Frank C. Taraburelli, a native of Revere, Massachusetts, was only 20 years old at the time. A Ranger in the Second Battalion, his weapon of choice was an M3A1 Grease Gun. Though few were issued at the end of the War, the Rangers got the first ones off the assembly line.

In March, 1945, Frank had volunteered for a special combat patrol to feel out the defenses on the Siegfried Line. His actions of wiping out a German machine gun nest with fire from his M3A1 and the use of a hand grenade won him the coveted Silver Star. His memory, even today, is sharp and clear. He vividly remembers how he took out four German’s with a five-round burst from his trusty M3A1. His most cherished souvenir is a fireman’s axe that he took from a German he had recently dispatched. As proof we have seen an actual photograph taken shortly after the action. This photograph shows the ingenuity in the modification of his weapon. Rather than the “movie commandos,” he had chosen not to tape three heavy magazines together. Instead, Frank had chosen a V shaped stick to attach two magazines with bullets up. This puts less wear and tear on the weak magazine catch and it is quicker to insert the new magazine.

A special patch was created and authorized for the use of the men who served in these Special Combat Patrols. It consisted of a “bloody battle axe,” similar to the one captured by PFC Taraburelli. On 9 June, 1945, eleven men were awarded special permission to display this commemorative patch on their uniforms.

9mm Conversion Unit

Since the original prototype was in 9mm, it should be noted that the Ordnance Dept. had intended that the SMG be used by the OSS and resistance groups behind enemy lines. Though the final design was in .45 ACP, there was a small but unsuccessful effort to creating a 9mm conversion unit for the versatile M3. There is no evidence that the OSS ever got any 9mms.

We have an original 9mm bolt, in the original box; Part Number C-153427. Also marked clearly on the bolt is RIA for Rock Island Arsenal. For some reason, not many were made as it is not uncommon for them to be found in issued boxes. Very few completed units are ever seen. Unfortunately, the 9mm magazine well adaptor for the M3 or M3A1 is even rarer. Its part number, C-153430, fits both, but try and find one.

In the 1980s, a retired engineer by the name of Roger Ladd set out to construct a complete 9mm conversion for the M3 and was soon frustrated by the lack of conversion units for the magazine well. He painstakingly measured the dimensions of the M3 .45 magazine and the 9mm Sten gun. He then fabricated an adaptor that would be attached to the Sten magazine. He took a Sten barrel and adapted it to an M3 barrel nut and combined with his new-in-box bolt and built and fired his conversion unit.

The M3 admirably fulfilled its mission goals. It was cheap to manufacture with a minimum of critical materials. It was rugged, reliable and easy to maintain. The latter version, the M3A1 had all the tools that were needed built into the weapon. The stock had a built in magazine loader and was so configured that it could be used as a wrench to loosen the barrel nut. An oiler was built into the pistol grip. The complete gun could be broken down into a thirteen inch package for clandestine operations. The gun was extremely versatile in that it could be suppressed and it could be made to shoot around corners. Pretty she wasn’t but was reliable and would always do the job.

| This article first appeared in Small Arms Review V13N8 (May 2010) |