by Mark Genovese

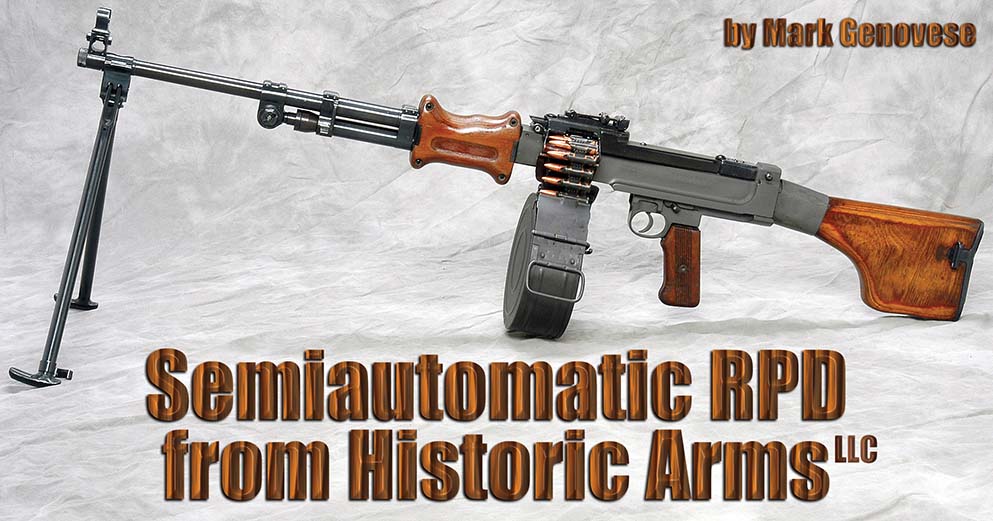

The Ruchnoi Pulemet Degtyarev, or RPD, began production in the early 1950’s at around the same time the Aberdeen Proving Ground was franticly trying to develop their own light squad machine gun, the T161E3 adopted as the M60. The RPD was designed to replace the venerable work horse of the Soviet Union, the 7.62x54R DP “Degtyarev Infantry” that appeared in 1926. The RPD utilizes the ever popular and incredibly inexpensive 7.62x39mm Russian intermediate cartridge as does the SKS and AK family of weapons. In the 1950’s, this weapon’s design was made to fill the same role as our BAR or the British Bren gun. In those years, the RPD was the lightest squad automatic in the world weighing in at 20 pounds fully loaded with a 100 round belt; in itself an amazing feat compared to our M60 weighing in at a whopping 24 pounds unloaded. The weapon’s overall length is 41 inches with a barrel length of 20 1/2 inches with 4 grooves right hand twist. Muzzle velocity is 2,410 feet per second and unloaded weighs just 15 pounds. Unlike the DP the RPD does not enjoy the benefits of a quick change barrel as it is permanently fixed and pinned to the receiver. This requires the end user to refrain from long bursts of sustained fire, no more then 100 rounds a minute, to avoid overheating the rather thin profiled barrel. This weapon was not intended for indirect fire and thus did not include a tripod. Rather, it was designed to be fired from the prone position using the attached bipod. The RPD appears to incorporate several successful firearm designs in the production weapon. The receiver, bolt carrier/operating rod, bolt and trigger mechanisms closely replicate the DP. The RPD and DP bolt use a simple and robust locking system, itself a modification of one of the earliest known types; the Kjellman-Friberg. The locking flaps located on the right and left side of the bolt are cammed out and into their broached locking surfaces in the receiver by the forward movement of the bolt assembly within the bolt carrier. As the bolt head spaces on the barrel face the outward movement of the locking flaps, are forced open by the slide tower. Allowing the tower to contact the rear of the firing pin, causing ignition. The gas cylinder design used on the RPD appears to be borrowed directly from the British Bren gun and can be easily adjusted to obtain the three different orifice sizes. The top cover belt feed assembly and feed tray looks to be an exact duplicate of the German made MG42 but in miniature. Even the RPD fifty round non-disintegrating locking belt sections bare an uncanny resemblance to the German manufacture. Contrary to some written publications, the RPD belts are not loaded by pushing the individual rounds into the belt so that the rear 90 degree hook of the link snaps into the cartridge extractor groove. The proper loading method is to lay the belt flat, open area facing up, then pushing each cartridge straight down in the link with the 90 degree hook facing the primer, exactly the same way you would load a double stack magazine. With practice it should take no longer then five minutes to load two fifty round sections. A cartridge is then inserted in the last link locking the two belt sections together and the belt is then rolled into a circle and fitted into the sheet metal drum. The drum is attached to the firearm via sliding onto the dovetail mating surfaces under the receiver from the rear forward. A drum lock is provided under the receiver.

THE HISTORIC ARMS SEMIAUTOMATIC CONVERSION

For years I have admired the RPD for its thin sleek styling, light weight, solid billet steel machine work, old world polish and bluing. But above all was its cartridge, the 7.62x39mm M1943. Back in the eighties, one could buy a Chinese 1,440 round case for under $70.00. Those days are gone thanks to Clinton, but Russian ammunition can still be had for $65.00 for a 1000 round case. Because transferable RPD’s have reached astronomical figures it was only a matter of time before an enterprising and talented individual developed a viable working semiautomatic conversion for the little RPD. Mr. Lennis Savage III, owner of Historic Arms, LLC (1486 Cherry Road, Franklin, Georgia 30217, phone (706) 675-0287) received his signed letter of release from the Department of the Treasury Bureau of Alcohol, Tobacco and Firearms on October 24, 2003 after submitting three uniquely different working prototype RPD firearms. This method cut the lengthy BATF approval process in half to an astonishing ninety four days by offering several firearms to pick from. The one thing that can make a project like this possible is an aggressive, uninhibited and very talented machinist gunsmith. This is hard to come by as after forty years in this business, all the old guard are burning out at an alarming rate. You need a guy who is relatively young and still believes he can conquer the known Class Three world. Len, and his partner John Craig, were born for this project. The RPD semiautomatic would prove to be complex and difficult in reality. The receiver starts life as thirty three pounds of billet hard steel. Over two hundred CNC steps and many hours later it morphs into just three and three quarters pounds of pure mechanical beauty. The second hurdle would be the machine broaching necessary to the inside of the receiver to accept the Kjellman-Friberg locking flap bolt system. After much hand ringing and gnashing of teeth by the engineers at Master Piece Arms, Carrolton, Georgia, it was decided the broaching tools necessary to machine the six degree radius cuts on the inside right and left of the receiver to accept the bolt flaps were not available and would be cost prohibitive to manufacture. It was back to the drawing board. An inexpensive and reliable solution was finally worked out. They would machine 1/8 inch wide by 5/8 inch tall slots through the outside of the receiver to the corresponding inside measurement, then precisely lay a bead of stainless weld in the slot for the bolt flaps to interface with the receiver. The reason this type of weld was used is that it is relatively elastic and can take repetitive abuse. The machined slots are then welded shut and machined down to the outside receiver dimensions. The right hand bolt carrier channel was deleted from the receiver per BATF regulations as this would disallow the insertion of a full automatic carrier and bolt. The original RPD barrel is threaded and screwed into the receiver, head spaced, then pinned in place. Next the gas tower bleed hole is drilled and the gas fitting permanently attached. The front site is then mounted permanently at the top dead center. With this procedure it would be impossible to reinstall the complete barrel assembly on a new machined receiver, head spaced and have the gas block and sight line up at the top dead center. Len and John did some serious brain storming and again came up with a cost effective method to keep the project moving forward. Remove the threads, turn the breech end of the barrel assembly down to .920 diameter and press fit the barrel to the receiver with a 4,000 pound hydraulic press, cross drill and install two pins, not one as in the original. Now came perhaps the most difficult challenge; the disconnecting trigger group, semiautomatic firing pin and recoil system. Several options were brought forward and tested; a hammer fired lower based on the FNFAL and two sliding striker fired systems. The hammer option was unsuccessful with light primer hits and inconsistent results, leaving the striker fired system with the most promise. Len and John concluded that their already successful semiautomatic Bren Gun (look for this article in a future SAR issue) and its trigger group plus sliding striker could be adapted with just minor changes. The Bren trigger assembly has the forward 13 1/2 inches of the lower removed, a simple disconnecting sear replaces the fully automatic parts, slightly repositioned and re-welded in such a way that the selector switch cannot be moved into the full auto position. Next the bolt carrier slide tower surface that used to contact the original firing pin has been completely machined away into a groove end to end to accommodate the new closed bolt semiautomatic 4 3/4 inch long firing pin thus rendering the fully automatic firing pin useless. The longer firing pin overhangs the rear end of the bolt by approximately 3/8 inch to allow the new sliding striker to contact the firing pin in the closed bolt position, initiating primer ignition. The recoil spring system is unique in that it must be perfectly balanced and in harmony with the striker recoil spring. If the primary spring is weak, the bolt will not come to battery. If the striker spring is weak you will have light primer hits as they play against each other. The transition from open bolt to closed bolt operation will create belt loading challenges which have been effectively addressed with a well thought out, spring loaded bolt hold open device conveniently located just forward of the trigger. By pulling the cocking handle to the rear position and pushing the hold open button up with your index finger will secure the mechanism, a light tug of the charging handle frees it. Even the mechanically challenged will have absolutely no problem field stripping this weapon for cleaning and maintenance. A single pushpin at the upper rear of the receiver can be removed effortlessly by pulling the trigger group recoil spring and stock straight back and off the weapon. Next the striker will move straight back and out as well. Grasp the cocking handle and pull back to its recess, remove it to the right and the bolt carrier and bolt will follow to the rear. Remarkable in its simplicity and robust manufacture. I purchased this firearm through the Historic Arms exclusive distributor, Mr. Phil Thompson, owner of Hit and Run Guns (4771 Britt Road #E-5 Norcross, GA 30093 phone (888) 207-2220). It was delivered in three working days packaged in a high quality Winchester gun case. Accessories included four new hundred round drums with two fifty round belts each, four new canvas carriers as well a tool kit that is stored in the butt stock and a weapon canvas carrier. I sighted the weapon in and test fired 500 rounds of surplus 1966 dated Chinese copper wash steel cased rounds on three separate occasions for a total of 1,500 rounds. Much to my surprise, at 213 yards this little belt fed out shoots my pre ban $10,000.00 H&K21. It is lighter, does not leave a green and purple bruise on my shoulder and will not dislodge my cornea. During testing there was a minor bump in the road. After firing 1,000 rounds the fifty year old roller bearing that drives the top cover feed mechanism failed. Len immediately overnight packaged the part and several other spares with instructions. It took all of three minutes to make the necessary repairs. In my opinion, this semiautomatic is well built, well designed of robust material, simple to operate and easy to maintain. The company thoroughly guarantees its product, and it is reasonably priced. The perfect entry level belt fed.

| This article first appeared in Small Arms Review V8N2 (November 2004) |