By Jean Huon

Since 1946, many assault rifles were developed in France:

- at the Centre d’Expérimentation de Mulhouse, with the collaboration of German engineers who continued the development of the StG 45 (M), which was to become the CETME and later the G 3,

- at the Châtellerault Arsenal (MAC),

- at the Tulle Arsenal (MAT),

- at the Saint-Etienne Arsenal (MAS). This establishment carried out the most models of study with two or three prototypes each year from 1948 to 1962. The last of them was nearly adopted but it fired the 7.62mm NATO cartridge and the military headquarters was looking for the new small calibre, which had just appeared. Then it was urgent to do nothing…

However, at this time, various military interventions in Chad, Kolwezi and Lebanon, demonstrated the lack of an assault rifle in the French Army. To avoid the problem, a few thousand SIG SG 540 rifles, then manufactured by Manurhin for export, were supplied.

(Claude Jacquinet)

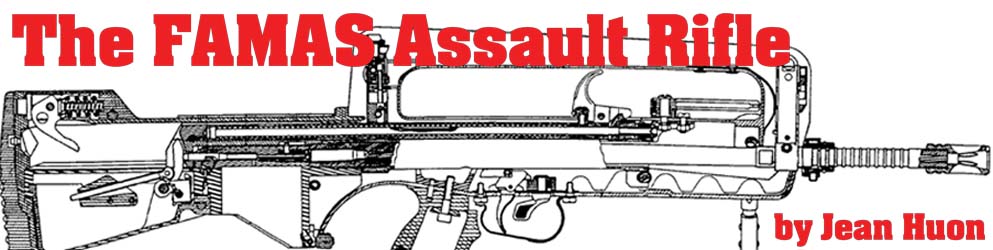

THE FAMAS F 1

In 1967, the French Army made known their desire to replace the individual weapons currently in use (submachine gun MAT 49 and semiautomatic rifle MAS 49/56) with a single weapon that can deliver single shots or full auto up to 300 meters and launch anti-tank or anti-personnel rifle grenades. The date to realise the new rifle was fixed in 1975 and preliminary studies began in 1969.

Ballistic tests carried out by the Etablissement Technique de Bourges of different ammunition made it possible to determine which cartridge was best suited for their needs; and chose the 5.56x45mm with the decision made in August 1970. The Saint-Etienne Arsenal was retained to develop the weapon. The ergonomic study was made jointly with the laboratory of Anthropology of the Medical college and it emphasized that it is advisable to create a weapon of the Bull Pup design. The choice of the mechanism was determined for a delayed blowback bolt. Indeed, ballistic tests showed the superiority of this mechanism compared to the system with gas port:

- no mechanical stress on the gun being likely to deteriorate the vibratory mode of the barrel at each shot,

- no internal turbulences of the gas tube. (These two elements allow a better accuracy.)

- Highest cyclic rate of fire power,

- smooth recoil when the bolt opens,

- no cook-off,

- less fouling,

- the weapon can be used in all climates without adjustment of any gas port, and

- launching of grenades does not require any preliminary action on the mechanism (no closing of gas port like the MAS 49- 56).

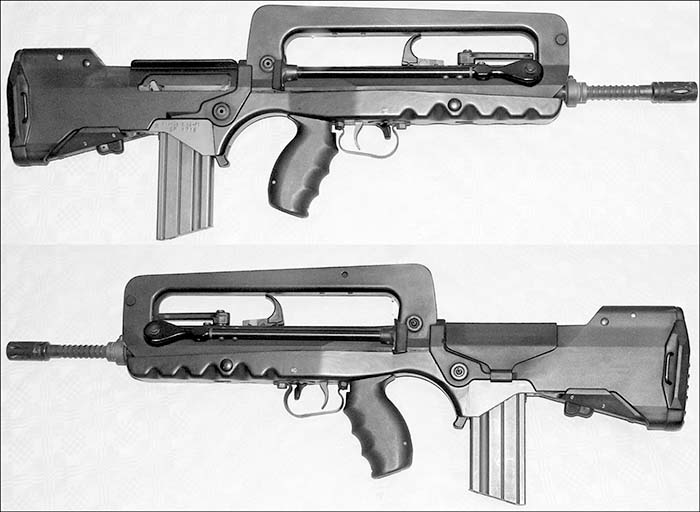

Following these experiments, and under the direction of Chief Engineer Paul Tellier and Small Arms Engineer Alain Coubes, the research board of MAS started to develop prototypes with ten A1 rifles in 1971, ten A2 rifles in 1972, ten A3 rifles in 1973 and twenty-nine A4 rifles at the beginning of 1974.

However, a short delay imposed by the program required the possibility to look at other weapons, and other tests were made with the German HK 33 and the Belgian CAL, if the French prototypes did not give satisfaction. These tests were also carried out with the American rifle M16 A1 used as weapon of comparison.

In spite of the efforts of the manufacturer, the new French rifle prototypes revealed many imperfections during the trials; in particular on the level of reliability. Due to these results, it was decided to stop the study in September 1974.

The evaluation of the foreign weapons continued and various modifications were made. The foreign prototypes did not prove entirely satisfactory and in May 1975, the Defence Ministry returned to the MAS weapon.

The study and the experiments of the French 5.56mm start again and the Type A5 is ready in August-September 1975. The development of this model gave way to the Type A6 prototype and MAS delivered 23 A6 prototypes for official evaluation in October 1976.

In spite of the important improvements noted on the level of reliability, it remained to correct three essential defects:

- lack of sighting device,

- insufficient reliability of the 3-round burst device, and

- poor resistance of the barrel, which had at this time six right grooves.

A new A7 prototype was presented in May 1977, and its experimentation was finished in July. It showed that the defects observed on the preceding weapons were solved except the 3-round burst device. The results having been considered to be satisfactory, the Chief of Staff of the Army came to a positive conclusion about the adoption of the MAS rifle without the 3- round burst device, by a decision dated August 8, 1977. The weapon then received the official name of: Automatic Rifle MAS 5.56 Model F 1.

While the manufacturer completed the development of the industrial infrastructure necessary for production, field trials were made by the 75th Infantry Regiment in Valence with 29 prototypes to detect and determine certain minor imperfections on the level of the user and make proposals for remedies.

The study of the 3-round burst device continued up to September 1977. A new system underwent tests by the manufacturer at the end of 1978, and the official evaluation took place in June 1979. The results being positive, the Chief of Staff made the decision of adoption of the F.A. MAS 5.56 F 1 with 3-round burst device, on July 24, 1979. It was installed in all manufactured rifles after serial number 27,000, and the other FAMAS rifles before that number were retrofitted.

Since this date, nearly 300,000 weapons were produced, thus making it possible to equip all of the first line troops of the French Army. The monthly rate of production reached 5,000 rifles per month.

Since 1984, the FAMAS F 1 was proposed for export and several countries, including Senegal, Lebanon, Gabon and Djibouti, acquired this weapon but in limited quantities. China bought one specimen, perhaps to make a copy.

In spite of particularly brilliant presentation campaigns abroad, the FAMAS never did enter on the international market because of a too high price. It was possible to get approximately seven Kalashnikovs for the price of one FAMAS).

Manufacturing

The Saint-Etienne Arsenal made the frame from a light alloy forged part and did the final assembly. The barrel and the bolt were produced by Tulle Arsenal and other components of the FAMAS are manufactured by subcontractors: Forges de Bologne (forged frame), Verney-Carron (tube wrap), Lhôtellier-Montrichard (synthetic material), Kléber-Colombes (butt plate), and GIE Loire-Emep, Giso, Flonic- Orbey, Socop, for the other parts.

Description

The FAMAS F 1 is a Bull-Pup design weapon and the nickname of “bugle,” by which it is sometimes called, is a pure invention of journalists.

The FAMAS is a very compact weapon with short overall length. It is entirely sheathed in a plastic material containing fibreglass, giving it great robustness. This makes the rifle resistant to shocks and crushing yet remains functional even after falling from a height or passing under the wheels of a truck.

The frame is machined from a block of high-strength light alloy starting from an outline coming from forging. The magazine housing is at the front and the firing device at the rear. The bolt moves in grooves located at the upper part.

The barrel passes through a tube wrap that holds both the rear and front sight. It has a fluted chamber and six grooves up to the first months of 1982 after serial number 11,000. Later guns have a three groove barrel with one turn in 305mm (12 in). The part of the barrel that protrudes over the handguard is arranged as a grenade launcher with a ring stop and a 22mm diameter flash hider.

The cocking lever is located at the top of the handguard and a device permits it to stop in the front position after cocking. The handguard is rectangular and made of two shells joined together. The lower shell receives the pistol grip, which is located exactly at the center of gravity point of the gun. This permits a perfect balance for the FAMAS. The grip is hollow and can receive an oil can.

The trigger guard can be folded on the right or on the left and the selector and safety lever is located just behind the trigger. The trigger mechanism is located in abox and includes the trigger, sear, hammer and 3-round burst device. The connection between the trigger and sear is realized with a flat rod located in a groove milled on the right face of the frame. The higher shell is surmounted by a bridge which provides several functions: carrying handle, materialize the line of sight, protection of the cocking lever and a scope mount. The sights are made of a single eyepiece adjustable in height for shooting up to 300 meters and comprised of a large hole for rapid fire and two others on foldable blades for more accurate shooting, and a blade front sight, adjustable in deviation. For night shooting, the line of sight is materialized by luminescent pellets. If the light is poor, it is possible to use a foldable enlarged eyepiece and an oversized front sight.

The rear part of the rifle has a plastic stock with a flattened hexagonal profile. In front are two ejection ports, one on each side. It is easy to reverse the ejection side after the intervention of a gunsmith. The ejection port that is not used is closed by the cheek rest. This permits the FAMAS to be used both by either a right handed or left handed shooter.

A buffer made of a spring and a return square is located at the top of the stock. The butt plate is made of Neoprene. The bolt has a mobile head and an amplifying inertia lever. The bolt head bears a reversible extractor (for both sides) and an ejector.

The gun is loaded with a 25-round straight magazine introduced behind the pistol grip.

Bayonet

The FAMAS F 1 receives the F 1 bayonet, a knife derived from the Model 1958, which was used with MAS 49-56 rifle. It is fitted over the barrel. The two edged blade is 215mm (8.46 in) long and receives a phosphate finish. The handle consists of two black plastic grips and two rings. The sleeve is of black plastic, with an olive green synthetic holder and metallic hook. A parade variation is chrome plated with black varnished holder with red wire and chrome plated sleeve. It is used by the two infantry regiments of the Garde Républicaine.

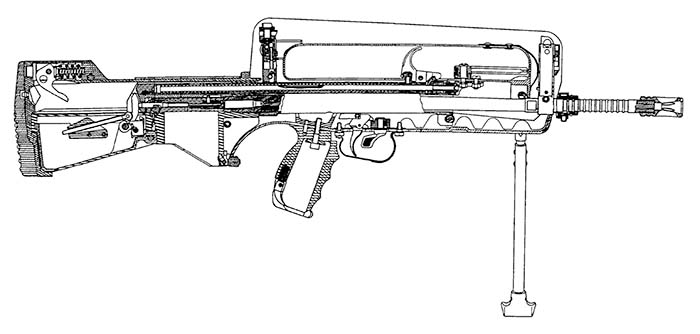

Accessories

Accessories for the F 1 include a removable and folding bipod with tubular legs, universal olive green synthetic sling, which permits transport of the weapon on the shoulder, in the back or across the chest, a special single shot plastic magazine for a grenade launching cartridge, blank firing device, mirror training sighting, extractor for broken cases, cleaning rod in four parts, chamber brush, barrel brass brush, barrel nylon brush, oil can, brush, accessories pouch, magazine pouch for three magazines, technical manual MAT 1057, and a grenade launcher M203, to launch 40mm grenades. This can be installed on the FAMAS F 1 with a device made by Société des Artifices Titan (used by the Air Force). A similar adaptation made by MAS was not retained.

Disassembly

- Remove the magazine and ensure there is no cartridge in the chamber.

- Remove the stock assembly pin.

- Remove stock and cheek rest.

- Remove the handguard assembly pin and remove the handguard.

- Remove the firing mechanism’s box pin and take off the firing mechanisms box.

- Pull the bolt back and remove the assembly pin. Remove the assembly pin of the mobile unit. Dismount the mobile head, amplifying inertia lever and firing pin.

The FAMAS F 1 is used by the French Army, Gendarmerie and Air Force. These weapons are fitted with a three groove barrel with rifling of one turn in 305mm or 12 inches. The Commandos Marine also used the FAMAS F 1 with a three groove barrel, but with a rifling of one turn in 228mm or 9 inches.

Variations

- FAMAS F1 Export. This weapon was equipped with a barrel 9-inch twist allowing the use of 5.56mm NATO ball SS 109 cartridges (U.S.M 777). A version with a 7-inch twist was also available.

- FAMAS Open Sight. On this model, a 1.5x scope is integrated into the upper handguard, which permits shooting with both eyes open for a distance of 500 meters. Two marks placed on the reticle are used for the anti-tank grenades and replace the azimuth device for shooting at 65 and 100 meters.

- FAMAS Sniper. The upper handguard receives a NATO Stanag device that permits the use of a 4×25 day scope or Sopelem OB 50 for night shooting.

- FAMAS Short. This gun had a 408mm (16.06 in) barrel and is appropriate particularly for a use in confined spaces or aboard a vehicle.

- Simplified FAMAS. Similar to the standard model but without the grenade launching device.

- FAMAS Police. Experimental short gun, possibly intended to eventually replace the MAT 49 for the police. A few models were made about 1975, but this model was not retained and the Beretta M 12 S was chosen.

- FAMAS Gendarmerie. Weapon with conventional organization (magazine before the pistol grip) and wooden stock.

- Semi-automatic FAMAS carbine. It had a 531mm (20.91 in) barrel, no grenade thrower device, receives no bayonet and uses the .222 Remington cartridge. It was marketed for the civilian shooter until 1993 and was later classified as a military weapon regarding the new European Community rules.

- FAMAS Pellet Rifle. A repeating rifle made for training; it was not retained by the Army but was sold on the civilian market until the fatal law of 1993. It shoots 4.5mm pellets placed in a special magazine located in the pistol grip. The pellets were powered by a CO2 cartridge.

All these weapons could be provided in black, olive green or sand plastic except the semiautomatic FAMAS and the FAMAS Pellet Rifle. None of these models was manufactured in series.

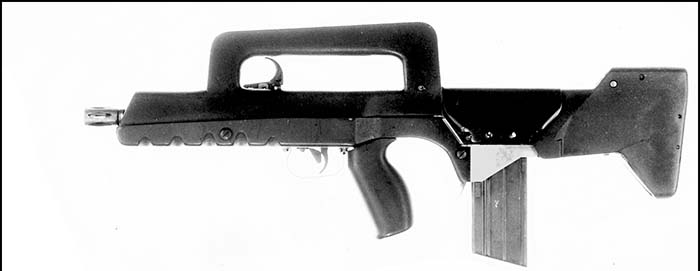

FAMAS G 1

In spite of excellent results on the technical plan, highlighted at the time of presentations abroad, the FAMAS did not manage to take a lead in the international market. This led the manufacturer GIATIndustries (a former state organization which covers all the arsenals and became a private company in 1990) to study and propose a new FAMAS with a 40% less cost.

Some functions were removed on the basic model, but remain available as an option (3-shot burst device, night sights, bayonet, bipod, universal belt, scope). The grenade sight and ring stop were removed. A broad arcade protects the trigger and replaces the trigger guard permitting shooting with any types of glove. Many elements were altered to obtain a lower price. The straight 25-round magazine used with the FAMAS F1 was kept. The G 1 FAMAS did appear just after GIAT became a private company, including F.N. Herstal in Belgium, who received the responsibility to sell the small arms produced by GIAT.

FAMAS G 2

A more advanced version of the FAMAS G 1 is the FAMAS G 2, which takes on the characteristics of the G 1, but now added the use of M 16 magazines, rifled bore with 7, 9 or 12 inches twist and utilizing the M16 A2 bayonet. The use of anti-personal or anti-tank grenades is still possible and a 40mm grenade thrower can be mounted on the FAMAS G2.

Several variations were proposed to include the Standard model, Short barrel, and Sniper variation with a day or night scope. All these weapons were the subject of presentations to many foreign countries. In France, the Navy did adopt the FAMAS G 2 as standard with a 9 inch twist barrel and the French bayonet. 10,000 specimens of them were ordered.

Low Profile FAMAS

To modernize the infantry troops, the French Army developed a new program named FELIN (Infantryman with equipment and integrated radio transmissions). It is defined in several versions: team leader, marksman, collective gun crew, and sniper. It includes: communication and transmission device combining a day/night camera, sight, navigation system and energy management device; camouflaged battle dress fireproofed, treated anti-mosquito and a low infra-red signature; chemical nuclear and bacteriologic protection, and ballistic protection. The FELIN system weighs 24 kg (52.91 lbs) and it is fed by refillable batteries in the AIFV. It is associated with a low profile FAMAS.

The low profile FAMAS was developed by GIAT-Industries and other partners under a program established by the STAT at the Satory Proving Ground. It underwent a renovation treatment and the upper handle grip was removed and replaced by a Picatinny rail receiving a sight tube, a laser sight or a compound glass-camera. The front grip received a control cluster for the electronic system. The former barrel was replaced by a new one with a 7- inch twist to ensure the compatibility of the ammunition with those of the MINIMI light machine gun. The cocking lever tilts to one side or the other and the legs are lower and bent. A new bayonet is also being used, with a 178mm (7 inch) blade manufactured in Italy by Extrema Ratio.

Short barrel FAMAS Police model. (Police Nationale)

FAMAS .222 Remington semi-automatic carbine. (MAS)

FAMAS pellet rifle. (MAS)

FAMAS G 1. (F.N. Herstal)

FAMAS G 2 for export. It had no bipod and no grenade lanching device. (GIAT-Industries)

The new generation of FAMAS will be carried out by GIAT-Industries at the Saint-Chamond arsenal (Saint-Etienne is closed now) by transformation of existing FAMAS F 1s. The new barrels will be furnished by Beretta in Italy. 20,000 F 1 rifles will be converted to low profile FAMAS.

Ammunition

The FAMAS shot the F 1 or F 1 A bullets, an exact replica of the M 193 ammunition. Other loadings were: tracer, armor piercing, short range, grenade blank, blank, and dummy. The Army retains steel cartridge cases but the Air Force prefers brass cases. Since the closure of all the cartridge factories in France at the end of the1990s, French forces use cartridges supplied from various countries such as Belgium, Canada, Dubai, and Israel.

The first FAMAS prototype developed in 1969. (Jean Huon)

Right and left side of the FAMAS F 1. (Jean Huon)

| This article first appeared in Small Arms Review V11N3 (December 2007) |