By Virginia Hart Ezell

Inventing the M16 was an evolutionary process. It began as a combination of ideas from several men. As individuals, they all seem to have had several things in common. They had an enduring belief in the value of their ideas. They were risk takers. They were designers with little or no formal engineering training. But they were passionate about the art of design. Mr. L. James Sullivan was one of the early pioneers in the development of what would become the M16 assault rifle and application of the 5.56 mm round that would come to dominate military small arms around the world. The following interview with Mr. Sullivan provides an insight into the evolution of the M16, and his other design ventures.

SAR: Tell me a little bit about your background. Where did you go to school? Are you an engineer by training? Have you always been an inventor? Were you always interested in firearms?

Sullivan: I took two years of engineering at the University of Washington in Seattle. The Korean War was on by then, so a few months before I got drafted, I left school to go to the Sparling School of Deep Sea Diving in Long Beach, Calif. I wanted to become a diver in the Army. I couldn’t imagine anything more exciting. In the 1950s, the John Wayne movies “Wake of the Red Witch” and “Reap the wild Wind” made a big impression on me. I wound up in the Army as a diver repairing oil pipelines in Inchon Harbor in Korea. Hardly the romantic John Wayne image.

Anyway I was a terrible student, with barely passing grades, but I was fascinated with guns and that was why I went into engineering. Through that, I got a background in math and physics. But I have always called myself a gun designer because that’s what I am. “Engineer” was a title I was granted by the companies I worked for but it is a title I don’t want to usurp from people with the degree.

On the other hand, the university system can only teach what’s been done before. Designing is half engineering and half originality. You need both to design superior technology and originality is not something that can be taught. Like art or music, it is within the individual.

I love mechanisms, especially machineguns. I love the challenge. And there is plenty of stuff left to do, although most gun companies have not designed anything new in 50 years and don’t know how to anymore.

SAR: What do you mean?

Sullivan: Well, for example almost every military small arm today fires semi- and full automatic but can’t hit anything on full auto. Full auto weapons have to be designed for controllability, and I mean deliberately, and with not just hope for that left. Full auto firing makes the barrel too hot – so hot it will burst in 500 rounds. So a man can’t fire all the ammunition he can carry. Barrel heat comes from bullet friction, not gas temperature, so design a bullet that doesn’t go through the barrel with its brakes on and the barrel can fire all the ammo the man can carry or lay his hands on.

And magazine capacity? You can empty a 30-round magazine in three seconds. But you can’t change a magazine, pocket the empty and resume firing, in three seconds. So, the man spends more time reloading than firing which increases his vulnerability in combat.

These are 101-year old problems and are slowly being solved by the world’s gun designers, not by the gun companies. That’s how it was usually done before, but the process was slowed after 1950 when the military adopted the “French Arsenal System,” a derisive term meaning to design by committee.

Now guns are supposed to be designed by government contractors per formal requirements written by soldiers and experts. Sounds reasonable but the contractors have never designed a gun before and the experts who write the requirements may be expert gun users but are blind to the opportunities and limitations of technology. They can only ask for what has been done before or for impractical things like caseless [ammunition] and then protect their worthless projects from competition for several years by dismissing all real advances in small arms as having “No Requirement.”

Look at the SAMP 2000 (Small Arms Master Plan). All the money [in the budget] was dropped except for the OICW (Objective Individual Combat Weapon). One frame combines two guns in one, a standard rifle and one that fires an explosive round. That explosive round is supposed to be set off by a computer device that can exactly tell range and communicate that information to the round so that it will explode next to the target, and presumably cause some damage. So, by formalizing the requirement and giving a fortune to contractors who can keep straight faces, they think it will happen. But that is not how innovation works. No matter how much the government spends or pushes to change technology in a particular direction, it doesn’t speed up innovation or fool Mother Nature.

For starters the size and weight limitations of the shell would need an explosive that is four times more powerful than any known explosives and the shrapnel material would have to be denser than any material on this planet just to equal the effect of the 40 mm M203 explosive round, which is adequate if it explodes close to the target. Then they have to develop the technology to make it explode where they want plus or minus a few inches. Mortar designers have been trying to develop similar technology for 50 years but aren’t there yet. Part of the problem is cost. One odd fact about explosive shells with sophisticated fuses is that little ones don’t necessarily cost less than big ones. I guess they think the formal requirement solves that problem by stating the allowable cost.

The OICW will probably end up like the last boondoggle, the Advanced Combat Rifle (ACR) program, whose formal requirement was that it have twice the hit probability of the M16, which was reasonable for once since it had already been done. The Singapore 5.56 mm Ultimax had already out-hit the 5.56 mm M16 and all other 5.56 mm weapons by way more than 2 to 1 at the Royal Military College of Science at Shrivenham, England. But when that was pointed out to the officer running the ACR program, he wasn’t interested. He only tested guns that fired freak ammo – caseless, semi-caseless and multi-projectile – that all failed for the same reasons that each had failed before. The program was a total failure. Cost – $100 million – and they never tested the technology that worked.

SAR: When did you become a member of the M16 design team? What drew you to this particular project? Did you know Stoner before joining the project? How long were you with the M16 project and Armalite?

Sullivan: After I left the Army, I went to work for Boeing as a tool designer. Then I read about the AR-10 and Armalite – in Time magazine I think. I was impressed with Stoner’s unique gas system invention, which used the rear of the bolt for the gas piston (unlike the Ljungman or French M1949 gas tube systems).

So, I wrote Armalite’s president, Charles Dorchester, sent him a design drawing for an expendable magazine to get my foot in the door and asked for a job. I started as a draftsman. They were just finishing the final U.S. prototype of the AR-10 at the time. The gas tube was on the side of the barrel and the gas got piped through a transfer tube into the side of the bolt carrier. They wanted the gas tube and transfer tube moved to the top where the transfer tube would be less exposed, but the cam pin and cocking handle left no place for the stationary transfer tube. So I combined it with the carrier key and let it move with the carrier. It worked so they let me design after that, starting with the AR-15.

I had never met Gene Stoner before I joined Armalite in 1957. He, of course, had been there for several years (started in ’53 or ’54 I believe) and had brought his 30-06 prototypes with him with his unique gas system and 8-lug rotary bolt concepts that were then used in Armalite’s AR-10 and AR-15. He was Chief Engineer and my boss at Armalite and later at Cadillac Gage on the Stoner 63 program.

Stoner was a great guy with a tremendous sense of humor and a pleasure to work for. He was a brilliant inventor as everyone knows but he was not a one-man show.

First of all, he had nothing to do with the Armalite AR5 and AR7 survival rifles or the .222 “Stoppette” rifle or AR9 or AR17 shotguns. Those were all designed by other people, mostly by John Peck and Art Miller. Stoner designed two guns while at Armalite, the AR-10 and the AR-16 (not to be confused with the M16), both 7.62 mm NATO caliber assault rifles. But he is also credited with designing the 5.56 mm AR-15 (M16) “scaled down” from his AR-10 and the 5.56 mm AR-18 “scaled down” from his AR-16 and has been called the “Father of 5.56.”

However, the first 5.56 mm assault rifle designed at Armalite was the “Stoppette” designed by a guy, whose name I’ve forgotten, using the .222 Remington cartridge. Stoner didn’t believe the small caliber (5.56 mm) cartridge was a suitable military cartridge and designed only .30 caliber rifles until 1973. In the meantime (1957 to 1959), Bob Fremont and I designed the AR-15 (M16) and its 5.56 mm cartridge (modified from .222 Rem). Art Miller designed the AR-18 in 1963 after Stoner left Armalite.

In 1962, Bob and I joined Stoner again at Cadillac Gage where he was designing the 7.62 mm Stoner 62 rifle and machine gun. The owners of Cad Gage wanted a 5.56 mm model so Bob and I designed the Stoner 63.

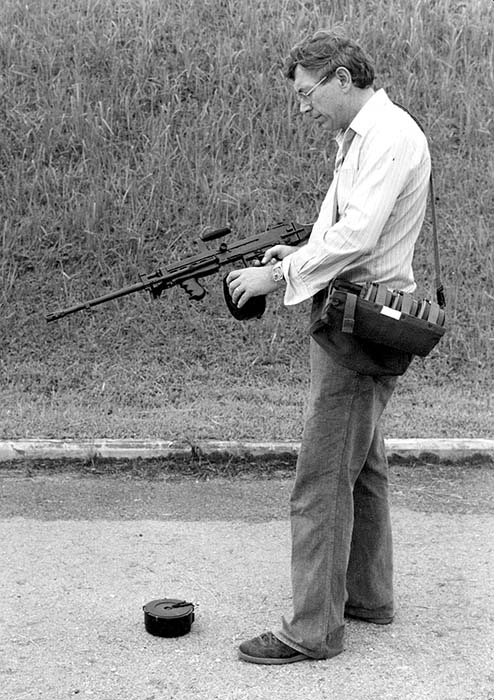

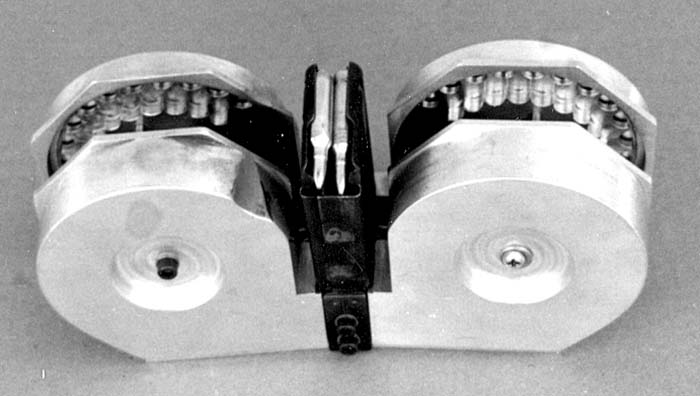

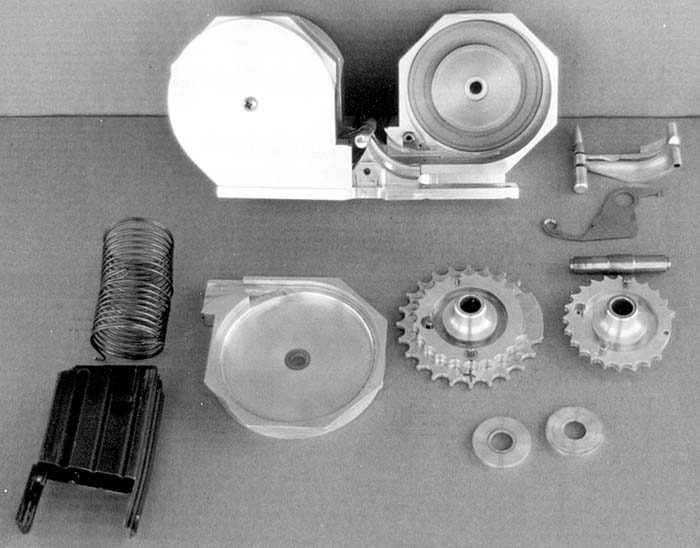

I designed three more 5.56 mm weapons after that, the Mini 14 for Ruger in ’67, the Singapore Ultimax 100 in ’78 and a double drum rifle/machine gun in ’81 called the ARMi for Beretta. The Mini 14 and Ultimax were successful but the ARMi died when the Italian military adopted an earlier Beretta design. I did however salvage my double drum magazine from the ARMi program and redesigned it as the C-MAG in ’84, which has been adopted by the Germans so it’s done okay.

I believe Stoner designed two 5.56 mm weapons, the FARC in 1973, which was never produced, and the Stoner ’86 machine gun (designed in ’86). It’s rumored that the ’86 MG is starting in production. I wish it well.

SAR: What were some of the more memorable moments in the M16 project? What were some of the difficulties?

Sullivan: From the start, we (Bob Fremont and I) put the AR-15 gas tube on top and used the AR-10-type cocking handle on the first prototypes. But the Finger hook of that type of cocking handle has to have an open slot in the top of the receiver which weakens it and since the hot gas tube was now just below the hook, the hook got so hot on full auto it burned your finger when trying to cock. So I redesigned the cocking handle to pull from the rear which doesn’t get hot and that allowed the receiver slot to be closed off so the AR-15’s receiver became stronger than the AR-10’s.

Although the two guns generally look the same, most of the details in the AR-15 differ from similar details in the AR-10 in ways that made the AR-15 parts more readily interchangeable, simpler and cheaper to make, easier to takedown, smoother operation, stronger, and with increased spring room which made the AR-15 more reliable and eliminated the need to replace springs that could set.

We designed the cartridge for IMR tubular grain powder instead of Winchester’s Ball powder and contracted with Remington to make the ammo. We therefore developed the gun and gas system for the pressure curve of IMR powder and other characteristics of that ammo.

Unlike the AR-10, which had only marginal room for its extractor spring, the relatively larger bolt of the AR-15 had adequate spring room to operate reliably with our ammo. Although we made a modified bolt with even more room, it proved unnecessary during extensive test firing so we went into production with the apparently adequate and simpler design. That became a bad choice later.

We made three other bad choices – the cartridge rim should have been thicker and/or stronger, the buffer should have been heavier, and the chamber of the barrel should have been chrome plated. Omitting the chamber chrome plating was outright stupid but none of the “bad choices” caused problems during our tests or the Army’s tests of the first Colt production guns or the first combat reports from Special Forces in Vietnam, which said that the AR-15 and cartridge were absolutely deadly and effective and superior to the Army’s .30 cal. M-14. By 1962, the world’s press was calling the AR-15 a miracle or “Super Gun,” but that didn’t last long.

In the meantime, we completed the AR-15 testing and development and Bob Fremont left Armalite in 1959. During the next year I designed the .22 AR-7 Survival Rifle and left in 1960 after Armalite assigned the AR-15 rights to Colt. Stoner left in 1961. Art Miller stayed and designed the AR-17 shotgun and 5.56 mm AR-18 assault rifle and AR-180 civilian model. Art had returned from Holland in 1959 after he had converted the AR-10 design to metric. Armalite had been a division of Fairchild Aircraft but was cut loose about 1961, after the AR-15 was assigned to Colt. Armalite supported itself thereafter from the sales of the AR-7, AR-17 and AR-18.

After leaving Armalite, I worked at National Cash Register (NCR) for two years until Stoner invited Bob Fremont and myself to join him for a new gun program at Cadillac Gage. Stoner was just completing his .30 cal Stoner 62 convertible rifle and machine gun. Bob and I designed the 5.56 mm Stoner 63 version from 1962 to 1965. Stoner left in 1963 to develop his 6425 Bushmaster 25 mm gun at TRW. Bob Fremont left in 1964 to join colt and correct some of their AR-15 production problems. I left to join Ruger in 1965 after the Marines had tested the Stoner 63, ordered 300,000 and been shot down by the senate funding committee which decided that the Marines should use what the Army uses (in other words, the AR-15 which by then had been adopted and officially designated the M16).

In the meantime, the Vietnam War was heating up, Colt was getting big orders for the AR-15/M16 and then someone in the military changed the 5.56 mm ammo powder charge from IMR to Ball powder. They did it without tests or checking with Armalite or even notifying Colt who, of course, continued to fire the acceptance tests with IMR powder. Colt didn’t learn about it until they read in the newspapers that all the M16s in Vietnam were jamming, one Marine unit had been overrun, and everyone killed because their M16s jammed.

The field investigation found that the guns were all jammed by a fired cartridge that had failed to eject and that none of the dead had a cleaning rod to clear the jam. The world’s press blamed the gun and its reputation changed from the best to the worst overnight. But further investigation showed that that Marine unit had trained with the M-14 and never seen the M16 until they were issued M16s without training or cleaning equipment when they arrived in Vietnam and were sent into combat. But none of that explained why a gun that used to work didn’t work anymore so it gradually became obvious that the jams were caused by the change in powder.

To say that IMR powder is better than Ball powder is no more true than to say that gasoline is better than diesel fuel, but if you tried to run your gas engine on diesel fuel it wouldn’t work. And that, in effect, is why the M16 didn’t work with Ball powder.

Specifically, Ball poser has higher gas port pressure, which causes the gun cycle to speed up. That causes two types of malfunctions, light strike misfires from bolt carrier bounce and failures to extract a cartridge that has stuck in the chamber because it didn’t have enough time to relax its fire-formed press fit.

Our earlier “bad choices,” (the light weight buffer, weak extractor spring, thin cartridge rim and no chromed chamber), made those problems worse, but, except for the chromed chamber, all of the problems and causes would be cured by going back to the IMR cartridge the gun was designed for. So that is what Stoner, representing Armalite, argued. But the Army argued that it had already stockpiled 100 million rounds of Ball powder ammo and it would take months to fill the pipeline and replace it. Congress investigated and issued the Ichord Committee report finding mostly the Army at fault in “that the failure on the part of officials with authority in the Army to cause action to be take to correct the deficiencies of the 5.56 mm ammunition borders on criminal negligence.” [See page 5370 of the Ichord Committee Report].

I wish I could say that Stoner or Fremont or myself saved the day, but Colt’s Chief Product Engineer, Foster Sturtevant, solved the problems with a heavier buffer assembly having a plurality of inertial masses acting in delayed sequence to oppose bolt rebound. It slowed the cycle back down, reduced the bolt carrier bounce that caused light strike misfires and gave the cartridge time to loosen up in the chamber so it extracted better. Furthermore, it was a simple change allowing riflemen to just change buffers in the field. Another simple fix by Colt designer Bob Roy was to add a rubber plug inside the extractor spring to increase spring force. These cures got the Army off the hook and allowed them to keep using Ball powder ammo.

Although those cures have proven to be good sound improvements, Ball powder is still not compatible with the M16 and should never have been issued for that weapon. It fouls the gas system and wears out the piston rings.

SAR: What other projects have you worked on since the M16?

Sullivan: After the Marines were not allowed to buy the Stoner-63 I quit Cadillac Gage and went to work for Ruger. I designed a bolt action rifle, the Model 77, and the Mini-14. Both have sold one million each. I stayed with Ruger for three years, from 1965 to 1968. The I went to work for Hughes Advanced Armament, part of Hughes Helicopter. That was later sold to McDonell Douglas. I spent 10 years there. For five years, I worked on a worthless caseless ammunition project. All died ludicrously when the breaches wore out and blew up the magazines during testing. Some lasted several hundred rounds, but we did all of our shooting with a long string.

One thing I did design at Hughes was the 7.62 mm chain gun. Lenny Price invented it and designed it for 30 mm on the helicopter and 25 mm on the Bradley [infantry fighting vehicle].

The British use the 7.62 mm as the coaxial machinegun on the Challenger [main battle tank]. The reason they use it is because it ejects the brass forward, outside the vehicle so most of the sound and breech gas are also ejected outside the vehicle.

A motor driven gun makes sense for a vehicle. As a motor driven system, it does not matter what kind of ammunition you use. A special ballistic match flash tracer can be fired along side the main gun on the tank to see if the main gun will hit the target. It was first used in combat in the Gulf War.

Hughes was already started on the 30 mm version for a helicopter. By taking Lenny Price’s idea and proposing it as a part of its helicopter system, Hughes was able to get a contract for the helicopter and the gun. But the Army wanted to see the gun work first. So, we made the first 7.62 mm prototype in six months, which proved the chain gun principle. It meant a lot to Hughes because they got not only the bigger chain gun contract but the helicopter contract as well.

Armalite was back in business by then. They let me have an office there to do work at night [while working at Hughes]. I worked on a .22 rifle for John Wayne. He had a good time; took it out on his yacht and shot at cans or whatever was out there floating in the water. Then a new business manager working for John Wayne pulled the support for the project, said he was too busy sorting out Wayne’s bigger investments. But it was fun for a while.

Armalite knew people at CIS [Chartered Industries of Singapore]. CIS had spent a fortune on a factory to make M16s but it was standing idle after they had supplied the Singapore armed forces. They wanted a rifle to replace the M16 and I agreed to work for them. I left Hughes and went to live in Singapore. CIS really wanted a light machine gun. That’s when I designed the Ultimax, between 1978 and 1981, and that’s when I first started developing controllable full-auto weapons.

I wanted to make a light weight controllable full auto weapon so I modified the Davis Recoilless Gun Principle. The Davis gun shot a bullet out the front and a sandbag out the rear so that all of the recoil was in the motion of the sandbag and none of it in the gun. It didn’t matter how light the gun was because it wasn’t the recoiling mass. In the Ultimax I used the bolt carrier as the sandbag and threw its weight to the rear with a conventional gas system. But instead of throwing it out of the gun, which would have made it recoilless, I gave the bolt carrier enough room and spring force to slow it to a stop before it hit the rear wall. The Ultimax is therefore not recoilless, but the force of recoil delivered to the shooter is only the spring force. To see how that compares to a “normal” recoil force, consider that recoil is a measure of force times time so the longer the time the lower the force. The Ultimax stretches the time out over the whole cycle time which is 100 times longer than delivering it during the bullet acceleration time in a bolt action rifle so the recoil force (and force of the spring) is 100 times less than the force delivered by the bolt action. Furthermore, it is delivered as a constant push during a multi-shot burst, not as a series of individual sharp blows. That, however, is only the theory. Due to friction and the fact that man is a rubbery mount that smoothes out recoil spikes, the Ultimax is nowhere near 100 times better than the M16, but it outhits the M16 by about 8 to 1. The priniciple is called “constant reaction” and I’ve patented its equation in 21 countries.

SAR: Are you surprised by the longevity of the M16?

Sullivan: Yes, I am surprised especially because of the limitations of the smaller caliber. I know all the arguments for high velocity ammunition, all the comparisons that are made. The 5.56 mm round is a weaker, shorter range round. But we have to live in the world the way it is.

SAR: What are you working on now?

Sullivan: I have since worked out variations on the constant recoil principle. One was for a very powerful light weight sniper rifle which cut its recoil spike in half (followed by a low force push) so it could be twice as powerful as 7.62 mm NATO but with no greater spike. Proposed it for the SAMP 2000 Objective Sniper Weapon, got a development contract (the only one I’ve heard), got a single-shot firing fixture made at Saco Defense, which proved it worked and that was the end of it. The SAMP 2000 budget got diverted to the OICW after that.

Got a couple more in the works. One is the “Counterpoise” kit that makes the M16/M4 carbine more controllable. The other is a 7.62 mm belt-fed rifle that will be a full-performance machine gun weighting only 11 pounds instead of 23 pounds like the M-60 or MAG58, and [it will be] far more controllable. And unlike other belt feds, which are almost impossible to reload on the move, a walking man will be able to rapid reload as fast as changing a rifle magazine. And it will select fire full auto, open bolt and semi-auto closed bolt for rifle accuracy. So it can be added to the 5.56 rifle squad without subtracting and thus regain long range accuracy.

SAR: How does an idea for a design begin? How do you get your ideas?

Sullivan: I work on a standard drafting board. Calculators are wonderful things. One of the things I regret is not working with CAD [computer aided design] over the years. Designers will go further, faster with it.

In inventing you see a problem and then design a solution. Sometimes it takes a while. Sometimes you see a problem no one else has. Sometimes it’s like a flash, like a light bulb going on. Usually it’s nothing like the “Eureka” type of discovery. More often you think of a solution and then dismiss it because the solution has a different problem. Then later you solve that new problem – sometimes years later. It’s not something that comes finished and ready to go. You have to work on it.

Eugene Stoner is often credited by the press as the “designer of the M16” when in fact he is only the inventor of the M16. So what’s the difference? And who cares?

From a business standpoint, only an invention is patentable so the identity of the inventor and people he sells it to are important but the identity of anyone who designs that invention is irrelevant because the designer doesn’t own the invention. Stoner assigned his patented gas system invention including early prototypes to Armalite in return for a royalty agreement. Armalite then paid the costs needed to design and develop that invention in the form of the AR-10 and AR-15/M16 ready for production and then licensed or assigned all rights to Colt for royalties that they shared with Stoner. Strictly from a business standpoint the fact that Armalite hired designers to help Stoner is no more relevant than the fact that they hired a janitor to clean his office.

Furthermore, it’s not good business to include irrelevant details in a press release or advertisement so it’s common practice for gun companies to either omit any individual name or to credit one person for all the work. Armalite at least credited Stoner, but Colt tended to omit even Armalite’s name.

Why should we care who the designers were? For historic accuracy and because their work determined the value of the product just as much as the invention did. I have over 200 patents worldwide. I guess some people can sing, some people invent. It’s just built into the person.

SAR would like to thank Mr. Sullivan for sharing his views with our readers, and we hope to bring more information about his designs and current projects in future issues.

| This article first appeared in Small Arms Review V4N5 (February 2001) |