The right side of the AR-10A2 rifle after the sunset of the 1994 Federal Assault Weapon Ban. Notice the bayonet lug and flash suppressor. Also notice the difference in the width of the barrel from the tip of the front sight base forward. This rifle also has one of the newly designed and manufactured ArmaLite magazines.

By Christopher R. Bartocci

On October 1, 1954, ArmaLite became a division of Fairchild Engine and Airplane of Hollywood, California. Unknown to any of the founders of this company, they would alter the course of America, as well as many other nations, and the concept of what an assault rifle of the future was to be. The new ArmaLite weapons would introduce a new generation of materials and manufacturing techniques to make the most advanced, accurate and light weight battle rifles available.

Eugene Stoner went to work for ArmaLite as a Senior Design Engineer. Stoner and his team (Art Miller, Jim Sullivan, Bob Freemont & others) took the advanced materials used in the aircraft industry (aluminum alloys as well as synthetic materials) to design a light weight modern 7.62x51mm caliber assault rifle, the AR-10. Prior to its introduction, virtually all 7.62mm small arms were made of the traditional steel and wood materials. This led to the continuing use of heavy weapons that were difficult, if not impossible, to control on automatic fire and with using wood stocks, prone to the wood swelling when wet as well as cracking.

Stoner claimed that his primary interest was always the development of 7.62x51mm caliber rifles. As stated in an ArmaLite sales brochure from 1959, the AR-10 was truly “Tomorrow’s Rifle-Today.” The AR-10 made use of modern aircraft grade aluminum alloy receivers dramatically reducing weight compared to conventional steel receivers. The stocks (stock, pistol grip and handguards) were manufactured from advanced synthetic materials adding several benefits to the rifle. These synthetic materials were unaffected by the environment; impervious to rain, humidity, snow or heat. Most importantly to the troop in the field, it was light weight. This enabled the soldier to carry the new AR-10 with 50 rounds of 7.62mm to match the weight of the M1 rifle alone.

Another planned design benefit of the AR-10 was the use of low cost high capacity magazines that held twenty rounds of NATO ammunition that would have allowed the troop to carry preloaded magazines that could be discarded when done. This enabled the soldier to carry substantially more ammunition, therefore providing significantly more firepower on the individual level.

The AR-10 utilized an extremely simple gas system that both decreased weight and increased the accuracy over that of other weapons in its class. Gas was directed by a gas tube/exhaust pipe into the bolt carrier group. This gas delivery method was first seen in use on the Swedish Ljungman Gewher 42 and later would be utilized in the French MAS combat rifles. The design that would make Eugene Stoner one of the most important small arms designers of the last century was his design to make the gas tube run under the hand guards from the front sight base to an opening in the bolt carrier group. The expansion chamber was created inside the bolt carrier group between the rear of the tail of the bolt and the rear of the bolt carrier, eliminating the need for a heavy piston rod, nor any rod attached to the barrel that would decrease accuracy due to interference with barrel harmonics. The gas system consists of a gas tube, which looks like a long exhaust pipe that goes from the front sight assembly/gas block to the bolt carrier group. As the projectile passes the gas port located under the front sight assembly, the gas is directed back to the bolt carrier by it traveling down the gas tube, pressurizing the system, and is lead into an expansion chamber within the bolt carrier group. The expansion chamber is made between the rear of the tail of the bolt and the back of the bolt carrier. That pressure drives the bolt carrier rearward. Just as the bullet leaves the barrel, the cam rotates the multi-lug bolt out of alignment unlocking the bolt from the barrel extension, extracting the fired cartridge case and ejecting it from the rifle. As the carrier moves rearward it does a couple of things. First, the bottom of the carrier pushes the hammer back regardless if it is to a disconnector or auto sear. Then the buffer/ buffer spring is compressed. Once the bolt carrier assembly has traveled to its furthest point rearward, the spring and buffer return the bolt carrier group forward, stripping a cartridge off the magazine, feeding, chambering and locking the bolt into battery ready for the next shot. This is an inline system meaning the tip of the barrel is inline with the center mass of the buffer/ stock, thereby increasing accuracy and reliability while decreasing recoil.

Battling the “Not Made Here” Syndrome

During this development stage of the AR-10 rifle, the United States Army was looking to update its arsenal from the outdated 8-shot M1 Garand. Although once touted as the greatest battle implement ever, time, as well as warfare, changed. A rifle with a high capacity magazine and selective fire capabilities was needed desperately. Especially since it appeared the U.S. was falling behind in the advancements in battle rifle development. The Germans saw this need in World War II and adopted das Sturmgewehr; the world’s first true assault rifle giving the shooter controllable and accurate semi or automatic fire at the discretion of the shooter thereby massively increasing firepower of the unit at the individual level. Around the same time, the Soviet’s began development of their own assault rifle, which was not adopted until 1947 when the AK47 made its world debut and was about to set the bar for effective combat weapons. The U.S. would not take this lack of initiative or vision into account until US troops came onto the receiving end of Mikhail Kalashnikov’s new rifle in the rice paddies of Vietnam. Not until then would the U.S. Ordnance Corps realize how far behind they were in small arms technology.

When the U.S. military was looking for a rifle to replace their obsolete M1 Garand, trials were held with the requirement it would fire the newly adopted 7.62x51mm NATO cartridge. Although the obvious conclusions to the requirement was that they wanted an advanced rifle design that would fill the role of several weapons currently in use including the M1 Garand, M1/ M2 Carbine, BAR, Thompson SMG as well as the M3 SMG. What Springfield Armory came up with was none of the above, especially in the advanced category. They put forth for the trials their T44,which was essentially an M1 Garand with a removable 20 round box magazine and a selector switch that allowed fully automatic bursts that the average soldier could not control. The rifle was just as heavy even though it used the slightly less powerful cartridge. The other entry was the T48, which was a version of the FN FAL rifle. The trials showed much interest in the ArmaLite AR-10, especially in weight, reliability and accuracy. Nevertheless, the winner was declared as the M14 (the T44 rifle). The M14 would go down in history as the shortest serving small arm in U.S. history when it was replaced within 6 years with the AR-15/M16 rifle.

ArmaLite was devastated by this failure. In hind sight you would have to ask yourself if they were upset because their candidate lost or if it was because they knew they had the better weapon, one that was more advanced than anything currently fielded anywhere in the world. They knew it was Ordnance Corp politics that would put an outdated arm in the hands of their troops who were soon to deploy to the jungles of Southeast Asia. It was there that the Ordnance Corps would realize they got the wrong gun and they needed a true assault rifle fast. But that is a different story.

After the trials were over, interest in the .30 caliber cartridge was now getting put on the back burner to the new high-velocity .22 caliber cartridge. ArmaLite would now focus on downsizing their AR-10 tothe AR-15 to fire this new 5.56mm cartridge. The rest is history. The AR-10 went into the Ordnance Corps scrap heap, a victim of poor politics. Small numbers of AR- 10 rifles were produce by Artillerie- Inrichtingen of Zaandam, Holland, but eventually went away. The AR-10 would have to wait until the early 1990s before it would be revisited and appreciated for its advanced design and benefits to U.S. troops, but it would be the U.S. Special Operations Command who would revive it. Gene Stoner would team up with C. Reed Knight, Jr. at Knight’s Armament Company to revive the rifle he could never get out of his head. There, the SR25 would be born: a 7.62x51mm caliber rifle that would have many of the updates from the current M16A2 family of weapons.

The ArmaLite name went into ambiguity and remained a company who made brilliant advancements in small arms development but never had the selling knowhow to make it to the top.

ArmaLite Makes a Comeback

In the late 1980s, several companies would start producing copies of the AR- 15/M16. One of them was Eagle Arms of Coal Valley, Illinois. However, ingenuity and research and development at Eagle Arms were pretty much limited to reverse engineering Colt AR-15 and M16 rifles and producing versions for commercial sales. That was until January of 1994 when anenergetic and true firearms designer bought the company. Former U.S. Army Ordnance Officer and civilian employee of AMCCOM at Rock Island, Mark Westrom restructured the company and began development on new products. On the top of that list is what Westrom named the M- 10: a resurrection of the AR-10 7.62mm rifle. This was somewhat after Knight’s came out with their SR25 rifle. Another landmark event was about to take place for Westrom when he purchased the rights and trade mark of ArmaLite. The new company was called ArmaLite, Inc., with Eagle Arms being a subsidiary of that company.

Westrom had some choices to make with his M-10. The first one was a given – now the rifle could legitimately be called the ArmaLite AR-10. The next series of questions was how he should go about designing it. The first option was to go off the original prints. This had two problems. First was the rifle would look very strange and out of place compared to the current M16-series rifles. Secondly, many advancements had taken place over these intervening years with the evolution of the M16 series and those improvements could not readily be implemented on the original caliber design. The original AR-10 was never a finalized combat ready design. Once it was adopted it would go through a development process to get it ready for issue: all those things that Ordnance Corps neglected to do with the M16 development during the Vietnam War. The next option for Westrom was to redesign it from the ground up. Westrom was up for the challenge but with the development of the SR25, another option needed to be entertained. If Westrom was to base his AR-10 off the Stoner designed SR25, he could tap into a new market. By keeping interchangeability with the SR25 on the major components, he would have a secondary market for the new AR-10 rifles parts. So the third was the option chosen. Westrom kept the upper receiver, bolt and bolt carrier interchangeable with the SR25. But the lower would be different as well as an entirely different design principal from Knight’s.

Knight was, and still is to this day, first and foremost a defense contractor with limited commercial sales. When Stoner developed the SR25, he wanted to keep as much interchangeability/parts commonality with the M16A2 as possible (60%). With military logistics and resupply being what they are, this only made sense. Westrom felt that several of the componentsused on the SR25 were not sufficientlystrong enough for use in the 7.62mm rifle. Westrom felt he would design this as a 7.62mm caliber rifle and parts interchangeability would not be a priority. The first rifle to be introduced by ArmaLite would be their AR-10A2, the infantry rifle.

The AR-10A2 “The Infantry Rifle”

It is necessary to look at the time period when the AR-10A2 came out. This was while the main U.S. battle rifle, the M16A2, still utilized iron combat sights. Today, iron sights (fixed) seem to be outdated. With the adoption of the Swan/ NATO Mil-Std-1913 rail and the plethora of hi-tech optics and accessories, the old reliable iron sights are now more so thought of as back-up sights. Even though the M16A2 is still in production for the U.S. military, flat top M16A4 rifles seem to be taking over. The original AR-10 rifle was designed when iron sights were standard and troops were taught how to use them, and use them well.

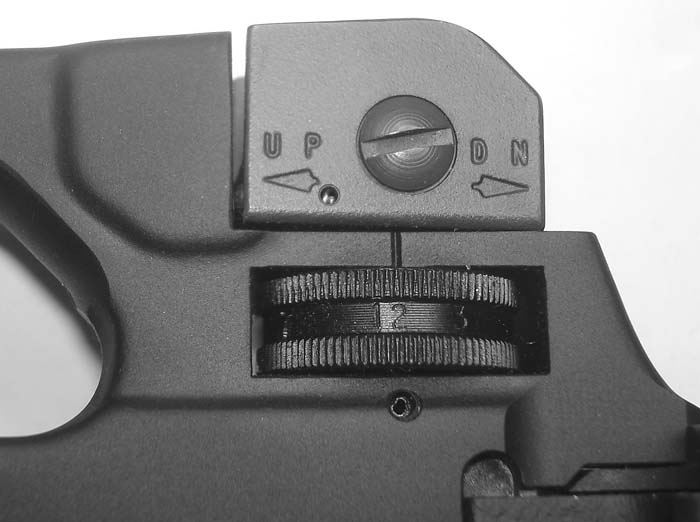

The AR-10A2 utilizes the fully adjustable rear sight which is adjustable for elevation as well as windage and is adjusted without the need for any tools. The elevation increments were set for the trajectory of the standard 7.62x51mm M80 ball cartridge. If someone is comfortable and accustom to the M16A2, they will be right at home with the AR-10A2. The AR-10A2 is likened to an M16A2 on steroids. The front sight is the standard 4 position square sight.

The upper receiver, like the original AR- 10/AR-15, does not have the forward assist assembly. The weapon system was developed by Stoner to function as is and there was no need for a mechanical device to drive the bolt closed if it fails to lock.He felt (as does the M14 operator’s manual) that you do not force a cartridge into the chamber. You remove it and chamber a new cartridge. Forcing the bolt closed is more likely to cause a more serious malfunction than to prevent it. This is why the original AR-10, the Stoner developed SR-25 and the new AR-10A2 do not have one. Westrom has been asked for it and always explains to his customers why it is a bad idea.

The AR-10A2 has the M16A2 rifle’s fired cartridge case deflector. The fired cartridge case deflector is a pyramid shaped deflector that is part of the forging right behind the ejection port. Using high speed photography, research showed that as cyclic rate increases, the ejection pattern shifts rearward. This is what will cause fired cartridge cases to strike left handed shooters in the face. The original deflector rib used on the early AR-10 and AR-15 was sufficient with lower cyclic rate (caused by powder type) but as more Ball powders began to be used, the deflector rib did not extend out far enough to deflect the fired cartridge case. The new deflector extended out much further than that of the original deflector rib. The fired cartridge case strikes the rib and either bounces forward off the deflector or deflects it so it will not come in contact with the face of a left handed shooter.

The handguards used are the standard M16A2 handguards that ArmaLite offers in both black and the ArmaLite trademark green furniture. The rifle uses the standard A2-style canted slip ring. The front sight tower is another innovation of ArmaLite. Rather than the conventional drilled and staked front sight assembly, Westrom chose one that is held on with set screws. The purpose of using set screws was to allow the rifle’s front sight base to be shifted to zero the front sight for windage, while at the same time leaving the rear sight mechanically zero/centered in the rear sight base. The original rifles, in order to be Assault Weapon Ban compliant, had no bayonet lug. With the sunset of the ban in 2004, Westrom resumed production of standard front sight assemblies with bayonet lugs. Newer models are now staked in place on the AR-10A2 rifle but the other models retain the set screw front sight assemblies.

The 20-inch AR-10A2 barrel is chrome plated with a manganese phosphate finish.The barrel has a 1 turn in 12 inch rifling twist, which will stabilize all military grade 7.62mm NATO ammunition. The barrel has been improved throughout the years. All of Westrom’s weapons are works in progress: they are constantly improved and updated. The earlier rifles used M16-type barrel extensions. In 2004, ArmaLite made a product enhancement to the AR-10 rifles utilizing M4-type extended feed ramps in both the barrel extension and upper receiver. The standard M16 rifle gas tube is one of the components that Westrom felt would not be sufficient for use in the AR- 10. The standard gas tube would only be inserted about half way into the carrier key on the bolt carrier and Westrom felt this could cause unnecessary gas leakage. He extended the length of the gas tube so itwould seat to the rear of the key to ensure a better gas seal.

Also in compliance with the assault weapon ban, ArmaLite provided their AR- 10A2 rifles with muzzle brakes because they could not use the politically incorrect flash supressor/compensator. The first generation muzzle brake had three gas escape vents on the right and left side. It was later replaced with a muzzle brake with two vents. Current post Sept 14, 2004 rifles utilize a proper M16A2-style muzzle brake. Of course there are many aftermarket types that can be used as well. All earlier versions utilized a heavy barrel from end to end. Newer production rifles utilize a lighter barrel from the muzzle to the front of the front sight assembly thereby assisting with making the rifle a little less muzzle heavy.

The bolt carrier group has gone through much evolution since the original. In Stoner’s original design, the gas tube ran along the left side of the barrel from the front sight into the left side of the bolt carrier group. Later, ArmaLite made a design change that placed the gas tube on top of the barrel where it remains to this day in both the 5.56 and 7.62mm weapons. By the time Artillerie-Inrichtingen went into production, these modifications had already been made. The weapon was originally charged from a handle that was inside the carrying handle and the original carrier group was all chrome plated. They utilized a cam pin as well as the standardtype extractor and ejector. The firing pin was free floated and held in place by a machined steel retaining pin. The multi lug bolt had lineage to one designed by Melvin Johnson. The actual mechanics of how the assembly works has not changed for more than 40+ years.

When Stoner went to work on his SR25 rifle, he applied many of the advancements made in the 5.56mm rifles throughout the years while retaining his signature chrome plating of the bolt and carrier. He utilized the standard M16 carrier key. The firing pin retaining pin was one of the most significant enhancements. Stoner redesigned it to be “soldier proof,” making the pin captive so it would not be lost during field cleaning. Westrom kept both the bolt and carrier compatible at the sub level. However, Westrom went with the more durable and proven manganese phosphate finish. Inside, the bolt carrier and key are chrome plated. He also went with a larger cotterstyle firing pin retainer pin. The firing pin is where ArmaLite went off the reservation of tradition. The original AR-10 rifle was designed to work with Mil-Spec M80 7.62mm Ball. Most all automatic weapons prior to the AR-10 had free floating firing pins. The primers were hard enough that inertia of the firing pin, from a closing and locking of the bolt would not cause the weapon to slam fire. However, in commercial and law enforcement applications of the AR-10, the rifles would have to be compatible with commercial .308 Winchester ammunition. Commercial production primers are not made to the same hardness specification of military ones, so when firing many different types of commercial ammunition, the rifle would slam fire. Westrom took the most logical and simplest road to correction by added a firing pin spring to prevent the slam fire condition. The ArmaLite extractor assembly had gone through many updates and continues to do so to this day. In fact, one of the most criticized components of the AR-10/ AR-15/M16 weapon systems is the extractor. Due to the design, there is but a very small compartment for the extractor spring to function. The thickness and diameter of the spring has been taken to the max. This part does wear out quicker than pretty much any part of the weapon. The first major enhancement to the ArmaLite extractor was the addition of the internal plastic buffer. This has been standard on military M16’s since the mid-1970s. This buffer kept the extractor spring straight and offered additional force. The next major change was to come out of USSOCOM at Crane during their M4 reliability enhancement programs. They developed a rubber O-ring that slid over the existing extractor spring/buffer. This 10¢ piece of rubber increased the extractor force by a factor of 4. The O-ring has been in use with SOCOM for several years and only a few years ago was finally authorized by the big Army as a reliability enhancement. The newest enhancement offered by ArmaLite, specifically for their AR-10 carbines, is another embedded extractor that fits inside the original. This is in conjunction with the rubber O-ring. As with the 5.56mm weapons, the shorter carbines/shorter gas tubes increase the cyclic rate of the weapon. The bolt is opening sooner while larger amounts of residual pressure exist in the cartridge case. Thus, the extractor is pulling out a cartridge that is still somewhat stuck to the chamber. This increases the fatigue in the extractor springs.

The lower receiver is what takes a good departure from the original AR-10 and SR- 25 design. Westrom went with an M16- type 7175-T74 aluminum forging. Westrom paid particular attention to give a clean, familiar, M16A2-style look to his rifle. This includes the magazine release button fence as well as the co-witness selector marks on the right side. The bolt catch was another part of the AR-10 that he felt the M16A2 bolt catch was not strong enough to halt the massive 7.62 caliber bolt group. So Westrom re-designed the bolt to have more mass and to be significantly more robust. ArmaLite has just come out with another enhancement to the bolt catch that would go with a newly developed ArmaLite magazine.A standard M16 rifle stock and buffer extension are used. Again, they are offered in black or ArmaLite green.

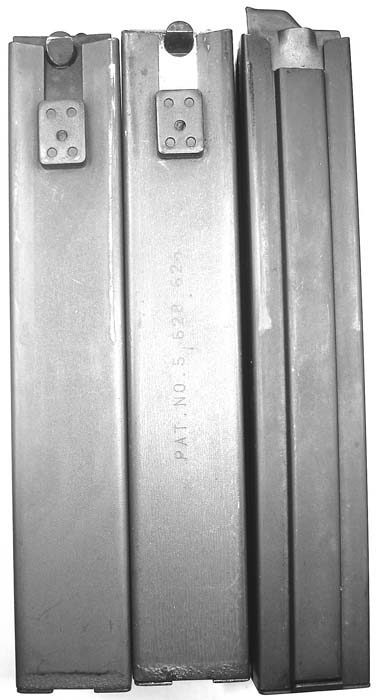

Of all the unique aspects of the AR- 10A2, or any other of ArmaLite’s AR-10 rifles, the magazine would have to be the most interesting. The chosen magazine system was based on many reasons but the driving reason was due to the assault weapon ban that prevented manufacturers from producing high capacity magazines. The original AR-10 magazines and the Knight magazines worked incredibly well and were definitely the preferred choice. But due to the timing, original magazines were rare if not impossible to find and Knight magazines were extremely rare and, when found, quite pricey. Westrom wanted all his customers to have affordable high capacity magazines. With the limited availability of the standard magazines, he needed an alternative. Due to the decommissioning of the M14 rifles many years ago, there were huge stocks of military 20-round magazines. They were reasonably priced and very well designed. So Westrom set out with his engineers to make the M14 magazines work in his AR-10 series rifles. By modifying the feed lip angles and the magazine well, the winning combination was achieved, though the follower had to be replaced for the magazine to actuate the bolt catch. Due to the fact there was no rib on the rear of the M14 magazine that would guide the follower and provide the surface that would engage the bolt catch, Westrom had to come up with a follower design that would operate the bolt catch. The design was a spring loaded plunger with a guide cut in the back of the magazine that would allow the plunger to extend rearward prior to the last shot being fired. When the last cartridge is fired and the bolt carrier group moves all the way rearward, the plunger lifts up the bolt catch locking the bolt to the rear. This modification was made by sending the magazines into ArmaLite or update kits were provided to gunsmiths. Now with the assault weapon ban lifted, ArmaLite designed their own magazine. This new magazine would of course be compatible with all previous weapons and based off the M14 magazine design. But a rib was manufactured into the rear of the magazine to accommodate the new follower. The new follower works similar to that of the standard AR-10 or SR- 25, where the rear of the magazine raises the bolt catch into engagement. ArmaLite did develop a new bolt catch for this magazine. Studies conducted by ArmaLite showed that more than 90% of the previously made rifle’s bolt catches would engage the new magazine. But even 90% is not good enough for Westrom and he makes the improved bolt catches available for weapons that need it to function with the new magazines.

With today’s combat conditions and new technology, iron sights seem primitive. But to many combat veterans they are still the most viable of all sights. They are impervious to weather, heat, humidity, water submersion and mud. They do not, under normal conditions, get knocked out of alignment. The AR-10A2 keeps the spirit and intent of the original AR-10. The original intent for the rifle was primary iron sights with the ability to mount optics. ArmaLite offers a variety of AR-10 rifles including the modern Mil-Std-1913 flat top upper receiver. However, sometimes going back to the basics leads to the most overall sound weapon system. The AR-10A2 is just that. With recent operations in Afghanistan and Iraq, the long range capability of the 7.62x51mm cartridge could be exploited and this is the perfect rifle to do it. Whether with optics or iron sights, the old design is truly state-of-the-art. This 50 year young rifle, as well as this family of weapons, will serve the U.S. and allies for many years to come. The legacy and the continuing success of the AR-10/AR- 15 series rifles is a tribute to Gene Stoner and his dedicated team of designers who, in the 1950s, were just too far advanced in the small arms world and they did not have the insight to see that Stoner truly did develop “tomorrow’s rifle today.” It is true that Gene Stoner lived to see his initial design used as the downsized AR- 15 /M16/M4 series of weapons utilized by millions of soldiers and police officers around the world. However, it is only tragic that he did not live to see that the initial 7.62mm concept of the AR-10 has gone full circle and equips the most advanced troops in the world, and has achieved much fame and popularity.

| This article first appeared in Small Arms Review V11N6 (March 2008) |