Photography & Story by David Lake

Only in the last 30 years has the weapon accessory mounting solution become standardized. In decades (and century) past, scope mounts and sling attachment points have been created and crafted by individual gun builders. Many larger manufacturers’ proprietary systems have survived and become mainstream. Some odd or antique mounting configurations continue to plague their owners by limiting or even making scope mount options impossible. Assuredly, there will always be a place in this industry for the rare and obscure. As well, there will surely be increased demand and need for continued refinement and standardization among these systems.

THE APPLICATION

The tactics and strategies on today’s battlefield are always evolving, so too must our weapons evolve to remain viable and advantageous. Our weapons must be universal and adaptable. The user of any weapon is always better served by a specialized system. Every combat soldier has a role, and every combat soldier’s weapon must be ideally configured to serve that role.

Modern weapons may be asked to don any number of peripheral accessories—Optics: scopes, red dots, magnifiers, night-vision or thermal ocular; Illuminators and target indicators: those that project light and aiming dots both within and outside our natural visual spectrum; altimeters, GPS units, range finders, clinometers and ballistic computers; bayonets, bipods and slings attachment points; forward pistol grips, hand-stops and barricade stops; less-lethal launchers and direct impact devices; belt-boxes; flare launchers; grenade launchers; short-barreled or AOW shotguns; and sheathed knives, spare magazine holders, ammo caddies and battery storage. The absurd is not off-limits to the well accessorized rifle of today. Bottle openers, cup holders, name tags, repelling gear and even a chainsaw have all found their way onto the handguard of an AR-15.

OPTIC MOUNTS

Weaver

The Weaver, by record and merit, deserves an honorable mention. It is the genesis for our current, most successful and widely adopted mounting system, the Picatinny. It is difficult to identify the Weaver’s exact birthdate; suffice to say that it’s old. One can find photo evidence of its commercial presence around 1950. Weaver’s firm (and continuing) hold on the market stems from the fact that it is a highly affordable scope mount system that is easily adapted to fit almost every commercially available rifle. It’s as near a universal system as was ever created. The simplicity and foresight in the design suggests true genius by the developer. The system is based on a simple aluminum extrusion with the operative profile being that of a truncated or flattened hexagon. The wide flat on the dorsal plane features cross-slots, or longitudinally bifurcated cylindrical voids that mechanically lock the binding screws in place. The lateral features of the weaver are opposing convex 90-degree shoulders set at a 45-degree aspect to the top plane. The interfacing ring-mounts are expected to grab the rail below its widest section on the flats that recede back toward the weapon. The sixth side would be the contact patch with the weapon itself. This surface is varied in height and contour to place the upper five planes in common alignment with neighboring mount bases. The weaver system was created with the ideal plan that only a few dozen mounts could satisfy any mounting requirement across hundreds of gun and optic combinations. And it does this with surprising perfection. Confer and verify with any man born before 1960 who still hunts with a blued-steel rifle stocked in real wood. He likely has a set of 60-year-old weaver mounts on that rifle.

The design of the weaver rail, as it is intended to interface with the ring-mount, provides a stable and positive mechanical lock. The ring-mount might engage the top surface and the lower part of the opposed 90’s on the sides. Or the ring may only grab firmly onto the upper and lower faces of the 90-degree side rails—or a combination of these conditions. In all cases, the ring-mount cannot slip or fall off the rail; but only if the ring’s binding screw remains tight. Of course, ideal conditions never prevail in the real world. As scopes get larger and heavier, rifles get lighter, and cartridges become impossibly powerful, stresses on optic mounts can exceed the strength of the materials used in their construction. So, there are indeed shortcomings and downfalls to the weaver system. Heavy recoil can overcome friction and cause a weaver ring to shift on the mount. The round cross-slot does not provide a true vertical abutment to resist recoil, so any shifting of a weaver ring in its base can result in vertical displacement as the ring climbs out of the slot. Even a slight shift on the base can cause the scope to lose zero. Worst case, this scenario can result in a split ring or deformed clamp that can no longer maintain a positive mechanical purchase on the rail.

The Weaver system can be manufactured without the need for high precision manufacturing processes. This is the true genius behind the design. Except that nowadays, there are enough variations in ring mounts and “weaver-type” or genuine imitation bases that some combinations are totally non-functional. The proliferation and pirating of the weaver system kills the guarantee of any level of mounting strength or even compatibility or consistency of datum surfaces and dimensions and spacing between locking surfaces and cross-slots. And of great import today, as we demand flexibility and modularity in everything, a weaver-type mount and ring combination is unlikely to maintain zero after being removed and subsequently reattached. This is all unacceptable to the discerning shootist of today. Modern Picatinny mounting solutions all seem to guarantee 100% return-to zero satisfaction. So, our connection to and application for the weaver may have seen its day. This might see the kind of break up that begins and ends with, “Weaver … we love you, but …” There is in fact little need for concern, however. Weaver does in fact now offer a line of “tactical” mounts and bases. The bases are made from steel and profiled to meet M1913 Picatinny rail spec. The ring mounts are massive and overbuilt from 7075 aircraft-grade aluminum. These are not your grand-dad’s weaver mounts. Weaver’s tactical line surpasses expectation. They’re made from supreme materials and manufactured to exacting standards.

Armalite

The AR-10 carry handle was first used as a scope mount around 1959 by the Dutch. The internal contour and structure of the carry handle on the Armalite AR-10 and later the AR-15 were seemingly designed with the forethought that they would perform as a base for optics. The contour where the mount meets the optic includes opposing 45-degree shoulders that serve to consistently align the optic as it is drawn into the wedge formed by the interior angles. The system only requires a single mounting fastener—usually a knurled nut or screw. One advantage to this mount’s design is its integration into an existing feature of the rifle—no intermediary mounts or adapters are required. Thus, it is light, strong and repeatable. And this mount pattern was designed to maintain full utility of the fixed iron-sights on the weapon. The downside to this system is that the shooter cannot make a solid cheek weld—the optic is placed so high above the intended line of sight, an add-on cheek riser must be used to elevate the comb to an operative height. But in doing so, the iron sights cannot be used. Weapon utility is compromised in this condition. To maintain full utility, the rifle can be aimed and fired with the head suspended above the stock comb. But accuracy and shooter comfort (and thus his proficiency) during prolonged use are both equally compromised.

After the AR-10 and AR-15 projects had moved on, the great men of Armalite would eventually produce the AR-18. This was an attempt to broaden the company’s reach and market share by offering a more affordable option to the AR-15. This weapon platform included an optic base that was formed in the shape of a triangular dovetailed wedge, tapering toward the rear. The dovetail was engineered and oriented such that the scope, while mounted, could only shoot tighter onto the dovetail under recoil. The mount uses a spring plunger to keep the mount pressed firmly forward onto the dovetail in case of reverse recoil or incidental rearward pressure. And as a failsafe, the optic mount incorporated a swinging lock that would be actuated by the user’s thumb before the dovetail could be disengaged. The system allowed for one-handed attachment or removal of the optic from the firing position. As excellent a design as it is, the exact pattern has only ever been used on the AR-18 and its commercial variant, the AR-180. It is an excellent and ingenious device that deserves another chance at widespread success. It is the opinion and wish of the man writing this that Armalite should bring this mount back to commercial presence immediately.

The basic idea of the wedge-type mount may be attributable or derived from other sources. Years before the AR-18 existed, the BALVAR scope and mount from Bausch and Lomb relied on a spring plunger to keep the scope wedged into an adjustable base. The presence of a spring plunger used to press the mount into a wedge is present in several European optics mounting systems. SIG used something akin on the STG57 rifle. We see more modern generation of SIG rifles still using a similar mounting system—with a spring plunger forcing the scope base onto a triangular dovetail wedge (although quite small in comparison to the Armalite). Some mounts for the SIG system feature a mechanically arrested plunger to provide a more positive lock than spring pressure alone.

Warsaw Pact Rail

The Warsaw Pact Rail is commonly encountered on AK variants and other small arms of Eastern-European or Soviet origin like the PSL, SVD, VSS, etc. (post-1950). This rail base is a horizontal dovetail riveted to the side of the rifle; opposite the ejection port. This configuration lends well to the basic design of the AK—the sheet-metal receiver top cover is not solidly affixed to the receiver (some top covers do exist that incorporate a scope base but tend to lose zero every time the cover is removed). The scope mount clamps and locks onto this rail while a simple pin provides a positive stop against the rearmost face of the rail. This hard stop combined with friction generated by the clamping mechanism is generally sufficient to resist recoil. The mount has been proven to be imminently reliable in strength and tends to “return-to-zero” after removal. There are mounting adapters for the Warsaw Pact Rail that provide Picatinny rails, STANAG rails and even direct ring-mounts. The only demonstrable flaw to this system is its bulk and location. Some mounts of this pattern can increase a rifle’s width by almost an inch. The only imaginable failure would be attributed to the height of the mounting adapter. The optical device may be up to 3 inches away from the base rail. This extra-tall structure can compound the moment load on the mount. Perhaps not a demonstrable concern, but the possibility can give pause to the average “western” shooter who is used to a low-set scope mount right atop of his rifle.

Picatinny

The “Pic rail” is obviously based on the old weaver base, but with a more comprehensive, precise and robust structure. The rail’s profile and relative proportions have been refined to provide a predictable and consistent surface for any nominally crafted accessory designed to interface with the system. The Picatinny is correctly named M1913—the MIL-STD-1913 criteria defining the new mount was adopted and published February 3, 1995, by the DOD. Later, it was adopted into the NATO standards of agreement as STANAG 2324. It is presumed that the development and standardization of the mount were in response to the need identified in the first Gulf War (if not all other recent previous military actions). As warfare evolved away from a daylight-only venture on a directional battlefield, our soldiers needed their rifles to exercise some optical versatility. The battle rifle would have to become capable of operating with iron sights, red-dots, short-range and long-range telescopic sights and even dedicated night and thermal vision scopes—and of switching between them routinely. The Picatinny was the answer, and continues to be the answer, to the multi-role universal weapon system. Beyond universal adaptability, the Picatinny ensures near-perfect return-to-zero for optics after removal.

NAR

The “NATO Accessory Rail” is best explained as a redefined Picatinny rail. The new standard institutes a revision in the overall tolerance and operative datum points in an attempt to improve consistency and strength of the accessories meant to interface with the rail. The older Picatinny defined the four outer faces along the edges as the critical interface. The NAR calls out the relation between the top flat and two lower angles as the critical data points. The new definition ensures that the mounting devices made to this new spec make solid contact on those three datum planes. It has been insisted that this system will eventually allow for power and data transfer between the weapon and the accessories and peripherals. This ideal is expected to lead to the integration of smart systems into the battle rifle. Battlefield communication, navigation, onboard logistics and even a soldier’s vital stats are expected to become centralized in the rifle of the future.

STANAG

This is an acronym for “standardization agreement” among NATO nations. There are thousands of STANAGs in place to ensure that we and our allies are operating by consistent procedures and with compatible equipment. For example, the implementation of STANAG 4172 made 5.56 NATO a standard among NATO nations. The STANAG 4179 standardized the magazine pattern among 5.56 NATO chambered small arms. STANAG 2324 defines the universal adoption of the MIL-STD-1913 rail as the optic mount for small arms. Despite all the specifics and code-speak, there is one mount configuration that has become known simply as the STANAG. You’ll be hard-pressed to define it by more specific terms.

This mount pattern consists of a pair of square pockets at each end of the base. These square recesses interlock with lugs that protrude from the optic—usually these lugs are cast into or machined directly into the body of the optical device. Mounting relies on a pair of large screws to fasten the optic to the mount base. Return-to-zero after removal is nominal at best, but the system proved reliable enough to become the most widely used standardized mount system in Europe before the M1913 Picatinny came into favor. The STANAG mount pattern was a standard kit on numerous commercial and military arms from last century. Variants of the FAL, FN49, MAS, Swiss K31, SIG SG-510 and most HK rifles have been originally made, or can be fitted, with aftermarket STANAG-patterned scope mounts. The STANAG mount held enough market shares, as did the optics designed to interface with it, that one can still easily procure any array of adapters to convert a Picatinny-equipped rifle to accept a STANAG optic or convert a STANAG -based rifle to accept adapters for Picatinny style optics.

ACCESSORY MOUNTS

It seems unlikely that the Picatinny could ever be replaced as the prevailing standard as the optics mount for the small-arm. It has experienced continued success as an accessory mounting platform on the battle rifle; its presence may have spawned the booming accessory market as it is today. But there is a great need by both the consumer and professional markets to accessorize and expand a rifle’s capabilities. The obvious place to affix this burden was the handguard. These handguards were typically aluminum and exhibited four lengths of M1913 Picatinny rail at the top, bottom and sides (hence, quad). From the mid-‘90s every premium and professional grade AR-15 was expected to include a “quad” rail as standard kit. Some RIS (rail interface system) handguards are strong enough to serve as a mounting point for other weapons. There are indeed 12-gauge shotguns and grenade launchers designed to grab directly onto a Picatinny handguard. This solves some of the difficulty of removing the lower half of the handguard to expose the barrel for launcher mounting. This capability also allowed launcher mounting on barrels that might lack the specific provisions for direct launcher attachment. Picatinny rails were soon found on upper receivers, buttstocks, magazine pouches and even the sides of scopes and the tops of scope rings. A shooter could accessorize his rifle to a point of nausea. However, the high-profile, obtrusive shape and inherent weight of the pic left much room for refinement. It was soon realized that it was impossible to utilize the total 39 inches of rail afforded by the average rifle length quad handguard. The average shooter might only utilize 2 to 4 inches of rail, to attach one to three peripheral items.

Around 2009-2011, we saw a growing trend in “quad” handguards. They began losing the bottom and side rails—only the top rail section would remain. The rest of the handguard would present with a regular pattern of tapped holes or pockets arrayed around an otherwise smooth handguard. The user was free to attach small sections of pic rail where he needed them. So, the RIS, as it was originally created in the “quad” pattern would soon need to evolve. Many brands released their own modular handguard system, and some still survive as proprietary offerings with a fair fan base. There are two clear heavyweights in terms of accessory mounting systems. VLTOR Weapon Systems gave us the KeyMod, and shortly after, Magpul Industries presented the world with the M-LOK. After exhaustive R&D and the associated cost, these companies made their new standardized patterns public domain. Any manufacturer of weapon accessories could reproduce the mount and the interfacing accessories.

KeyMod

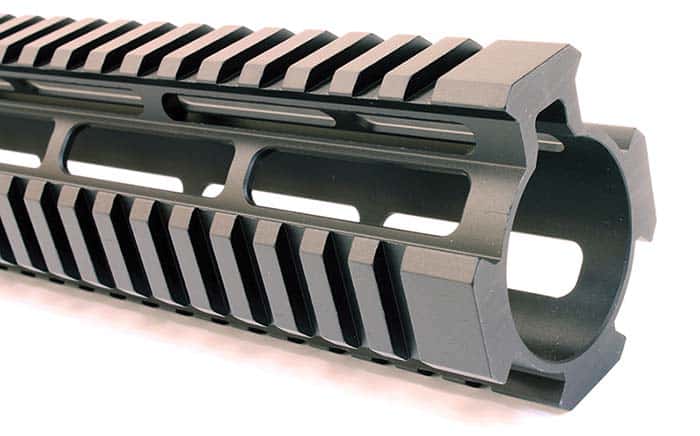

The VLTOR Weapon Systems KeyMod system was the first new modular mounting pattern to become standardized since the M1913 Picatinny. And for many years, it was the best if not the only option to the “quad” handguard. The design is complex as it demands a level of precision in the manufacture of the handguard and accessory mounts. The “key” as it is described, comes from the shape of the pocket. The widest portion is a 3/8-inch round hole, with a narrow pocket extending from one side. The narrow section is relieved on the back (or inside of the handguard). A contoured “nut” passes through the wide portion, and then becomes mechanically locked behind the shoulders of the narrow section. The accessory mount features a fixed cylindrical lug on the back face that locks into the large cutout behind the nut, thus preventing it from slipping out the way it entered the pocket. If the binding screws remain tight in the nut, the mounting arrangement will stay put. The only limitation one might point out is the thin web of material between each keyhole. In destructive testing, this narrow web is regularly where material failure initiates.

M-LOK

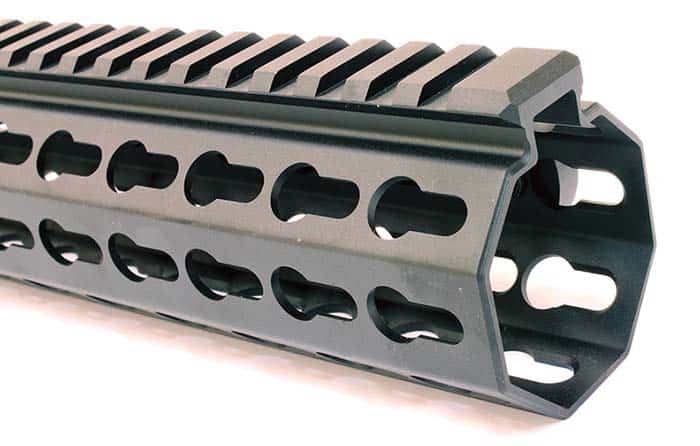

The M-LOK pattern calls for a small T-shaped recess in the handguard—narrow cut facing outward while the head of the “T” is cut on the back, or inside surface. Lateral locking is achieved by a fixed stud set between two T-nuts. The stud and one T-nut essentially match up to each end of a short pocket (each pocket is 1.26 inches long), while the other T-nut straddles the web between the pockets (.315 inch). Each T-nut is engaged by a screw—accessible from the outside of the accessory adapter. Upon tightening the screw, the T-nut swings 90 degrees until the head of the T comes into full mechanical interference with the back side of the slot. The nature of this design transfers load forces to the steel locking screws and appeals directly to the strength of the material used in the handguard’s construction.

These two systems provide the same service—modular accessory mounting on a rifle’s handguard. Some have wondered, and others argued, about which is superior. Pullout and shear strength of the M-LOK have been tested and proven to be superior in strength to the KeyMod—up to three times stronger under abusive testing. Some M-LOK pattern handguards have been tested to resist 1,400 pounds before mount failure. KeyMod can be expected to fail near 400 pounds. Also, M-LOK’s return-to-zero after removal is up to 50% better than KeyMod. That said, most accessory mounting bases are short Picatinny rail sections fastened onto the handguard, and accessories are mounted to those rail sections. It is safe to assume that under actual use, only the accessory would be removed from the Picatinny section; the Picatinny’s return-to-zero is largely dependent on the clamp or mount chosen. It is worth noting here, that direct-connect accessories do exist for each pattern. These accessories are largely limited to flashlight mounts, forward grips and sling attachment points.

And as far as abusive testing to the point of material failure, by all intents and purposes, nobody who has bought a rifle with their own hard-earned cash should ever be expected to subject their rifle to that kind of use. As these patterns are indeed open-source, any company may produce the handguards as well as the accessory mounts for them. The patterns are well defined, but there is no guarantee as to material quality or dimensional tolerances used in their construction. Once again as we see the proliferation of a market we will also see knock-offs and clones and the diminished quality that comes with them. Any of these handguards would be more likely to fail under normal use due to material and manufacturing faults than failure directly attributed to the mounting pattern you’ve chosen. Quality never disappoints. The comparison test in reference above was performed by USSOCOM, and results were published in May 2017. The test is exhaustive and conclusive; it’s worth a quick study. The numbers demonstrate fact, but real-world application and consumer acceptance will decide the fate or coexistence of these two mounting patterns.

There will always be room and opportunity to improve on any current system. It might seem unlikely that we’ll see any major shift from our current systems considering our current state of refinement and the level to which the world has become vested in the Picatinny-type rail. The NAR might just be the last chapter in this treatise.

| This article first appeared in Small Arms Review V22N2 (February 2018) |