By Christopher R. Bartocci

The Black Rifle business has never been bigger or stronger. Nearly every company in the industry is making AR-15/M16/M4 rifles, components or accessories. Some of the companies make very high end gear for the professional user whose very lives depend on their equipment, and others are more suited for range shooting at paper targets. However, some of these manufacturers are literally on the cutting edge; creating components to carry the weapon system to the next level by increasing durability and reliability as well as making it extremely versatile allowing it to be set up mission specific.

Magpul is just one of those companies taking it to the next level. The company was founded in 1998 on a single product created by former Marine Corps Amphibious Reconnaissance Sergeant Richard Fitzpatrick. Anybody who has ever tried to pull a magazine out of a pouch under stress knows how difficult it is to get the magazine out. Troops learned a trick to speed up the process by taping a piece of 550 para cord to the bottom of the magazine creating a loop which they could grab quickly, or duct tape tabs. So when Sgt. Fitzpatrick got out of the service, he designed the Magpul (U.S. Patent 6212815): a rubber slip over loop that slid over the bottom of the magazine. A rather simple design, but it took off like wild fire. The company manufactured the Magpul for 5.56mm, 7.62mm and 9mm/.45 caliber magazines in black, olive drab green as well as flat dark earth. Law enforcement and military personnel bought them up. They sped up the reloading process and made it easier to pull magazines out of weapons with dirty magazine wells or out-of-spec magazines that fit tight. You would be hard pressed to find a SWAT team in the U.S. that does not use them for their M16 or M4 rifles. That innovation went on to the M93 Modular Stock (Out of production and replaced by the UBR) and the MIAD grip. The innovation of the company has also got into firearms design with their multi-caliber Massada. Magpul relies on real world users to drive their engineers to develop products that are needed in the field: soldiers designing for other soldiers.

The MIAD (MIssion ADaptable) Pistol Grip

The pistol grip was another area that Magpul felt could be improved. Not just in ergonomics and use with gloves but as a storage devise as well. The MIAD grip is a pistol grip that is customized for the user. Both the front and back strap are removable and can be custom fit for the user. The front strap has 4 different options. The F1 is the flat A1-style insert. This omits the finger swell for those who prefer it. The F2 has the finger swell identical to that of the standard M16A2/M4 grip. The F3 insert is for those who wish to use the MIAD as a vertical fore-grip. The F4 insert incorporates both the finger swell and enhanced trigger guard into one piece. The enhanced trigger guard is large enough to allow troops with heavy gloves to easily manipulate the trigger. There are three back strap inserts. The insert used depends on the size of the shooters hand. The B1 is the insert for the user with small hands. The B2 and B3 inserts both have an extended web area in the rear of the insert. The B2 is for those with medium size hands and the B3 is for those of us with really large paws.

The inside of the MIAD serves as a storage compartment with various cores offered by Magpul. The most innovative core offered is the Bolt/Firing Pin core. This core holds an M16/M4 bolt group with inserts for a firing pin as well. There are two cores available for those who use battery powered optics. The AA/AAA/N core offers the ability to carry two of each type of batteries. There is an additional insert that the two skinny AAA batteries fit into and slide up into the MIAD. A waterproof cover fits over the top of the core to protect the batteries from water. The 123 core carries the larger 123 batteries commonly used in tactical flash lights. That also has a waterproof cap that fits over the top. The final option is the three 5.56x45mm cartridge holder. This core holds three rounds of ammunition. The MIAD is the most innovative and versatile on the market. No other lets the shooter fit it to their hand size and preference. The MIAD can be had in black, foliage green and flat dark earth.

The Magpul Enhanced Trigger Guard

The standard M16/M4 rifles have, since day-one, a winter trigger, which by pushing in a detent and pulling downward gives easy access to the trigger guard. That has not changed. However, there is a major disadvantage to not having the trigger protected. The trigger could easily get caught on clothing or any other gear and get unintentionally pulled. Magpul saw this danger and developed a solution to unintentional discharges due to an unprotected trigger. The enhanced trigger guard creates a deep loop-shaped trigger guard allowing heavy gloves to be used and still have a protected trigger simply by replacing the original trigger guard. The standard roll pin goes in the rear of the trigger guard and a small hex pin in the front right side to lock it in place. This feature is also offered with the MIAD grip F4. The main difference is the F4 is made of super tough polymer and the Enhanced Trigger Guard is made of aluminum. For those who do wish for a folding trigger guard, Magpul offers the Enhanced Trigger Guard in both folding and non-folding variations. Both Knight’s Armament Company and LWRC offer this as standard on their rifles.

The PMAG (Polymer Magazine)

Perhaps of the entire line of advanced accessories Magpul Industries offers, the PMAG is the most revolutionary designed magazine in their catalog, and maybe in the industry. Throughout the years, many attempts have been made to manufacture synthetic magazines for the M16 family of weapons and, for the most part, it has been a complete disaster. The only success was to be made by Diemaco in Canada. Their first attempt was a failure but their second was well received (although not by the Canadian military) by Diemaco customers abroad and Law Enforcement. The magazines were good, but did not have the durability that many would rely on in real world situations nor extreme rough handling. Magpul showed a prototype magazine at the 2007 SHOT Show with a cowboy boot heel digging into it. A magazine was requested for T&E (test and evaluation) and the first one received was a black PMAG without observation windows. A genuine GI, Okay Industry magazine was used as the standard for comparison. Magpul has posted numerous videos of their testing on the construction of the PMAG. This includes running them over with a good size Chevy 4×4. They ran over a GI magazine, H&K high reliability, Orlite, Thermold and PMAG magazine. The test included a slow run over, fast run over and a grind with the magazine under the tire. The only magazine to make it through all the tests was the PMAG and, after the testing, the PMAG was the only survivor and was test fired without failure. This set a new bar for magazine reliability for the M16 weapon system. It proves once again that new age polymers are stronger and more reliable than conventional steel and aluminum.

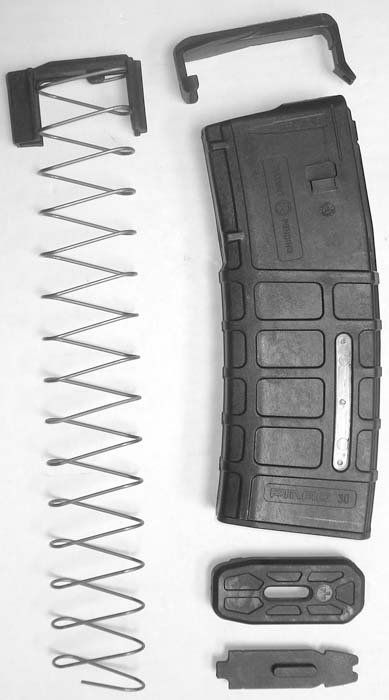

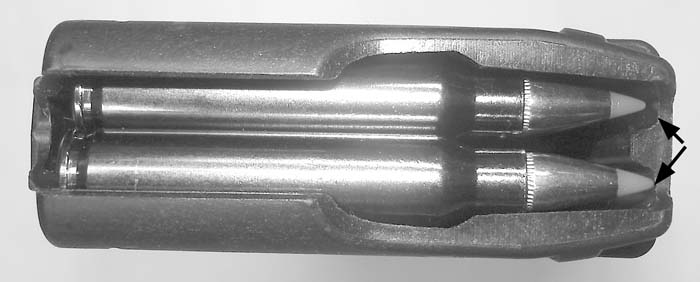

The construction of the PMAG is from the ground up and not a modified version of a previous design. The mag body itself has several departures from the standard magazine. Other than being made of polymer, the shape is quite different though it will fit in a standard mag pouch. The magazine has no bends in it like the standard GI magazine that has two bends. The shot column in the PMAG is one constant curve consistent with the way the cartridges sit increasing feed reliability. There are four gripping grooves on the sides and five on the front and back of the magazine. There are two different mag bodies; the first is called the PMAG, which has a solid magazine body, and the second is called the MagLevel PMAG, which has a window. The MagLevel PMAG has an additional change to go along with the windows. The magazine spring has blaze orange painted on it showing when in the magazine how many cartridges are in the magazine. The PMAGs drop free from the magazine well either empty or loaded. Due to the numerous manufactures and wide variety of specifications, some weapons may experience the magazine sticking in the mag well and have to be pulled free. Testing shows Colt and FN GI rifles made to military specification have had no issues with the magazines dropping free. The construction of the magazine allows the use of the standard U.S. GI stripper clip and loading tool to be slid and used on the back of the magazine. Additionally, the Maglula LuLa can be used to load and unload the PMAG as well as their Bench Loader which is designed for the standard GI M16 and British SA80/H&K high reliability magazine.

The follower is also a great improvement in the reliability of the magazine by utilizing a no-tilt follower. If you were to take a standard GI magazine with either the black or green follower and push downward on the front of the follower, you could jam the front of the follower into the inside of the magazine. This can cause the tip of the cartridge to jam on the inside of the front of the magazine body. The PMAG follower will not do this. There is no way for the follower to come out of alignment in the magazine body ensuring constant shot column location and proper feeding position on the top of the magazine. Realizing this benefit, Magpul has offered this style follower as a reliability enhancement to standard GI magazines. The enhanced followers are offered both in orange and grey and replace the standard GI followers.

The next true innovation of the magazine is the addition of a removable cap that serves a couple purposes. The most obvious is a dust cover to keep unwanted dirt and sand out. The next is to allow the magazine to be stored for an indefinite amount of time without damaging the magazine. When the magazine is to be stored for long periods of time, the cap when installed pushes downward on the top cartridge in the shot column taking pressure off the feed lips. What damages magazines over time is the force of the cartridge on the feed lips leading to the feed lips spreading apart and eventually even the spot welds can break on the standard magazine. The PMAG does not require the use of the protective cap. Magpul testing has shown that there is no feed lip creep in 11 months when stored without the dust cover. It is designed to be used for long term storage. If one should choose to use the cap on duty magazines, a simple loading drill addition would be to hook the back lip of the cap on the inside of the magazine well and pull: removing the cap and allowing the magazine to be inserted into the rifle.

The test and evaluation magazines have seen several thousand rounds through two magazines without failures of any sort. Most fire has been fully automatic out of Colt M4 carbines. A drop test was conducted with a loaded PMAG and a loaded GI aluminum magazine. Both were dropped from 7 feet on their feed lips on concrete. The GI magazine failed and was unusable. The PMAG fired the ammunition and was loaded twice more with no malfunctions. The PMAGs are offered in three different colors in both standard PMAG and MagLevel variations: black, foliage green and flat dark earth. The PMAGs are in use with several law enforcement agencies including the Rochester Police Department SWAT team. Additionally, they are seeing use in the Global War on Terror with American forces in both Afghanistan and Iraq.

Additional Magazines and Accessories

The aluminum and stainless steel MagLevel magazines are standard GI-style magazines with some major enhancements. The MagLevel aluminum magazine is a standard GI-style magazine with the MagLevel system that allows the operator to know how many rounds are in the magazine. There are 5, 15 and 25 round indicators on the window on the left side of the magazine. The stainless steel magazine offers the same MagLevel system but comes with a black Teflon finish. Both magazines also come standard with the Magpul Self-Leveling- Followers. Both magazines also come with the options of either the Magpul Ranger or LPlate floor plates.

The Ranger and L Plate Floor Plates

The Ranger Plate incorporates a finger loop right into the magazine floor plate to allow rapid magazine control and repeatable index for magazine removal from magazine pouches. The floor Plate/loop is made of a rubbery material to prevent breakage from rough handling. This variation is also offered in the Speedplate configuration for the Glock models 17, 18, 19, 22, 23, 26 and 27 magazines. They have a full loop and a compact loop.

The L Plate floor plate is flat and features integrated holes for use with para cord. Both the Ranger and L Plate can be used on any standard GI magazine by simply replacing the standard floor plate with the Magpul ones. Both floor plates are available in black, foliage green and flat dark earth colors.

XT and Ladder Rail Covers

With the increase in the use of rail systems, there has been a demand for rail protectors, not just to protect the rails but the shooters hand as well. Many companies have offered them and some companies offer them in different lengths to cover portions of unused rails not in use by vertical pistol grips or flashlight or any other accessories.

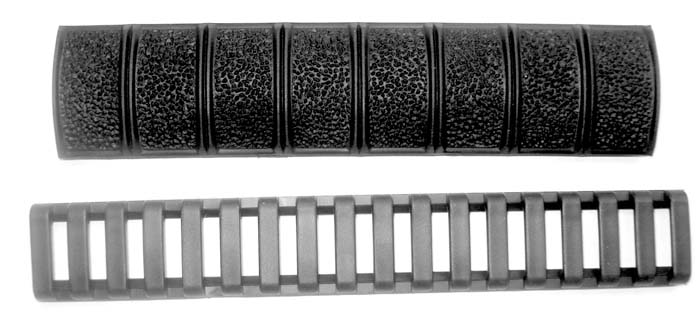

Magpul offers two different versions of rail covers. The XT panels feature a heavy texturing to provide the most positive grip in any conditions. The six inch panels can be cut into eight different lengths to custom fit your rail needs.

The Ladder rail covers offer a low profile rail protector that can be cut into 18 different lengths. It protects un-mounted rail sections and covers sharp edges. Both the XT and Ladder rail covers can be obtained in black, olive drab and flat dark earth color.

Magpul M4/AR-15/M16-Series Enhanced Stocks

CTR (Compact/Type Restricted)

The CTR stock is an advanced stock assembly designed to replace the standard GI type sliding buttstock. There are many aftermarket stocks available from a number of manufacturers. Most are very similar adding a battery compartment or a more ergonomic shape. The CTR offers a very unique feature: a shielded operating lever and a positive lock. That positive lock prevents the operating lever from being pushed accidentally and the stock collapsing with tough handling. Magpul offers a rubber butt-pad as well as cheek risers (.25, .50 and .75 inches) to custom align the shooter’s cheek weld to their individual optic. The CTR also uses a friction locking system that secures the stock to the buffer tube eliminating rattling and instability. Additionally featured are ambidextrous quick detach sling mounts. The CTR is offered in two configurations. The first is the Mil-Spec that has the proper dimensions for a Mil-Spec buffer tube (Colt). The second is what is called the Commercial configuration. There is a different dimension used in non-Mil- Spec buffer tubes that normally have six positions instead of four. However, both Lewis Machine and Tool and VLTOR offer Mil- Spec buffer extensions with six position engagement. The CTR is available in black and flat dark earth colors.

UBR (Utility Battle Rifle)

The UBR, as of this writing, is in the final stages of development and getting ready to go into production. What separates this stock from the CTR is that it is designed to offer the same stability as the standard fixed rifle stock. With the adaptability of theM16/M4 family of weapons to larger caliber (6.8 Rem SPC, 6.5 Grendel, 7.62x39mm, 7.62x51mm, etc.), the UBR is designed to take the recoil and offer a constant cheek weld regardless of the position of the stock. The buffer extension comes with the UBR and is proprietary to the UBR. The stock moves independently from the cheek weld area as the cheek weld area is permanently fixed to the buffer extension. The stock is a separate piece that extends and contracts to the shooters choice of length. The shooter’s anchor point on the stock will not change. There are no sharp edges on the UBR to catch on anything. The shooter will also have options for a storage module, extended rubber buttpad, aluminum strike plate with 1.25 inch sling loop, wider triangular shaped cheek piece, front and rear quick detach sling mounts as well as an integral strike plate. The stock length closed is 8 inches and fully extended is 11.3 inches. The UBR will be offered in black, foliage green and flat dark earth.

The PRS (Precision Rifle/Sniper)

The stock has much to do with the accuracy of the rifle. Stability, cheek weld, proper length for the shooter and the ability to anchor the non firing hand are all key elements. The PRS does all these important jobs. The sample stock was placed on a Knight’s Armament Company 7.62x51mm SR25 sniper rifle. As the rifle came from the factory, it had a standard mil-spec A2 rifle stock. The A2 stock was removed and the PRS installed with no special fitting or tools; only a standard screw driver was used.

The PRS was designed by Magpul specifically for tactical precision rifles in the M16/SR- 25/AR-10 family of weapons. Both the aluminum buttpad and cheek weld are precisely adjusted with machined aluminum dials with posi-click detents. The rifle is adjusted for the individual shooter and can be changed by a simple dial. This means the shooter will have precise cheek weld for the optic on the rifle and will have the proper length according to the length of the shooter’s arms. There is an anchor point for the non shooting hand as well. On the bottom of the PRS is a Mil-Std-1913 rail for use with a monopod. There is a slipcover to protect the rails when not in use. Magpul offers the PRS stock in either AR- 15/M16 or AR-10/SR-25 variations. The difference between the two consists of a small cheek piece for the SR-25/AR-10 versions to allow the longer charging handle to function properly. Additionally the PRS is made for the FAL rifle (PRS-FAL) as well as the Heckler & Koch G3/91 (PRS-G3). As with all their other lines, the PRS is offered in black, olive green and flat dark earth.

Shooting impressions were incredible. After the PRS was adjusted to fit my long arms and big head, I found the stock made a big difference in my shooting. The rifle itself will fire 1/2 MOA all day long; better than me usually. But the feel of the rifle changed with the use of the PRS. It felt sturdier and more solid. Using the anchor point on the stock I was able to hold the rifle steadier with little effort and my groups consistently tightened. With Black Hills .308 match 168gr OTM bullets, the rifle shot consistently under 1/2 MOA at 100 yards. This stock is a must for anyone shooting tactical variations of this weapon system.

v Magpul is a growing company with incredible products. Their PMAG will set a new industry standard for durability and reliability in M16/M4 magazines correcting 40+ year old problems with magazine durability issues and should be seriously considered for the U.S. Army Enhanced Magazine Program. These magazines already fit the bill for that requirement and are fielded with several units now. The enhanced followers are also setting a reliability standard. The original Magpul has been in use with military/special operations forces as well as law enforcement all over the world. Their stocks are in use by the same exclusive group of users. This equipment is being fielded by U.S. forces in both Iraq and Afghanistan. This goes to show you what one operator can do when he thinks there has to be a better way, and does it himself.

Contact Information

Magpul Industries, Corp.

P.O. Box 17697

Longmont, CO 90308-0697

Phone: (877) 4MAGPUL

(303) 828-3460

Fax: (303) 828-3469

Email: magpul@magpul.com

| This article first appeared in Small Arms Review V11N5 (February 2008) |