By Frank Iannamico

While the British Sten gun of World War II is more familiar to collectors, the Lanchester was the first British submachine gun preceding the Sten Mk II in service. In fact, the heavy and quite expensiveLanchester was the catalyst that launched Great Britain’s desire for an inexpensive and lightweight replacement weapon for the primary purpose of defending England’s aerodromes from a possible German airborne invasion.

Even before their entry into the war, the British Government was procuring Thompson submachine guns from the United States. The Thompson, originally designed in the 1920s, was dated, heavy and very expensive. What the British needed was their own submachine gun. During the 1920s, Birmingham Small Arms, Ltd. (BSA), under the direction of the British Government, did manufacture a few “European” carbine-style 9mm versions of the Thompson. But after testing, decided that there was no significant advantage over the standard U.S. model. During the summer of 1940, the British decided that they would copy and manufacture the German MP28 II submachine gun; a 9mm weapon that was simple to use and accurate at ranges out to 200 meters. Most importantly was that the manufacturing drawings and several examples of the German weapon were already in British hands. Ironically, the German MP28 II, like the American Thompson, was a twenty-year old design.

The Lanchester’s single-feed doublestack box magazine was also copied from the German design. There were two variations of the magazine. One had a 32-round capacity and the other a 50-round capacity. The 32-round configuration was the same magazine later used for the Sten guns. The double-stack single-feed magazine would prove to be the weak link of both weapons.

The British based Sterling Engineering Company, Ltd. was the company chosen to manufacture the Lanchester. On 13 June 1941, the first contract was signed. The Lanchester was made in two separate plants: the Sterling Engineering plant in Dagenham, and Sterling Armaments, North Hampton. The first deliveries were expected by September of that year. There were few changes from the original German design; the most obvious was the brass magazine housing and the shroud-mounted lug designed for the British P-1907 bayonet. The Lanchester was 1.5 inches longer and weighed 1.4 pounds more than the German weapon it was copied from. The name of the British submachine gun came from George H. Lanchester, an engineer employed at the Sterling factory who had been placed in charge of submachine gun production.

Lanchester Machine Carbine Mk1

As production plans were being laid, it was quickly realized that the Lanchester Machine Carbine was not going to be as cheap or easy to manufacture as was originally planned. During production there were several changes employed to both reduce cost and increase production. The original Mk1 Lanchester had a select-fire capability: firing either semiautomatic or full automatic. The selector switch was located at the front of the trigger guard. This characteristic was eventually deemed unnecessary as it complicated the design and had caused some reliability problems.

Lanchester Machine Carbine Mk1*

The original design was reconfigured and designated as the Lanchester Mk1*. This variation fired full-automatic only. Discarding the semiautomatic feature also allowed the breech bolt and firing pin to be redesigned requiring fewer machine operations. In place of machine screws, the rear sight and trigger housing were now welded directly onto the receiver. The rear sight was changed from the original adjustable tangent type to a much simpler two-leaf flip design calibrated for 100 and 200 yard ranges. During early production, a brass buttplate was fitted, but brass being a critical wartime material, was replaced by steel version. A directive was issued requiring all existing select-fire Lanchester Mk1 weapons to be converted to the Mk1* full-automatic versions, making an original select-fire Lanchester nearly extinct.

Additional Contractors

To keep pace with the wartime demand several new companies were brought on line to produce the Lanchester: W.W. Greener and The Boss Company. The two companies only produced the later fullautomatic Mk1* model.

The manufacturer of any particular Lanchester can be easily identified by the markings on its magazine housing. Sterling made Mk1 select-fire models were marked with the letter S, and a serial number prefix A. Sterling made Mk1* models were marked SA M619. W.W. Greener made guns were marked M94 with a serial number prefix G. Boss guns were marked with the name Boss or their code S 156, and a serial number prefix of H. In addition to the prime contractors, a number of other companies were subcontracted to make small parts.

The Lanchester Today

When Lanchester production was terminated during October 1943, nearly 75,000 Lanchester machine carbines had been manufactured. After the war ended a number of the weapons were sold off or given to affiliated commonwealth governments. However, many of the Lanchesters remained in the service of the British military as late as 1979. After being in service for nearly 38 years, most of the remaining Lanchesters were declared obsolete and subsequently scrapped. Only a few examples were spared for reference and museums.

A number of original Lanchesters did make their way into the U.S. NFA registry and these guns are included in the Curio and Relics list. Most examples in collector’s possession today are the Mk1* full-automatic only variation. Firing a Lanchester is quite an experience; the 9.6 pound unloaded weight of the piece together with its 9mm cartridge makes it an extremely accurate weapon in its full-autoonly mode. There is little felt recoil and virtually no muzzle climb making it a joy to fire, and easy to hold on target. The Lanchester would make for a worthy competitor in the popular subgun competitions.

The negative aspect is that the Lanchester does have a few problem areas. The firing pins and extractors are quite prone to failure, and there are few replacement parts available due to the scarcity of the guns. Currently there are no aftermarket parts available. The other downside of a Lanchester is original examples are not especially common, and like most original receiver Curio & Relic eligible subguns, they can be quite expensive.

Sten Conversions

Back in the good old days, prior to May 19, 1986, the British Sten MkII was one of the easiest submachine guns to construct. Parts kits were widely available and the receiver tubes could be easily manufactured. As a result there were a lot of Sten guns and receiver tubes produced and registered. Those familiar with the Sten know (arguably) that they are certainly not the most eye-catching of submachine guns; in fact to those unfamiliar with weapons, it doesn’t even look much like a real gun.

Fortunately, the dimensions of the Sten gun’s receiver tube allow it to be utilized in a few other more desirable configurations. Enterprising and talented Class 2 manufacturers have sought, and received, approval from the Technology Branch of ATF to turn Sten tubes into guns other than the utilitarian Sten. One that comes to mind is the popular Sten to Sterling Mk IV conversion. The Sterling is a very desirable submachine gun, but transferable examples are quite rare and those that are available are exceptionally expensive. The Sten tube to Sterling submachine gun changed the situation allowing for an affordable replica for the cost of a registered Sten tube, a Sterling parts set and labor.

Now, there is another ATF approved Sten tube conversion pioneered by Don Quinnell of Don’s Gun Shop in Ft. Myers, Florida. Sten owners now have anotheroption: Sten to Lanchester.

The Sten to Lanchester Conversion

Before any Sten tubes could be reconfigured, the conversion details needed to be worked out, documented, andsent to the ATF Technology Branch for approval. Only after receiving official authorization could the conversion work proceed.

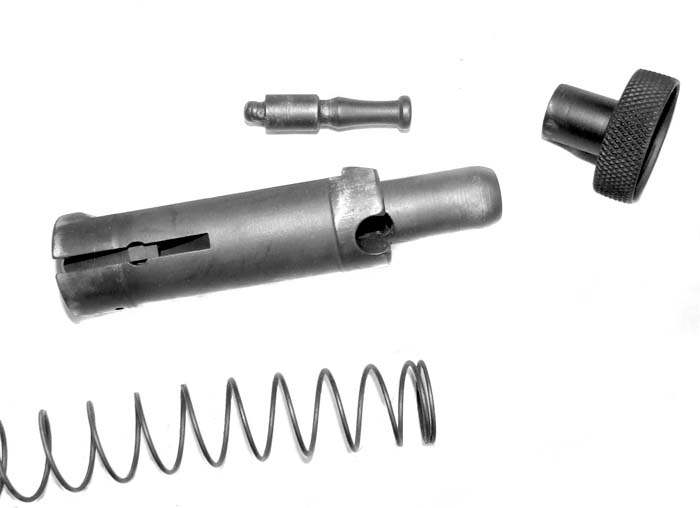

There were a few problems encountered. First of all, the cocking handle slot on a Sten tube is at a slightly different orientation than that of a Lanchester. This problem was easily overcome by using the original Sten bolt. The Sten bolt and recoil spring, inexpensive and relatively common, also addresses two design flaws of the Lanchester mentioned earlier; the firing pin and the extractor. The Sten uses a fixed integral firing pin and the robust extractor claw is nearly indestructible. To give the conversion a more authentic appearance, Don’s shop manufactures a bolt cocking handle patterned after that of the original Lanchester.

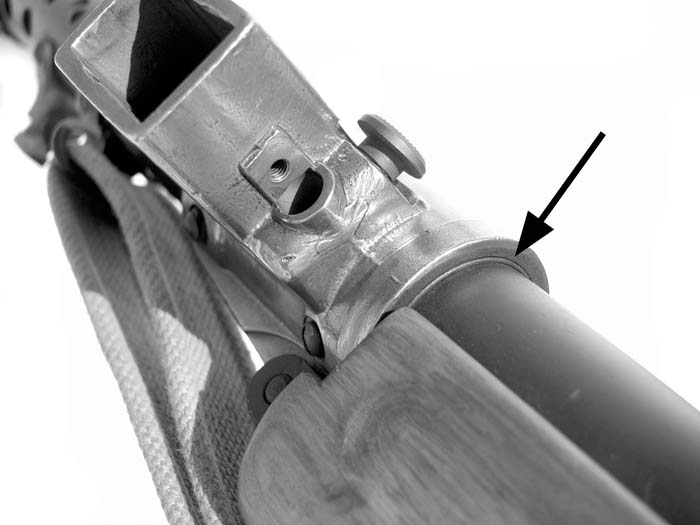

One other problem was that the Sten receiver tube has an outside diameter that is slightly smaller than that of the original Lanchester. This resulted in a loose fit between the receiver tube and Lanchester magazine housing. This was solved by using a thin .015-inch spacer installed between the housing and the receiver. The perforated barrel jacket of the Lanchester is attached to the Sten tube by welding. For attachment of the original endcap, a receiver extension with swept-style threading was fabricated and welded to the rear of the Sten receiver. As the finishing touch, the original wood stocks are painstakingly refinished, and the brass pieces polished and coated with a baked on clear coat.

Don’s Lanchester conversion field-strips like an original except for one small detail. Original Lanchester bolt handles are not removable. The cocking handle slot on a Lanchester extends to the end of the receiver, allowing the removal of the bolt assembly after unlatching the receiver and titling it to access the endcap. To remove a Sten bolt, the cocking handle must be removed before the bolt can be removed through the back of the receiver.

The Sten and Lanchester have very similar cyclic rates of approximately 600 rounds per minute. However, once converted, the Sten-Lanchester will no longer have a select-fire capability.

Don reports that his shop is currently working on a bolt conversion that would allow the use of the very reliable Sterling magazines in his Lanchester conversions. Completion of the magazine conversion would address the last weak link in the Lanchester: the magazine.

Don’s Gun Shop also performs the Sten to Sterling conversions as well as all types of fabrication, conversions and builds on semiautomatic and Class III H&Ks AKs FN-FAL, FNCs, as well as the more common gunsmith and refinishing jobs.

Sources

Don’s Gun Shop

3112-3 Palm Ave.

Ft. Myers, FL 33901

Phone: (239) 334-6779

Email: DGSMFG@AOL.COM

Other Lanchester Sources

Lanchester Reproduction Stocks

Keystone Arms

PO Box 599

Mill Rift, PA 18340

Phone: (570) 491-4867

Lanchester Display Guns and Parts

International Military Antiques, Inc.

PO Box 256

Millington, NJ 07946

(908) 903-1200

| This article first appeared in Small Arms Review V11N5 (February 2008) |