By John Morrison

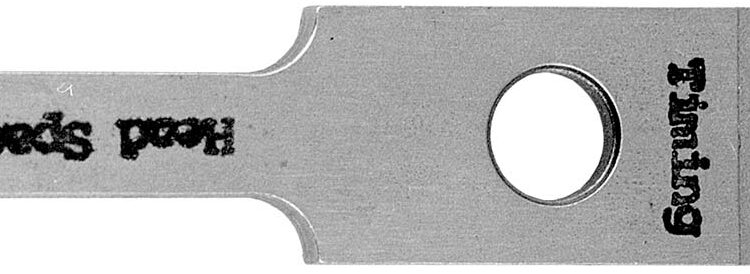

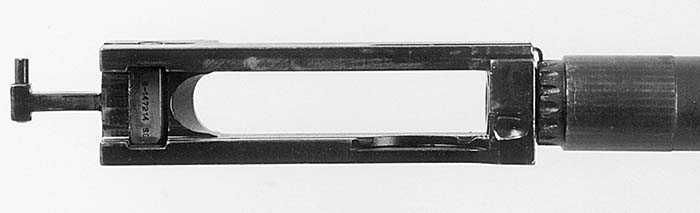

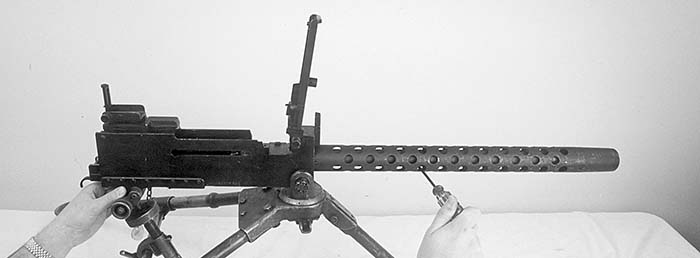

Head Space is the distance from the rear of the cartridge to the face of the bolt when the cartridge is fully seated in the chamber and the bolt is in the locked position.

Check the firearm to ensure it is not loaded. No live ammo or empty casings are needed to set the head space or timing.

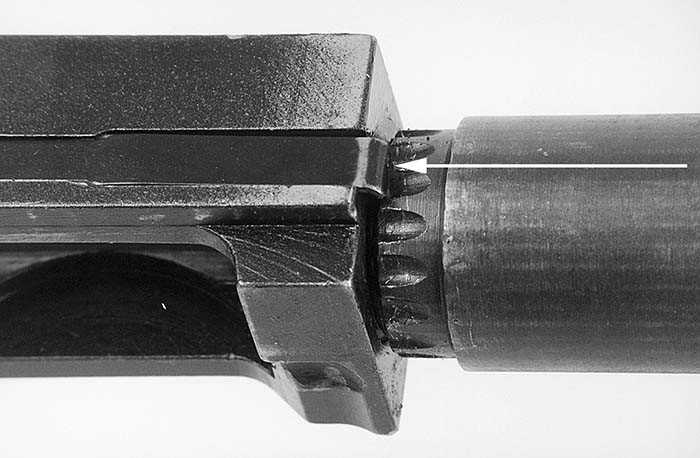

With the bolt face is the surface on the bolt that has the firing pin hole in it, not the very front surface of the bolt. The rail lugs are the very front surface and normally make contact with the barrel face when the gun is firing.

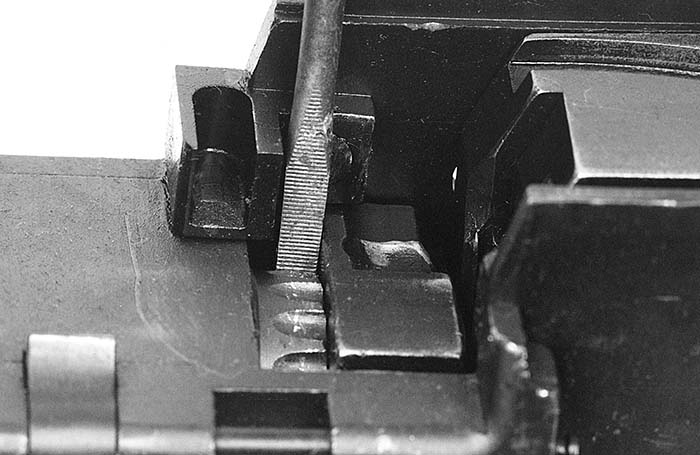

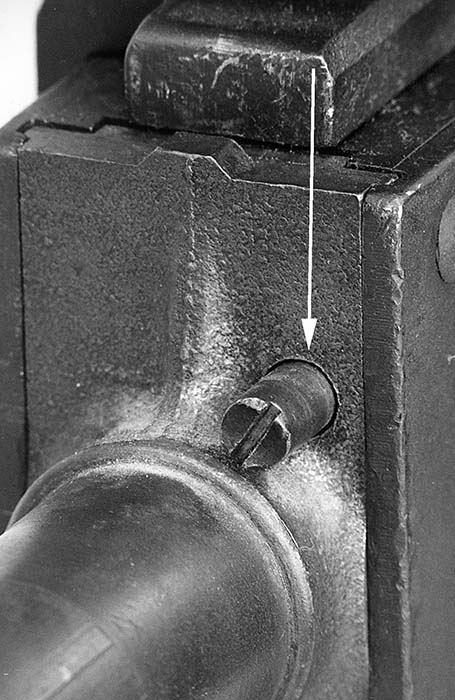

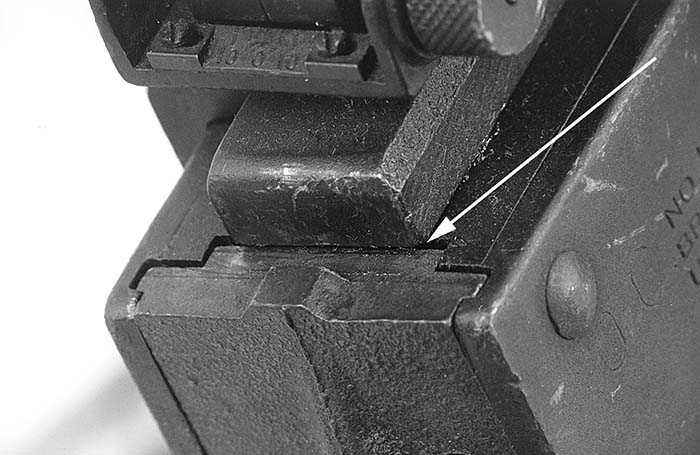

The .125 thick portion of the head space, all recoiling parts must go fully forward without being forced. The tension from the recoil spring should be sufficient. In this position, the barrel extension is in contact and flush with the face of the trunion (no gap). You will not be able to see the adjustment notches on the barrel. They will be completely inside the trunion.

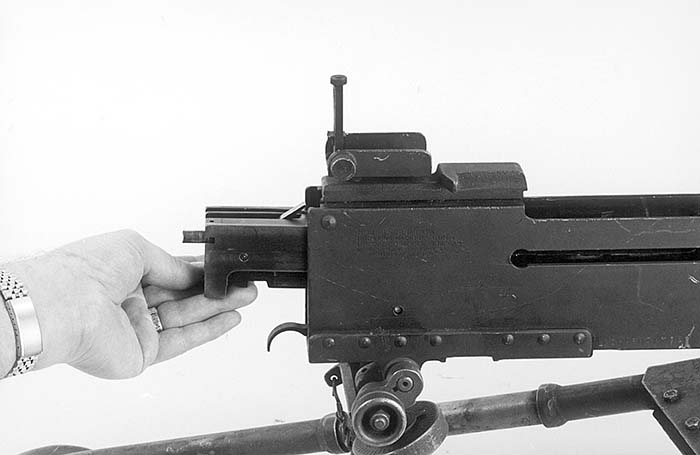

If the gun will not completely close to this position, the head space is already too tight. The notches on the barrel will be visible at this point. You must unscrew the barrel one or two notches at a time with the blade of a screw driver, combination tool, or a cartridge point, until the barrel extension closes fully against the trunion face.

Using the Gauge

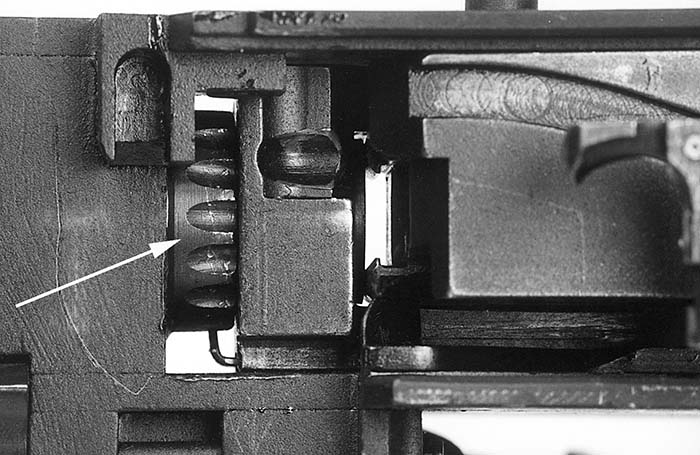

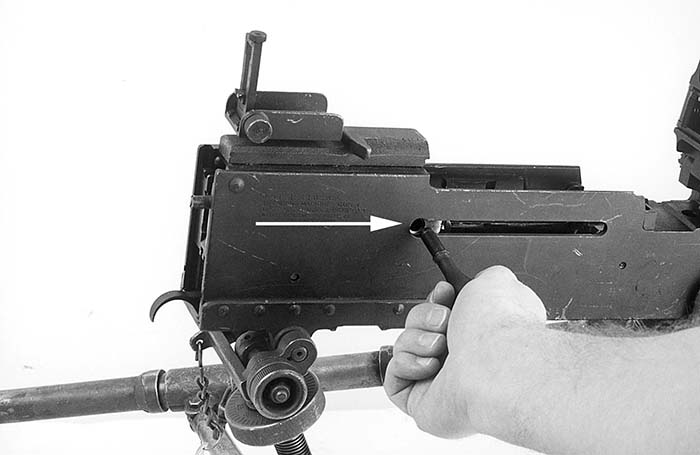

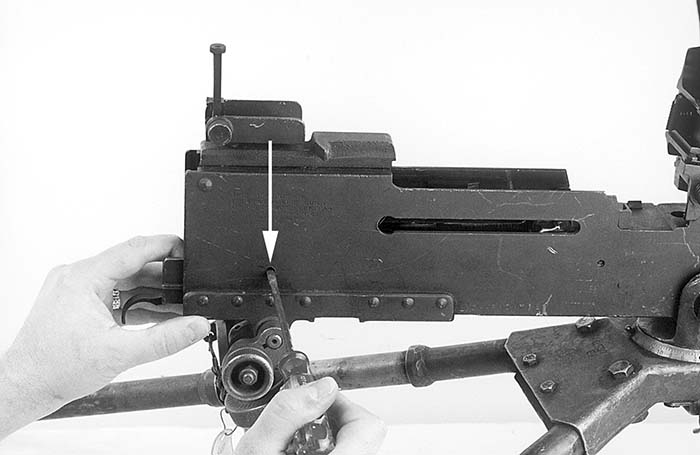

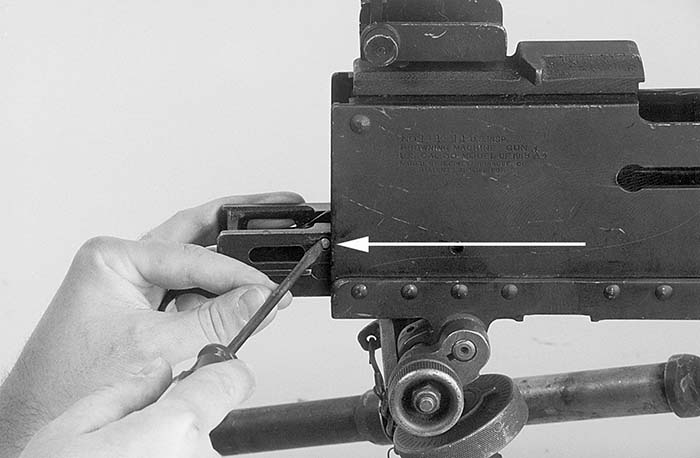

Pull the charging handle approximately 3/4” to the rear from the closed position. Insert the .125 end of the head space gauge between the bolt face and the barrel face. Turn the barrel in, one click at a time, until the gauge is tight between them. Back the barrel off one click. If the barrel is between clicks, back off to the nearest click, then one whole click. (Head space is set)

When these adjustments are completed with good, serviceable parts and a proper chamber depth in the barrel, the head space will be correct.

One or two clicks in or out may be required for a better performance with used and worn parts or for the use of substandard non-GI ammo.

Common Problems of Head Space Set too Tight

1) The gun operates sluggishly or erratic because the parts are binding.

2) Extraction trouble may occur because of improper locking and unlocking.

3) If the adjustment is very tight and the barrel notches can be seen, the bolt handle will not go fully forward and the firing pin will not drop when the trigger is pulled.

Common Problems of Head Space too Loose

1) A ruptured cartridge

2) Split cases (with good ammo). Bad ammo may have split cases before you fire it.

3) The bolt can be moved slightly from the front to the rear independently of the barrel and the barrel extension.

If problems from a too tight or too loose head space are present after setting per these instructions, turn the barrel one click at a time but not more than two clicks total in either direction from the original setting. If there is no improvement in performance, there is some other mechanical problem with the gun, or there is a problem with the ammo being used.

The only exception to this is the .308 conversion (with an original Israeli .308 barrel). The chamber depth in these barrels is .010 more shallow than a GI type barrel. It would be safe to turn the Israeli .308 barrel two more clicks out beyond these recommended adjustments if the gun shows signs of a too tight head space problem.

All the head space adjustments are done with a charged bolt and cocked firing pin. Do not pull the trigger and drop the firing pin on the head space gauge. It may break your firing pin!

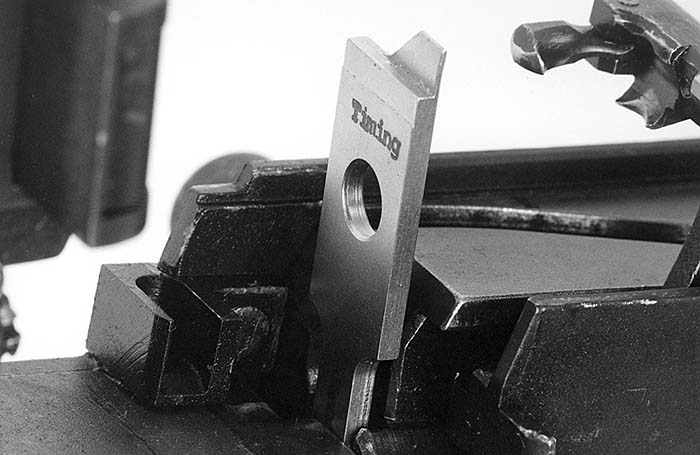

Timing Adjustments

Charge the gun to cock the firing pin and let the bolt drop fully forward. The firing pin should be cocked and inside the bolt face. If the firing pin can be seen sticking out of the bolt face before the trigger is pulled, do not attempt to fire the gun with live ammo. The timing is way too fast. An entire belt of ammo can be fired without the trigger ever being pulled.

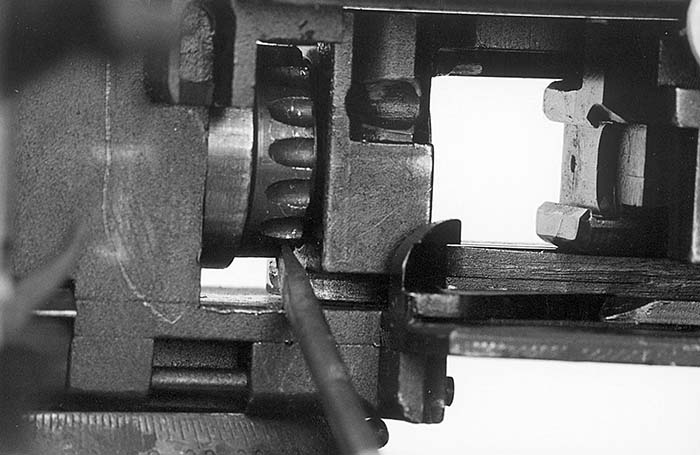

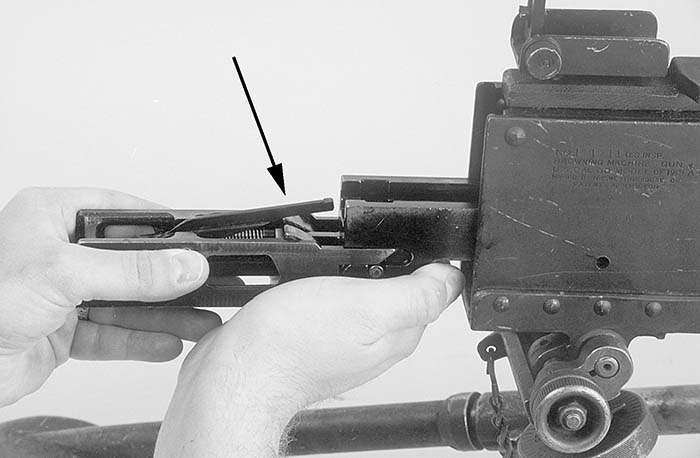

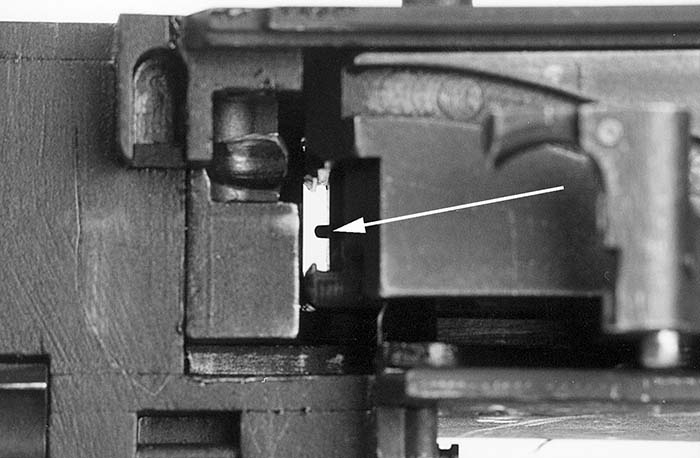

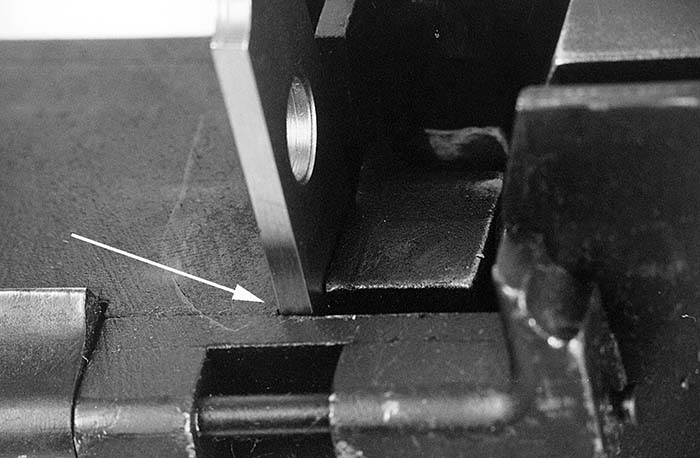

With the gun charged and the firing pin cocked, pull the charging handle back just far enough to put the .120 thick portion of the timing gauge between the barrel extension and the trunion. Let go of the charging handle. The gauge is held in position from the recoil spring pressure. Pull the trigger to see if the gun will fire. It should not fire. This is the ‘no fire” portion of the gauge. If the gun does fire, the timing is too fast and will need adjustment.

If the gun does not fire, then pull the charging handle back far enough to remove the gauge and let the barrel extension close so the .030 portion of the gauge is between the trunion and the barrel extension. Pull the trigger. The gun should fire at this setting. This is the ‘fire’ portion of the gauge. If the gun does not fire, your timing is too slow and will need adjustment.

Adjust Timing as Follows

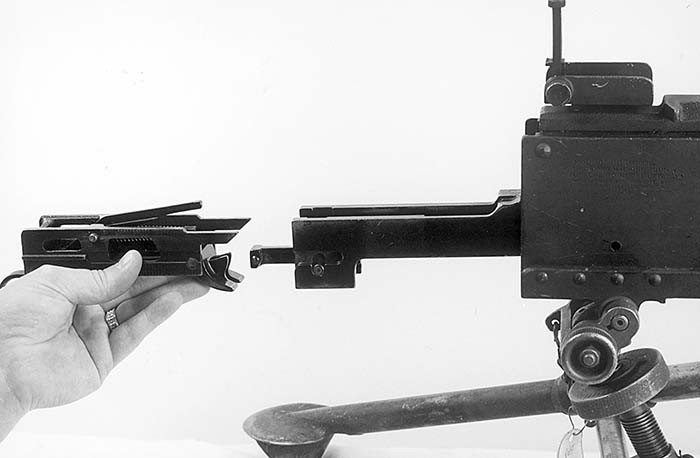

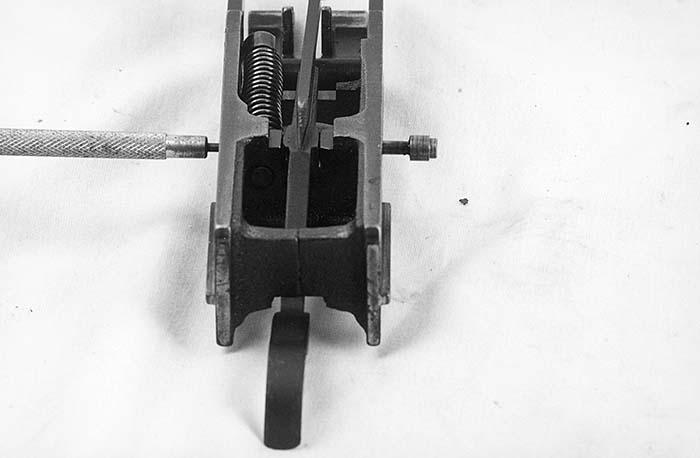

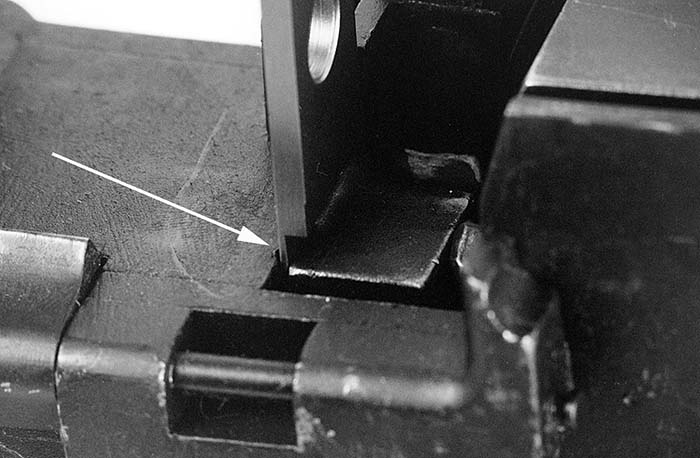

The trigger bar must be removed from the gun for adjustments to be made. The dovetail end of the trigger bare that engages the sear in the rear of the bolt must be bent upward or downward to speed up or slow down the timing. Do not try to bend too much in either direction at one time; small mounts are best. It may take a few tries. This aera of the trigger is thin and semi-soft. It is made that way jut for this type of adjustment.

If the timing of the gun is too fast and needs an adjustment, the dovetail end on the trigger bar will need to be bent upward. In order to know what is upward, you need to look at the trigger bar as if it is in the trigger assembly.

Bending this end downward will correct a slow timing problem and get the trigger bar to trip the bolt sear that much sooner, thus speeding up the timing.

Changing parts or a combination of parts on any gun can adversely affect your timing and head space adjustments. Always re-check these adjustments when the parts are changed in the gun.

At one point, Ohio Ordnance Works, Inc., made the gauge shown in this article. If you’re looking for one, hit them up and maybe they have one kicking around

| This article first appeared in Small Arms Review V2N9 (June 1999) |