By James Bardwell

The 1994 federal ban on making new high capacity magazines for civilian sale has created a new field of endeavor for fertile minds – extending the life of the existing supply of grandfathered magazines.

One such inventor is Scott T. Long of STL Tactical. He has developed a way to preserve the useful life of the Zytel magazine made for the SWD M11/9 9mm Parabellum machine guns and pistol. The same magazine is also used in the SWD M11A1 .380 caliber machine gun.

At a time when a magazine making ban seemed far-fetched, SWD elected to make magazines for their M11/9 guns inexpensive, by using a molded plastic magazine. When the magazines are new they work pretty well. Eventually the plastic feed lips would wear out, the rounds of ammunition would not stay in the magazine, but would pop out the top, and the magazine would be thrown away. Throwing magazines away is no longer an option. While it would be theoretically legal for someone to make replacement magazine bodies for the pre-ban magazines, no one is doing so. There have been a number of ways to deal with this problem. One manufacturer makes replacement magazine wells for these guns, so that they will use STEn magazines. Other makers are converting metal magazines for other guns to work in the M11/9. STL Tactical took a different approach.

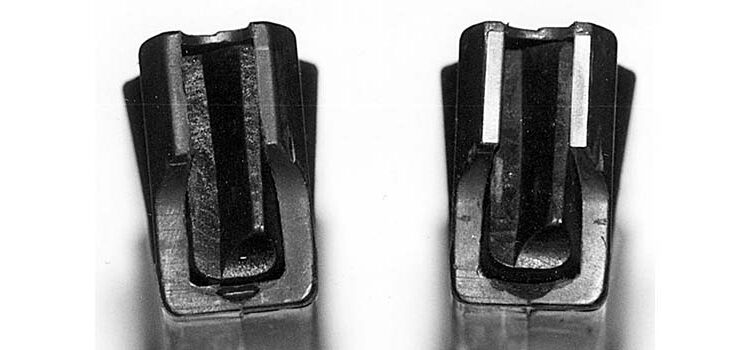

STL takes the customers plastic M11/9 magazine, whether it is new or used with worn out feed lips, and adds two steel inserts on the feed lips. The insert covers the top of the lips, and extends into the body of the magazine, along the sides. A small amount of the plastic is machined out so the insert, when glued in place, will not protrude from the wall of the magazine. If the magazine is already cracked or split it cannot be helped by this modification. Mr. Long said he originally envisioned a full metal sleeve for the magazine, sort of like a Glock magazine, which would support the rear of the magazine as well as the lips. However after some experimentation he found that the cost of manufacture and of installation would be much more than customers would pay.

One advantage to modifying the plastic magazines in this way, over other solutions, is with the .380 ACP SWD M11A1 machine guns. Unlike the original Powder Springs and RPB made .380 MAC style guns, SWD elected to have their M11A1 guns use the same magazine as their 9mm M11/9. The smaller, metal, .380 magazines for the RPB and Powder Springs guns were a little scarce, and SWD apparently didn’t feel the need to tool up to make an additional magazine. So the magazine well/pistol grip assembly for the SWD M11A1 guns is the same as on their M11/9 guns. Unfortunately, the Zytel magazines don’t work with .380 ammunition. The ammunition pops out the top, even when the magazine is new. This situation is not true of the .380 M12 pistols that SWD made long after the M11A1 guns, they use a magazine that is similar, if not identical, to the magazines the RPB and Powder Springs .380 guns were designed for.

A sample magazine was tried in both an SWD M11/9 machine gun, and an SWD M11A1 .380 machine gun. Function was flawless in both guns. After about 300 rounds through the magazine, of both .380 and 9mm ammo, there was no noticeable wear on the metal lips. The modification should certainly extend the life of the Zytel magazines by many hundreds of rounds. And the modification greatly increases the reliability of the SWD .380 MAC guns over using converted metal magazines.

The cost of modifying one customer-supplied magazine is $12.00, including shipping, with discounts for multiple magazines.

STL Tactical

P.O. Box 251

Pipersville, PA 18974

(610) 847-2291

(610) 847-9989 FAX

EMAIL stl@epix.net

| This article first appeared in Small Arms Review V2N8 (May 1999) |