By Christopher Bartocci

Since the introduction of the Colt Commando and XM177-series carbines, the U.S. military has had a need for a compact version of the M16, the longest serving small arm in U.S. history. Even though never officially adopted, these carbines saw extensive use in every theater of operations the U.S. and her allies were in.

(Photo by Petty Officer 2nd Class Robert M. Schalk. U.S. Army photo)

In 1985, U.S. Government contract DAAA21-85-C-0192 was awarded to Colt for the development of the XM4 carbine, the first general-purpose carbine since World War 2. The contract had very specific wording in regards to parts commonality with the newly adopted M16A2 rifle. Particular effort was made to keep as high of a number of parts compatible with the M16A2 as possible. As first envisioned, the XM4 was to be used for troops who could not carry a rifle but needed more firepower than a handgun. It was to fill the same role as that of the M1 Carbine.

Parts Commonality as Defined by DAAA21-85-C-0192

Specifically stated in the requirements was that the carbine would utilize the newly adopted M855 ball cartridge as well as be functional with existing M193 ball ammunition. The barrel will have the same 1 turn in 7 inch rifling twist as the M16A2 and be 14.5 inches in length. The barrel must be made to accept the current MILES shooting simulation equipment as well as utilize the M16A2 compensator. The carbine must have the 3-round burst limiter of the M16A2. The polymer furniture must be made of the same high impact material as the stock, pistol grip and hand guards of the M16A2. The upper and lower receivers are to be the same as the M16A2 amongst many others.

The parts commonality requirement was troublesome to Colt engineers but they understood the government’s position. With over 7 million M16-family of weapons in service at the time, they did not want to make any dramatic changes to an already proven design. Owing to the different operating characteristics of the carbine, Colt felt there should be some changes. Due to the gas port being so much closer to the bolt, higher pressures existed in effect, significantly increasing the cyclic rate of fire. This caused issues with bolts breaking, bolt carrier bounce, failures to extract as well as feed. However, the government was very much stuck on interchangeability over durability/reliability. Colt engineers felt that a redesign of the bolt and barrel extension would significantly enhance the carbine’s performance but this would have been a major violation of the interchangeability requirement.

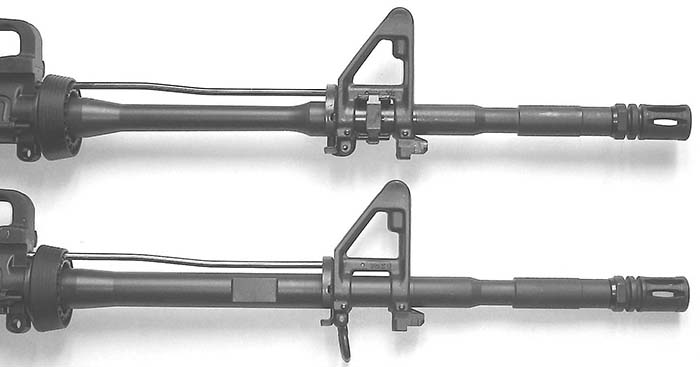

During the development phase, Colt engineers found certain changes that must be made for the carbine to function reliably. One of the first improvements made to the XM4 was to correct failure to feed. Due to the shape of the M855 bullet and the higher cyclic rate, the cartridge would stall where the barrel extension met the upper receiver. To correct this, both feed ramps were extended on the barrel extension as well as the upper receiver. After much experimenting with buffer designs, a new buffer was implemented to combat the bolt carrier bounce issues during burst fire. Because of the higher cyclic rate, as the bolt carrier moved forward, the bolt would lock releasing the automatic sear in turn releasing the hammer to strike the firing pin. But at that moment when the carrier struck the barrel extension it would bounce back just enough to disallow the firing pin enough clearance to strike the primer. Thus, a new buffer was adopted for use in the XM4. This new buffer (H) would remove one of the steel weights and replace it with a weight made of tungsten weighing nearly twice that of the standard steel weight. This extra mass slowed down the cyclic rate on the closing stroke eliminating the problem.

Another requirement was to have an increase in the carbine’s ability to dissipate heat, keeping the shooters hand cooler during firing/handling under normal conditions. To answer, Colt’s Henry Tatro developed a hand guard (U.S. Patent No. 4,663,875) with double heat shields.

Several other parts were modified to increase reliability such as the burst cam, stock and ejection port dust cover. The first production M4 carbines were delivered with standard M16A2 fully adjustable rear sights. This was soon to be replaced with the Mil-Std-1913 flat top upper receiver. The M4A1 carbine would only be issued with the flat top upper.

The true “heart and soul” of the M4 carbine is the Mil-Std-1913 flat top upper receiver. The Colt/ARMS, Inc. designed flat top upper receiver and dovetail is the modularity of the carbine. This enabled the use of an entire new generation of advanced optics including reflex sights, thermal sights, optical sights as well as night vision. The dovetail enabled optics to be mounted at a comfortable eye level rather than the awkward mounting of an optic on top of the carrying handle of the standard A1 and A2 sights.

The Adoption of the M4 and M4A1 carbines

On August 15, 1994 the U.S. military adopted the M4 and M4A1 carbines. The only difference between the two is the M4 has a “burst” setting and the M4A1 has an “auto” setting. The vast majority of M4A1 carbines would be manufactured for the United States Special Operations Command (SOCOM).

The military specifications were drafted for the carbines including the inspections to be performed by Colt personnel as well as the on-site government inspector. The specifications state the endurance tests and allowable malfunctions per lot. The mil-specs have also written the processes of proof testing and magnetic particle inspecting of all barrels and bolts.

As of this writing, Colt has provided the U.S. military with an excess of 340,000 M4/M4A1 mil-spec carbines with tens-of-thousands more on order. This does not include foreign or law enforcement sales.

The Finalized M4 Carbine

The M4 carbine is a lightweight (5.9 pounds unloaded), gas operated, air cooled carbine capable of semi-automatic and burst fire (auto for the M4A1). Nearly 25% of the components of the M4 are not interchangeable with the M16A2, M16A3 and M16A4 rifles. With the telescopic stock fully extended, the carbine is 33 inches long and with the stock closed, 29.8 inches. The carbine uses the direct gas or gas impingement system utilizing an “exhaust pipe” that goes from the front sight assembly (where the gas port is located) back to the bolt carrier. The expansion chamber is located in the rear of the bolt carrier between the rear of the bolt and the front of the inside of the carrier. This creates a hammer-like blow that drives the carrier rearward unlocking the bolt, extracting and ejecting the fired cartridge case. The spring loaded buffer is compressed on its rearward motion and then drives the bolt carrier group forward stripping a cartridge off the top of the magazine, feeding, chambering and finally locking the bolt into the barrel extension. The benefit of this system is lightweight and accuracy. The barrel does not have some heavy piston attached to it preventing the natural barrel harmonics affecting accuracy. The drawback is that it directs fouling into the bolt carrier. This requires more frequent maintenance with extended use and is cleaned with normal cleaning solvent and brushes. Millions of rounds have been fired through the XM4 and M4 carbines in test conditions and this carbine is the preferred weapon by U.S. Forces.

Government Procurement

Once adopted by the military and the TDP finalized, the M4 went into production in 1994. Once in production, modifications or improvements would be extremely difficult for Colt to make. Any change would have to be authorized by Rock Island Arsenal and if the military in general were pleased with the performance they would not authorize any changes, particularly ones that add new parts to the inventory or create interchangeability problems with current weapons.

Popular belief is that the M4 carbine has not been improved by Colt since its adoption. Throughout the M4 design and procurement, Colt has proposed changes and updates for the M4 only to be overruled. An excellent example is the belated adoption of the “M4 Extractor Spring” which is identified by its gold color. Colt had redesigned the spring to give significant more strength, which is a major reliability enhancement in the carbines. Rather than adopt a new spring, which Colt was installing in all of their rifles and carbines except the one being delivered to the U.S. Department of Defense, the military put M231 Port Firing Weapon extractor springs in the M4s, just so as not to add a new part to the inventory. It was not until mid 2003 that this important reliability enhancement was authorized by Rock Island Arsenal and implemented into production. During the development phase of the XM4, Colt engineers proposed modifications to the bolt and barrel extension that would make the carbine handle better when being fired with water in the barrel. This idea was rejected by the government for reasons such as a violation of parts commonality and that they could not justify the cost/benefit of the change. They felt that the number of occasions that the weapon would be called upon to fire under such conditions was minute. Colt was overruled. Colt would not revisit this reliability enhancement until the development of their SCAR entries, which had “Over the Beach” requirement.

Without the direction or request from Colt’s customer, the U.S. Government, to make changes and improvement, Colt would not invest large amounts of resources into improvements if their largest customer would not accept them. Colt had proposed changes to the Army for a redesign of the bolt and related components to increase durability and reliability. Colt estimated the two year project would cost between one-half and two million dollars. Due to lack of funding as well as lack of government interest, the project never commenced.

There are two very different types of troops using the M4 family of carbines. The U.S. forces at large are very happy with the M4 carbine and prefer it to any other available weapon. The Special Operations Forces operators have been displeased but use them in a very different way from the rest. This situation makes it difficult for Colt to address SOCOM’s needs and make modifications. The M4, coming from an existing family of weapons, caused and still causes great difficulty to design the carbine to function to it’s potential with the requirements for interchangeability and the current attitude towards making changes within the government. On March 1, 2000, the Project Manager at Rock Island Arsenal stated, “The M4A1 carbine is already 3 times as reliable as called for in the specifications.”

SOCOM Taking the M4 to the limits and beyond.

As previously stated, the M4 was to be a lightweight carbine that was to be used by people who could not carry a rifle but needed more firepower than a pistol. However, once the M4A1 got into circulation within the special operations community the compactness, modularity, ease of operation and performance was immediately seen and they adopted the M4A1 as their main weapon. They would admittedly push the carbine well beyond its design intent.

SOCOM began reporting durability issues with their M4A1 carbines including blown barrels, broken bolts, failures to extract and over heating. None of which the regular Army units nor anyone else in the U.S. military were experiencing. Investigations immediately began by Rock Island Arsenal to determine if these problems were in fact problems with the design or manufacturing process of the carbine, or if the carbine was being used beyond its design intent. At this point, Colt was not able to make any changes to the firearm without this determination. The M4A1 is procured by the U.S. Army and subjected to the TDP. Any changes or improvements requests/requirements would have to be made by the U.S. Army, not SOCOM. This is the major difference between SOCOM employing a standard issue weapon versus them procuring their own weapon. By procuring their own weapon they are the customer and can make changes as they see fit. This is the case of the SCAR but not with the M4A1.

The first major investigation found the issue regarding blown barrels was clearly due to excessive operation beyond what the carbine was designed. The M4A1 was being used as a light machine gun or a SAW (Squad Automatic Weapon) laying down large amounts of cover fire. The barrels would reach their transformation temperature that is between 1,100 and 1,375 degrees. At these temperatures the barrel becomes soft and loses its heat-treating. Structural failure is just a matter of time. According to Rock Island’s testing, to get the barrel to this temperature you would have to fire 540 to 596 rounds within 3 to 3-1/2 minutes. The average infantry soldier does not carry this much ammunition as his combat load – the average being 210 rounds. This was clearly beyond the capabilities of a lightweight carbine and Rock Island Arsenal felt that this was not a deficiency in the design or manufacture of the weapon. Due to this type of use, Colt now provides all M4A1 carbines with a heavy barrel designed by Rock Island Arsenal and improved buffer to cope with this type of use. Recent interest has been given to the superiority of cold hammer forged barrels such as that used by H&K, IMI and Glock. The question has been asked, “Why does the M4 not have a hammer forged barrel?” The answer is very simple. Colt has offered them to the government and been rebuffed. Diemaco in Canada, now owned by Colt, has made them for the Canadian military since 1983.

Many SOCOM groups have problems with maintenance of the weapons, in particular replacing worn out components. One SEAL team said they did not keep track of malfunctions during missions to report back to an armorer to have the weapons fixed. Additionally, the training weapons that these operators use are the same ones they take into combat. The barrels and bolts have an unknown number of rounds through them. SOCOM operators fire an average of 24,000 rounds per year in training alone. Most all of the criticisms regarding this weapon system have come from a small element within the SOCOM community.

This weapon system has been in use with the British Special Forces for quite sometime. The SAS use the SFW (Special Forces Weapon) manufactured by Diemaco (now Colt Canada). These specialized carbines beat out Heckler & Koch G36 (identical operating mechanism to the HK416 and the XM8) and the SIG 500 series rifles and have seen action in both Afghanistan and Iraq. Unconfirmed reports say that the British Special Forces spent more money on the test and evaluation of these weapons than they did on the weapons they procured when the award was given to Diemaco. In addition, Diemaco (Colt Canada) has been asked to quote on weapons to replace the “perfected” L85A2.

The M4 is the preferred weapon for American forces overseas and the biggest problem they have with it is that there are simply not enough to go around. Clearly SOCOM needed their own weapon that would be suited for their requirements and that did not materialize until recently with the issuance of the SCAR developmental contract. Many people in the community speculate that the SCAR competition was conducted purely to keep the Program Executive Officer Soldier from forcing the XM8 on SOCOM.

Further Advancements at Colt

Colt has now split off into two companies. Colt Defense LLC is committed to military and law enforcement sales and Colt’s Manufacturing Company focus is the commercial market.

Colt Defense LLC is dedicated to providing military small arms throughout the world to the United States military and allies as they have done for nearly 170 years. Colt Defense has been diligently working on many military programs such as the SCAR program in which they submitted three entries. The SCAR (Special operations Combat Assault Rifle) program was, without a doubt, the most grueling firearms test ever conducted anywhere in the world. It was unwritten but clear that SOCOM wanted a piston driven mechanism. Colt developed a rifle with a piston mechanism as well as two direct gas rifles. The contract was awarded to FN Herstal of Belgium. Colt’s entries came in 2nd, 3rd and 4th. These are some of the most advanced military small arms in the world. Currently, Colt is working on a submission for the OICW and has plans to introduce a piston-operated Law Enforcement Carbine in early 2006.

In May of 2005, Colt purchased Diemaco from Heroux Devtek in Canada. Now called Colt Canada, Diemaco has been a supplier of parts to Colt for several years due to Diemaco manufactured mil-spec components from the Colt TDP. With the acquisition of Diemaco, Colt will take advantage of their excellent research and development team as well as their state of the art manufacturing facility.

Some sources would lead you to believe that the future of Colt and the M4 is on uncertain ground. The reality is, however; the U.S. government has recently placed a $55,000,000 order for M4s, to be delivered within 12 months, in addition to other large quantities of M4s for delivery in 2005 and 2006. With the U.S. military looking at a replacement weapon for the M16 and M4 family of weapons, their days could be numbered. However, if history has shown us anything in the last 40 years is that the military has tried to replace this family of weapons before. The ACR or Advanced Combat Rifle program of the mid 1980s for example. This was a trial of truly advanced weapons involving new types of ammunition including caseless, duplex and flechettes. The baseline rifle was the Colt M16A2. In the end, nothing achieved better combat performance than the baseline M16A2. The M16A2 has gone on to evolve into the M16A4 and the M4 carbine and, if given the opportunity, has much life left in it. This is why this family of weapons has been around for so many years because it evolved to the changing modern combat conditions. It would be far better for the U.S. military to improve the M4 and to keep the combat proven family of weapons than to invest in a new weapon that is not compatible with any of the current optics, mounts, magazines and SOPMOD components.

Now what of the future? The XM8 is not new or advanced but based off another Stoner designed weapon from the early 1960s; the AR18. Another unanswered question is why the government is spending money on a foreign weapon development without even the rights to the design. This was an issue that Colt dealt with during the Vietnam War. The decision was made in 1968 to sell/license the government the rights for the M16/M16A1 so if need be there could be other suppliers in case of a national emergency to procure needed small arms to equip our soldiers. Will there be enough of advancement in technology to justify the change to a new weapon? It hardly makes sense since the same ammunition is used so no difference in lethality or range. The U.S. military’s current weapon systems have been combat proven in every theater in the world. The M16/M4 families of weapons have long proven themselves the hard way: on the battlefield.

| This article first appeared in Small Arms Review V9N10 (July 2006) |