By Jean Huon

Less known and less widespread than the Uzi, the Czech VZ 23 SMG, and others, were the first to bring important technology innovations in the design of this type of weapon.

It is at the end of the World War that the first machine pistols appeared. In a sense resembling small rifles, they were manufactured according to traditional methods with machined steel parts and fitted with a wooden stock. Among these first models were the Italian Beretta 1918, German MP 18 and, a bit later, the American Thompson.

Along with these first models, in the 1920/1930s, many other weapons appeared, again using the same process to produce the likes of the STA 1924, Steyr, Bergmann, Star S.I 35, Erma, Beretta 1938, MAS 38, PPD 40, etc.

A new era was introduced by the Germans in 1938 with a more modern weapon using newer technologies with stamped sheet metal, aluminium and plastic and was followed by the MP40. Other countries also introduced efficient manufacturing technologies and materials resulting in guns such as the Sten, PPS43, M3 and M3A1. Some post-war weapons took a similar design such as the Star Z-45 star, MAT 49, Vigneron, etc.

At the end of the 1940s a new design was developed: a hollow breech and a magazine introduced into the handgrip. The gun became more compact, the firing hand is placed at the center of gravity and a better balance of the mass limits the effects of the recoil.

This design appeared for the first time in Czechoslovakia from its inventor, Vaclav Holek, and the first applications were the CZ 148, 447 and 476, which were the forerunners of the VZ 23 and 25; built in 9mm Parabellum. About the same time, a similar design was made in Israel by Uziel Gal.

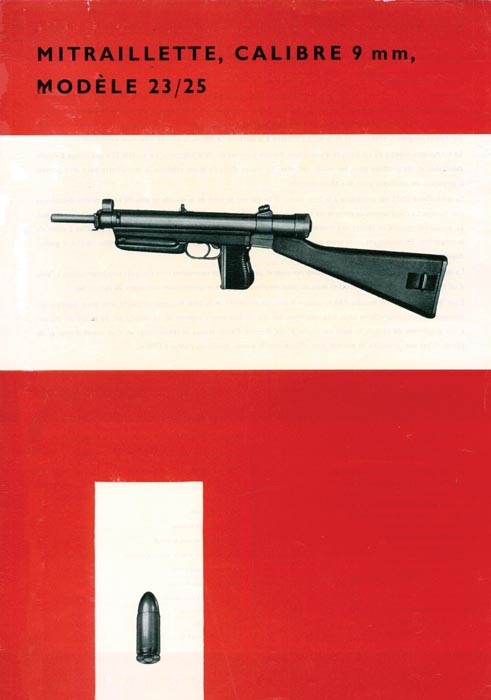

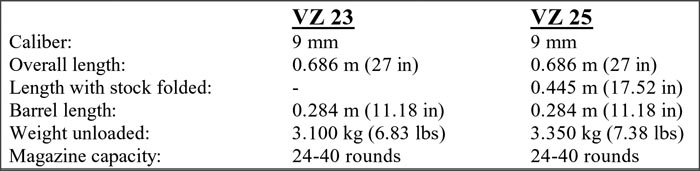

VZ 23

The VZ 23 is made of many stamped sheet metal parts. Only the barrel, bolt and some secondary parts are machined. The first models were blued and later models were painted gray.

The receiver frame is made of a 40 mm diameter tube (1.57 inches). The ejection port is located on the upper right and the slot for the cocking lever is on the left. The rear part of the tube has a plug and the barrel screw is located at the front. Beneath the receiver tube frame is the magazine housing; which is also used as pistol grip, and the trigger mechanism containing the trigger, sear, safety, their pins and springs.

The triangular stock is made of wood with a sheet metal butt plate. This stock is fixed on the frame with a machined collar installed behind the grip.

The bolt is made from a machined massive block of steel, tooled with a big hole in its main central part, which moves around the barrel that gives a better balance during shooting. The bolt is fitted with the extractor, firing pin and cocking lever.

The small diameter recoil spring is fitted with a rod and is located on the left side. The rod is installed on a circular rear plate that also acts as the ejector.

The barrel is particularly long compared to the overall length of the weapon. It is bored 9mm and has six right-hand grooves. It is secured in place with a threaded muzzle nut at the front end of the frame.

The front stock is made of a mixture of wood and phenolic resin, as is the pistol grip. On the right side of the front stock is a stripper guide that holds ten rounds and allows feeding into the magazine.

The rear sight is made of a four sided oblique rotary drum marked for distances from 100, 200, 300 and 400 meters. It is affixed to a collar that is welded to the collar that the stock is affixed to. The front sight is a blade protected by a hood and is located at the front of the frame.

The gun works with a blow-back bolt and has two safety devices: the cocking lever, pushed by a spring, locks the bolt in the front position and has to be pushed down before cocking; and rotary lever locks the trigger when it is pushed to the right.

Loading is made with a vertical box magazine introduced in the pistol grip. The capacity of the magazine is 24 or 40 cartridges.

On the left face of the stock is a lug that is intended for mounting a sling, and a ring is located at the left front end of the frame.

VZ 25

The VZ 25 is a variation with a metallic stock that can be folded on the left side. It is made of an aluminium rod with a sheet metal folding butt plate.

When the stock is folded it is locked by the butt plate on a hook located below the front swivel. The SMG can be fired from the hip with the stock folded, using the butt plate as a front pistol grip for the second hand.

VZ 24 and VZ 26

The VZ 23 and 25 were used by the Czech army until 1952. After this date, Czechoslovakia was forced to align its armament on that of the Soviet “big brother.” The result was the development of two new submachine guns using the 7.62mm Tokarev cartridge: the VZ 24 with fixed stock and the VZ 26 collapsible stock. The result was two new weapons because simple conversion was not possible because: the 7.62mm barrel has four groves; magazine dimension are 40×24.7 mm instead of 35×24.8 mm (1.57×0.97 inches instead 1.38×0.98 inches); the magazine housing is inclined 87° and 90° on the other model; the base plate of rear sight is welded directly on the frame as the collar which connected it to the stock support disappeared; a 32-round magazine was retained and the VZ 24 and 26 are five ounces heavier than VZ 23 and 25.

Markings

The VZ 23 and 25 are marked with the year of production over “she” over the serial number located on the left side of the stock collar that is welded to the rear of the receiver tube. The VZ 24 and 26 are marked “she” over the serial number over the year of production and is located on the left side at the rear of the receiver tube.

Accessories

The VZ 23, 24, 25 and 26 were issued with a green fabric sling with leather ends, two pouch pockets each holding two magazines for a total of four, and a cleaning kit.

Service Use

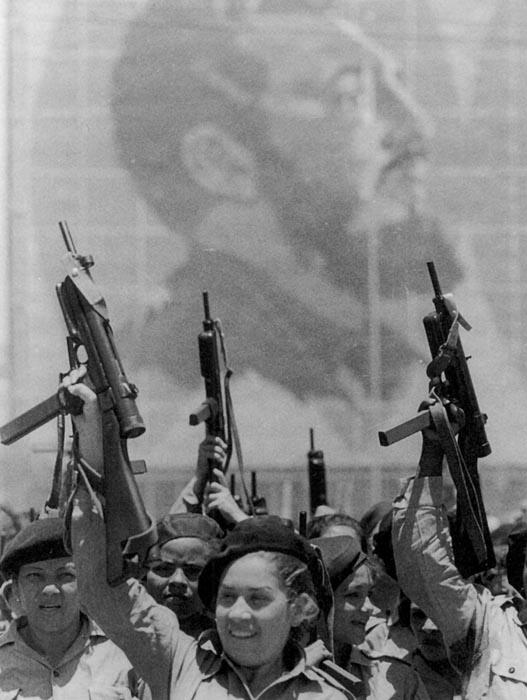

The VZ 23 and 25 remained in service in the Czech Army until 1952. After that, the VZ 24 and 26 were used by the Czechs and other countries of the Warsaw Pact, such as Rumania. The VZ 23 and 25 were widely distributed all over the world. They were seen in Cuba, Syria, Nigeria, and in the hand of terrorists such as the Irish IRA and Basque ETA.

Disassembly-Reassembly

- Remove the magazine and clear the weapon.

- Push the centre of the rear plug with a cartridge or any other tool, and turn the plug to remove.

- Push down the cocking lever and extract to the rear the bolt, recoil spring and rear plate assembly.

- Remove the recoil spring, rod and rear plate from the bolt.

- Using the bolt as a tool, unscrew the nut that retains the barrel.

- Remove the barrel.

- Reassembly is carried out in the inverse order.

| This article first appeared in Small Arms Review V13N2 (November 2009) |