By Robie Kulokivi

For fifteen years there has been a formidable, South African-made tool on the market for police and military use. If the requirement is a weapon for close combat, entry missions, or supportive, close-range firepower, then there is one design that has been unsurpassed.

The revolving, close combat shotgun

A firearm loaded with multiple projectiles for each load could easily be considered a shotgun, especially if it has a bore without rifling. With the large variety of weapons available today we know that this is not the whole truth. But going back in time 400 years, considering the technology available to produce firearm barrels, the way of short distance warfare and the fact that the firearms were muzzle-loaded until only very recently, it is very easy to understand why shotguns were considered effective. Using the terms “shotgun” and blunderbus loosely one could say that these weapons have been used in combat applications for over 400 years.

The smooth-bored barrel was the very first type available in early firearms. It was noted that hit probability over a distance was higher if the muzzle-loaded weapon was charged with many projectiles while dispersion from a short-barreled blunderbus was fairly wide, pattern density was poor. The main advantage of a load of shot was the potential of wounding several opponents with a single pull of the trigger, giving time to perform rather a slow reload through the weapons muzzle.

The occasional need for quick reloading of early weapons led, in time, to variants of guns that incorporated manually rotated chambers. The simplest version was a rifle with several barrels attached around a central spindle in a cylindrical form. The gunner loaded each barrel from the muzzle with a shot load. After firing one barrel the gunner manually turned the next barrel in line with the firing mechanism, and could thus fire the next shot much faster. Weapons of this configuration were heavy and cumbersome. There was need to reduce weight for mobility.

A remarkable step in the evolution of the revolving shotgun was taken in the late 1830’s. With the advent of Samuel Colt’s revolving percussion rifle, a mechanism for automatically indexing the cylinder was introduced. The mechanical function was the same as we see in the revolver today. The ability to better understand metallurgy, produce weapons to exact tolerances and devise better tools for manufacture had increased since the early days of revolving firearms. The same advances had not been made in loads for the chambers of those weapons. The ignition system had improved from matchlock and flint to percussion caps, but basically all weapons were muzzle loaded, be it from the muzzle of the barrel, or the muzzle of the revolving cylinder.

The muzzle-loaded revolver has the potentially dangerous phenomenon of multiple chamber discharge present during firing. This could happen from hot powder gases escaping from the gap between the forcing cone of the barrel and the front of the cylinder. When it happened the gunner was likely to seriously injure his supporting hand.

As the accuracy of standard muzzle-loading rifles increased so did the distances in combat. The interest in the shotgun never grew to a larger scale in military applications. It was probably only the US Army that understood the advantage of the shotgun in close combat. The revolving shotgun, with its user un-friendly drawbacks of the time, was almost forgotten. The standard cased cartridge would change all that, in due course.

Before WW II, there were some serious trials with the revolving shotgun concept. The most important product was a design by Charles J. Manville. The basic 12 gauge (18.5 mm) design incorporated previously untried features; one being a 24 chamber spring-assisted cylinder. By pressing the trigger the gun fired and rotated the next chamber in line with the barrel. The operator had only to release and press the trigger again for the next shot. The Manville shotgun had a front and rear pistol grip and no stock. When reloading the gun the rear (frame with the cam housing) was removed from the barrel and cylinder assembly, thus exposing all the chambers for loading.

The main materials used to construct this weapon were steel and aluminum. The barrel was of steel, and the aluminum cylinder had chamber inserts of steel. Further development of this weapon occurred in 25 mm and 37 mm for police departments to use in riot control. The Manville Corporation discontinued the production and development of its family of weapons in early 1940, concentrating its effort on other products.

The Manville design has been marketed to the law enforcement and military since the middle of 1980 by Hawk Engineering Inc. as the twelve cartridge 37 mm or 40 mm MM-1 version. It has never been reintroduced as a shotgun.

By the end of 1970 another American revolving shotgun was being introduced. This weapon is known as the 18.5 x 70 mm Pancor Jackhammer. The concept has been developed by John Anderson, and it has advanced the revolver principle even further. The ten-chamber, revolving cylinder is factory pre-packed with loaded cartridge. For reloading the complete cylinder (with the cartridge cases) is removed, and an unfired cylinder is replaced. The weapon incorporates an extensive use of plastic materials, combined with steel. The development of the weapon and its ammunition started in 1978, and continued for almost a decade, but only prototype production has been achieved. The current status is unknown to this writer.

In early 1983 a South-African product was introduced to the weapons market, a robust revolving chamber shotgun of a design that has proven to be hard to beat.

FIRST THE STRIKER

A South-African company (called Armsel and based in Johannesburg) started producing the 18.5 x 70 mm STRIKER combat shotgun in 1983. In the country of origin this weapon has since been marketed by Aserma Manufacturing as part of Reutech Defense Industries (RDI). The Striker shotgun and grenade launching derivatives have also been further designed and made in the USA by Penn Arms.

The Striker was an innovation by Hilton Walker and Hans Kornberger, two South-African gun designers. Mr. Kornberger moved to the USA in late 1980 and established the marketing company for American sales.

The original Striker design incorporates some remarkable features that have refined many of the original ideas from the Manville guns.

The standard model of the Striker has a front and rear pistol grip, a folding stock and a collimating dot sight. The sight is also a South-African product called the Armson O.E.G. (Occluded Eye Gunsight).

To fire the Striker the shotgun is held by its grips. The safety is removed by pressing the cross bolt to the left. When the trigger is pressed the revolver drum moves slightly clockwise to align the cartridge primer with the firing pin. Further pressure against a force of approximately 6 kg at the end retracts the hammer and lets it fall in the manner of a standard double action revolver. When the trigger is released for the second shot the revolver drum is indexed to almost present the next cartridge in line with the firing pin. The next pull of trigger again moves the drum so that the primer is inline with the firing pin and this cycle continues for a maximum of twelve shots. To empty the chambers of cases, the safety is placed on, and the hinged cover at the loading port is opened. By fully pulling on the ejector rod, (which is on the right side of the barrel) each cartridge case may be individually ejected in turn.

Apart from the cross-bolt safety which only restricts trigger movement, there are two other major safeties. The important one operates by keeping the chamber (primer) out of line with the firing pin until the trigger is pulled. The third safety feature is the fact that a relatively heavy trigger pull retracts the hammer, to eventually allowing it to fall on the floating firing pin. The weapon is safe to carry fully loaded, even if the cross-bolt safety has not been applied. Only a deliberate pull of the trigger will fire the Striker shotgun.

The total length of this basic model is 500 mm with the stock in the folded position and 780 mm with it extended. The barrel is 300 mm and cylinder bored.

If necessary (under the emotional stimulation of armed conflict) it is possible to fire all twelve cartridges in five seconds. The recoil is evenly distributed trough both grips and butt of the stock. This, combined with the weight of the weapon, reduces felt recoil to a great extent.

THE PROTECTA MODIFICATION

The basic Striker construction has been improved with slight changes and a variety of features. In 1991 a new version of the combat shotgun was introduced by Aserma Mfg. as the PROTECTA. Externally and technically very much like the Striker but with drastic changes in both chamber indexing and cartridge case ejection. The South African designers of the new features were Hilton Walker and Pat Farquharson.

The Protecta modification had an substantial impact on some of the more central issues in this combat shotgun concept. Size and weight and general ergonomics of the basic Striker remained the same but there are four details which demand further attention.

1. Operation of the Weapon

The rotating chambers are indexed manually with the axial movement of the front grip. The front grip is pushed to the right until it stops, and is then returned to its original position until it stops and locks. The movement is 30 degrees. The shroud of the barrel also turns axially with the front grip and as the index arm assembly is connected to the shroud the movement is transferred. The front grip and shroud are held in their normal position with the help of an index locking detent and the force of its spring. When sufficient force is applied the lock is released, and the grip can be turned to the right. The index assembly also has a floating index pin, which in the earliest models was spring assisted. This index pin travels in a star shaped track in the front of the chamber drum assembly called the index plate.

The track forms a star with twelve outer and inner points. If we study one segment of the star track, which is the distance the index pin must travel for one indexing movement between chambers, it forms the letter “V”.

The left upper end of the V is the place where the index pin rests when the front grip is in its normal position. When the grip is turned the pin travels down along the track to the point of the V. The floor of the track goes from deep to shallow to get abruptly deep again at the point. The ledge formed by the sudden difference in depth prevents the floating indexing pin from retracting the same way.

When the front grip is returned to its normal position the index pin travels to the right upper end of the V. Again the floor of the track goes from deep to shallow until it deepens at the upper end, forming a ledge to prevent rearward movement. Now a complete indexing cycle has been made.

To the operator the indexing movement is very short, fast and positive. If one would attempt to fire the weapon with only half the movement made, there would be no effect, as the primer of the cartridge is totally out of line with the firing pin.

Indexing of the chambers can be done by either turning the front grip or by keeping the front grip stationary and turning the rear grip clockwise and back. The method used is up to the preference of the operator.

2. Safety Features

One safety feature was described above. The Protecta can not accidentally be fired out of battery, the indexing movement must be complete.

As opposed to the Striker the Protecta is indexed so that the primer comes directly in line with the firing pin. Thus a new feature has been included as is with most double action revolvers. Unless the trigger is deliberately pulled the hammer can not transfer its blow to the firing pin. There is a hammer block which is removed only after a full rearward pull of the trigger. The trigger pull is 6 kg (13.2 pounds) and the trigger is lockable with a cross bolt safety.

3. Reloading

This has been vastly improved since the Striker by the fact that the new system ejects empties during firing. To load, place the cross bolt in safe position and open the newly designed loading port cover. The cartridges are placed in each chamber by indexing the drum. Close the cover.

To fire, press the cross bolt safety to the left then pull the trigger. Index the following loaded chamber in line with the loading movement of the front grip. The loading port cover opens automatically, exposing the cartridge case head of the previous round. When the trigger’s pulled again the shot is fired, and part of the powder gas is bled from the chamber mouth and forcing cone. This expands into the chamber with the empty case, pushing it forcefully to the rear. When the case is completely clear of the chamber it collides with the rear wall of the ejection opening frame and is flung to the right. All cases are ejected automatically, except the last. The last case can be ejected manually with the ejector rod when preparing to reload the gun.

This system has speeded up the reloading cycle quite a bit, since the early, manually-ejected Striker version.

The powder gas assisted ejection directs some amounts of gas and debris in the direction of the operator. If the gun is fired from the left shoulder eye protection should be mandatory to prevent injury to the right eye.

4. Amount of parts for construction.

The change from the Striker spring assisted rotary motion to the manually indexed version of the Protecta system cut the amount of parts only slightly. The most important difference is in the drum of chambers that consist of 60% less parts than in the Striker version. Production cost is probably smaller also.

When a standard model is perfected it is time to produce models for special applications. The shotgun is a formidable and very practical close combat weapon for entry teams, if it is correctly sized to be operable indoors. RDI has answered that call.

THE BULLDOG

By the middle of 1992 the first suggestions of a special version of the Protecta were discussed. However, it was to take some time before the potential benefits of the proposed model were to materialize. By February of 1995 the matter was at hand again. By March the technical engineers at Aserma Mfg. had built the final version. This was definitely a tool for the entry team to us in a confined space. The ultra-compact shotgun was appropriately named “BULLDOG”.

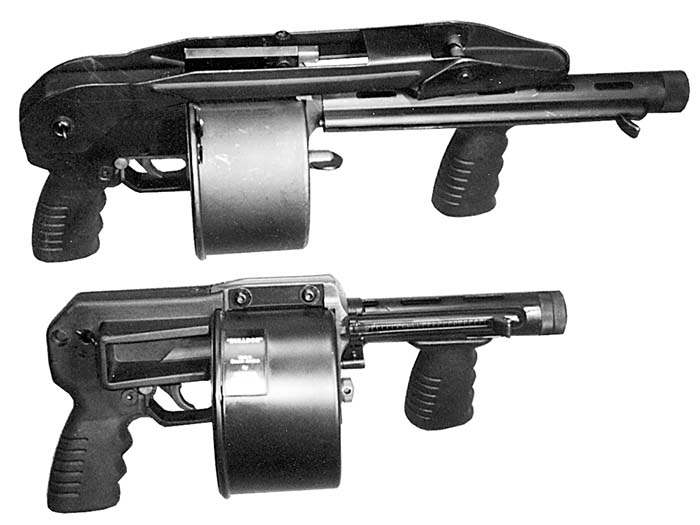

The overall appearance of the 18.5 x 70 mm BULLDOG combat shotgun is intimidating. The total length is 400 mm with a barrel length of 171 mm. The weapon has no collimating dot sight. It has no stock and is meant to be operated from a sling rest, either from the high forward position under the line of sight, or from a low close to body waist level, eyes on target. The loaded weight is 3.9 kg. (8.4 pounds)

The weapon is loaded with eleven cartridges. By sacrificing one cartridge as compared to the standard Protecta some gain has been achieved. The loading port cover is omitted from the Bulldog, making the loading faster yet simpler. The chambers are filled with the indexing method up to number eleven. The twelfth chamber remains empty at the loading port after the weapon is fully loaded with eleven cartridges. After the first eleven cartridges are fired one empty will remain in the drum This works as a marker case for the twelfth chamber. The weapon is loaded again, only now the empty case marker is at the loading port when the weapon is completely reloaded with the next eleven cartridges. The marker is the first to eject when firing is commenced. A new marker case remains after the cycle is repeated. Reloading is very quick with the Bulldog, and can even be performed in slow run if necessary. The ejection port frame is of great aid in placing cartridges.

Even if the barrel is only 171 mm long the weapon still retains the manual ejector rod. It is meant as an aid when unloading an unfired weapon, or in removing cartridges left in the drum. It can also be used to push out the last empty cartridge case depending on the model of the plastic case. The manual ejector pushes from the case mouth, not the inner floor of the case.

The ergonomic demands have been dealt with in this design as well. To facilitate the short barrel the front grip has to be placed more rearward than the standard model. Considering the 145 mm circumference of the chamber drum assembly, the position of the supporting hand would be very awkward if the grip pointed straight down. The Bulldog has a front grip placed at a 45 degree angle to the left to facilitate easier gripping and indexing of the drum. This of course makes it a weapon for right-handed users. It is not readily ambidextrous. For left-handers a point-down grip can be provided, as a point-right grip would place the supporting hand in the path of ejected cases.

The weapon is easily stripped for user maintenance. First make sure that the cylinder is unloaded. The tools needed for dismantling the Bulldog and Protecta are one 5 mm Allen key and a small screwdriver. By inserting the shaft of the Allen key in the hole of the fixing shaft head in the middle of the drum assembly it is screwed counter clockwise to release. The four Allen-head screws that fix the drum cover to the frame are removed. Remove the screw that connects the index arm to the barrel shroud with the screwdriver. Remove the index arm assembly. The complete drum assembly is removed by pulling it down and away from the frame. The cover plates are removed from the rear of the drum. The chamber drum is lifted out of its cover. The plastic rear grip with frame can be removed by loosening the Allen head screws that retain it. The dismantled weapon is easy to service. Assemble in reverse order.

While doing some extensive firing with the Bulldog at the shooting Range: I noticed the following: The shotgun is easy to point at ranges under 30 meters. The gun carries well when fully loaded with the sling across the body. Recoil movement is stronger than the Striker, so the 1 kg (2.2 pounds) reduction in weight carries a penalty. There is scarcely any lift of the muzzle during recoil. The movement is essentially a kick straight back, with slight clockwise torque. This is probably due to the front grip placement. When firing for extended periods the right hand upper knuckle gets sore because of the connection between the ejector opening frame and firing hand. The use of gloves helps to mitigate that.

On targets 10 m (11 yards) distant the shot spread is 300 to 500 mm depending on the type of cartridge. If there is a need to fire slugs accurately it is good to invest in an accessory dot sight and folding stock, and to fire with shoulder support.

The Bulldog ejects its empties very briskly. Cheaper brands of cartridges lose their spent primers in the process. The positive ejection lands the cartridge cases two meters to the right of the operator.

The operation of the indexing system takes some time to learn instinctively. This is especially so if one is very familiar with pump action or self-loading shotguns. In the beginning of familiarization with the Bulldog I repeatedly pulled the trigger twice on the same cartridge. When the indexing movement is accepted by the hands operating the gun, firing can be very fast, if and when necessary.

Reloading the empty weapon can also be a very quick operation, after initial training. As noted, this can be performed while moving on foot, either walking or in a slow run.

This South-African combat shotgun product has proven to be a sound design from the start. Since 1983 it has evolved to the model known as Bulldog in 1995. I am certain that the company producing this tool for entry teams will listen to potential customers in the future, and offer model variations for different applications.

| This article first appeared in Small Arms Review V1N9 (June 1998) |