By Dan Shea

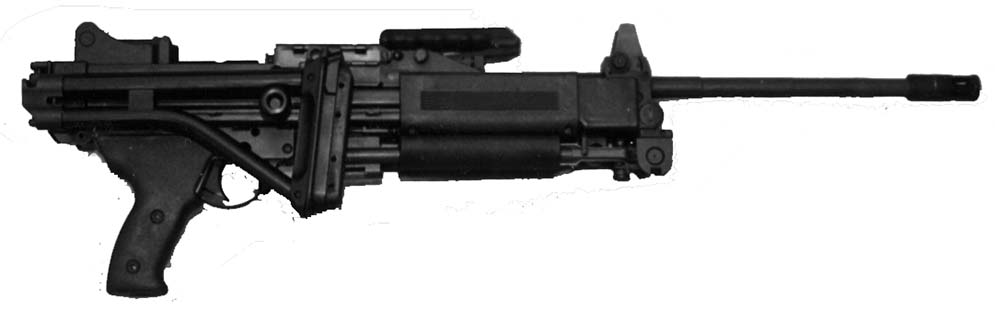

Some chase after Holy Grails, some fame and fortune, some peace and tranquillity. This particular author has been trying to get his hands on the elusive Israeli Negev LMG for a long, long time. I saw a Negev being demonstrated at the ADPA Small Arms Symposium in Reno Nevada during June of this year. The scene may have been reminiscent of a seagull landing on a french fry- I was pretty excited about it. Arrangements were made to visit O.F. Mossberg’s facility for a test. Uzi/America gave me the chance to take a real close look at the Negev at their headquarters in North Haven Connecticut. I can’t say that my wandering days in search of elusive machine guns are over, but this was definitely a high point for me. In short- the Negev lived up to its reputation as a finely made, extremely reliable machine gun. – Dan

In the desert setting, the Negev looked very much at home, as did Ephraim Yaari, the Director of Anti-Terror and Special Weapons for Israeli Military Industries (IMI). Ephraim had just finished an impressive demonstration where he took a Galil rifle and literally dumped a handful of desert sand and stones into the receiver, then emptied a magazine with no malfunctions (more on this in another edition of SAR). He picked up the Negev, did a precise demonstrator’s manual of arms with it, inserted a belt, and proceeded to fire hundreds of rounds of 5.56 x 45mm ammunition from various positions. It was one of the more impressive displays on the firing line that hot June day, especially considering the impact of the fabled Negev LMG on the spectators. Ephraim fired the Negev one handed, held at arm’s length. He fired it close to the body, one handed. In both instances, with the different grip of the gun, the Negev sat on a single plane. It held its point of aim on fully automatic, just as smooth as could be. A very impressive demonstration, indeed.

The Negev has an interesting history. It appeared in firearms related journals as a reference in the mid 1980’s. Never anything that I could chase down, and then it disappeared from the scene. It was an experimental machine gun, perhaps IMI’s response to the SAW program. The Negev development continued in relative secrecy until the IDF (Israeli Defense Force) approved the design in 1992. Jane’s Infantry Weapons 1991-92 has an entry for it, but sightings have been rare. Peter Kokalis once told me he saw several in El Salvador. It would certainly not be unusual for a country as war torn as that one to be evaluating every design that it could.

IMI is somewhat secretive in regard to their contracts- as they should be. Defense information is not something to be idly bandied about. I did manage to find out that, yes, there have been foreign contracts filled- at least one in 1993, and yes, the IDF has adopted the Negev since 1996. The Chief of the IDF Armament Corps has been quoted as saying this was the best light machine gun in the world.

Disassembly of the Negev:

Is it? That is a pretty subjective statement- we don’t know his full frame of reference, other than he is in a serious army- under constant threat. He has adverse conditions to deal with, and uses machine guns every day. He has had access to most of the ones that are presently on the market. In fact, a little research made for an interesting discovery that may lend credence to his comment. The IDF has “American Credit dollars”, which for all intents and purposes means that they can purchase items from approved sources with other peoples money- no cost to themselves. Just fill out the proper forms, and voila! You have the product. In the case of the Negev, IDF had to purchase them with their own tightly allocated cash, at a higher unit cost than the other available LMG’s. Yet, they chose to spend that extra money- one must wonder “Why”. Journalists are taught to “Follow the money”. In this case, I find a military group that is under constant threat, utilizing scarce resources to obtain what they consider to be the best. They “Put their money where their mouth is”- that shows me that the belief in the Negev runs pretty deep with the end users.

What did my live fire and analysis of the Negev find? In a nutshell, a well designed, user friendly, smooth shooting light machine gun. It had some exceptional qualities, and I did not find any one thing wrong with it. Seriously- nothing. It was comfortable, well made, accurate, easy to control, and ergonomic as could be. Maybe there was something- there is the matter of the cost- in excess of $9000 (US) per gun- this is significantly above the market for similar light machine guns. Each Negev does come with a spare barrel, if that is a consolation.

The Negev LMG is being imported to the United States by Uzi/America Inc, a subsidiary of O. F. Mossberg and Sons, Inc. Bob Tinari was my contact there, and he is “One of two guys” who run the shop. Bob is definitely a gun guy. We hit it off right away, and started taking just about every gun in the place apart and talking about the changes, features and improvements. He has the new closed bolt Uzi series of submachine guns (Pretty impressive), the Galil family including the Sniper (Upcoming test in SAR by Mark White) and the Micro Galil (Upcoming test by yours truly). He also was the designated Negev operator, having been trained on it in Israel. We proceeded to tear the Negev down then put it together and shoot it. (It’s a tough life, and I would like you readers to know that Bob and I did discuss how we deserve all of your sympathy.)

My observations:

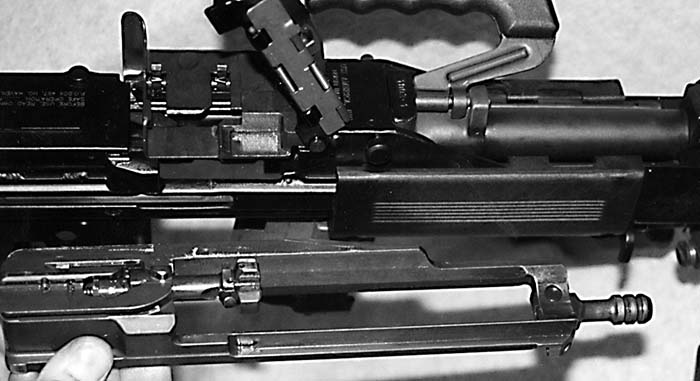

The Negev is light- very easy to carry. It is compact- with the side folding buttstock it would be very useful for paratroopers. The soft magazine pouch is a real plus- it molds around the weapon for firing control and positioning is much easier than with the damnable hard plastic ammo boxes most SAW ammo comes in today. The soft pouch was ordered in 150 round size for IDF, has been made in 200 round, and IMI will supply in any size the customer requires. The top of the soft pouch locks into the magazine well just like the magazine does, and the magazine configuration is in either standard (Galil 35 round) or M-16 30 round- these are not interchangeable. There is no action required to shift from a belt feed to a magazine, but you can not have both loaded to the weapon at the same time. Loading and unloading was very easy to accomplish- no fumbling around.

Sight acquisition through the aperture (Peep type- so sue me already, that’s what it is- a round “Peep” hole) was quick, and natural to the line of sight of the operator.

So far, the operative words here have been “Easy” and “Natural”. This is not very technical- but accurate from the user’s perspective. Machine guns are weapons of war, made for men who are fighting for their lives. Delicate, complex parts have little use on the battlefield. On the Negev, if you want to change your fire selection, it is immediately and comfortably available to the thumb on the upper grip housing. Need to change the barrel? Open the receiver cover, button pushed, and the barrel slips easily out and to the front. It does not matter what position the bolt is in. The barrel is in a “Well” in the handguard, so you can keep your profile as low as possible while changing barrels. Air cooled machine guns need frequent barrel changes in tough fighting situations and their resultant high rates of fire, and the lower you can keep your profile when in such a situation, the better. The ease of using the operator parts of a weapon can tell the observer a lot about who designed the weapon.

It is pretty obvious that the designers of the Negev LMG understood high adrenaline situations and the resultant simplification necessary to keep the weapon effective, as well as the “Keep a low profile” necessity as well.

Reliability under adverse conditions is just as important as ease of operation. Starting on the outside; the finish is apparently the same as that on the famous Galil family of rifles- it wears very well. I beat on the buttstock a little bit when Bob wasn’t looking, and put some body weight on the bipod. Inquiring minds want to know what happens when the pressure is on. The buttstock was very firm and solid, yet released easily for folding. The bipod was sturdy enough to support body weight, and, I dare say, the inevitable “Body slam” onto the weapon that many soldiers inadvertently utilize when they leapfrog through a firefight.

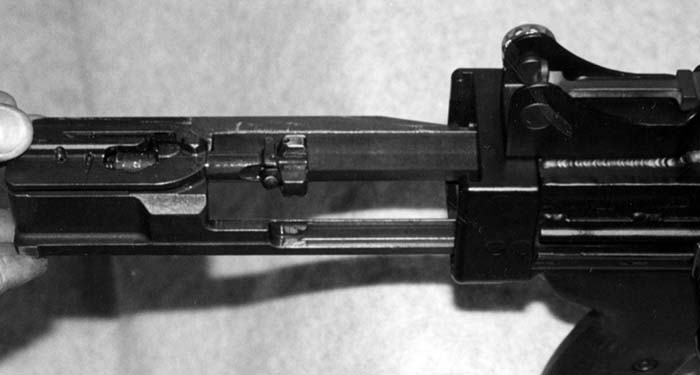

More interesting things were happening inside the Negev. The field strip was simplicity itself, no catches other than the trigger guard-, which is a separate piece and required a lot of attention to get back into position. While this may be simple for the soldier or demonstrator who is trained in installing it- this would probably be my suggestion point- make this trigger guard attached to something so it doesn’t get lost when you can’t see your hands at night while you are disassembling it. This disassembly was not intended for night- it was intended for well lighted areas, and the purpose of this removable trigger guard is for arctic conditions- firing with a glove. (The design is very good, I would just suggest a modification that allowed for retention similar to that of the M16 winter trigger design.)

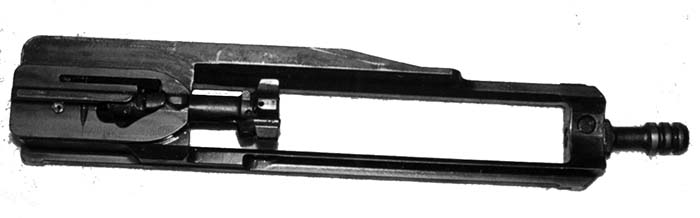

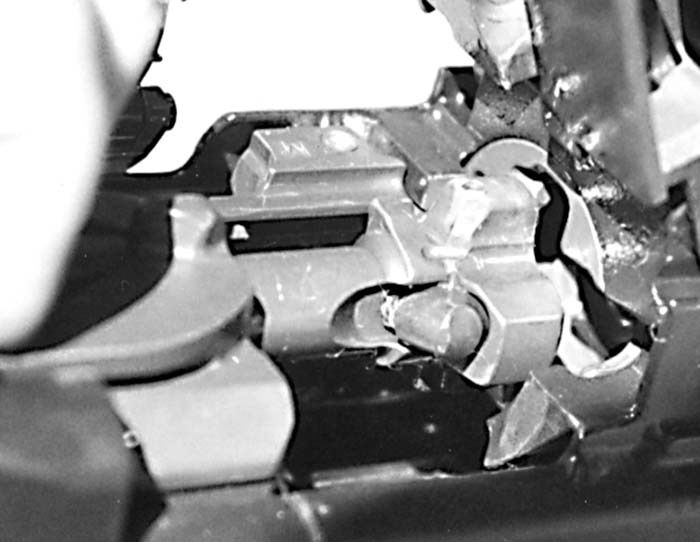

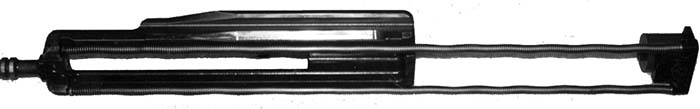

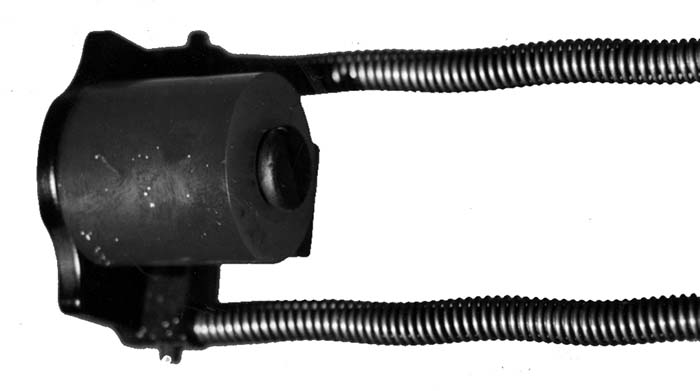

Once inside, you can see the odd skeletonized bolt carrier. The way that the gas system works on the Negev, pressure is taken off from the barrel in a fairly standard manner, where it acts immediately on a gas piston that is part of the bolt carrier assembly. There is no mechanical advantage lost in transfers or linkage here- and there is another side effect that may provide the answer to the smooth recoiling of the Negev. There are dual recoil springs that connect to the bolt carrier at the front, ahead of the bolt. This allows for a very long recoil stroke. As evidenced on Eugene Stoner’s exceptional design of the Stoner LMG, this allows the bolt carrier to “Run out” on the spring, instead of contacting the body of the receiver. Without actual impact, the recoil barely causes any movement of the firearm from the point of aim on the successive shots of a burst. Further inspection of the polymer buffer at the rear of the recoil assembly showed there were no significant marks on the buffer. Although the buffer design leaves room for a bolt to clear, it appeared to me that there was never any significant strike there. Running out on the springs is one of the best ways to smooth the recoil and point of aim “Chatter” on a machine gun. This design is successful.

The bolt itself is basically a Galil bolt. One might consider that IMI is taking a chance by using a bolt that was designed for rifle fire and using it in a sustained fire machine gun, but the design of the Galil locking system is excellent and very durable. Remember the rumored “No problems” in testing….

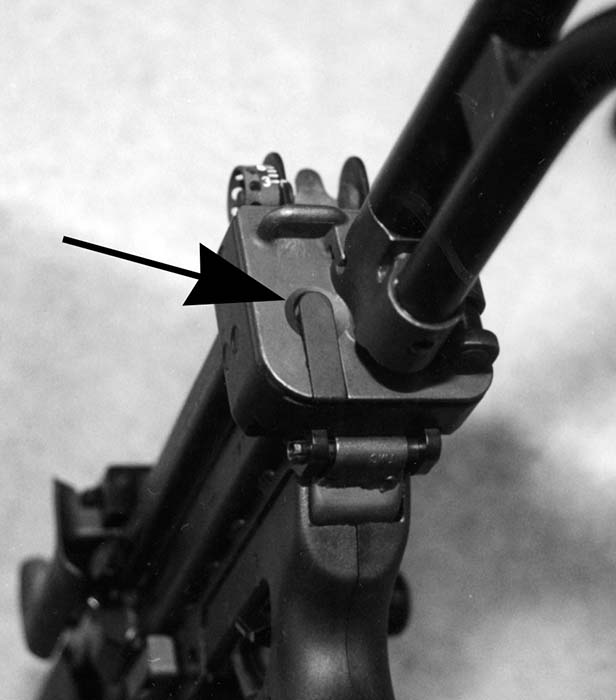

Rates of fire are adjustable by using a very easy to access regulator setting on the front sight base. The rates are adjustable for a reason- the designers feel that the optimum rate of fire for this weapon are in the 700 to 850 rpm area, and belts and magazines produce different “drags” on the firing mechanism. The first setting is for magazines- 700 to 850 rpm. The second is for belt fed situations at 700 to 850 rpm. The third setting is for adverse conditions- it increases the gas pressure so the rate of fire accelerates to 850 to 1000 rpm. What this does is guarantee that the dirty, muddy, Negev will still function at 700 to 850 rpm. The Grenade Launcher function is utilized in position 1, there is no special position for it. The IDF does not utilize the Negev to launch rifle grenades.

Industry rumors are that the IDF has taken delivery of 1500, that these have already seen combat, and that there have been no malfunctions what-so-ever. At least the “Buzz” is pretty impressive. Perhaps not as impressive as what I saw in the desert in Reno, or in the shooting room at O. F. Mossberg & Sons….. The Negev LMG was one of the smoothest machine guns I have ever fired- the trigger control was perfect, and bursts were easy to control. It would take another twenty or thirty thousand rounds of firing before I could give a final evaluation of the possibility of malfunctions, but the rumors about the controllability of this gun are proven true, and I saw no signs of malfunctions anywhere. Just a solid, reliable, comfortable design that was capable of devastating accuracy. The Israeli Negev LMG gets a big “Thumbs UP!” from The Small Arms Review…

For more information to government agencies and prospective dealers:

Bob Tinari

Service Coordinator

Tel- 203-230-5476

Fax- 203-230-5478

Uzi America Inc.

PO box 497

North Haven, CT 06473

The Israeli’s live in an uneasy peace. At times they have had enemies all around- and have persevered and defeated them.

This hardy life circumstance breeds a low tolerance for tools that don’t work. The weapons of the IDF must be solid, function under extreme conditions, and be extremely reliable. Their lives depend on it. When we discussed the testing criteria that the Negev must undergo, I was not given the statement that it “Met or exceeded NATO specs”; I was given a list of the IDF tests that they tortured the Negev with. Other machine guns did not fare so well in the trials- and IMI was not interested in discussing the failures of the other machine guns. IMI spoke only of the success of the Negev.

Some of the technical tests that the Negev mastered before it’s adoption:

1- Accuracy and dispersion 2- Endurance testing. Normally, this is 3 LMG’s x 10,000 rounds searching for failure rates and service life of the main parts. IDF performed 3 LMG’s x 50,000 round tests. 3- The handguard heat retention test results were acceptable. 4- Climate testing was performed for a range of -20 to +70 degrees Celsius, which is the operating environment of the IDF. 5- Adverse conditions testing- Sand, Mud, Water Spray and Water Immersion in a salt fog. 6- Cook off and barrel heating tests 7- Mechanical Stress to Mil STD 810C 8- Solvent / Liquid compatibility 9- Possibly one of the most interesting was the “Sea Immersion” testing- where the Negev was taken to the beach, and tested after continual drenching in the waves- note that the waves contain not only salt water, but sand from the beach.

THE NEGEV LMG DATA

Caliber: 5.56 x 45 NATO M-193 or SS-109

Operation: Gas, open bolt system

Method of fire: Selective fire

Rate of fire: Variable by gas regulator adjustment 700 -1000rpm

Locking method: Rotating Bolt

Feed Mechanism: either 35 round Galil box magazines, or disintegrating Metallic links. M-16 30 round box magazines may be Used with an adapter. Belts may be used in either a soft Assault pouch of 150 rds (other sizes available) or From standard ammunition boxes.

Weight with barrel And bipod, no feed device: 7600 grams

Wt 150 rd full soft assault pack: 2100 grams

Wt empty Galil 35 rd magazine: 320 grams

Wt full Gallil 35 rd magazine: 720 grams

Overall length, standard config: 1020 mm O/A

Length, Stock folded: 780 mm Barrel

Length, standard: 460 mm Barrel

Length, Short: 330 mm

Barrel twist: 1:7 RH

Sight line radius: 440 mm

Width: 60 mm

Muzzle velocity: 915 m/s

Sights:Front- Post

Rear: Aperture, drum adjustments 300-1000m

Night: Folding w/ tritium (Not US model)

Trigger pull: Semi-automatic 6 kg

Full Automatic: 2.5 kg

These are maximum trigger pull weights, these may be a bit lower depending on spring conditions, etc.

| This article first appeared in Small Arms Review V1N1 (October 1997) |