By Thomas T. Hoel, historical and technical editing by Dan Shea, Photos by Dan Shea

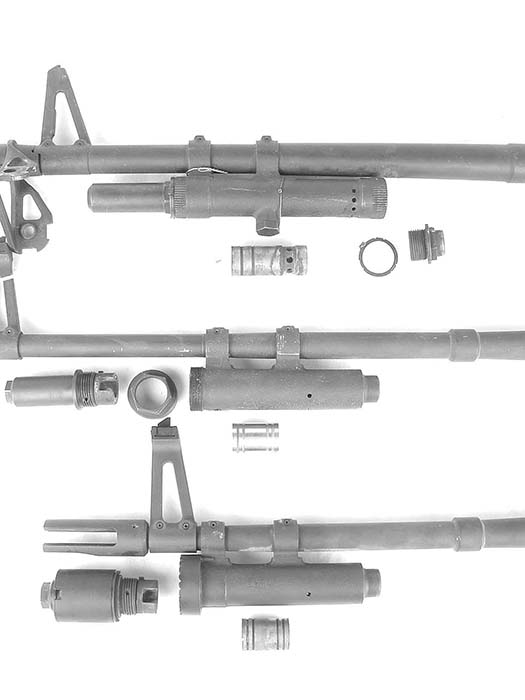

The operating system group is considered to be the heart of the M60 machinegun’s basic design, and it is here that the potential for the most common and expensive wear and damage within the whole weapon can occur. The operating system group consists of the operating rod, bolt group and the recoil/counter recoil parts. If problems with these parts, or improper operation of this group, are allowed to occur they can also greatly affect several other attendant systems within the weapon, primarily the barrel and the feed system and it’s components.

The kinetic motion of the weapon centers on the reciprocating movement of the operating rod, and the rotational action of the bolt assembly as it is driven forward and backward by the operating rod throughout the operational cycle. The bolt and operating rod are involved in a seemingly very simplistic relationship. But it is the inherently violent momentum of their interdependent movements that result in a host of wear-related problems that must be dealt with for continued reliable and safe operation.

Both the bolt and the operating rod are manufactured from high-grade ordnance steels, close-tolerance machined, stress-relieved and heat-treated to provide exceptional strength-to-weight ratios and resistance to wear and failure. Despite this, both parts will evidence clearly visible wear and deformation almost from the first time they are put into use. While it’s always unsettling for a new operator to discover these wear patterns, this is a natural occurrence and while it cannot be avoided, it can most certainly be mitigated. However, the fact that the gun quite normally “wears-in” new parts in this group, does not mean these parts should be ignored. If left unattended, these areas of galling and peening can produce dangerous stress concentrations, possibly leading to premature failure. As a consequence, all of the military manuals covering both operational field use and normal maintenance delve into this topic in great detail.

There are known locations within this system that generate wear. Together, the cam cut on the bolt body underside for the operating rod, the bolt locking lugs, and the cam ways in the barrel extension are designed to force the bolt body to rotate, both in locking and unlocking actions. The points of contact along these two camming surfaces are subject to greatly localized stresses, and will seek to spread this stress over a greater surface area. This action is what produces the visible areas of galling or peening visible on the bolt lugs, barrel extension cam ways (rare), and operating rod yoke (or yoke tower). This phenomenon was recognized early on, and several steps were taken to help alleviate the problem. The most noticeable modification was the addition of a roller bearing on the operating rod yoke, though more subtle changes were made in the angular diversion of the cam paths used, and a generalized increase in the contact areas of the individual components. If the formation, even if small in surface area, of galled or peened edges is observed, immediate corrective action is required to prevent continuing damage. Any evidence of galling or peened edges must be removed to restore the normal passage of lines of stress. There are three main locations within the system where this type of wear is observed.

First, examine the yoke tower of the operating rod along its frontal face, receiver guide ways, and the firing pin bearing channel. These surfaces essentially serve as forward and rearward travel limit stops for the bolt body at the end of its camming slot travel.

Conversely, the large mating surface area of the bolt camming groove located along the bolt body underside effectively spreads out any stresses within the bolt body there, and wearing of the sharp edges on this camming cut is unusual. Normally, a smoothly polished interior travel surface will be seen, with occasional evidence of slight surface deformation(s). In accordance with service publications such as TM 9-1005-224-23&P (or -24), visible surface burrs, gouges, or galling on the yoke tower and attendant firing pin bearing channel and receiver guide ways do not render the operating rod unserviceable, provided the damage is corrected by returning the surface(s) to a smoothly contoured area.

Experience has shown that on the yoke, the rear edges of the firing pin channel will evidence the most burring, directly above the firing pin roller bearing. (Note that the right-hand top edge, as viewed from the rear, is manufactured with a forward raked cut to the top edge; this is normal and reduces wear at this corner)

Use of the proper method for disassembly the bolt body from the operating rod yoke will greatly reduce operator induced wear during maintenance at the firing pin channel location, a major cause of premature wear here.

To correctly disassemble, invert the operating rod and bolt group, grasping the inverted top of the bolt body in the left palm, rear end facing away. While grasping the shank of the operating rod forward of the sear notch, apply pressure rearward against your left palm compressing the firing pin spring. Apply this pressure straight back until the yoke just starts to rotate…do not allow yoke to rotate. While holding the yoke firmly against rotation and firing pin spring tension, lift the forward end of the operating rod gently upward, carefully allowing the front edge of the firing pin channel to come up out of the bolt camming slot, and then slowly ease the firing pin forward to clear until it stops. Do not allow firing pin to snap forward. Done properly, neither the yoke tower or bolt body will slip out under pressure of the firing pin spring, which often times will cause gouges or burrs to form if allowed to happen. Reassembly is performed by reversal of these steps.

The second area to observe is the bolt head, and its locking lugs (and cartridge feed lug). These areas, in conjunction with the cam ways in the barrel extension, are the most stressed in the group as they bear the full intensity of the firing pressures of the cartridge. These areas encounter the brunt of the horizontal and rotational shock during bolt locking and unlocking actions as contact along these points is what starts and stops the violent rotation, and subsequent linear movement, of the bolt assembly in each direction of travel. These lugs will usually show more signs of wear than the corresponding cam ways in the barrel extension, and will be where the most attention must be directed in terms of preventative maintenance actions taken by careful removal of burrs or peening. Even more so than with the operating rod yoke, extreme care must be taken here when correcting any wear to make absolutely sure no lug contours are changed or excess material removed as safety of the locking action can be compromised. The top locking lug also forms the cartridge feed lug (cartridge stripping lug), and as such has significantly less material to start with than the lower locking lug. The top lug should always be given the closest scrutiny for any possibility that the incurred damages might not be removable by normal corrective action(s), without altering the underlying strength of the lug. The common wear pattern observed on the lugs is for the frontal surfaces to evince galling or slight burring around the sharp edges of the lug(s) where they travel in the cam ways of the barrel extension. Again, in accordance with service publications such as TM 9-1005-224-23&P (or -24) these minor deformations of the frontal surfaces of a particular lug are not cause for rejection of the bolt body as long as these areas are returned to a smooth contour.

The most severe damage that can occur to either the bolt lugs or barrel extension cam ways is in the form of cracking or chipping. Heavy gouging or deep indentations formed in this area will almost always lead to incipient cracking, and evidence of this type of damage is cause for an immediate inspection for integrity and subsequent rejection of the component. The equivalent problem may be observed along the exterior edges of the barrel extension cam ways. If any evidence of cracks, incipient cracking, or chipping, is determined to exist on the surfaces of the cam ways, a full inspection of the barrel extension (cam ways) is also immediately indicated. The only safe method for proper determination of any cracking suspected in the above areas is to subject the area to a fluorescent dye-penetrant test (with equivalency to MIL-I-25135), or MagnaFlux(r). (Virtually all aircraft service and repair shops will be able to offer these inspection procedures). If such an inspection procedure is unavailable, the only safe recourse is to replace the suspect part.

For all other cases of correctable repair, the proper remedial action is to carefully restore to a smooth surface the sharp edges of any galled, burred, or peened area by stoning with a fine grit polishing stone, without altering the basic underlying contour of the area. When using this technique great care must be taken not to alter or remove any of the underlying material, but merely to smooth out and remove the tiny displacements. (Never use a coarse grit stone or highly abrasive compound. 800 grit is an ideal basic) A final polishing of the affected area is recommended. Once these initial wear-in displacements are corrected, additional stoning is usually not required. However, if any of these components are changed, were-in problems may again arise. This may also occur if the firing pin or operating rod roller bearing are replaced. In rare instances, the spools of the firing pin may exhibit wear, which is, in turn, indicative of excessive wear of the firing pin channel edges. A damaged yoke roller bearing will cause excessive wear patterns on the inside surface of the bolt camming cut in the bolt body. It is therefore prudent to monitor these areas as well for additional signs of galling, burring, or peening, if any of the component parts of the operating system are exchanged.

The operating rod both retains the bolt and helps to cause it to rotate by a camming action as it is driven back and forth. The bolt is also supported and guided in its reciprocating movement by the feed-cam actuating roller, which is supported by the two bolt guide rails that form an integral part of the receiver. The gas tube, lower receiver operating rod supporting rail, and the bolt guide rails are the primary vertical support members for the operating rod and bolt assembly. Smooth and unbinding free movement along these paths of support is critical for correct functioning of the bolt and operating rod. It is always recommended to inspect these areas first, if wear begins to appear on either the operating rod tower or the bolt lugs. A simple lack of proper lubrication can cause excess drag along these supporting areas, which may lead to sluggish operation of the weapon in general, or failure even to fire a chambered cartridge. Lubrication of the operating group and its supporting components is critically important.

For virtually the entire military operational use of the M60, there have only been two normally approved MIL-SPEC lubricants, LSA and CLP. LSA (Lubricating oil, Semi-fluid, Automatic weapons, MIL-L-46000B) is a medium weight lubricating fluid, actually an emulsified mixture of multi-grade lubricants designed to provide effective lubrication protection over a wide range of atmospheric and temperature extremes. LSA was approved for field use in virtually all small arms in inventory and is a substantially effective general weapons lubricant when used in areas appropriate for its composition and formulation. Due to its chemical composition, LSA stocks that have been allowed to sit idle for any length of time will drop out of emulsion; to restore the lubricant to its full specification the mixture must be vigorously shaken, by mechanical means preferably. (To restore small quantities, individual containers can be heated in boiling water for a short period, or placed in a microwave oven set on Low for several seconds, and then shaken by hand.)

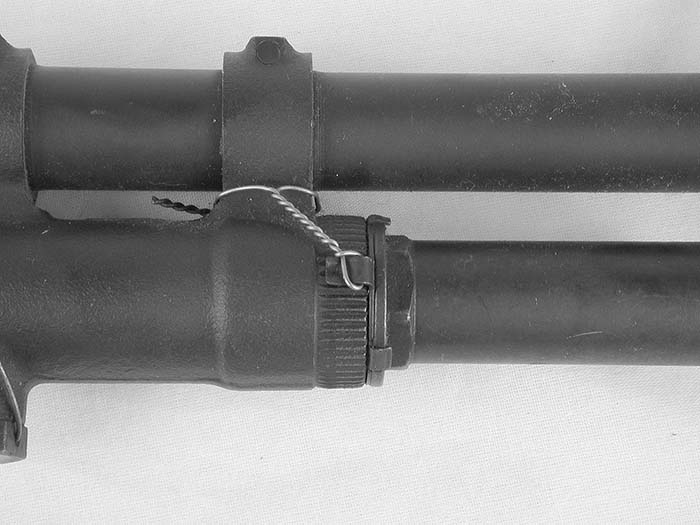

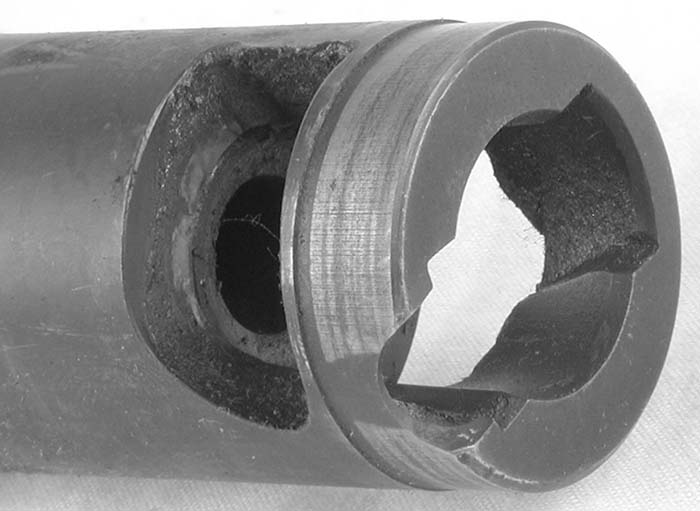

Standard M60 GPMG gas cylinder. This one is particularly nasty and came from a very old barrel that hadn’t been cleaned since the Stratford Hollow shoots, left in the back of a travel box. Note the scale and carbon build up, that made it necessary to drive the piston from the system with a rod and hammer. This is a prime example of a piston that would not slide when the barrel was tilted. It is not, however, beyond saving. Some good old fashioned cleaning solvent and scrubbing, and it will be usable again.

CLP (Cleaner, Lubricant, Preservative, MIL-L-CLP) was adopted to address what were considered to be shortcomings when maintaining weapons with the previous standard combination of LSA and RBC (rifle bore cleaner, MIL-C-372B or C). CLP is a complex formulation of cleaners (powder solvents), synthetic and natural lubricants, and anti-rusting and anti-corrosive (anti-acidic) compounds. While touted as a miracle formulation, CLP in general and widespread use has proven to be less than satisfactory for any of its intended uses. Its primary value as a weapons lubricant is dependent upon micro-grannular deposition of DuPont™ Teflon® (a fluoropolymerized lubricant) particles carried in suspension. When proper deposition of these minute particles occurs in the grain structure of a treated metal surface, the resulting lubrication properties are phenomenal. The main problem has been that successful Teflon® deposition rarely occurs and the remaining petroleum-based carrier fluid is not an effective lubricant, leaving much of the weapon unprotected from accelerated wear. It is mandatory that bulk concentrations of CLP be thoroughly agitated before use to efficiently distribute the Teflon® particulates in uniform suspension. For maximum Teflon(r) adhesion and deposition, the area(s) to be treated must be cleaned down to the bare metal surface with no trace of prior lubricants or preservatives remaining. Additionally, CLP does not achieve its’ maximum potential lubricity without numerous, long-term, continued applications.

Both LSA and CLP have their places and can be used effectively, although LSA is a far better choice for general lubrication of small parts if thorough cleaning and complete re-lubrication cannot be accomplished after every shooting session.

Neither LSA nor CLP are the best lubricants for several locations on the M60. On small parts, with small surface contact areas and low operating contact pressures, they are sufficient, but for large contact areas under heavy pressures another lubricant type is preferred for civilian use of the weapon.

Just as was found with long term experience with the .30 M1 Garand, .30 M1 Carbine, and M14 rifles, the use of any lubricant other than a heavy weight, high viscosity, grease for the bolt and operating rod contact areas led to immediate and disastrous problems. These critical parts often “froze” when used with lightweight lubricating fluids, even in ideal atmospheric conditions. The similarity of the operating components of these weapons to the operating system in the M60 suggest the same lubricant choice in certain highly stressed areas such as the operating rod yoke, bolt camming cut surfaces, bolt locking lugs, barrel extension cam ways, bolt and operating rod guide rail slots, feed cam actuator roller, and feed cam lever. The benefit of using such a high viscosity, extreme pressure, type of lubricant on these areas is that even under extreme operating conditions the lubricant will tend to stay where it is needed, continuing to provide vital lubricity.

The military standard for such applications is the unsurprisingly named MIL-SPEC lubricant, Rifle Grease (Grease, Rifle, MIL-G-46003 (ORD) Amend. 2). GI Rifle Grease is a high-grade, high-viscosity, temperature-stabilized, all-petroleum base lubricant with exceptional qualities for extreme pressure use and is formulated with anti-rust and anti-oxidant properties. While no longer a MIL standard lubricant, it is widely available as surplus stock. If GI Rifle Grease cannot be found in sufficient quantity for cost-effective use, it is also acceptable to use a more modern substitute. These products should conform to NLGI No. 2 multi-purpose applications, and will usually be found as a lithium-12 hydroxide base, molybdenum disulfide bearing, and extreme-pressure grease, such as generic automotive “wheel bearing grease.”

Liberal, but careful, application of this type of high-viscosity lubricant will provide long-term benefits significantly greater than if the weapon is maintained solely with CLP, LSA or other lightweight lubricants. Synthetic weapons lubricants such as MilCom TW-25B, and other such purpose-designed lubricants, are excellent for general use on the components of the M60, for those weapons in military use. However, civilians are not bound to consider all the same operational considerations as a military user, and use of the high-viscosity greases are more beneficial on certain components.

The last area of the operating system we need to consider is that part of the operating rod group that interacts with the fire control mechanism and counter recoil components.

The firing mechanism of the M60 is a relatively basic and straight forward design employing a simple spring loaded, single form sear which acts in combination with another simple machined cut on the underside of the operating rod. The sear is pulled into or out of engagement with the sear-cut on the operating rod by mechanical action with the movement of the trigger and its spring, and the sear spring. At least, that was the intention of the design. In use, however, the firing mechanism has two idiosyncrasies that must be understood and examined. The following applies to any variant of the basic design, and although with the M60D aircraft weapon variant the trigger is replaced with a linkage and trigger bars, the actions involved are exactly the same as in the ground guns.

The sear engagement surface cut on the operating rod underside is neither overly large, nor particularly aggressive, in its engagement with the sear. This has led to a reasonably accurate branding of the weapon as being prone to experiencing “run-away” operation. While the inherent design does indeed play into it, there are a few things the operator can do to prevent the situation from happening. As a relationship of the way the sear is forced to engage and hold the operating rod to cease firing, the operating rod sear engagement cut is placed under considerable impact loading which can over time cause the face angle to distort, lessening the available engagement contact area. This may continue to the point that the mere impact of the operating rod hitting the sear nose will cause the face on the rod to simply jump over the sear nose allowing the gun to fire additional rounds. The successful engagement of the sear with the rod face is dependant upon the nearly perpendicular mating of the two surfaces, any proclivity for either face to lessen that angle of contact through damaged contours, may be enough to prevent the trigger mechanism from holding fast the operating rod. While a certain amount of this distortion is unavoidable, the greater part of this wear is unnecessary. The most important thing any operator can do to prevent wear of these surfaces is to control the trigger mechanism in such a way as to prevent the two surfaces from experiencing “casual contact” as the gun operates. “Casual contact” occurs when the operating rod sear notch comes into partial contact at any point with the sear nose. This will inevitably cause frictional wear and low-level impact loading, forming galling or peening of the top edges of these surfaces, and greatly increasing the tendency for a run-away. For the sear nose and operating rod to function with the least amount of contact wear, they must never be allowed to contact each other, except when placed into sudden, full and complete engagement. Too often operators will not fully activate the trigger, allowing a small portion of the sear nose to continue projecting into the path of operating rod as it cycles. The gun will fire in this condition, but accelerated wear of the firing control parts is guaranteed also. The give-away is to view the underside of the operating rod and see if there is a polished track along its bottom edge. There should only be evidence of contact at the sear engagement notch, and nowhere else. If a polished track is present, the sear nose, via the trigger action, was not being pulled down out of the way. Again the correct remedial action is to restore these surface faces and remove the damage, without altering the underlying angular relationships of the base contours. Past a certain wear point, this may not be possible and replacement of the component may be required.

On the other end of the firing control spectrum is another problem that may result in a run-away gun. The sear must rise forcibly into the path of the operating rod in order to engage and hold the rod to stop firing. The sear is under spring pressure to provide upward vertical travel of the sear nose. In order for the trigger pressure to be within acceptable limits (trigger pull should be tested to be within a 6.0 lbs minimum, 11.5 lbs maximum), this spring cannot be overly powerful. When a run-away gun is encountered, the first item to check is the sear spring. Examine the sear spring to be sure it is not broken, or damaged. Additionally, serious problems can arise if the sear spring has taken a set over time. It can progress to the point where the operating rod is able to over-ride the sear nose if it is not being pushed far enough upward. Sear springs are an often-overlooked maintenance item, but should be routinely replaced with a progressive maintenance policy every 3,000 rounds at least. It is also acceptable to replace the stock spring with a custom spring with a higher spring rating. The compression length must remain the same to prevent jamming of the mechanism. Proper trigger manipulation combined with a higher rate custom sear spring will greatly increase the useful life span of sears and operating rods as they will encourage proper, full face surface, engagement of the two parts.

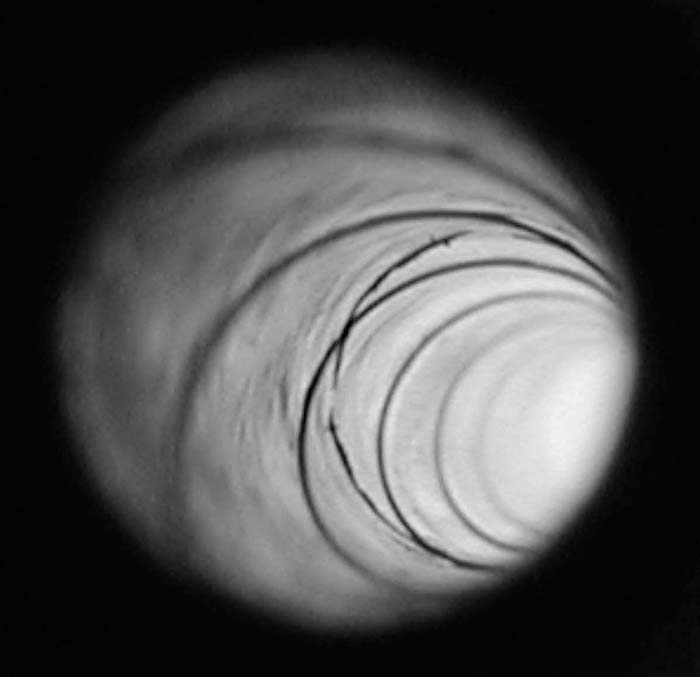

Finally, the recoil spring should be inspected. There are two variants of recoil springs currently available, and each has its own advantages and disadvantages. The gun was originally fitted with a multi-strand spring to combat the well-known tendency for single wire coil springs to potentially lose some of their strength rating due to spring wrap. The use of a multi-strand spring is exceedingly effective in the M60. However, with use it can become damaged as the spring itself is in nearly full contact with the inside surface of the operating rod tube and over time this will cause wear to occur in the form of flat spots There is nothing that can be done to totally prevent this from happening, it is inherent in the design of the recoil system. In order to allow the spring to deliver its greatest possible useful life, the coils should be checked often for flat spots, and the spring wire itself should be rotated to a different indexing each time the gun is disassembled so that wear is spread around the full exterior of the wire rope coils as much as possible. It a flat spot has completely worn through one strand, or is close to doing so, the spring should be replaced. The newest single strand coil spring introduced with the E3/E4 variants is intended to help eliminate the flat spotting associated with the wire-rope type spring. While the new spring design is also quite efficient, the single strand spring also requires the use of its own dedicated guide rod as the coil wire diameter is different than the older version spring. The new style spring can also be prone to wear, and is more susceptible to spring-wrap damages if strained. If this occurs, it can jam inside the operating rod spring tube, and become difficult to disassemble.

Although either version of main recoil spring is serviceable in the civilian realm, the surplus older style wire-rope springs are much less expensive and no new guide rod is needed. For use of either type recoil assembly, the spring guide rod should be smooth and free of any nicks or burrs that may catch a wire strand. Polishing of the spring guide rod to eliminate as much friction as possible is beneficial. Also, liberal use of lubricant inside the operating rod tube, the spring, and along the spring guide rod is recommended to enhance spring life, as long as this excess lubricant is thoroughly cleaned after each shooting session to preclude accumulation of abrasive material.

The recoil buffer unit and its retention yoke must also be inspected. The buffers in use since the mid-1960s and currently still issued are sealed hydraulic spring type, and essentially are maintenance-free except for periodic inspection for damage, including leaks. If the buffer starts to fail, often the first sign will be marked increase in pounding felt at the shoulder stock by the operator, The buffer retainer yoke will also begin to deform in a backward direction. If left unattended, the yoke may cause damages to the receiver channel and guide rails, along with the butt stock eventually. If the rear face of the butt stock appears dented or deformed outward, immediately inspect the buffer assembly and buffer retainer yoke. If any obvious signs of fluid leakage from the buffer body are present, replace the entire buffer unit.

The buttstock itself is supplied as a manufactured assembly, and cannot for all practical purposes, ever be disassembled or repaired beyond minor touchup of the finish. Individual spare parts are simply unavailable for this assembly, unless from a salvaged unit that has been broken down.

This brings us to the last and final area of consideration on the M60, which we will cover in Part 5 next month. It is an area that results in the most common problems and the costliest repairs for the civilian owner, yet virtually all of these problems are avoidable.

| This article first appeared in Small Arms Review V7N5 (February 2004) |