By Robert G. Segel

Themed “Freedom’s 2nd Army,” the 135th National Rifle Association Annual Meetings & Exhibits will take place May 19-21, 2006 at the Midwest Airlines Center in Milwaukee, Wisconsin. More than 300 exhibitors representing every major firearm, ammunition and accessory manufacturer, as well as hunting outfitters from around the world, will be set up at the show. Seminars, business meetings, special interest sessions, fund-raising auctions and banquets will occur throughout the weekend. 45,000 people are expected to attend this major weekend event.

In addition to the huge array of commercial displays, an extremely popular show area are the exhibits of some of the finest and rarest firearms in the United States shown by NRA affiliated collectors associations. Collecting firearms of all types is an integral part of the National Rifle Association membership and the opportunity to see some of these rare and historic firearms is, in itself, worth the visit.

Collecting rare and historic automatic weapons has, unfortunately, been a stepchild to the larger collecting community for many years. The good news is that is finally changing and is beginning to be accepted as a legitimate collecting discipline.

In the last several years, the Thompson Collectors Association (TCA), an NRA affiliated organization, exhibited rare and historic Thompson submachine guns a number of times at the annual NRA shows. The exhibits were extremely popular and well received, winning a number of prestigious NRA Gun Collector Awards for their exceptionally professional presentations. But more importantly, they led the effort to break the “barrier” and underserved “stigma” of collecting Class III weapons. They were the leaders in helping to establish the legitimacy of historic Class III collecting within the arms collecting community and have demonstrated that collecting historic automatic weapons is just as reasonable, and important, as collecting Colt Single Action Armys, Winchester repeating rifles, Revolutionary War muskets, or anything else in the historic weapons collecting repertoire. They followed up on their mission of legitimizing the collecting of automatic weapons by putting together and sponsoring a Thompson exhibit at the William B. Ruger Gallery of the National Firearms Museum in Fairfax, Virginia (see Small Arms Review Vol. 8, No. 1, October 2004). So popular was this exhibit, it was extended for another four months beyond its original run.

In their efforts to continue this legacy of promoting Class III collectibles, the Thompson Collectors Association board of directors have voted to sponsor, along with the Dallas Arms Collectors Association, an exhibit at this year’s NRA show in Milwaukee. The title of the exhibit will be The American Genius of Sir Hiram Maxim: Father of the Modern Machine Gun. The theme of the exhibit will be the brilliance of American Sir Hiram Maxim and his invention of the world’s first truly automatic weapon. This groundbreaking 10×20 exhibit will feature six different historic models of the Maxim gun, along with rare accessories, highlighting the genius of Hiram Maxim and the contribution he made to the arms world. The foresight and dedication of the Thompson Collectors Association and the Dallas Arms Collectors Association in their continuing efforts to make Class III collecting acceptable to the wide-spread firearms collecting community should be commended and applauded for their hard work that benefits all of us.

So modern and revolutionary in its design and operation, Maxims were used by many countries throughout the world at the turn of the twentieth century. Efficient and reliable, some models were made, under license, by manufacturers in other countries. To the layman, the words “German Maxim” are one and the same. In reality, Hiram Maxim was an American, living and producing his guns in England, and licensing manufacturing around the world, including Russia, Switzerland, the United States, and, of course, Germany.

A thumbnail history of the six featured Maxims that will be on display at the NRA show in Milwaukee follow.

Argentine Maxim Model 1895

Argentina was an early user of the Maxim and began by ordering 50 Maxims from the Maxim Nordenfelt Co. in England in 1895. In 1898, a second order of the Model 1895 was placed with Deutsche Waffen und Munitions Fabriken (DWM), a licensed Maxim manufacturer in Germany, for another 150 guns. Even though most South American countries adopted the French Hotchkiss machine gun, by 1902, Argentina had 200 of these early Maxims in their inventory. Beautifully made with its water jacket, feed block, fusee spring cover, receiver floor plate and rear grip plate made of brass, the Model 1895 was a stunning, and lethal, piece of the firearm maker’s craft. This model had the early straight style of crank handle, an 1889 style lock and wooden roller belt assist located within the brass feed block. The gun also has provisions for attaching a commercially made 2×12 optical sight made by Carl Zeiss of Jena, Germany and a shoulder brace made of steel and wood. The gun was mounted on an Ackland tripod that was manufactured by VSM (Vickers, Sons & Maxim) in England.

All 200 of Argentina’s Maxims were originally chambered in the 7.65x53mm 1891 Belgium Mauser caliber and the long sight bar affixed to the upper receiver was calibrated for this round-nosed, high trajectory bullet. Each gun was fitted with a brass data plate on the top cover over the feed block reading, “Cartoucho Mauser Argentino 1891” indicating the use of the 1891 Mauser cartridge. In 1909, Argentina adopted the new 7.65x53mm Spitzer round with the pointed bullet and flatter trajectory. All of Argentina’s Maxims were then rebarreled for the new cartridge and the long sight bar was shortened for the high-speed, flatter trajectory of the new cartridge. The brass cartridge data plate had the “1891” milled out and “1909” engraved in its place to reflect the change. Because of the restamped “1909”, the gun is often mistakenly identified as a Model 1909.

Though well equipped, Argentina did not participate in any major conflicts during the period that the Maxim was in their inventory. In the late 1950s, Argentina decided to sell some of their now obsolete weaponry and 91 Model 1895 Maxims were exported to the United States. Those that remained in Argentina were used to decorate various officers’ clubs, donated to museums or sold to Argentine collectors. Of the 91 guns imported into the US, 8 were exported, 28 ended up in government custody for museums, storage or destruction, and the remaining 55 are now mostly owned by collectors.

U.S. Maxim Model 1904

The US Maxim Model 1904 was the first rifle caliber heavy machine gun approved for use as the standard service type by the United States Army in 1904. The army was interested in the new Maxim gun as early as 1887 and procured examples of the “World Standard” Maxim Model 1889 and Model 1900 for testing. After sporadic testing, the Chief of Ordnance finally gave approval for adoption in 1904. The first order for 50 guns and tripods were manufactured by Vickers, Sons & Maxim (VSM) in England in the US caliber .30-03.

The Ordnance Department wanted the Maxim to be made in the United States and enlisted the Colt’s Patent Fire Arms Company to manufacture the gun. Problems arose and it was several years before Colt’s could begin production. In the meantime, the Ordnance Department ordered another 40 guns from VSM. When Colt finally began production in 1908, they continued with the serial number sequence for the model type. The first Colt produced Maxim Model 1904 began with serial number 91. By 1908, the service cartridge had changed from the .30-03 to the .30-06. The 90 guns produced by VSM were all converted to the new service cartridge while all the Colt guns were manufactured in .30-06.

In all, there were a total of 287 Model 1904 Maxims produced. The first 90 guns (serial number 1-90) were made by VSM in England. The remaining 197 guns (serial number 91-287) were made by Colt.

Colt had no desire to produce tripods or wheeled mounts for the gun. All of the tripods were made by VSM in England and wheeled carriage mounts were produced by Rock Island Arsenal (RIA). The tripods and wheeled mounts were ordered separately from the guns, and though serial numbered, they were thus not numbered to a specific gun. VSM produced 176 tripods and RIA produced 111 wheeled carriages.

The US Model 1904 Maxim was issued to US infantry companies and to cavalry troops. Mules were the primary means of transport. The gun was well made and reliable but was not popular in the field. The Model 1904 Maxim had the distinction of being the heaviest Maxim ever produced weighing in at a total of 145 pounds (gun with water – 65 pounds, tripod 80 pounds). Besides the normal heavy brass and steel make-up of the gun, the Model 1904 Maxim had an oversized water jacket holding 9.5 pints of water instead of the normal 7 pints. Nevertheless, the gun was widely used and saw service in such distant outposts as the Philippines, Hawaii, Mexico, Central and South America. Yet, it never saw active combat service, being relegated to training purposes. The gun was not used overseas in World War I but remained in the United States as a training weapon where it was ultimately replaced with the Colt Vickers Model 1915 and the Browning Model 1917.

Few of these historic US machine guns have survived. They saw a brief service life, quickly being declared obsolete and scrapped for their metal and brass components. Of the 287 guns made, there are less than 10 Model 1904 Maxims being registered as transferable to private individuals with another 4 or 5 in museums. Additionally, there are even fewer original 1904 tripods that have survived, again, being scrapped to salvage their large brass content, making the tripod even rarer than the gun.

Swiss Maxim MG11

In the interest of maintaining their peaceful neutrality, Switzerland has a long history of fielding the finest equipment available and was quick to realize the advantages of rapid fire weapons. They acquired Gatling guns in 11mm in the 1870s and Gardner guns (in the then prototype Swiss 7.5x55mm cartridge) in the 1880s.

In 1887, Hiram Maxim arrived in Thun, Switzerland to compete in the long-range shooting trials with his “World Standard” Model of 1887 machine gun in 11mm. The Model of 1887 “World Standard” was a massive weapon chambered in the rimmed .45 caliber/11mm black powder cartridge. The Swiss were impressed and placed an order but they wanted the gun chambered in the new and experimental 7.5mm Swiss cartridge. Maxim thought he could just “tweak” his large gun to accept the smaller, rimless round but encountered major reliability problems with many malfunctions. Ultimately, rather than convert the 11mm Maxim, he redesigned the gun specifically to accept the 7.5mm rimless cartridge. This resulted in Maxim’s first “Reduced Caliber” (approx. .30 caliber) machine gun. This gun was tested in 1889 and the decision was made to adopt the Maxim into the Swiss army.

The Swiss began by purchasing 72 Maxims from Maxim Nordenfelt in England in 1894 and designated as the MG94. Then, with some improvements, another 40 guns of the improved model were purchased from Maxim’s new company Vickers, Sons & Maxim (VSM), as well as Duetsche Waffen und Munitions Fabriken (DWM) in Germany in 1900 and designated them as the MG00. When DWM introduced their new Commercial Model in 1909, which was substantially lighter than the previous Maxims, the Swiss tested it and adopted it in 1911, designated it as the Maschinengewehr 11 (MG11) and ordered 167 guns.

When World War I interrupted their source of supply in 1914, they began to produce their own Maxims, under license, at Waffenfabrik Bern in Switzerland. Production began in 1915 and continued to 1946 with 10,269 Maxim MG11s being produced.

The MG11 was mounted on the DWM designed Commercial Model 1909 tripod which was also produced at the Waffenfabrik Bern factory. This tripod was more stable than any other tripod in use at the time and was considered the finest mount available.

There were a number of optical sights used with the MG11 for both direct and indirect fire. The more common early style direct fire sight used with the MG11 was made in Germany by Carl Zeiss of Jena. There was also a specialized long-range telescopic sight used in mountain fortresses.

The Maxim MG11 as made by the Swiss at Waffenfabrik Bern is rightly considered the finest Maxim ever made. The quality of workmanship, fit and finish surpasses any other Maxim made and is worthy of the dependability inherent in all Maxim guns. Because of its neutrality, Switzerland has a stringent policy concerning the export of its military weapons and thus Swiss maxims are exceptionally rare outside of Switzerland. There are only six Swiss MG11s in the United States making it one of the rarest types of its kind in US collections.

German Maxim MG08

In 1892, the Maxim Nordenfelt Co. of England entered into an agreement with Ludwig Loewe & Co. of Berlin granting them the rights to produce Maxim guns in Germany for Germany, the entire German Empire and her allies. Maxims were produced by Ludwig Loewe under that name for several years until, because of a growing anti-Semitic movement, Loewe changed the name of his company to Deutsche Waffen und Munitions Fabriken (DWM) so that the name of Loewe would not be connected with it. DWM then became a public company owned by, but administratively separate from, the Loewe engineering firm.

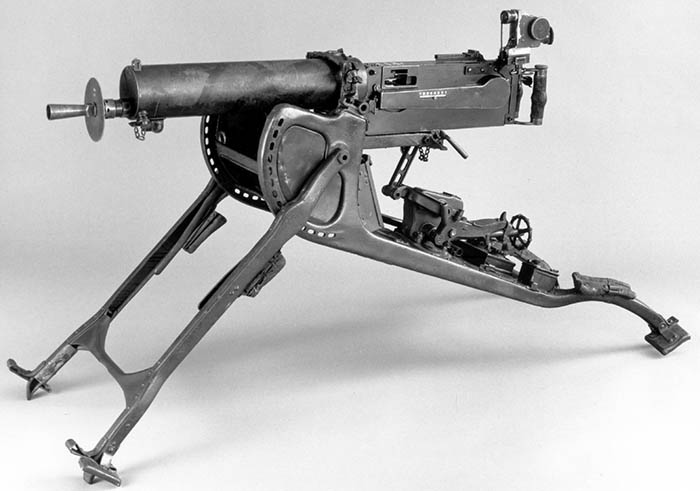

The German army adopted the DWM Model 1901. After observations gained from the Russo-Japanese war, the German army suggested changes in the Maxim; particularly addressing the major problem of weight of the gun and mount. The government arsenal at Spandau, working alongside DWM, began to implement the suggested changes by redesigning the heavy parts of earlier guns with lightweight steel. Thus the water jacket, trunnion block, feed block, fusee spring cover and backplate assemblies became much thinner and lighter resulting in a 17 pound weight reduction from 57 pounds to 40 pounds. A bracket for mounting an optical sight was added to the receiver and the cocking handle knob was increased in diameter to provide a better grip. The sledmount was redesigned with lighter materials and the wheels were removed. This mount provided unequaled stability with resulting incredible accuracy, though it later proved difficult to set up on uneven terrain. The improvements were completed in 1908 and the new gun and mount became standardized and adopted by the German army as the Maschinengewehr 08 (MG08) and the Schlitten 08 (sled 08).

At the outbreak of World War I in 1914, Germany had approximately 5,000 Maxims and was the only country that truly recognized the value and importance of the machine gun on the battlefield in terms of firepower and strategic advantage in both attack and defense. This resulted in an aggressive armament of machine gun companies within regiments and battalions. Tens of thousands of MG08s were eventually produced by the government arsenal at Spandau and DWM to equip the German army. Training in operation and tactics was crucial to the operational success of the MG08 and machine gunners were all hand picked, particularly personnel for the “marksman” units. Woefully, hundreds of thousands of Allied soldiers were slaughtered in the fields of France and Belgium in the futile old-world massed assaults against the well dug-in German machine guns. The ultimate defense to this onslaught was the inevitable trench network to shield the foot soldier from the fusillade of bullets.

Warfare of the past five thousand years abruptly changed with the new weapons of war as developed during the industrial revolution of the late 19th and early 20th century. No longer were the massed attacks with foot infantry or swift assault with cavalry capable of overwhelming an enemy equipped with the modern tools of war. As with all advancements, the eventual downfall of the emplaced heavy machine gun came about with the advent of mobile warfare, most notably with the development and advancement of the tank and airplane. But the heavy machine guns of the early twentieth century epitomized the state-of-the-art martial development of firearm design and function.

German Maxim MG08/15

The British were able to gain a small tactical advantage over the emplaced German heavy machine gun by issuing large numbers of lightweight, air-cooled Lewis and Hotchkiss machine guns. Man-portable and prized as the ultimate front-line weapon, these light machine guns in rifle caliber proved extremely valuable on the battlefield. So highly were they valued that the Germans went to great lengths to capture and use them. They even printed a field manual on the Lewis gun for their troops.

In 1915, Germany established a large group of engineers to develop a light machine gun to counter the Lewis gun. With a relatively large number of designs to work with, they ultimately decided to stick with the Maxim action as it would be the least disruptive to current production facilities and training. The result was a hybrid “light” machine gun called the Maschinengewehr 08/15 (MG08/15). The MG08/15 went into production in late 1916 and was first issued generally to troops fighting in the Verdun sector in early 1917.

The MG08/15 was a lightened MG08 fitted with a bipod, shoulder stock and pistol grip. The reduction in weight was achieved by making the receiver walls thinner and reducing the size, and thus capacity, of the water jacket. Further weight-saving changes included a smaller feedblock, cutouts on the top of the rear and bottom front of the receiver sideplates to eliminate enclosed “dead” space, and eliminating the use of the cartridge ejection tube and spring in favor of a simple hole in the lower front of the stepped receiver. The recoiling parts of the gun – barrel, barrel extension, crosshead, connecting link and lock – were kept the same as the MG08 except a muzzle sleeve was screwed on to the already threaded muzzle end of the barrel. The only other interchangeable parts were the feed slide and belt holding pawls, roller and pin. All otherMG08/15 components were somewhat smaller and lighter than their MG08 counterparts. Additionally, since this was now a portable “light” machine gun, the MG08/15 receiver was fitted with a bracket to accommodate the affixing of a special spooled 100-round ammunition drum. Two of these drums were fitted in a wooden transit box and accompanied each gun.

Wanting to quickly supply the German Army with light machine guns, seven factories produced about 130,000 MG08/15s – making it the most common German machine gun of World War I. Manufacturers included: Gewehrfabrik Erfurt; Rheinische Maschinen & Metallwaren Fabrik, Sommerda; Maschinen Fabrik Augsburg-Nurnberg (M.A.N.) Nurnberg; Siemens & Halske (S&H) Berlin; J.P. Sauer & Sohn, Suhl; Gewehrfabrik Spandau; and Deutsche Waffen und Munitions Fabriken (D.W.&M.F.) Berlin.

The MG08/15, like its big brother the MG08, was extremely reliable and fired at about the same rate of 500 rounds per minute. It is interesting to note that the steel used in both guns was very hard and designed to withstand denting from shell fragments and other small low velocity projectiles. Only a well placed rifle bullet or direct shell fragment to the receiver could be sure of putting it out of action. British snipers were instructed to shoot at the receiver casing of the gun, rather than at the gunner, as the theory being that the gun was harder to replace than the man behind it.

While the MG08/15 was a reliable weapon, it had the distinction of being the heaviest “light” machine gun ever made. It was big, bulky and not easily controllable on its small bipod; it was designed to be a “trench broom” by a walking operator equipped with a large leather sling for support. Fully loaded with water and the 100-round drum, the gun weighed 49 pounds. Not an easy load to carry “over the top” under fire and in the muddy fields of no-mans land.

Russian Maxim M1910

Since 1865, Russia purchased and used a large number of Colt Gatling guns; even later manufacturing their own version called the “Gorloff.” With his success with sales to Italy, Switzerland and Austria, Hiram Maxim traveled to Russia in 1889 to demonstrate his new invention in St. Petersburg. The Russians had no concept of what an automatic gun was and thought the crank handle on the side of the Maxim gun was manually operated. This “little” gun could never replace the Gatling. Maxim fired an entire belt in half a minute and the Russian officers were, indeed, truly impressed. The Russian army and navy began purchasing Maxims from Maxim Nordenfelt in 1889. In 1899, Russia purchased more Model 1899 Maxims from DWM in Germany.

The Russo-Japanese war (1904-1905) was the first major conflict in which both sides used machine guns. The Japanese used the French designed Hotchkiss and the Russians used their heavy brass Maxims. Though relegated defensively to the rear along with artillery firing over the heads of their advancing troops, the Russian Maxims performed exceptionally well; most notably at the battle of Mukden repelling seven strong Japanese attacks.

The heavy brass Maxims were mounted on high, wheeled artillery-type carriages exposing the gunners to concentrated fire. With exceptionally high loses sustained by Russian machine gun batteries at the Yalu River battle, Russian Maxims were then mounted on heavy tripods with armor shields.

The Model 1905 was the first Maxim actually manufactured in Russia and was produced at the Tula Arsenal. This was the basic Model 1899 that still had the heavy brass water jacket, feed block, trunnion block, etc., but incorporated a few of the improvements found it the “new pattern” 1901 commercial Vickers-Maxim that included the “S”-shaped crank handle and easily-stripped lock.

By 1908, VSM (Vickers, Sons & Maxim) and DWM were producing guns that were lighter in weight, replacing the brass parts with steel. The Russians acquired some samples of VSM’s “new light” Model 1906 with the steel fluted water jacket and adopted it as the Model 1910. The Model 1910, as produced in Russia, now weighed in at just 44 pounds, producing a weight savings of 16 pounds over the Model 1905.

Wheeled transport was popular due to the weight of the gun but a new distinctive low wheeled mount with a small armor shield was developed by Colonel Sokolov soon after the adoption of the Model 1910. It featured a cradle designed to slide forward and back on curved rails allowing large adjustments in elevation and depression. The early mounts were quite heavy at about 100 pounds and included two folding legs that could be swung down to form a tripod raising the wheels off the ground. Sine the entire platform was so robust, the legs were later eliminated.

Production of the Model 1910 continued through the World War I years until 1917 when production dropped of considerably due to the disruptive Russian Revolution in 1917. Production picked up again in late 1918 and all through the interwar years. During World War II, production went into high gear and it remained the standard heavy Russian machine gun. An interesting modification was made in 1943 by the addition of a large, distinctive “snow cap” incorporated to the top of the water jacket to allow the insertion of snow (water) into the water jacket. The Russians actually copied this feature from the Finns who used such a contrivance on their own Maxims during the Russo-Finnish War of 1941-1944.

The Russian Maxim soldiered on for over four decades and more Maxims were built in Russia than all the other countries in the world combined. Production estimates indicate that over 600,000 guns were produced, including those given to the North Koreans, Chinese and others who received assistance from Russian armament programs after World War II.

| This article first appeared in Small Arms Review V9N8 (May 2006) |