By Frank Iannamico

During World War II the British designed and manufactured the 9mm Lanchester machine carbine and magazine that was basically copied from the German MP28II maschinenpistole. The magazines were first used for the Lanchester in a 50-round capacity, and later in the Sten machine carbine with a 32-round capacity, both configurations are interchangeable, but will not fit or function in a German MP28II. The Sten was copied and manufactured in several countries during and after the war.

The British magazines were made of stamped sheet metal; a double-stack single feed design – a configuration that was both hard to load by hand, and less reliable than a double feed design. Despite their questionable reliability they were made by the millions. If one didn’t work it was usually just replaced with another or discarded. An estimated 42,000,000 Sten magazines were produced during World War II.

The magazine bodies were formed from a single piece of sheet metal. The process used to attach the ends of the magazine’s sheet metal body varied by manufacturer. Some were rolled together and spot welded at the back. Other contractors used a separate backstrap spot welded to the main body. A few manufacturers welded the seam at the front and some magazines were formed from tubing – no seam welding required. To form the feed lips a thick steel collar was spot welded to the top of the body. The removable floor plate was made of sheet metal and bent to slide onto the rails formed on the bottom of the magazine body. The floor plate was held in place by a protrusion on a plate attached to the bottom of the magazine spring.

Sten Mk1 Magazines

The early 32-round Sten Mk1 magazines can be identified by the four “witness” holes punched into the back of the magazine body. The holes theoretically allowed the soldier to see how many rounds there were inside the magazine, each hole signified 8 cartridges. The Mk1 follower was similar in design to that of the 50-round Lanchester magazines except the legs were shorter and the cross brace connecting the legs together was eliminated.

Sten Mk2 Magazines

Problems with the early Sten magazines led to the development of the Mk2 model. The holes in the rear of the Mk1 magazine allowed water, dirt and other foreign matter to enter the body and jam the follower. A second problem was the Mk1 followers without the cross brace. During extended use, the follower’s legs would sometimes spread apart and drag on the inside of the magazine body, causing a failure to feed malfunction. Although a cross brace was used on earlier 50-round Lanchester magazines, designers felt it was unnecessary on the shorter legs of the 32-round magazine’s follower. The Sten magazine was redesigned as the Mk2 model by eliminating the “witness” holes in the back of magazine and adding a cross brace to the follower. Many existing Mk1 magazines were upgraded to the Mk2 configuration during Factory Thorough Repair programs (FTR) – the British equivalent of a U.S. arsenal rebuild. During the FTR process the holes in the rear of the magazines were filled and the followers were replaced with new ones having a cross brace. The most common Sten magazines found in the U.S. today are the Mk1 variant, with the “witness” holes still open, although most of those examined did have the Mk2 cross brace type followers.

There was another common problem encountered in the Mk2 Sten that was not directly related to the design of the magazine. This problem was caused by the horizontally placed magazine housing sagging downward, causing the top of the magazine and cartridges to be misaligned with the bolt. The Sten Mk2 was designed with a magazine housing that could be rotated 90 degrees for storage or transporting. The housing was secured in its firing position by a spring loaded plunger mounted on the housing that fit into a hole in the receiver. Wear on the locking pin hole would allow the housing to sag when a loaded magazine was inserted into the weapon. This problem was permanently solved with the Sten Mk3 model that had its magazine well welded directly onto the receiver tube.

Indian Magazine Conversion

The Indian Army issued the Sten in large numbers, and quickly became aware of the problems with the magazine’s reliability. To solve the problem the magazines were converted to a single stack design. This was more reliable than the original double stack, which had to funnel the cartridges into a single file at the top for feeding into the weapon. The conversion was accomplished by the insertion of two brass rods on each inside surface of the magazine body. The rods keep the cartridges in a single line. The trade off was the magazine’s capacity was reduced to only 19 rounds. The Indian Army felt the increase in the magazine’s reliability justified the decrease in its cartridge capacity.

Sten Magazines Today

The original designers of the Sten magazine could not have ever imagined the long life the magazines would have years after the end of World War II. Because of the large quantities and low cost of surplus Sten magazines, they have been adapted for use in a number of modern firearms. The very first prototype MAC 10 submachine guns were designed for the Sten mags. More recently they were used by Masterpiece Arms for use in their line of 9mm modern semiautomatic MAC-type pistols. They have also been used for one company’s 9mm/AR-15 conversions. In some cases where magazines for certain weapons are expensive or unavailable, Sten magazines have been altered to fit and function in those weapons, while other firearms were designed around the Sten magazines. To replace the problematic Zytel magazines used in the SWD M11/Nine there are magazine well conversion kits, designed that adapt the M11/Nine to use Sten magazines.

The magazines for the British Sterling submachine guns, developed after the Sten, were more carefully designed. The Sterling submachine gun had very well made double stack, double feed magazines that have low friction roller type followers. However, Sten magazines will fit and function in a Sterling, but unfortunately Sterling magazines cannot be used in the Sten.

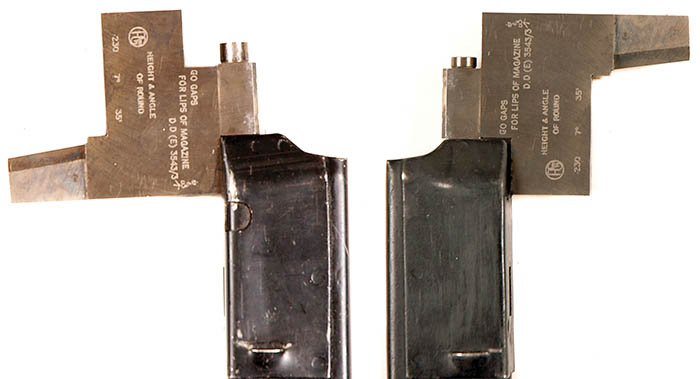

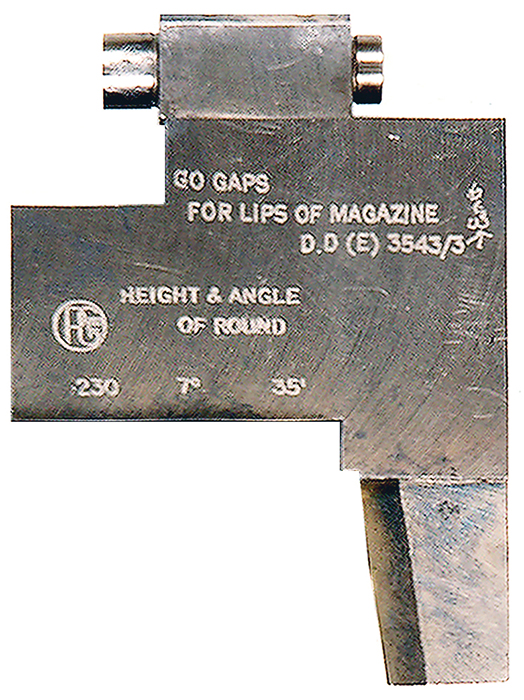

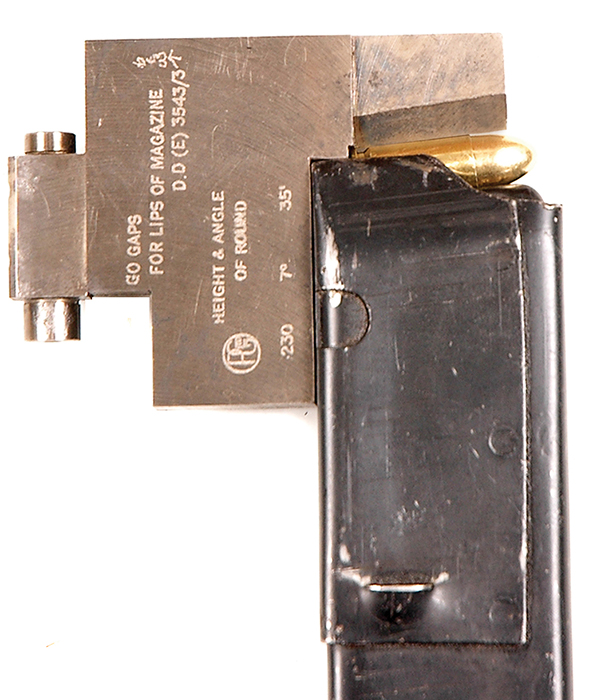

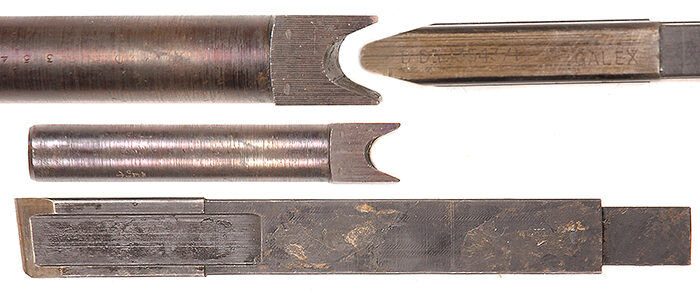

One of the contributing factors to the Sten magazine’s functioning problems is the feed lips’ propensity to spread apart when loaded. This condition will get worse when the magazine is stored fully loaded over a period of time. When the feed lips spread apart the angle of the top cartridge changes, resulting in jams and failures to feed. To keep the magazines reliable the top cartridge must be at a 7 to 8 degree angle. British armorers used a special gage to check the width of the feed lips and correct feed angle of a cartridge. For out of spec magazines a mandrel and forming tool were used to bring the magazine back into a serviceable condition.

To maintain the correct angle the feed lips may need periodic adjustment. This can be accomplished by gently tapping on each feed lip until the top round in the magazine is at the correct angle. An inexpensive protractor or a smart phone with a level app can be used to measure the angle of the cartridge.

| This article first appeared in Small Arms Review V17N3 (September 2013) |