By Jay Bell

Several months ago, I received word from Ernest Wrenn, owner of Socom Mfg., a Class 2/3 dealer and manufacturer located in North Augusta, South Carolina, that he was planning on releasing a run of CNC machined billet aluminum AR-15™ style receivers with “SPECIAL” features. “This has been done ages ago…” I thought, thinking about the older models that I had seen, the ones that had been milled out of bar stock. Knowing the prices that some other manufacturers sell billet receivers for, I wondered what would be so good about this latest incarnation of the AR-15™ to justify the imagined cost. So, on an impulse, I asked that Ernie keep me in mind when the product was finished, as I would be interested in looking one over for purchase.

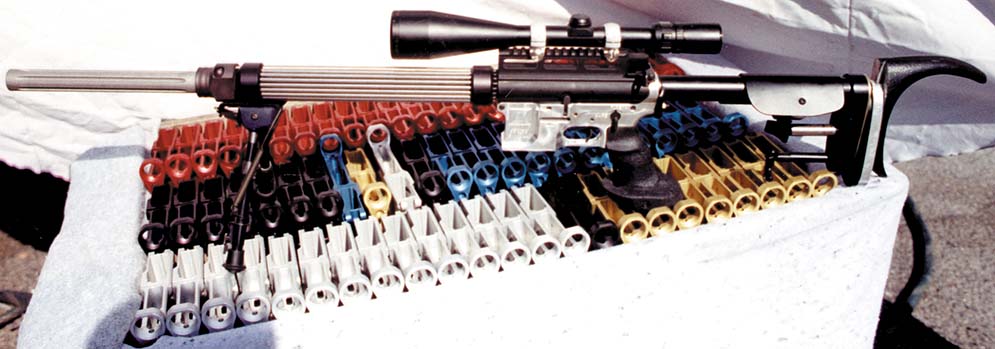

In the meanwhile I received regular updates from Ernie with some pictures showing various stages of the production…I could see a lot of unusually shaped bare aluminum, but no real features as of yet. Then, one day, the receiver arrived.” WOW! WHAT A SHOCK!!!!!”

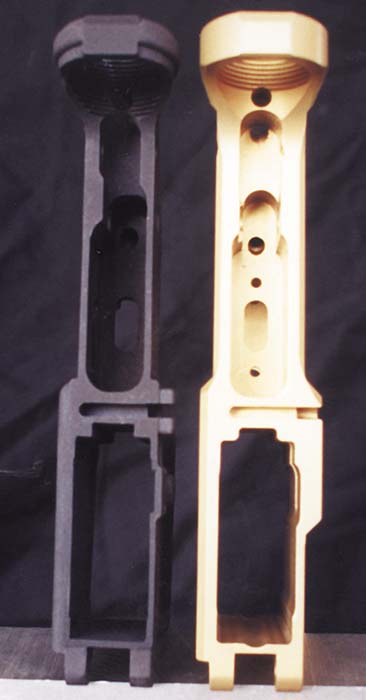

The “DIAMOND BR-15™” series AR-15™ type receiver is machined from what started out as a 7lb. brick of forged T-6 Aircraft aluminum alloy. Since this was initially a project in design, the billet route was chosen for two specific reasons: strength, and the fact that there were no raw forgings available that would enable the designer to include all the features he wanted.

For strength, billet is an excellent choice. The material is denser due to the forging process, lending it better strength than a casting of the same size, and also avoiding the weakening inclusions that castings can sometimes contain.

Also, the billet was an excellent choice if the maker wanted to expand on the proportions of the A-2 reinforcements, and add the other custom features they desire.

The first thing that struck me was the finish. The first sample I received was silver anodized, not quite matte, but more of a satin finish, similar in look to satin hard chrome. Since I prefer to keep “The Black Rifle” black, I promptly asked Ernie to ship a black anodized receiver to me, which he did, and I made a shooting buddys day by passing the silver receiver to him for purchase. On a quick inspection, both receivers seemed identical, aside from the finish, even down to the exact same tooling marks in the exact same places. After passing through the NICS check system at my FFLs shop, and taking the black stripped receiver home, I was finally able to make a complete examination of the lower.

I noted how much heavier the receiver seemed than a standard A2 lower from Colt or Bushmaster, and how clean and sharp the markings and lines of the receiver were, especially the edges, which are all beveled and sculpted. On the left side of the receiver was a large “diamond” logo and the serial number, on the right side was the manufacturer markings, model designation, and caliber designation.

All the machining and engraving was done on a 5-axis CNC mill, Not only does that ensure that there are no hidden fractures from roll stamping, but it also ensures that all the sides are machined fully parallel to the other, there are no off center or angled surfaces that are not designed that way.

I also noted other features that were rather unusual: 1: All the takedown pin areas were highly reinforced. 2:The rear of the receiver contains a recessed jackscrew that will press against the upper receivers rear lug, and is used to take the wobble or slack out of the upper/lower receiver fit. 3:The receiver sides are easily twice as thick as a standard A2 lower receiver is. This thickness means more stiffness to resist twist or deformation. 4:The lower contains adjustment screws for both trigger reset and trigger stop, accessible through the trigger-guard, which is a solid piece of the lower receiver. 5: The magazine release area is heavily fenced in. 6: All the detent holes seemed to be tapped, except for the one at the front takedown pin. 7: The magazine well has no “taper”, but is instead parallel to the top of the receiver. 8: Fire control markings are on both sides of the receiver in large, easily readable engraved letters: “FIRE” and “SAFE” 9: Included with the receiver was a short list of instructions, some grub screws for the capture pin areas, and a short Inconell pin for the bolt hold-open.

Since I hadn’t really expected the delivery of the receiver so soon, I was caught empty handed: no lower receiver parts kit! Ernie had said that this would take current mil-spec “small pin” fire-control parts, I made a quick order to Bushmaster Firearms for a lower completion kit. When the kit arrived several days later, I sat down at the workbench and got busy installing.

True to claims, the semi-auto fire control parts fit into the lower receiver with no problem whatsoever. A longer pin for the hammer would be nice for aesthetic reasons; the receiver is thick, and the pin is inset a tiny bit on both sides. The bolt hold-open was also tapped, which meant that no punches were needed, and no rollpin to install. Just insert the bolt hold-open assembly, insert the pin, and tighten the screw down (too easy).

The rear takedown pin detent hole was also tapped, and the instructions said that the spring must be shortened to accommodate the capture screw. I took off several coils until I had a good pressure fit, and tightened that screw down. No more lost or bent up springs when switching butt-stocks! Anybody that has switched a stock out has chased these things around… INCOMING!!

After I had fully assembled the lower with a Choate “Hook Style” butt-stock and a standard A2 pistolgrip, I started looking at the instructions for the trigger adjustment. Now, adjustable match triggers are a bit pricey, as we all know, but this lower has the feature built right in, just use your standard trigger. The adjustment consists of a pair of screws that are in the bottom of the receiver. These screws can be tightened or loosened to press against the front and rear of the bottom of the trigger to adjust the length of creep, and the trigger reset distance. The instructions give some rather pointed cautions about adjusting the trigger properly. Adjusted too closely, the shooter may experience some “hammer follow” or “doubling” due to improper adjustment, basically , the disconnector could be interfered with. I personally adjusted mine to what felt like a standard AR pull and release, leaving final adjustments to the trigger for a trip to the range.

Now, since this is a post-ban receiver, none of the other current uppers that I own would’ve been legal for installation since they are in pre-ban configuration, so out come the parts boxes (and the credit card for more parts orders!)

I ordered and received a DPMS™ “Hi-Rise” upper from Tom Liemohn (Total Silence MFG, in WA.) This one I chose as a fitting complement, as the upper is very thick and rigid, and includes the proper height riser built in for mounting a telescopic sight.

In addition, this upper is “slickside”, it has no forward assist or brass deflector, which is no problem for me, since I’m a right handed shooter, and adds to the clean lines of the rifle.

Also for the upper, I purchased an aluminum free-float handguard, a JP Enterprises adjustable gas-block, and a JP Enterprises single chamber “Recoil Eliminator” brake. The brake is blind pinned and welded to permanently cover the threads on the barrel, making the rifle comply with the ’94 AW ban. All of this was wrapped around a 1/7 twist Colt™ heavy barrel that was a takeoff from another rifle. I topped the whole thing off with glass from Springfield Armory, a 4-14×40 Tactical Government Model™ with the 5.56 range-finding reticle.

After I assembled the upper fully, I mounted it to the lower, expecting some fitting issues due to the different manufacturers. There were no tightness problems, the takedown pins lined up properly and required no undue force to insert. There was a very slight bit of play between the upper and the lower receivers, and here’s where the upper/lower fit screw comes in handy. Since uppers and lowers from the same manufacturer can sometimes fit poorly, one common recourse to this problem is the “Accuwedge”, the little rubber plug that went under the rear lug of the upper receiver to eliminate play. With this lower, you close the receiver halves, insert the pin, and start tightening the adjustment screw that is found at the rear of the receiver, above the pistolgrip. The interior end of this screw is flat, and pushes against the rear edge of the upper receivers mounting lug, forcing it tight against the takedown pin, completely eliminating ALL upper receiver play, and the associated rattle and instability.

Now it was time for a trip to the range! The first thing here was to set the JP gas block system for best functioning, this was easily accomplished, and only required a couple of shots. After that, I started fooling with the trigger adjustments. This was also easy, as the adjustment screws are accessible through the bottom of the trigger guard, no need to open the upper to adjust from the top. After several adjustments, I deliberately tried to “over adjust” the trigger to cause a malfunction. In the one extreme I got hammer follow, no doubling at all. In another case, I over adjusted the other way, and could not fire the rifle. At optimum, I currently have the trigger set to about 1/4” of creep before let-off. In rapid-fire, this lets you achieve a rather easy and startlingly fast rate of fire.

The only difficulty I noticed was that some mil-spec magazines seemed a bit tight in the lower, and were a little difficult to insert or remove from the magazine well, and would not eject fully on their own. On speaking to Ernie about this, he had also seen this, and has corrected this in all further runs of this receiver. He had kept the magwell measurement on the conservative side, and it seems some G.I. magazines have size variances in spec within government contract limits. I have noted this in my Eagle Arms manufactured rifle also, some magazines are just a little bit tighter than others.

All in all, I feel that this receiver offers the best deal out there as a base for either competition, casual target shooting, varmint hunting, or a great foundation for a post-sample M/16 in heavy pistol calibers that would normally batter a receiver.

One interesting thing is that the “DIAMOND SERIES” receiver rifle REALLY GETS ATTENTION!!!! While at the range I was asked many times “What kind of rifle is that?”…”Who makes that rifle?”…. and from one guy who drove a hot-rodded Chevy Nomad…”Is that a BILLET rifle? Cooool!” So the rifle does not only FILL the looks department, but also the quality department. As an added note, on my personal receiver, I filled all the lettering on my receiver with white paint, to accent the markings. It sure stands out nicely!

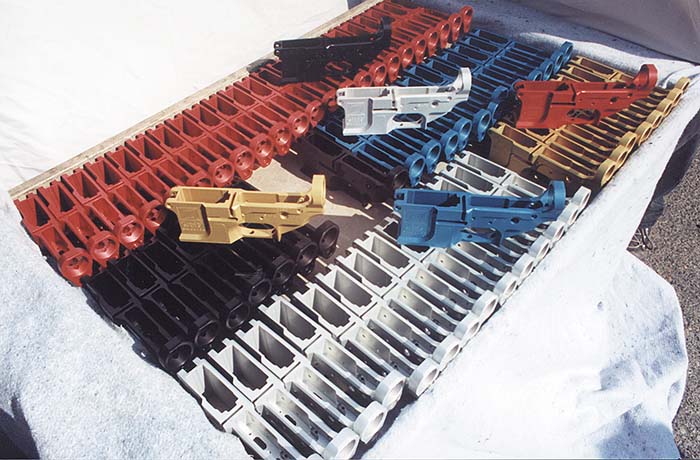

So, how much will this lower cost? Not as much as you may think! Retail cost for the first run orders is $295, and the price will increase to $350 for any subsequent run of receivers, and dealer pricing is available. Quite a deal since you figure that the average postban A-2 lower is about $110-200 without any of the other features. Also, the receivers are available in black, green, blue, red, gold, and silver anodizing. Silver or Black is the standard offering, the other colors are available for a $25 extra fee. The Diamond lower receiver is also available in Post-Dealer Sample M/16 configuration for a $25 extra fee. Matching billet upper receivers are “in the planning stage”, and entire assembled rifles are also offered.

For more information on the” DIAMOND SERIES BR-15” receivers and rifles, contact:

Socom MFG

Dept SAR

616 ATOMIC RD

N. AUGUSTA, S.C. 29841

PH: 803-442-9206

http://www.socommfg.com

AR-15™ is registered trademark of Colt’s Manufacturing Company, Inc.

Diamond BR-15™ is a registered trademark of Socom Manufacturing, ©2000

DPMS is a registered trademark of Defense Procurement Manufacturing Services, Inc

4-14×40 Tactical Government Model™ copyright© 1997 Springfield, Inc.

Bushmaster™ is a registered trademark of Bushmaster Firearms, Inc. / Quality Parts Co

Accuwedge™ is a registered trademark.

Defense Procurement

Manufacturing Services, Inc.

13983 Industry Avenue

Becker, MN 55308

Phone (612) 261-5600

Fax (612) 261-5599

Colt’s Manufacturing Company, Inc.

P.O. Box 1868

Hartford, CT 06144-1868

Tel: (860) 236-6311

Fax: (860) 244-1442

JP ENTERPRISES, INC.

P.O. Box 378

Hugo, MN 55110

Voice: 651-426-9196

Fax: 651-426-2472

Springfield Armory

420 W. Main St.

Geneseo, IL 61254

309-944-5631

309-944-3676 fax

sales@springfield-armory.com

Bushmaster Firearms, Inc

P.O. Box 1479

Windham, ME 04062

Orders: 1-800-998-SWAT

| This article first appeared in Small Arms Review V4N5 (February 2001) |