By Al Paulson

H&K’s Navy Silencers: Part I

As the U.S. Navy gained experience with the Mark 3 sound suppressor on the 9x19mm Mark 3 Mod 0 pistol after the system’s introduction to the SEAL Teams in 1967, it became obvious that the so-called Hush Puppy suppressor and modified Smith & Wesson Model 39 pistol had some notable shortcomings. Qual-A-Tec in Oceanside, California, developed a suitable replacement in the 1980s. By this time, the Navy had a requirement for a suppressed pistol that could be fired immediately upon exiting the water or even underwater. The new suppressed weapon from Q (as industry insiders refer to Qual-A-Tec), which employed the Heckler & Koch P9S pistol with extra-length threaded barrel, was the only system that could meet this requirement. After the Navy procured a limited number of the silenced pistols from Q (which was an R&D firm with extensive prototyping but limited production capabilities) and the Navy decided to buy this system in quantity, Qual-A-Tec licensed Heckler & Koch GmbH to manufacture the suppressor.

The Teams adopted the H&K P9S pistol with novel suppressor designed at Q but manufactured under license by H&K in Virginia. Simultaneously, the Navy also discovered that the otherwise outstanding aluminum silencer built in Germany for the MP5SD integrally silenced submachine gun was subject to severe saltwater corrosion. So Qual-A-Tec developed a stainless steel suppressor for the MP5SD-N, which H&K also built under license. This is the story of the Navy’s silenced P9S pistol and the special silencer developed for the Navy variant of the MP5SD submachine gun.

The story really begins with the Navy’s experience with the MK 3 suppressor and MK 3 MOD 0 pistol, which were manufactured by Smith & Wesson from 1967 through the early 1970s. The suppressor was based closely upon contemporary German silencers designed by Siegfried Huebner of Carl Walther Waffenfabrik in Ulm-Donau.

The MK 3 suppressor and MK 3 MOD 0 pistol were commonly used in Vietnam by SEALs for quietly eliminating noisy village dogs, hence the weapon quickly became known as the Hush Puppy. The point man on a Navy patrol might also carry the Hush Puppy so he could quietly eliminate a hostile contact. Some of these silenced pistols may have seen anti-personnel service with Project Phoenix.

While the Mark 3 suppressor was remarkably small and light for a centerfire pistol suppressor, it achieved these qualities with the use of elastomer wipes. The act of the bullet pushing through the wipes—which closed behind the bullet and trapped combustion gases normally perceived as a gunshot—adversely affected accuracy and limited the effective range of the suppressed pistol. This was an important consideration because the 158 grain (10.3 gram) FMJ round issued with the pistol would not reliably put down a hostile human or noisy dog with a center of mass shot. A CNS (Central Nervous System; i.e., brain) shot was necessary to instantly incapacitate a target. This is a tough shot to make with the limited accuracy delivered by the Mark 3 suppressor. Furthermore, this round would not always reliably cycle the suppressed Smith & Wesson pistol. Therefore, many operators employed the pistol with its slide lock engaged, the lever locking into notches cut on the sides of the slide. While using the slide lock made the Hush Puppy much quieter and avoided jamming the weapon with a partially extracted fired case, this practice had several distinct disadvantages. It eliminated the ability for a quick follow-up shot despite the potential usefulness of a follow-up shot when using FMJ pistol ammunition. The repeated recoil of a notched slide against a slide lock quickly cracked the slides at the notches, requiring a replacement slide after as few as 150 rounds.

Despite these liabilities, the Hush Puppy remained popular among the SEALs operating in Vietnam. But missions and technology moved on. The rise of global terrorism expanded the mission of some elite military units into the realms of counter-terrorism and hostage rescue. Since the Mark 3 suppressor used wipes, it could not be employed with the new high-performance hollow point rounds being developed in the mid-1980s. Clearly, a more robust pistol and a wipeless suppressor were needed to provide improved accuracy for the maturing tactical doctrine related to close quarter battle and hostage rescue. And a system was also needed that could use subsonic hollow point ammunition in order to achieve improved terminal ballistics for in extremis missions. Finally, the suppressed pistol had to cycle more reliably than the Hush Puppy with its original 158 grain ammunition. The innovative P9S pistol developed by Heckler and Koch proved to be a worthy successor to the MK 3 MOD 0 pistol.

The P9S Pistol

Introduced by Heckler and Koch GmbH in 1968 as an improved variant of the P9 pistol, the P9S might be viewed as a “delayed blowback” pistol, although H&K doesn’t like this term. A roller locking mechanism derived from H&K’s G3 rifle was used to provide a brief delay upon firing, until the chamber pressure dropped to a safe level. The P9S pistol was also noteworthy in its day for the weapon’s polymer frame, fixed barrel, double/single-action trigger, and extensive use of stampings in its fabrication.

Operation of the P9S is relatively novel for a pistol. Two rollers on a two-part breech block engage recesses in the barrel extension when the slide is closed. The heavy rear portion of the breech block pushes against the light forward portion, forcing the rollers outward. Upon firing, expanding combustion gases push the base of the fired case rearward against the light forward portion of the breech block. The slide’s inertia slows inward movement of the rollers, which must disengage from the recesses in the barrel extension before the breech block can begin to move rearward and begin the extraction and ejection sequence.

When a round is chambered, the extractor stands out and serves as an indicator. When the hammer is cocked, a pin protrudes from the rear of the slide. Both indicators can be seen easily in daylight or verified by touch in the dark. The internal cocked hammer can be released be depressing the decocking lever on the left side of the grip behind the trigger. Polygonal rifling provides a tighter gas seal between the projectile and bore (which produces slightly higher projectile velocity than conventional rifling), reduced bullet deformation (which should enhance accuracy at least in theory), less barrel fouling, and longer barrel life.

The standard commercial 9x19mm variant of the P9S pistol is 7.6 inches (19.2 cm) long, has a barrel length of 4.0 inches (10.2 cm), weighs 1.9 pounds (880 grams) empty, and features a nine-round single column magazine. A .45 ACP variant was made for commercial sales chiefly in the United States, but the Navy did not use this variant. While Heckler & Koch GmbH assembled the last P9S in 1989, Hellenic Arms Industry (EBO) SA of Athens, Greece subsequently manufactured the weapon under license, as recently as 1996. The Greek variant is called the EP9S pistol.

The Navy variant of the P9S with extra-length barrel was 8.2 inches (20.8 cm) long without the suppressor and 15.4 inches (39.1 cm) with the suppressor fitted. With the suppressor, the unloaded pistol weighed 3.2 pounds (1.7 kg). A loaded magazine would add 0.45 pounds (200 grams). All of the H&K P9S pistols delivered to the U.S. Navy included two standard barrels and one extra-length barrel threaded 1/2×32 TPI for mounting a suppressor. This latter barrel was issued with a thread protector. The Navy pistols also featured the target sights used on the Target and Competition Models since these sights were higher than normal and would extend above the suppressor. Fitting the suppressor to a P9S pistol with standard sights required a different sighting strategy. Since the suppressor was a grit-blasted matte stainless finish and the pistol sights were black (albeit with colored inserts), there was generally enough contrast to align the front and rear sights against the pale suppressor. Then with both eyes open, the operator could superimpose that sight picture over the target, rather like using an occluded gunsight. This strategy is neither as fast nor as accurate as using sights that see over a suppressor, which is why the Navy pistols featured the higher sights.

The fixed barrel design of the P9S is ideally suited for mounting a suppressor, since the silencer’s length and weight will not adversely affect the reliability of the weapon’s cycling. The typical semiautomatic pistol of centerfire caliber is hard to silence because the weight of the suppressor retards the rearward movement of the barrel, which provides energy to cycle the slide. Thus, the Smith & Wesson Model 39, its incarnation as MK 3 MOD 0 pistol, the Beretta 92F, or any other pistol that depends on the rearward movement of its barrel is more likely to malfunction with a suppressor than the H&K P9S, which does not require barrel movement.

The P9S is also well suited for amphibious operations since it features both a fixed barrel and a single-column magazine. A swimmer, for example, can lock out of a submarine with the Model P9S suppressor mounted and the single-column magazine loaded in the gun. The swimmer then rotates the gun until all the air bubbles disappear, and then chambers a round. The operator could then shoot the gun underwater or poke the suppressor out of the water if, for example, he needed to take a target off a boat, platform or beach. The single-column magazine of the P9S is crucial when the operator must traverse the surf zone off a beach, where suspended sand in the water works its way into the pistol. The P9S will cycle reliably in semiautomatic after being immersed in surf; the Beretta M9 (92F) will not.

As far as I know, the P9S is the only 9mm pistol suitable for amphibious operations. The Navy, for example, tested the H&K P7 pistol before selecting the P9S. The P7 did not work well when carried though the surf and sand zone, since sand that worked its way into the mechanism would prevent the cocking lever from moving freely. The double-column, single-position feed magazines of pistols such as the Beretta, SIG and Glock jam, so the swimmer only gets to use the round that was manually racked into the chamber. A second magazine may be inserted, but it will also cease to function after the first round is manually racked into the chamber. While the H&K P9S magazine design provides much of its reliability in this environment, the gun itself is also toleranced very nicely for this application.

The U.S. Navy SEALs usually issued the H&K P9S pistol with the H&K “Stainless Steel Suppressor, Small, 9mm”, which was referred to by H&K personnel simply as the Small Suppressor to distinguish it from the “Stainless Steel Suppressor, Large, 9mm” which Qual-A-Tec designed and H&K manufactured for the MP5SD-N. The Small Suppressor was designed to work with the MP5-N and MP5K-N submachine guns as well as the P9S pistol. The P9S pistol and Small Suppressor system became standard issue in the 1986, replacing the MK 3 suppressor and MK 3 MOD 0 pistol. The older suppressed pistols were retained, however, in reserve. Production of the Small Suppressor and Large Suppressor continued until 1992, when H&K began to develop a relationship with the Knight’s Armament Company for suppressor technology.

H&K’s Small Suppressor

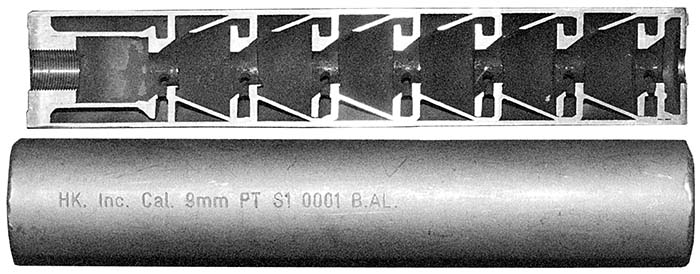

Designed by Qual-A-Tec but manufactured by H&K, the Small Suppressor was based on the patented designs of Charles A. “Mickey” Finn (U.S. patent 4588043). Finn also holds patents on these designs in Europe, Australia, and South Africa. Manufactured entirely of stainless steel, the Small Suppressor measures 7.75 inches (19.7 cm) long and 1.38 inches (3.5 cm) in diameter. The suppressor weighs 19.7 ounces (1.23 pounds; 558 grams).

While originally designed for the P9S pistol, the unusually robust and effective Small Suppressor proved to be an effective submachine gun suppressor as well. Therefore, the Navy did not purchase the Small Suppressor specifically for the P9S pistol. A given Navy purchase order might specify, for example: 1,000 MP5-N, 1,000 MP5K-N and 1,000 MP5SD-N submachine guns, plus 800 P9S Navy pistols and a quantity of Small Suppressors. The Navy did not purchase suppressed pistols per se, but rather would issue suppressors with one of the aforementioned H&K weapons when needed. The versatility of the Small Suppressor meant that the Navy needed fewer cans in inventory to meet their requirements.

The P9S suppressor incorporates baffles of the slanted sidewall type, which are welded together in a sealed unit. The slanted sidewall is a diagonal slot of similar radius to the bullet passage, centered on the bullet passage, that creates a diagonal channel at a 45 degree angle to the bore going from one side of the rear surface to the opposing side on the front of the baffle. Each slanted sidewall baffle creates a gas jet to push against the stream of combustion gases following the bullet. The gas jet dumps significantly more energy inside the suppressor than the same number of similarly spaced conventional baffles.

An unusual feature found on the 5.56mm prototypes of this basic design is that the slanted sidewall is used in the front end cap of the silencer as well as in its baffles. While one might think that a slanted sidewall would be counterproductive on the front end cap, this feature does actually enhance the sound reduction delivered by this can. The slanted sidewall was not used in the front end cap of either 9mm suppressor, however.

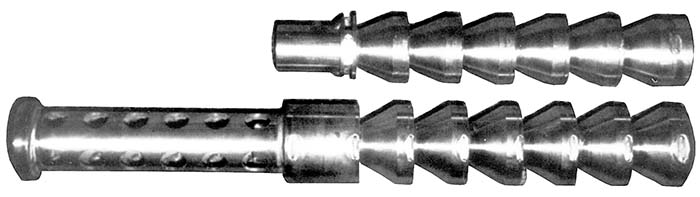

Finn’s patent includes three very different slanted sidewall baffles. Finn’s Type 3 baffle (called the “Third Embodiment” in the patent) is used in the Small Suppressor. Each of the six rearmost baffles in the Small Suppressor features an integral conical spacer in front of it with the apex pointed rearward. The conical spacer features a mouse-hole in its apex adjacent to the forward edge of the slanted sidewall, which directs its gas jet into the coaxial expansion chamber, formed by the spacer. The patent shows a second hole at the front (wide part) of the conical spacer, which directs gases back into the gas stream following the bullet. This hole at the front (wide part) of the cone has two functions: (1) the vent allows gases directed into the outer coaxial chamber surrounding the conical spacer to continue forward through the suppressor, and (2) the release of gas pressure from the front of the coaxial chamber prevents the buildup of back pressure that would neutralize the effectiveness of the coaxial chamber by preventing more gas from entering the rear of the coaxial chamber. Deflecting the gases away from the central axis of the suppressor slows the expansion process within the suppressor and provides additional surface area for cooling the gases. This reduces the amount of energy that would be perceived as noise. The seventh (front-most) baffle does not have a conical spacer.

The production variant of the Type 3 baffle incorporated into the H&K Small Suppressor eliminates the hole at the front (wide) part of the conical spacer. The cut-off chord in the rear face of the baffle (discussed later in this manuscript) indirectly serves the same function, so this hole could be eliminated in the final design.

A portion of the gases passing through the slanted sidewall in the center of the baffle is directed outward along the inner surface of conical spacer. Designing the conical spacer so its radius is less than the radius of the slanted sidewall facilitates this process. Gases flow from the inner surface of the spacer’s apex, forward at an acute angle from the central axis of the can, until striking the rear face of the next baffle. The rear face of the baffle generates more turbulence, robbing the gases of some energy. Two long slots milled perpendicular to the cut-off chord (one slot on either side of the bullet passage) vent combustion gases from the central core of the silencer through the rear baffle face into the annular expansion chamber milled into the outer edge of the baffle. These slots are 0.75 inch (19.1 mm long) and 1/8 inch (3.2 mm) wide.

The rear face of the baffle is machined to a slightly smaller diameter than the front face, enabling the front lip of the conical spacer to slip outside the rear two-thirds of the next baffle, abutting against the front rim of that baffle and forming the outer wall of the annular expansion chamber cut into the edge of the baffle. Gas from the outer coaxial expansion chamber formed by the conical spacer vents into the annular expansion chamber via a cut-off chord milled into the rear face of the baffle. Gas from the cut-off chord runs into gas from the two slots, creating turbulence that robs the gases of energy that would be perceived as sound. These commingled gases from the silencer core and the outer coaxial expansion chamber vent from the annular chamber through three outlets into the slanted sidewall bullet passage. These outlets have a diameter of 1/8 inch (3.2 mm) and are created by drilling radially inward from the annular chamber toward the geometric center of the baffle. All three outlets vent gases into the bullet passage at right angles to the gas stream following the bullet. The central of the three outlets is oriented 180 degrees from the cut-off chord that vents gases into the annular chamber. These three outlets add energy to the gas jet created by the slanted sidewall to push across the gas stream following the bullet. The diagonal gas jet is directed into the mouse-hole at the apex of the conical spacer (which is integrally machined in front of the baffle).

During fabrication of the unit, six baffles with integral conical spacers are welded into a single unit with each mouse-hole aligned with every other mouse-hole. A single (i.e., seventh) Type 3 baffle minus its integral conical spacer is added to the front of the baffle stack, which is welded to a cylindrical spacer that forms a coaxial chamber around the primary expansion chamber at the rear of the suppressor. Here the cut-off chord communicating between the annular groove and the slanted sidewall works in inverse fashion to the rest of the baffle stack. Gas vents from the bore, into the annular chamber, and then out the cut-off chord milled in the rear face of the baffle into the coaxial chamber surrounding the primary expansion chamber to the rear of this first baffle. A very short cylindrical lip on the front end cap fits tightly against the outer suppressor tube and holds the front-most (seventh) baffle in place.

The entire baffle stack is welded together and then inserted into the outer tube as a unit. Then the end caps are welded to the suppressor tube. Finally, the suppressor is line-bored to assure a perfectly aligned bullet passage.

In the next issue, we’ll wrap up the discussion of H&K’s Small Suppressor and conclude with a look at the Large Suppressor designed for the MP5SD-N integrally silenced submachine gun.

| This article first appeared in Small Arms Review V2N4 (January 1999) |