By Frank Iannamico

For many years, the U.S. Caliber .30 M1 carbine has been a very popular firearm among U.S. martial arms collectors. The M1 carbine and its unique cartridge were adopted during October 1941 just prior to the United States’ entry into World War II. The original concept of the carbine was to provide a lightweight weapon to replace the .45 caliber M1911 pistol and the submachine gun. The resulting M1 carbine was handy and lightin weight, especially when compared to the .30 caliber M1 Garand rifle and the .45 caliber Thompson submachine gun. For all of its virtues, the M1 carbine lacked only one thing, and that was a powerful cartridge. The often criticized .30 carbine cartridge had a 110-grain projectile in a tapered case that was 33 millimetersin length with a muzzle velocity of 1,970 feet per second. Those who carried the carbine into harm’s way either swore by it or swore at it.

With ten prime contractors and numerous subcontractors supplying parts formanufacturing the carbine during World War II, there are enough variations to interest everyone; from novice to advanced collectors, and of course shooters. Most of the civilian prime contractors that manufactured the carbine had never before been involved in the production of firearms. Their diverse previous experience ranged from the making of music jukeboxes to automobile parts. The only carbine contractor with any considerable gun making experience before the war was the Winchester Repeating Arms Company, who had also designed the carbine. International Business Machines, more commonly known as IBM, was the last prime contractor selected to manufacture the carbine during 1943. Previously, IBM had made Browning Automatic Rifles and had been contracted to produce a few M1 carbine components for other contractors. However, instead of just parts, the companywas chosen to be a contractor to build the carbine.

In addition to the large number of contractors are the numerous upgrades and modifications that the carbine underwent during its substantial U.S. military service life, which extended into the early Vietnam era. The most desirable variations of the carbine sought by collectors are those that are in their original World War II configuration with all the correct contractor marked parts for each individual carbine contractor. After a long period of service, numerous government rebuild programs during and after World War II, the Korean War and Vietnam service, such carbines are very rare. Some of the most recognizable features of a “correct” early World War II era carbine are those with the L-type two-position flip sight, flat bolt, “high” wood stock, 2-rivet hand guard, push button- type safety, and early barrel band without the bayonet lug feature. Be advised that although the aforementioned features are the most desirable to collectors, by the war’s end in 1945, many of the latest updated parts, such as the adjustable rear sight, round bolt, “low” wood stocks and lever-style safeties were being implemented into production, resulting in a carbine having such late features still technically being considered as a “correct” World War II production carbine.

International Business Machines M1 Carbines

IBM was incorporated in New York on June 15, 1911 as the Computing- Tabulating- Recording Company (C-T-R). The company’s origins can be traced back to developments at the close of the 19th century, making it one of the oldest companies in America still doing business. On February 14, 1924 C-T-R’s name was formally changed to International Business Machines Corporation. By then, the company’s business had expanded both geographically and functionally, including the completion of three manufacturing facilities in Europe.

International Business Machines, reorganized today as IBM, is very well known worldwide for their computers and the IBM operating system. Few however realize the company’s contributions to the war effort during World War II. When the war began, all IBM facilities were placed at the disposal of the U.S. government. IBM’s product line expanded to include bombsights, automatic rifles, carbines and engine parts: in all, more than three dozen major ordnance items. IBM’s president, Thomas Watson, Sr., set a nominal one percent profit on those products and used the money to establish a fund for the survivors of former IBM employees who became casualties of the war.

Of the estimated six-million M1 carbines produced from 1941 to 1945, the 346,500 carbines made by IBM was a small percentage. The M1 carbines produced by IBM were manufactured at Plant Number 4 located in Poughkeepsie, New York and some parts were produced at the company’s facility located in Endicott, New York. Serial numbers of IBM carbines range from 3,651,520 to 4,009,999. While the cost per unit price varied from contract to contract, the average price paid by the U.S. Government was $42.39 each. IBM only manufactured the “standard” configuration M1 carbine. They did not produce the M1A1 folding stock paratrooper or the select-fire M2 models. Like virtually all of the carbine manufacturers of the period, IBM engaged a large number of subcontractors to make their carbine parts. The company only made four parts in-house: receivers, barrels, bolts and trigger housings. Parts subcontracted by IBM would all include their manufacturing code, the letter “B”, in addition to the subcontractor’s letter codes. Approximately fifty-percent of the receivers used in the assembly of IBM carbines were made by the Auto-Ordnance Corporation of Thompson submachine gun fame.

During World War II production runs of all weapons, shortages of parts often occurred resulting in parts being obtained from surpluses at other contractor’s plants to keep theproduction lines moving. Therefore, it would be possible to have mixed contractor parts in a gun and still technically be correct. However, it was during Ordnance Department rebuild programs where the mixture of different contractor parts generally occurred. After contracts were terminated, huge surpluses of spare parts were collected and used for refurbishing or repairing unserviceable weapons. Most U.S. World War II era weapons were rebuilt at leastonce and often a number of times. During rebuild programs the weapons were upgraded with the latest parts, like the adjustable rearsight and barrel band with the bayonet lug. IBM carbine receivers used the integral spring guide design. Receivers made by IBM had the narrow type of tang while those produced by subcontractor Auto- Ordnance had a wider tang.

One of the major parts manufactured in-house by IBM was the barrel, marked with the letters IBM. Barrels made by the company before 1944 were dated while later barrels were not marked with a date. Barrel bands used on IBM carbines were the early Type 1 narrow or Type 2 wide bands. There were no Type 3 bands with the bayonet lug used.

The flat type bolts were used on most of IBM carbines although late in the war the round type bolts were introduced and replaced the flat type bolt. Original bolts had a dull blue finish.

While many carbine contractors used a milled one-piece trigger housing, those used by IBM were those fabricated from stamped parts and brazed together. This type of construction is easily recognizable by the brass colored seams where the parts are joined together.

The Auto-Ordnance M1 Carbine Connection

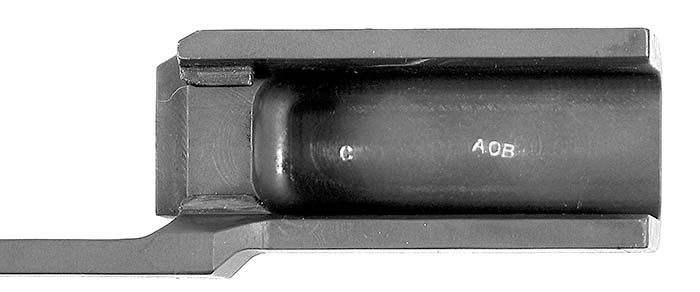

Thompson submachine gun enthusiasts are quite a dedicated group who like to collect virtually everything even remotely connected to the Thompson. One carbine that is of particular interest to this group of collectors is the IBM produced M1 carbine with receivers that were manufactured by the Auto-Ordnance Corporation. Such carbines are clearly identified with the letters AO stamped on the heel of the receiver. Auto-Ordnance also supplied IBM’s carbine program with bolts and operating slides, which can be identified by the contractor code markings: AOB, AOB-FF, FF-AOB or F-AOB. AO would of course designate Auto-Ordnance, the letter B was IBM’s contractor code, while the significance of the letter F is unknown.

For today’s collector the most desirable carbine would have all IBM contracted and subcontracted parts that were marked with the letter “B”. The early configurations would of course be the most desirable with the L-type sight and other early features followed by those with late war features. Thompson collectors would be most interested in the IBM/AO marked receivers, which also happens to be the most sought after variation of the IBMcarbine. While an all-original example can be difficult to locate they can be found with some patience and effort. An unmatchingcarbine would be easier to find and can be restored by locating and installing the correctly marked parts. Manyenthusiasts find a lot of pleasure in the challenge of searching for the correct parts and restoring their carbines to an original “as issued” configuration.

| This article first appeared in Small Arms Review V10N12 (September 2007) |