By Philip H. Dater, MD and the Small Arms Review Editorial Staff

Ruger Silent-SR Series Suppressors

Sturm, Ruger & Co., Inc. is the quintessential example of American capitalism at its best. The company was founded with a meager $50,000 investment by William B. Ruger and Alexander M. Sturm in a small, rented machine shop in Southport, Connecticut in 1949 for the purpose of manufacturing firearms. At that time, there were serious doubts within the industry with insider experts saying that “it can’t be done,” and that the entire industry was in decline. It was assumed that the large established name gun makers would continue to dominate the market.

What the industry didn’t count on was that this new company was guided by a number of innovative concepts, not the least of which was William B. Ruger’s desire to build each product “to a standard so that I would want one even if it was made by our competitors.” These basic principles of innovation, quality and value have earned the company the position of pre-eminence in the firearms industry over the past 68 years. Ruger, which is one of only two firearms manufacturers traded on the New York Stock Exchange, produces millions of firearms each year for hunting, target shooting, collecting, self-defense, law enforcement and government agencies.

Ruger’s first product was the Ruger Standard pistol in .22LR. With some design innovations inspired by the Japanese Nambu and cosmetics/ergonomics of the German Luger, it became wildly popular—it was comfortable to hold and shoot. A retail price in the 1950s of $37.50 (representing fewer than 40 hours minimum wage effort), decent accuracy and good reliability were winning factors. Designed with manufacturing economy in the forefront, it had a 4.75-inch barrel and fixed sights. Many a bullseye match shooter had one in the bottom of his bag to permit finishing a match when his finely tuned target gun malfunctioned. It was also found tossed in the bottom of fishermen’s tackle boxes. Its popularity (and that of the 10 /22 rifle) started an ever growing industry of accessory makers.

Ruger is no stranger to the National Firearms Act weapons, having developed and built several machine guns. In the late 1980s Ruger purchased the rights to the UZI and what became the MP9 from Uziel Gal, its designer. In 1995, Ruger introduced its MP9 9mm submachine gun. Although recognized as an improved UZI, the weapon never became popular or even well known. Bill Ruger held the belief that civilians should not have access to machine guns and established the company policy that no Ruger machine guns would ever be sold to civilians, including Class 3 firearms dealers. The market was to be domestic law enforcement and international military. However, noted in the company’s law enforcement catalog, marketing to law enforcement requires personal demonstrations by local Class 3 firearm dealers. The MP9 was discontinued in 1996. Ruger’s other venture into the machine gun market was a variant of their 1973 Mini-14, the AC-556, which looked exactly like the Mini-14 but had a selector switch (semi, burst, full-auto) at the receiver right rear. The standard AC-556 was offered in both blued and stainless versions as well as a shorter weapon with a folding stock and 13-inch barrel (AC-556K or AC-556F) in blue or stainless. With marginal sales (although far better than the MP9), production was discontinued in 1999 and support terminated 10 years later. Until William B. Ruger’s death in 2002, no Ruger machine guns were sold to civilians. The civilian marketplace was through sale of police trade-ins.

Part of Ruger’s success has been through good market research, outstanding engineering and production of innovative products without significant bureaucratic impediments to slow down development. Part has been financing through reinvestment of profits rather than using traditional debt structure. And part has been by doing manufacturing in-house. Ruger’s Pinetree Casting (Nashua, NH) is one of the foremost investment casting facilities, and in addition to many Ruger weapon receivers, does casting for golf clubs. In 2014, the company purchased Megamet Solid Metals Inc., based in St. Louis, Missouri, to add metal injection molding (MIM) casting capability not only for increased production capacity, but to markedly reduce development time for new products. Unlike many of its competitors, Ruger has not acquired related companies, either competitors or accessory makers.

The use of silencers has become mainstream over the past 4 to 5 years, a fact not overlooked by Ruger. Although their 10 /22 rifles sold in the international market were routinely threaded 1 / 2-20 for European rimfire silencers, it wasn’t until several years ago that domestic Ruger .22 rifles and pistols came threaded 1 /2-28 for the US market. Ruger looked at possible acquisition of a silencer company but after due diligence decided to start building suppressors in-house at their New Hampshire facility.

Approximately a year ago, Ruger introduced two sound suppressors designed for rimfire cartridges: the “Silent-SR” thread mounting muzzle suppressor and the “Silent-SR ISB” integrally suppressed barrel for their take-down 10 /22 rifle.

Both suppressors are attractively packaged in boxes with a fitted foam insert. Any necessary tools are included: a cast composite spanner wrench for removing the endcaps of the Silent-SR and a hex wrench for disassembling the integral Silent-SR ISB. All suppressors are supplied with a 12-page, well written and profusely illustrated manual that covers legal and safety aspects, specifications, attachment to the host weapon, use, disassembly and cleaning instructions. Disassembly for cleaning is simple, and it is virtually impossible to reassemble incorrectly. Both are finished in black Cerakote.

Testing Protocols

The first question posed by most users relates to sound performance since that is the stated goal of a sound suppressor. There are a number of ways to evaluate sound levels, starting perhaps with Mitch WerBell of Sionics fame in the 1970s where he lined up the office staff and shot two different suppressors behind their backs asking which was quieter. While this has merit in distinguishing suppressed from non-suppressed weapons, subtle differences are distorted by the individual hearing damage of different observers.

A more objective method is to use sound measuring equipment that meets the requirements of MIL-STD-1474D. Not all sound meters are capable of accurately measuring the short peaks of firearm sounds, and even some industrial precision meters do not have the necessary peak detector. There are two classic field portable sound meters that meet all the requirements of MIL-STD-1474D: the B&K 2209 and the Larson-Davis 800B with their appropriate ¼-inch pressure microphones. Originally costing in the $5,000 range, both are currently out of production but are frequently available at reasonable cost. Factory service and recertification services are still available. For testing both Ruger suppressors, two of the L-D 800B meters were used, both of which were recertified by Larson-Davis 4 months prior to this test.

MIL-STD calls for a number of measurement locations. For the purposes of the most meaningful and familiar results, sound levels were measured simultaneously at the standard Reference Location (1.6 meters above grass, 1 meter left of the muzzle 90O to bore axis) and at a simulation of the shooter’s left ear (SLE). The Reference Location gives an indication of how the target or down range observer will perceive the gunshot, and the SLE will give one of the better indications as to potential hearing damage. While some advocate using the shooter’s right ear, close contact with a rifle stock confuses weapon action noise with muzzle blast reduction. The simulated SLE positioning of the microphone is 8 centimeters rearward of the back of the receiver (70 centimeters in the case of a handgun) and 18 centimeters left of the bore axis. By measuring both locations simultaneously for each shot, variations in individual rounds are minimized.

For each weapon-suppressor combination, three rounds were fired non-suppressed, and the results averaged. This was followed by a five-round string with the results averaged. It has been found that this number of rounds is statistically significant. For each location, the averages and reduction are noted. In addition, first round pop is calculated by subtracting the average of the last four rounds from the first round. First round pop is caused by a secondary detonation of partially burned powder particles encountering oxygen in the suppressor. MIL-STD permits the use of weighting scales. For a number of years dating back into the 1970s, A-weighting was used. In recent years, a number of manufacturers have changed to C-weighting, which is more accurate for the sound levels encountered with firearms.

Both OSHA and MIL-STD-1474D state that hearing protection is required for short duration peak sound levels greater than 140 dB at the shooter’s ear.

A second item of concern in evaluating a suppressor is whether there is any degradation in accuracy (group size) when the suppressor is mounted. There is often a shift in point of impact which can be corrected by sight adjustment. Rifles were used in a solid rest (Lead Sled) for group size measurements both with and without the suppressor at a range of 40 yards.

For handguns, high speed video was performed looking for excessive yaw or tumbling with the suppressor in place. Frame rate was 5,000 frames/second with a shutter speed of 30 microseconds to provide stop action of the bullet in flight during the first 2 feet of travel. The high-speed camera used was a monochrome Olympus iSpeed FS.

A third concern primarily of military importance is night-time recognition of the shooter’s location from flash or heat signature visualization. Because these suppressors are designed only for rimfire, flash signature was evaluated using high-speed video and only when mounted on the MK-II pistol (generally the worst case scenario).

With either suppressor, it is necessary to utilize standard velocity or subsonic .22LR ammunition to avoid the ballistic crack found with high-velocity ammunition. This crack has been measured with CCI Mini-Mag ammunition at 142 dB 1 meter to the side of the bullet flight path. In the case of .17HMR or .22 Magnum ammunition, the ballistic crack of the supersonic projectile is acceptable, and live targets are confused because the suppressor masks the origin of the shot.

Test Conditions

November 4, 2017, was a bright, sunny fall day in Boise, Idaho. The temperature was a chilly 50F with a relative humidity of 37% and a station pressure of 686 mmHg. Wind gusts were less than 3 miles per hour. The speed of sound calculated to 1,107 feet/second.

The ammunition chosen for testing was CCI Standard Velocity .22LR with the 40 grain bullet. This was chosen because it is commonly available, accurate and remains subsonic in almost any barrel length chambered for .22LR.

The Silent-SR thread-mounting suppressor was tested on two weapons. One was a Ruger MK-2 pistol with a bull barrel shortened to 4.5 inches and mounted in a Ransom Rest. The other was a Ruger 77 /22 with the barrel shortened to 16 inches. The Silent-SR ISB was tested on a Ruger 10 / 22-TD, its normal host weapon.

Silent-SR Thread-Mount Suppressor

The Silent-SR is packaged inside a black ballistic nylon pouch with a convenient belt loop. The suppressor length is 5.4 inches, outside diameter is 1.05 inches, and the weight is 6.4 ounces. It is rated for .22 Magnum and .17HMR in addition to fully automatic .22LR. The length of the threads in the mount is .43 inches, standard for the industry, with a .12-inch thread relief in the mount for safe use with barrels not having a thread relief. The threaded mount is a part of the entrance chamber. There are a total of six baffles (type 17-4 stainless steel), all having a bore aperture of .25 inch. The front end cap functions as a seventh baffle. The rear (blast) baffle is symmetric, and the remaining baffles have significant asymmetry. All baffles have a general conical shape with integral spaces. The tight bore aperture requires barrel threads with a true 90O shoulder for alignment.

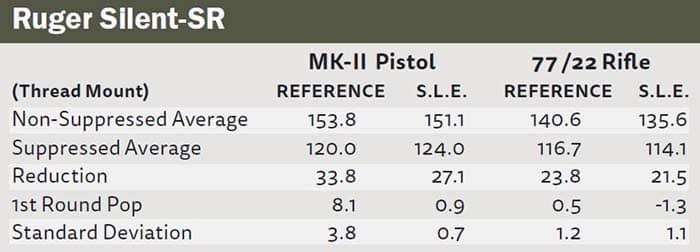

Sound measurement levels were obtained on both a Ruger MK-II pistol (4.5-inch barrel) and a Ruger 77 /22?bolt action rifle (16-inch barrel). Both of these weapons are used routinely by the author for rimfire sound measurements. Sound performance was excellent as shown in Table 1 with the absolute sound level at the reference location of 120 dB on the MK-II and 116.7 dB on the 77 /22 rifle.

It is important to remember that there will be day-to-day variations in the sound levels that appear to vary with location, humidity and ambient air temperature. Measurements made in a coastal location do not always correlate with those made in a high desert location such as Boise, Idaho. As a rule, five-round strings are statistically valid (standard deviation <1.5), which is why the tables include the standard deviation for the five suppressed measurements. The one exception was measurement at the reference location where the 8 dB first round pop increased the standard deviation. However, calculating excluding the first round resulted in an average of 118.4 dB and a standard deviation of 1.1, which is in line with all other measurements.

Although what is normally asked is the reduction, the more important measurement is the absolute sound level, both for far field and for hearing risk evaluation. First round pop can be eliminated with either an inert atmosphere (nitrogen, carbon dioxide, etc.) or a tiny amount of oil or grease in the entrance chamber. Absolute sound levels for the rifle are considerably lower than for the pistol, but the degree of reduction is significantly less. This is simply because the non-suppressed level on the rifle is significantly lower than on the pistol.

Accuracy and bullet stability were checked differently on the two weapons. With the Silent-SR mounted on the 77 / 22 bolt action rifle, a target was shot with and without the suppressor at a range of 40 yards. Adding the suppressor moved the point of impact down .176 inches (.421 MOA) but tightened the group from .795 inches (1.9 MOA) to .688 inches (1.64 MOA) with three shots touching. See Target 1.

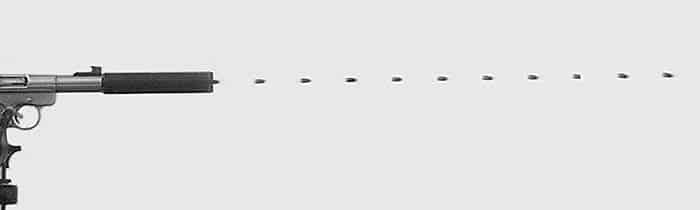

A check of bullet stability on the MK-II pistol was considered difficult lacking optical sights. Instead, a high-speed video (5,000 frames/second) was performed. Lighting was difficult lacking bright sunlight, so two compromises were accepted: 1) a shutter speed of 30 microseconds (instead of the preferable 2 microseconds and 2) image enhancement (which decreased resolution). Eleven consecutive frames showed the bullet in the first 24 inches forward from the end of the suppressor. These 11 photos were superimposed to show the progress of the bullet traversing this distance as shown in the photo. Starting at the 20-inch region, there is slight yaw, which is normal as the bullet transitions from rotating about its physical center to rotating about its center of gravity. There was no visible flash detected.

The manufacturer’s suggested list price for the Ruger Silent-SR thread mounting suppressor (model 19000) is $449.

Silent-SR ISB for the Takedown 10/ 22-TD

The Silent-SR ISB is a complete replacement barrel with integral suppressor assembly for the Ruger 10 / 22-TD rifle. Unlike similar offerings, the Ruger suppressor includes all hardware and the forend composite handguard. The suppressed barrel is 16.12 inches long, making it .5 inch shorter than the standard barrel, and weighs 41.9 ounces as contrasted to the 30.7 ounces of the standard barrel. The suppressed barrel bears a resemblance to the over/under double-barreled shotgun with a width of .925 inches and height of 1.52 inches. The bore aperture throughout the baffle stack is .280 inch.

The suppressed barrel is alloy steel and 10.62 inches long. The aluminum suppressor outer housing has been permanently attached to this barrel to make the overall length in compliance with BATF regulations. The front end cap and baffle stack are easily removed by loosening the assembly bolt, a process well described in the manual. The blast baffle is symmetric, and the remaining six are significantly asymmetrical. All are type 17-4 stainless steel.

Sound measurements were made using the same host 10 / 22-TD receiver and comparing the original non-suppressed barrel with the Silent-SR ICP integrally suppressed barrel. The results are shown in Table 2. The suppressed barrel measured an impressive 114.7 dB at the reference location, which is only approximately 4 dB louder than the hammer falling on a spent cartridge case.

Accuracy testing was performed in the same manner as for the thread mounting suppressor on the rifle. The range was 40 yards, and the weapon was shot using the Lead Sled rest. A fixed 10x scope was attached to the Weaver base supplied with the rifle. Five shot groups were fired with both the standard and suppressed barrels. The target is shown in Target 2. The suppressed barrel tightened the group from 2.9 inches (6.92 MOA) to 2.05 inches (4.9 MOA) and dropped the group center by .77 inches (1.84 MOA).

The group sizes, both suppressed and non-suppressed, were considerably larger than with the thread-mounted suppressor on the 77 /22. There are several reasons for this, not the least of which is a re-worked 2.5-pound honed trigger on the 77 /22 with no over-travel as compared to a rough 6-pound trigger on the 10 /22-TD with significant over-travel.

The second issue is with barrel lockup on take-down weapons. The 10 / 22-TD tensioning ring has to be adjusted when one barrel is replaced with another. The tension at lockup is not totally consistent, and there is the potential for almost imperceptible flex at the barrel/receiver joint. Even simple removal and replacement of the same barrel can cause a minor point of impact shift. The most accurate way to mount an optic on a take-down rifle is to mount it on the barrel rather than the receiver. In contrast, the 77 /22 barrel is mounted in a far more rigid manner using a V-block and torqued mounting screws.

The manufacturer’s suggested list price for the Ruger 10 /22-TD Silent-SR integral suppressed barrel (model 19001) is $629.

Comments

Both suppressors have their strong points, including excellent sound performance, tightening of the shot groups and obvious quality. The Silent-SR ISB for the 10 /22 Takedown is definitely the more compact weapon due to the requirement for a 16-inch minimum barrel length. What would be a worthwhile improvement to the integral Silent-SR ISB would be to supply a rail contoured to the .920 diameter of the steel portion of the barrel for barrel mounting of an optical sight. The thread mounting Silent-SR has the advantage of a wide variety of weapon platforms and the strength to hold up to multiple rimfire cartridges. While both are outstanding, the author has a bias for thread mounting suppressors because of their versatility.

SureFire LLC

RYDER 9-MP5

The stainless-steel-constructed RYDER 9-MP5 is a duty-use suppressor for the H&K MP5 sub-machine gun. The suppressor attaches to a standard three lug barrel via our patented Fast-Attach mechanism, similar to the way our best-in-class SOCOM Series suppressors attach. The suppressor is easily disassembled for cleaning, and the baffles are indexed and numbered for ease of reassembly. Designed for duty use, the RYDER 9-MP5 does not affect bullet performance or increase point of impact/point of aim as is the case with other sub-machine gun suppressors. When it comes to durability, performance, and ease of maintenance, the RYDER 9-MP5 is the clear choice for suppressing the MP5. www.surefire.com

SF RYDER 9-MP5

Caliber: 9mm

Length: 8in (20.3cm)

Weight: 15.6 oz (442g)

Diameter: 1.30in (3.3cm)

Material: Stainless steel

Finish: Cerakote

MSRP: $849

SRT Arms

SRT Integral M-16 / 9MM Uppers

Integrally suppressed 9MM AR15/M16. Integral suppressed upper, 9MM or .45 ACP., 1.5” OD tube. Pinned and welded 16” bolt face to end of tube, or removable for registered MG or SBR lowers. Ported barrel for additional sound reduction.Porting available to make 115 gr subsonic, or max velocity for use with 147gr subsonic. www.srtarms.com

Weight: Adds 1 lb to upper weight.

4130 tube, 7075 AL baffles and end caps.

Finish: Black Cerakote finish.

Absolute db at muzzle is 116-119 db depending on bullet weight.

MSRP: $780 using customer supplied barrel, handguard and upper receiver.

B&T AG

M.A.R.S. QD

Based on combat experience in Iraq, Afghanistan, B&T has analyzed evolving needs of operators and has evolved its products to perfectly serve the new needs. The new M.A.R.S. QD (Miniature Assault Rifle Suppressor–Quick Detachable) offers greater flash reduction, lighter weight and smaller size. For those who prefer the option to be able to mount/dismount the suppressor even during an operation, the M.A.R.S. QD is the perfect choice. It is the lightest quickest detachable mounting system on the market today. www.bt-ag.ch

Caliber: 5.56mm (.223) or 7.62mm (.308)

Length: 161mm (5.56mm) / 192mm (7.62mm)

Diameter: 39mm

Weight: 415 g (5.56) / 480 g (7.62)

Factory-Tested Sound Reduction: 26 dB (5.56)

Materials Inconel/Thermax Finish: sandblasted/grey

MSRP (USD): tba

B&T AG

M.A.R.S. DM

The M.A.R.S. DM (directly mounted) is the lightest and shortest assault rifle suppressor B&T produces. It´s screwed directly on the muzzle. This lack of any mounting system allows it to be almost 300 grams lighter and 50mm shorter than other suppressors with a mounting system. Therefore the impact on the balance of the weapon and the extension of the gun is negligible and not perceptible in combat. Despite its small size the M.A.R.S. is a full gown up suppressors when it comes to muzzle flash and sound reduction. www.bt-ag.ch

Caliber: 5.56mm (.223) or 7.62mm (.308)

Length: 126mm (5.56mm) / 142mm (7.62mm)

Diameter: 39mm

Weight: 380 g (5.56) / 450 g (7.62)

Factory-Tested Sound Reduction: 20 dB (5.56)

Materials: Inconel/Thermax

Finish: sandblasted/grey

MSRP (USD): tba

SRT ARMS

Integrally Suppressed 9mm AR-15/M16

Integrally suppressed upper, 9mm or .45 ACP, 1.5-inch OD tube. Pinned and welded 16-inch bolt face to end of tube or removable for registered MG or SBR lowers. Ported barrel for additional sound reduction. Porting available to make 115gr subsonic or max velocity for use with 147gr subsonic. www.srtarms.com

Caliber: 9mm

Weight: Adds 1lb to upper weight

Diameter: 1.5in

Material: 4130 tube, 7075 AL baffles and end caps

Finish: Black Cerakote

Factory-Tested Sound Reduction: 116-119 dB depending on bullet weight

MSRP: $780 using customer supplied barrel, handguard and upper receiver

ELITE IRON

DELTA MOD2

The Elite Iron DELTA MOD2 is a shorter version of the popular DELTA and is designed for .223 /5.56 rifles only. The compact design and lighter weight makes it a great choice for hunting and tactical applications. Baffle core design minimizes the POI shift. Thread pitch ½ -28. Full-auto rated. www.EliteIron.com

Caliber: .223 /5.56 only

Overall Length: 6.375in

Exterior Diameter: 1.5in

Weight: 17.9oz

Sound Pressure Level Reduction: 35 dB

Materials: Tube is made from 316 SS. Internals are machined from 17-4 H900 SS

Finish: Black Cerakote

MSRP (USD): $720

ELITE IRON

ECHO LITE 5”

The all titanium ECHO LITE 5-inch suppressor is primarily designed for use on handguns and can be used on rifles as well. It delivers solid performance in a lighter suppressor. The ECHO LITE 5-inch can be disassembled for cleaning. Includes takedown tool. Thread pitch 1/2-28 x .400. www.EliteIron.com

ECHO LITE 5”

Caliber: .22 LR only

Length: 5in

Weight: 4.7oz

Diameter: 1in

Material: Titanium

Finish: Black Cerakote

Sound Pressure Level Reduction: 31 dB High Velocity, 35 dB Subsonic

MSRP: $455

LIBERTY SUPPRESSORS

The Sovereign

The Sovereign rifle silencer is perfect for the law enforcement officer, hunter as well as the long-range shooter. It combines lightweight with numerous mounting solutions to create the most versatile and lightweight silencer to date. Titanium construction provides superior strength as well as low muzzle weight for less fatigue in the field. Combined with our LS1 muzzle brake mount, this is the ultimate package. www.libertycans.net

Caliber: 7.62mm

Overall Length: 7in

Exterior Diameter: 1.625in

Weight: 12.5oz

Sound Pressure Level Reduction: 33+ dB

Materials: Titanium/Stainless Steel

Finish: Black Cerakote Type C

MSRP (USD): $1,050

DAKOTA SILENCER

Varminter 4.0

Varminter 4.0 will be available early 2018. The Varminter is a 100% titanium hybrid that’s modular from 9 inches to 7 inches. It’s a hybrid because the 2-inch extension is a uniquely designed monocore baffle system while the 7 inch is all stacked baffles. The Varminter is completely serviceable and comes all the way apart for easy cleaning. Only the Varminter 4.0 .30 calibur will be modular, but Dakota Silencer will also be releasing the Varminter 4.0 in a .223. This will be the quietest Varminter the company has made to date. www.dakotasilencer.com

VARMINTER 4.0

Caliber: .30 and .223

Length: 7in; 9in with extension

Weight: N/A

Diameter: N/A

Material: Titanium

Finish: N/A

Sound Pressure Level Reduction: N/A

MSRP: N/A

THOMPSON MACHINE

The Poseidon 9mm

In production since 2009, the Poseidon 9mm is the smallest, lightest, hearing-safe 9mm suppressor on the market. Its excellent performance on .22LR hosts, .32acp hosts, and .380acp hosts gives it the versatility to match. The Poseidon is in use with military and law enforcement. www.thompsonmachine.net

POSEIDON 9MM

Caliber: 9mm

Length: 4.125in

Weight: 4oz

Diameter: 1.25in

Material: Hard anodized 6061 and 316 Stainless

Design: Monocore, Take-Apart Design

Suppression: Up to 25dB when wet and wiped

MSRP: N/A

About the Author

Dr. Philip Dater has been involved in the sound suppressor industry for over 40 years as Automatic Weapons Company (New Mexico) and Antares Technologies, Inc. His interest has been in the field of design, testing and manufacturing. He founded Gemtech in 1993 and retired in the summer of 2017 at the age of 80. He continues to consult and perform testing on a part-time basis, and several times each year teaches his signature course “Silencer History, Technology & Testing” at Phoenix Defence in Henderson, NV. www.phoenixdefence.com

| This article first appeared in Small Arms Review V22N2 (February 2018) |