By Frank Iannamico

With the price of center fire ammunition increasing and availability decreasing daily, the concept of a .22 caliber rimfire machine gun sounds very appealing. However, due to the diminutive cartridge’s straight rimmed case and inconsistency of manufacturing tolerances, designing a reliable, rapid firing full-auto weapon, and accompanying magazine isn’t as easy as its sounds – the operative word here is reliable.

The 9mm Uzi submachine gun is a perfect example. In the recent past, .22 caliber conversion kits for the full size Uzi have been manufactured by at least two companies, both having only limited success. However, despite having a known reliability concern, the kits, and their accompanying .22 caliber magazines, are able to bring double and sometimes triple their original purchase price. With some patience, tweaking and experimentation the aforementioned kits can sometimes be made functional.

There is little doubt that a market exists for a .22 conversion kit for the full size Uzi SMG, and Subgun Ordnance of Racine, Wisconsin has taken on the challenge and succeeded. Subgun Ordnance’s kit consists of a .22 caliber barrel, bolt and a magazine manufactured by Black Dog Machine LLC. Like the Uzi was originally designed, the .22 kit fires from an open bolt, and functions in both semiautomatic and full automatic modes of fire. After over a year of development, testing and refinements the kits are finally being manufactured and marketed, and UZI owners are lining up to purchase them. The kits are reasonably priced at approximately half of what one could expect to pay for one of the earlier kits manufactured previously by other entities on the collector market.

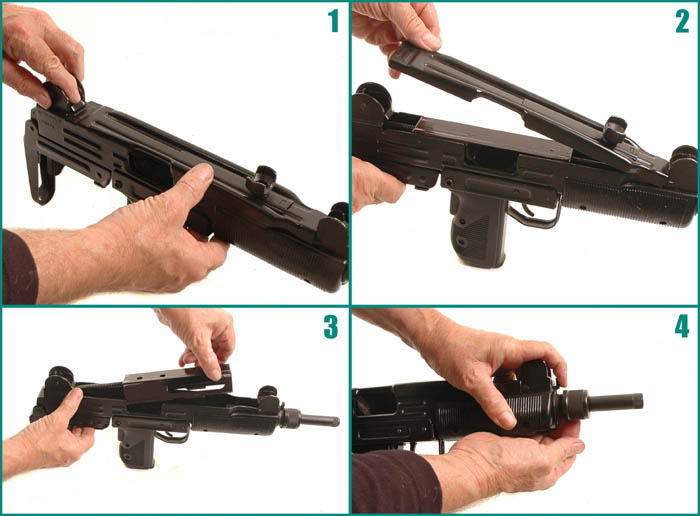

The barrel is manufactured from heat-treated 4140 steel with slots for the extractor and an integral feed ramp; the trailing edge of the feed ramp is located close to the magazine, which aids in reliable feeding. The barrel has a black phosphated finish. The chamber end of the barrel is designed to fit into the barrel ring on semiautomatic conversions, however when ordering a kit you will need to specify whether your Uzi is a factory submachine gun with large inside diameter barrel trunnion or a semiautomatic conversion with a semiautomatic trunnion, which has a smaller inside diameter, to insure getting a barrel that will fit in your particular gun. The conversion kits are designed for select-fire Uzis only and will not fit or function in semiautomatic-only versions, or conversions that have the receiver-blocking bar in place.

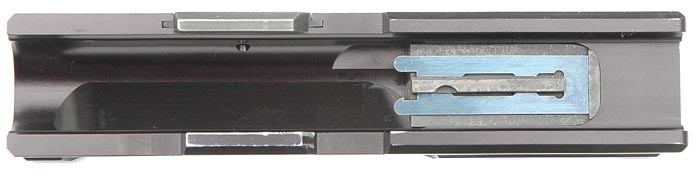

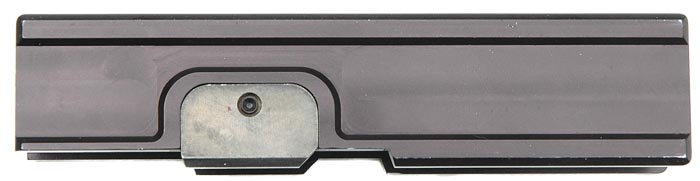

The bolt is manufactured of 2024-T4 aluminum with a steel insert on the right side serving as a sear engagement surface; the bolt face with the fixed firing pin and extractor are also on a steel insert secured to the bolt’s main body by two socket head cap screws. The integral steel firing pin is quite substantial and rectangular shaped for consistent ignition of the rimfire cartridges. The aluminum portion of the bolt has a blue-black anodized finish. The blued spring steel extractor is a key component and was designed by the well-known Tom Bowers of subguns.com fame. The original 9mm Uzi spring and buffer assembly are used with the conversion kit.

The 32-round magazines that were chosen for inclusion with the Subgun Ordnance kit are an existing item being manufactured by Black Dog Machine LLC for Vector manufactured .22 UZI conversion kits. The magazines are a double stack, single feed design manufactured from polycarbonate halves that are glued together to form the magazine body and have a slight curve to compensate for the rimmed .22 cartridges. The follower and floor plate are made from plastic and have a steel coil-type follower spring. The floor plate and follower are easily removed for cleaning, but caution must be used during maintenance as some chemicals like Hoppes #9, acetone or toluene, will dissolve the plastic and the adhesive that holds them together. The magazines are available in translucent smoke color or black, the body material is exactly the same with the color provided by an additive. The translucent model allows the shooter to observe how many cartridges are in the magazine, and although not as “cool” looking as the black color, they are more practical. No magazine adapter is needed; they fit in the standard Uzi mag well. Perhaps best of all the magazines are inexpensive and readily available.

Sounds Great, but does it Work?

The kit received by SAR for evaluation was not a special “gun magazine” test model. It is a standard production item and was brand new in the box and unfired. The kit came with one Black Dog Machine 32-round magazine.

For our test and evaluation the kit was installed in a standard size Israeli Military Industries (IMI) 9mm factory submachine gun. The kit was easily installed and fit perfectly. The bolt was cocked rearward and the trigger pulled: the reward was a full 32-round burst at approximately 900-1000 rounds per minute, followed by a face-distorting grin. After spending a minute or so reloading the magazine, the firing test resumed, however this time after a short burst the firing stopped. Retracting the bolt revealed that a cartridge had failed to feed. The reason was that the follower had not raised the cartridge high enough for the bolt to pick it up and feed it into the chamber. A slight tap on the floor plate was administered and the cartridge was raised into position and the firing resumed; until another stoppage occurred, same problem, the follower was not moving the cartridges into position. Since the .22 rimfire cartridge is inherently dirty, the magazine was disassembled, for cleaning, but upon inspection it was discovered that a cleaning wasn’t necessary. The magazine bodies have been reported to occasionally have small remnants of excess glue interfere with the follower’s movement. This glue can be manually removed or will be worn away with use. Another area to check is the rear of the follower that may have excess protrusion from its molding sprues; this too is easily removed with a small knife or file. After removing the excess glue, the sticking follower problem was solved.

The test Uzi was loaded and ready to go. This time the weapon was fired on semiautomatic for a few rounds and functioned perfectly. The selector was moved forward to the full-automatic position and fired again without any stoppages. Hopeful, the magazine was reloaded, a full 32-round mag dump was executed and the magazine was emptied without hesitation. It became painfully apparent additional magazines would be needed. Once again the magazine was reloaded. This time the Uzi was fired semiautomatic for five rounds, followed by a short burst in full-automatic and back to semiautomatic; again a flawless performance. The magazine follower occasionally blocked the last spent case from being pulled from the chamber, which is not a big inconvenience and does have the advantage of keeping the bolt from striking an empty chamber. However, the magazine should be removed before attempting to extract the last case to prevent unnecessary stress on the extractor. The testing continued with semiautomatic and full-automatic burst and full mag dumps. After over 2,000 rounds were fired, it was felt that the kit, other than a few minor failures to feed, could be deemed reliable, and fun. For the SAR test and evaluation several brands of .22 cartridges were tested.

For its performance during the 2,000 round SAR test, the Subgun Ordnance .22 Uzi kit receives my approval. Potential users of the kits must keep in mind that .22 caliber ammunition requires both the Uzi and magazines to be kept clean and free from debris. When cleaning, keep an eye out for spent .22 cases lodged in the receiver. While most of these didn’t cause any stoppages they do occasionally find their way into the crevices of the receiver.

The conversion kit manufacturer, Subgun Ordnance, has reported that they have tested numerous types of .22 caliber ammunition with their conversion kits and states on their website that reliability problems may occur with Remington bulk pack ammunition.

Magazines Tips

Many users of the Subgun Ordnance .22 conversion kits and magazines have reported 100% reliability right out of the box and others have required some magazine “tuning.”

The magazine is key to reliable function in any weapon. The following tips will aid in keeping the .22 Uzi running. While our test kit originally experienced a few magazine follower-sticking problems they were easily resolved by removing the excess glue inside the magazine body. Other users of the magazines have suggested the following tips to insure reliably.

The magazines are easily disassembled by depressing the small protrusion on the floorplate and sliding the floorplate off. Caution: removing the floorplate releases a compressed spring. Keep the spring contained and slowly release it being careful not to lose the small floorplate retainer that is located on the bottom of the spring. Tilt the magazine body upward to allow the follower to slide out.

One of the primary concerns is the magazine follower sticking. When something sticks, the first thing that comes to mind is to lube it, however with the plastic magazines something is required that would not harm the plastic materials used in the magazine’s construction or attract dirt: powdered graphite. Dusting the follower with a light coat of graphite makes the magazine easier to load to capacity, and helps increase feeding reliability. Other suggestions include smoothing and polishing the magazine followers to decrease friction. As with any magazine, reliability is increased when they are not loaded to full capacity. The .22 Uzi magazines seem to function best when loaded with 25-27 rounds. When filling the magazine make sure that the rim of the cartridge you are loading is located ahead of the cartridge’s rim loaded beneath it, this will keep the round from getting caught when the bolt picks it up.

The followers on early Black Dog Uzi magazine production were designed to hold the bolt rearward after the last round is fired. Although this feature helps prevents damage from the bolt contacting an empty barrel (with no brass case to soften the blow), it has also been reported that the stress of the follower in stopping the bolt’s forward movement has eventually cracked the leading edge of the magazine. If such an event occurs the magazine can be easily repaired with super-glue. The latest production magazines from Black Dog LLC are being manufactured without the hold-open feature. On older magazines the rear ramp of the follower can be filed down to disable the hold-open feature. Inexpensive spare magazine follower and spring kits are available from the manufacturer. As mentioned earlier, .22 caliber ammunition is dirty and as a result the magazines and weapon require routine cleaning to maintain reliably. The magazine manufacturer suggests cleaning the magazines with soap and water or WD-40.

One downside to .22 caliber full-automatic firearms is that it usually takes a lot longer to load the magazine than it does to empty it. To make the task of loading easier, Ken Christie of Christie Products offers a magazine loader specifically designed for the Black Dog .22 Uzi magazines. The magazine loader not only makes loading easier, the loader can be used to “set” the ammo stack in the magazine by giving a few extra downward pushes after the mag is loaded. During the testing it was discovered that loading the magazine with the aforementioned loader greatly enhancing the magazine’s feeding reliability.

Sources:

UZI .22 conversion kits

Subgun Ordnance

Phone: (262) 770-9894

Fax: (262) 635-8305

E-mail: subgun-ordnance@sbcglobal.net

Website: www.subgun-ordnance.com/

Magazines

Black Dog Machine, LLC

22843 Buskirk Drive

Middleton, ID 83644

Phone: (208) 585-6581

Website: http://blackdogmachinellc.net/

Magazine Loaders

Christie Products

Website: http://www.1022central.com/

E-mail: products@1022central.com

Extractors

Bowers

P.O. Box 430

Cornelius OR 97113

Phone: (503) 992-8697 Website: http://www.subguns.org/order.htm

Barrel Threading for Suppressors

Veronesi Gunsmithing

205 Oak Avenue

Seminole, PA 16253

Phone: (814) 275-4382

| This article first appeared in Small Arms Review V13N2 (November 2009) |