By Al Paulson

The P90 Personal Defense Weapon was originally designed by Fabrique National Herstal SA of Belgium as a personal defense weapon for troops whose primary mission is something other than the use of small arms. Thus, the P90 is intended for people such as vehicle drivers, operators of crew-served weapons, support personnel, and other troops who are often issued side-arms or submachine guns. The goal was a select-fire weapon of ultra-compact design that would provide superior hit probability to the aforementioned weapons out to greater distances thanks to the new compact 5.7x28mm round. These characteristics, combined with the availability of SB193 subsonic, L191 tracer, and SS190 supersonic ammunition for the P90, provides a very interesting package for Special Operations as well as for law-enforcement, counter-terrorist, security, and executive-protection applications.

Many of these additional missions would depend upon—or be enhanced by—the availability of a compact sound suppressor. That suppressor would have to be capable of sustaining substantial full-auto fire with standard duty ammunition (an impossible dream until very recently), while providing enough suppression with subsonic rounds to hide the fact that a shot has been fired when the tactical situation demanded stealth. FN Herstal SA asked Gemtech to develop a military quality suppressor for the P90 that would be compact, tolerate full-auto fire, and incorporate a snap-on quick mount which would retain the FN muzzle brake or at least incorporate that design into a replacement fixture.

Gemtech’s design team of Dr. Phil Dater, Greg Latka, and Jim Ryan devoted a great deal of time and energy into the project over the course of a year. Their impressive M4-96D suppressor for the M4A1 carbine—which Gemtech initially developed for the Naval Surface Warfare Center—was already in production, and this became the inspiration for the new SP90 suppressor. The process of adapting the M4-96D technology was more complex than one might guess. Some qualities of the new system made the design process easier, while others would provide challenges.

A plus for the designers was that the Five-seven (5.7x28mm) cartridge produces a substantially smaller volume of combustion gases than the 5.56x45mm round. Less gas means that the suppressor has less work to do, so the Gemtech team was able to make the SP90 shorter, smaller in diameter, and substantially lighter than previous designs.

Most of Gemtech’s design effort focused on engineering a revolutionary baffle stack that would not increase the P90’s cyclic rate beyond acceptable limits. This challenge, which one would expect from any compact blowback weapon, appears because a suppressor increases back pressure, which increases the cyclic rate of the weapon. At least theoretically, a suppressor could increase the back pressure of any compact blowback weapon to the point that the magazine spring does not have enough time to present the next round for the bolt as it cycles forward. Thus a design goal for any compact weapon is to tune the design of a suppressor so that bolt speed (i.e., cyclic rate) of the suppressed weapon falls within the optimum range for both the weapon itself and its magazine. Thus the contradictory challenges are to minimize back pressure for optimum reliability while creating maximum turbulence inside the suppressor to optimize the amount of sound reduction. In order to meet these challenges, Gemtech developed a baffle stack in which no two baffles are the same design.

Another design challenge was to develop a robust and fool-proof quick mount for the SP90 suppressor. Since it proved impractical to design a suppressor mount that would directly latch onto the outstanding FN muzzle brake, the Gemtech team decided to marry their Bi-Lock snap-on quick mount with the FN muzzle brake.

SP90 Design

Gemtech’s remarkable spring-loaded Bi-Lock mounting system provides excellent alignment with the P90 barrel and a robust means of attaching the SP90 suppressor that never loosens during firing (unlike screw-on suppressors using a single-point mounting system, which tend to loosen when subjected to semiautomatic or full-auto firing, unless permanently attached with ROCKSETT sealant or silver solder).

The name of this patented Bi-Lock mounting system comes from the two alignment lugs on the muzzle brake, which engage a spring-loaded collet in the back of the suppressor. The moving parts are sealed to minimize fouling from carbon and powder residue. To install the Gemtech SP90 suppressor on a barrel fitted with a Bi-Lock muzzle brake, simply align the suppressor with the brake, push down and rotate the can 90 degrees clockwise (as seen from the front) until the device can no longer be rotated, and allow the spring pressure to lock the suppressor firmly against the Bi-Lock’s twin lugs. Each lug has a different size, so there is only one way to install the suppressor. This feature minimizes the shift in the point of impact whenever the suppressor is mounted and keeps the shift repeatable (i.e., predictable).

Since stops in the mount prevent rotating the suppressor past the locking recesses in the interface piston that mate with the compensator lugs, the mounting procedure is both positive and very fast. Furthermore, the amount of pressure generated by the internal spring during mounting is considerably less than some quick mounts I’ve used on other weapons, making the installation process easier and faster, without sacrificing security.

When removing the suppressor soon after firing, be aware that the silencer could be dangerously hot. Use a heavy glove, hat or other protection to avoid burns. To dismount the Gemtech SP90, push it backward about 0.1 inch (3 mm) until the suppressor can be rotated counterclockwise (as seen from the front). Rotate the can 90 degrees and pull the suppressor clear of the flash hider. The Bi-Lock mount permits installing or removing a sound suppressor in just 1.5-3 seconds. It is safe to say that the Bi-Lock mount is an impressive engineering achievement.

The Gemtech SP90 suppressor is constructed from 304 stainless steel tubing, 303 stainless steel barstock, hardened 440C stainless steel for the interface piston, and Inconel for the blast baffle at the rear of the baffle stack. Inconel is particularly resistant to the heat and erosive effects of hot combustion gases, especially when the suppressor is subjected to full-auto fire. The Bi-Lock compensator is machined from 4140 steel which is then hardened. The SP90 is 7.25 inches (18.4 cm) long and 1.37 inches (3.5 cm) in diameter, and the suppressor weighs 19.4 ounces (550 grams). All suppressor components are coated in a matte black oxide, and the interface piston receives an additional coating of Sandstrom Products 9A Dry Film Lubricant to enhance corrosion resistance.

From a subjective point of view, the relatively modest length and weight of the SP90 gives the suppressor excellent handling characteristics when mounted on the FN P90. Whether engaging targets at arm’s length or at 100 yards (91 meters), target acquisition was very rapid and hit probability was outstanding. The sound signatures produced by the suppressed P90 were quite impressive. When using the supersonic SS190 ammunition, the surprisingly mild cough of the suppressor was followed by bullet flight noise, which was a muted and rather eerie ripping sound that ended with the distinctive thud of bullet impact. When using subsonic SB193 subsonic ammunition, the muzzle signature seemed dramatically quieter than an H&K MP5 SD, bullet flight noise was a barely perceptible hiss, and the noise of bullet impact was easily the dominant sound. While this is a very interesting design that produces a satisfying sound signature when fired with either supersonic or subsonic fodder, there is no substitute for rigorously evaluating the performance of a suppressor with repeatable and standardized scientific methodology. To this end, I tested the performance of the Gemtech SP90 suppressor using the following procedures.

Performance

Suppressor performance was determined by measuring sound signatures using the equipment and procedures specified at the end of Chapter 5 in the book Silencer History and Performance ($55 postpaid, Wideworld, Dept. SAR, P.O. Box 1827, Conway, AR 72033). The microphone was placed 1.00 meter to the left of the suppressor or muzzle according to U.S. Army testing procedures specified in MIL-STD-1474C. The ambient temperature during the testing was 73°F (23°C), and the speed of sound was 1,132 fps (345 mps). Velocities were measured in feet per second using a P.A.C.T. MKIV timer/chronograph with MKV skyscreens set 24.0 inches apart and the start screen 8.0 feet from the muzzle (P.A.C.T., Dept. SAR, P.O. Box 531525, Grand Prairie, TX 75053, 214-641-0049). At least 10 rounds were fired to obtain an average sound signature or muzzle velocity.

Two kinds of 5.7x28mm ammunition were used for the study. The supersonic SS190 round has steel core in front of an aluminum core toward the base, a projectile weight of 31.0 grains (2.02 grams), and a nominal published velocity of 2,345 fps (715 mps). The subsonic SB193 round is a lead core boat tail with a length of 0.753 inches (19.1 mm) and a projectile weight of 55.0 grains (3.58 grams) in front of 2.0 grains (0.13 gram) of ball powder. The SB193 round is still under development at the time of this writing, and an improved variant of the subsonic round is scheduled for field trials in the spring of 1998. Therefore, any data reported here on the subsonic round must be regarded as provisional.

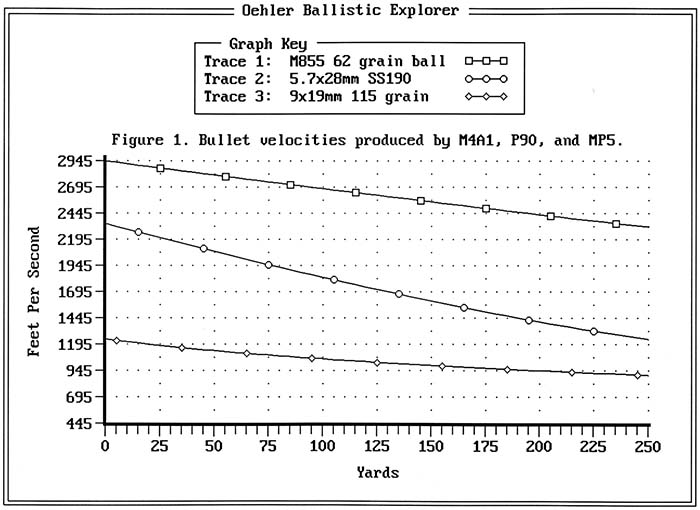

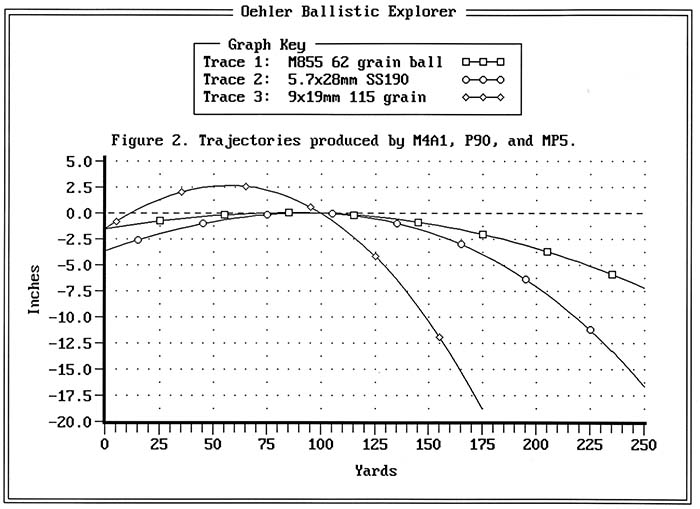

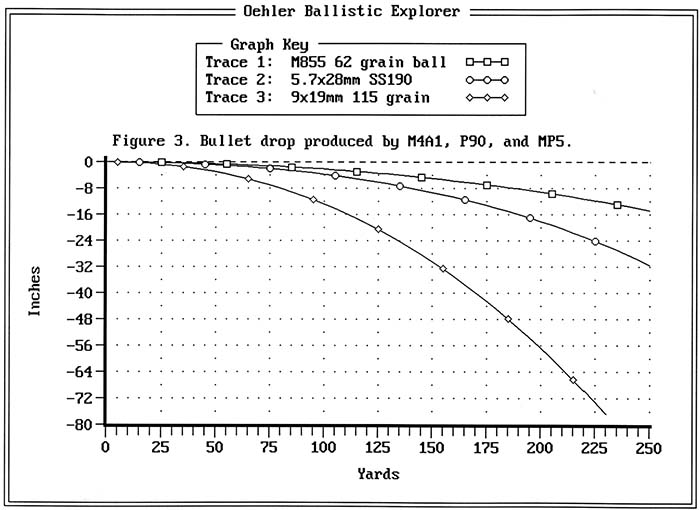

The sound signatures, which are more properly called sound pressure levels (SPLs), appear in Table 1 along with some comparative data for reference. Since the FN P90 might compete against both 5.56x45mm and 9x19mm weapons for law-enforcement applications, data on both categories of weapons are included. Unsuppressed and suppressed versions of the M4A1 were tested at 50°F (10°C). The MP5 and MP5 SD were tested at 71°F (22°C). Unsuppressed and integrally suppressed .22 rimfire rifles were tested at 83°F (28°C) to provide a baseline for sound signatures significantly less than normally encountered in the tactical environment. The net sound reductions appear in Table 2. Figures 1-3 compare aspects of the external ballistics (velocity, trajectory and bullet drop) produced by the SS190 FMJ round fired from a P90, a Winchester USA 9x19mm FMJ round with a 115 grain (7.48 gram) FMJ projectile fired from an H&K MP5 submachine gun, and an M855 5.56x45mm round with 62 grain (4.03 gram) projectile fired from an M4A1 carbine. The P90 produces a projectile velocity than falls in between the M4A1 and MP5, and provides performance reminiscent of (but a bit less than) the venerable old .22 Hornet, which was used in several survival weapons once issued to the U.S. Air Force. Thanks to the fairly brisk muzzle velocity and the P90’s high sights, Figure 2 shows that the P90’s trajectory is remarkably similar to the M4A1 out to the P90’s effective range of 150 meters (137 yards). Clearly, an operator of average skill will obtain much better hit probability or shot placement with the P90 than with the MP5 simply because of the flatter trajectory provided by the SS190 round.

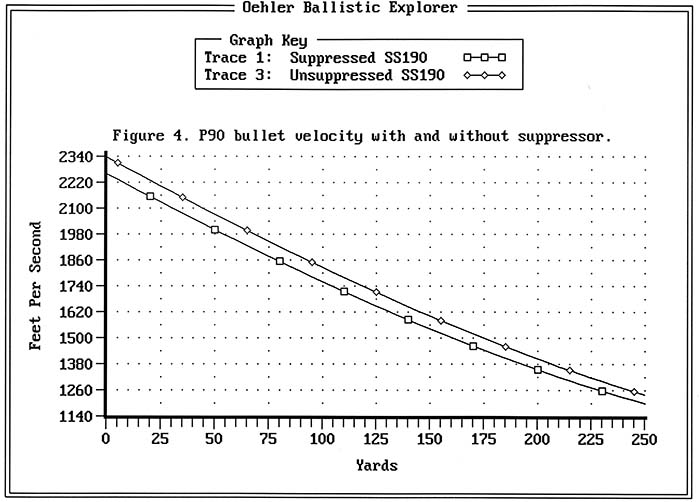

Mounting a suppressor on the P90 does have an effect on projectile velocity. The SS190 round produced a muzzle velocity of 2,339 fps (713 mps) when fired without the suppressor mounted on the P90 and 2,262 fps (689 mps) when suppressed. The SB193 subsonic round produced a muzzle velocity of 998 fps (304 mps) without a suppressor and 951 fps (290 fps) when the suppressor is mounted. Velocities decrease slightly when the suppressor is fitted to the weapon since the increased back pressure causes the blowback bolt to begin extraction sooner after ignition than the unsuppressed weapon. As Figure 4 shows when comparing bullet trajectories of suppressed versus unsuppressed P90s, this slightly reduced velocity when the suppressor is mounted has almost no effect on practical external ballistics when using the standard SS190 supersonic round, and should have even less effect with the subsonic round since there is significantly less velocity change in suppressed versus unsuppressed mode. A discussion of terminal ballistics is beyond the scope of this study. From an operator’s point of view, however, there are a number of conclusions to be drawn about the P90 Personal Defense Weapon and the Gemtech P90 suppressor designed for the weapon.

Conclusions

The P90 is compact, handy in close quarters, and yet provides rapid target acquisition and outstanding hit probability out to 150 meters. When fitted with the Gemtech P90 suppressor and using supersonic ammunition, the weapon is significantly quieter than a suppressed M4A1 carbine. This has direct implications regarding command and control in confined spaces, as well as both short-term and long-term hearing loss experienced by personnel operating in limited spaces. When using subsonic ammunition, the suppressed P90 is dramatically quieter than an H&K MP5 SD and is even quieter than some integrally suppressed .22 rimfire rifles, making a very stealthy weapon. The Gemtech suppressor will tolerate an unprecedented amount of full-auto fire for an intermediate cartridge, mounts or dismounts in the time required for a magazine change, and will not loosen during prolonged firing.

Assuming the terminal ballistics are suitable, the FN P90 with Gemtech suppressor seems even better suited for law-enforcement applications than for its originally intended role as a military personal defense weapon. Whether used as an entry weapon or a replacement for shotguns, submachine guns and carbines of pistol caliber in the squad car—the P90 seems to hold a great deal of potential for law-enforcement applications, especially when equipped with the outstanding Gemtech P90 suppressor. Fabrique National Herstal SA of Belgium is now entering the law-enforcement market.

The Gemtech SP90 suppressor removes more of the high-frequency noise than the typical suppressor designed for intermediate rifle cartridges, so the lower pitch sound signature of the Gemtech suppressor actually seems quieter to people with a normal range of hearing than the numbers in Table 1 would otherwise suggest.

The Gemtech SP90 suppressor provides excellent sound reduction, no adverse effects on reliability or accuracy, a relatively light and compact package, and superior durability when subjected to full-auto fire compared to previous generations of suppressors. The Gemtech SP90 suppressor represents an impressive state of the art, and I can recommend it enthusiastically. Qualified buyers interested in the SP90 sound suppressor should write FN Manufacturing Inc., P.O. Box 24257, Columbia, SC 29224, call FN at 803-736-0552 ext 241 or 290, or fax 803-736-9949. SAR

| This article first appeared in Small Arms Review V1N11 (August 1998) |