By Anthony Dee

One of the most interesting and obscure weapons of World War II was the ill-fated BEANO grenade. The idea for this grenade was initiated by the OSS in September of 1943. The most unusual concept of this grenade was that it would employ an impact detonating fuze rather than the conventional time delay. OSS also wanted it to be round, approximately the same size and weight as a baseball.

The OSS had set forth several specifications. They wanted it to be the same size and weight (51/2 ounces) as a standard baseball. They required that the grenade would reliably detonate when dropped from a height of 18 inches onto sponge rubber. It should be spherically balanced and have optimum lethal fragmentation. Also required were two arming mechanisms with the second one to arm the grenade during flight. The arming pin should also be replaceable for safety purposes.

Several fuze designs were considered. The British had used an impact type fuze that was very successful and was currently in use by British and Canadian forces. The OSS called upon their experience. Several other concepts were also considered from Italian designs. The combination of these ideas became the basis of the BEANO fuze.

Eastman Kodak Company of Rochester New York was contracted to produce several examples for initial testing. These were to be built at their secret “Lincoln” plant. The Lincoln plant was located in the heart of the city in an older residential neighborhood. Almost all of Kodak’s military contracts were carried out at this facility. The “Lincoln” plant still stands today, although it is no longer in use. However, it remains unmarked and nondescript surrounded by its high fence and guarded entrance. It is as unobtrusive a structure today as it was 60 years ago.

It was determined that the original weight of the grenade was too light and would have to be increased. A 12-ounce total weight was settled on, with the explosive content to constitute 9-ounces of that total. After testing for optimum fragmentation, a body constructed of 0.040-inch thick steel was chosen over magnesium or aluminum.

Two designs of fuzes were developed for testing and Kodak was to produce fifty of each type. Both types of fuzes were similar with the only differences being some internal components. They were both identical in the aspect of arming which was quite unique.

The thrower would place two fingers on a knurled, weighted “butterfly” cap. The safety pin was then pulled and the grenade was thrown. As the grenade flew through the air, the “butterfly” cap separated from the body. This cap would then catch the air stream and a length of nylon string attached to the cap would unwind. The other end of this string was attached to the secondary arming pin. When this pin was pulled from the fuze body the grenade became armed and would now detonate upon impact.

As Kodak was in the process of manufacturing the two batches of fuzes, the decision was made to use TNT instead of ammonium picrate as filler for the initial testing. When the fuzes were completed, it was discovered that they were too sensitive and almost half of them detonated when dropped from only 6 inches onto sponge rubber. Changes were made and an order for 2,000 was contracted. It was also decided that filler was to be changed to either Composition A (RDX) or Granular TNT. With these changes BEANO was now approaching its final form.

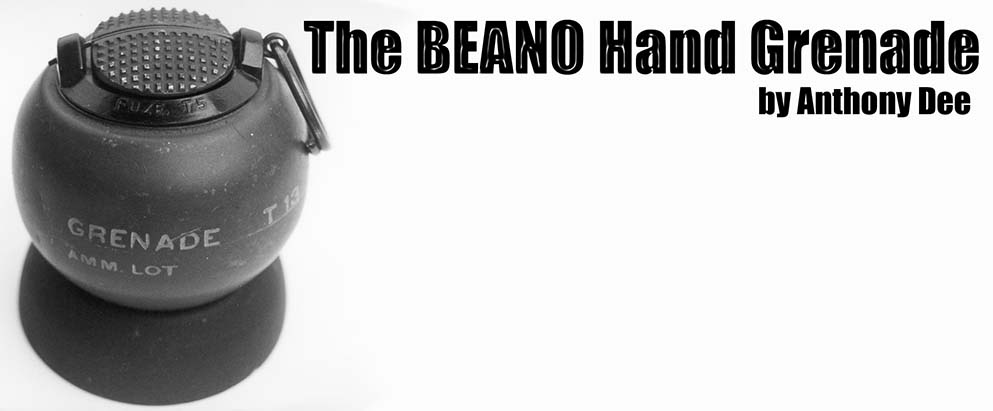

Several other tests were conducted and the filler was again changed to Composition A. This change improved the fragmentation lethality considerably. The fuzes were also improved and on 29 January 1944 the Ordnance Department officially named the BEANO as “Grenade, Hand, Fragmentation, T12 using Fuze, Grenade, Impact T5.”

Kodak completed production of the initial order and submitted them for thorough testing at the Aberdeen Proving Grounds in March 1944. These tests included Fragmentation, Sensitivity, Jolt and Jumble, Chemical Stability, Compatibility, Temperature Effect and Accelerated Aging tests. All of these tests went well and Aberdeen was satisfied enough to proceed and have the Infantry Board at Fort Benning, Georgia conduct operational trials using live grenades in the hands of Infantry soldiers. During a series of tests there were some minor casualties. Unfortunately three men were slightly injured by the accidental dropping of a grenade. Other issues were also raised at this time. BEANO’s effectiveness and reliability were questioned as several duds were encountered during cold weather testing. In spite of these problems on 2 June 1944 the Army ordered 825,00 units to fill OSS, Army and USMC requirements. Some of these production models were shipped to Fort Benning for testing by the Infantry Board with positive results until a civilian was killed during a routine throwing test on 3 November 1944 (Editor’s note: he threw the grenade straight up in the air and it came down and landed squarely on top of his head! Duh!). It was recommended that production cease until the fuze was re-designed. This was overruled and it was decided that after they were inspected, the grenades already produced should be issued while an improved fuze design (the “E1” and “E2” types) was being developed. Improved fuzes were in production by February 1945. However, at this same time 10,000 of the original “T5”-fuzed BEANO’s were sent to Europe for field trials. On 22 March 1945 testing revealed that of the 2,742 BEANOS thrown there was a 10% failure rate. This was primarily due to soft ground. There were also five premature detonations that had mortally wounded two men and injured forty-four others. On 29 March 1945 General Stilwell, Commanding General of Army Ground Forces, ordered testing stopped and suspended production.

On 15 June 1945 the order was given to cease production and destroy or store all old stock until a safer fuze could be implemented. The Ordnance Department was directed to determine the cause of the premature detonations and to correct the defects. Kodak continued to improve the fuze designs. The final design was the T13E3. This design was supposed to have cured the problem of the premature detonations. However, if the thrower did not hold the butterfly down as instructed, the grenade could prematurely detonate since the butterfly often jerked the safety pin from the fuze body as it was thrown. A new design featured a spoon-type safety lever similar to conventional grenades.

Other variations of BEANO were tried with a time fuze and a study was also conducted on a blast model filled with flash powder and another model filled with white phosphorus.

. With the end of World War II the need for the further development of BEANO was not warranted and further testing ceased. All stores were ordered destroyed and because of OSS involvement most of the records were classified. This grenade is seldom encountered today. The BEANO holds the dubious distinction of having killed and injured more of our own personnel than of the enemy.

The example used in this article was an intermediate test model. The body is marked T13, Comp. “A” and the fuze body is Marked T5. This particular fuze was used in the testing process. Evidence of oxidation from the 2 grains of mercury fulminate, potassium chlorate-antimony sulfide used as the primer mix is present around the firing pin and in the empty aluminum detonator cup. I have encountered a few other variants of fuzes, some of which were hand etched around the top with a scriber indicating the changes. I also have seen other examples of grenade bodies, including a blue painted inert training model that was weighted with sand. Today examples of BEANO are highly sought after by collectors of military ordnance and OSS memorabilia. Due to their unique history and rarity they command premium prices.

| This article first appeared in Small Arms Review V7N1 (October 2003) |