interview by Dan Shea

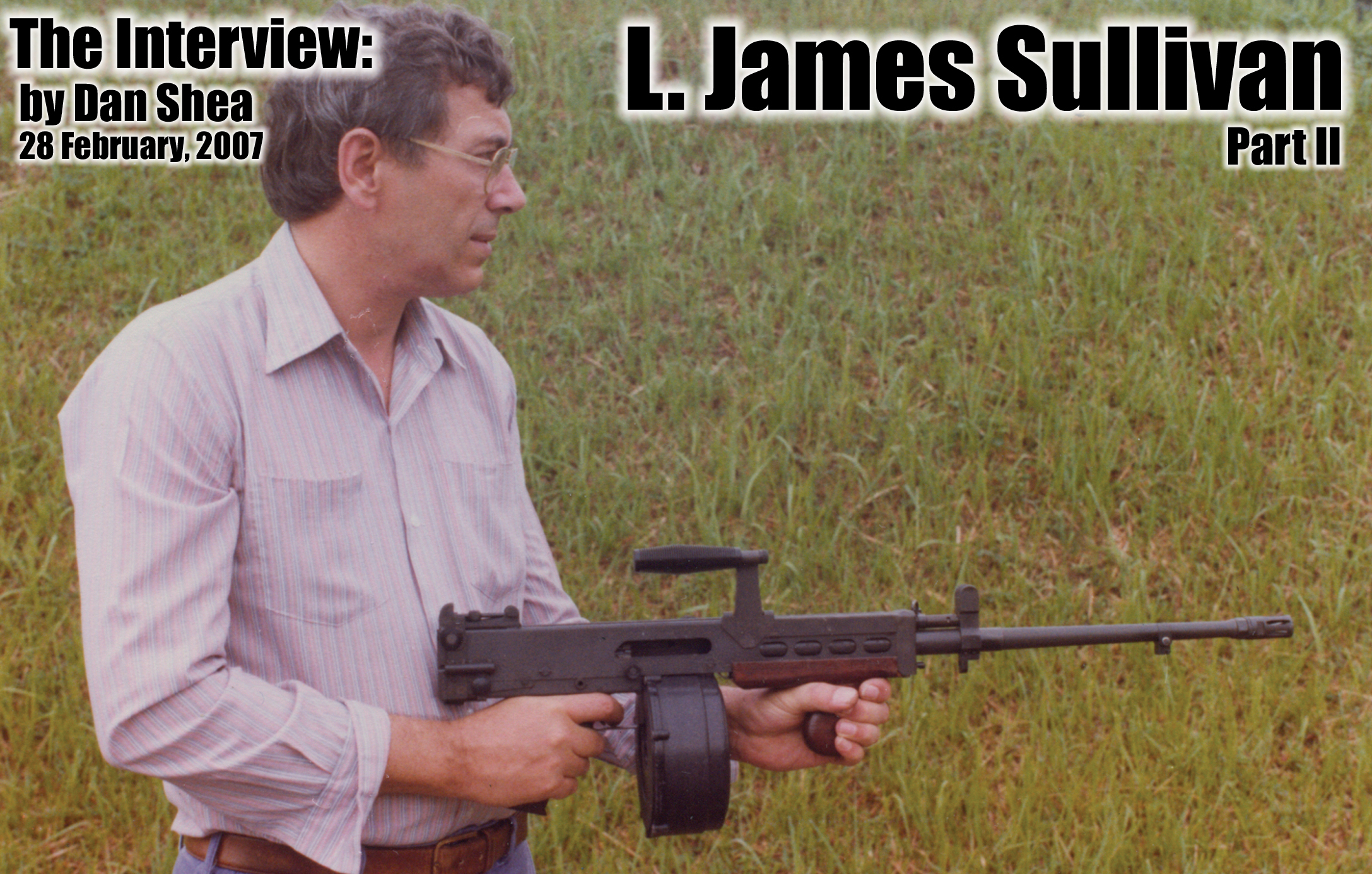

In Part I of this interview (SAR Vol. 11, No. 6, March 2008), Jim Sullivan fills in the blanks on Armalite and the AR-15 project, the Stoner 63 project, digs deep on the Ichord Committee regarding M16 failures in Vietnam, covers the Ruger Mini 14 and M77, as well as his work on the 7.62mm Chaingun, the EPAM, Chiclet Guns, and caseless ammunition. We now join the interview when Jim has moved to Singapore and is working through the Ultimax 100.

The following is Jim Sullivan’s favorite quote on preparedness regarding a 1917 exchange between Woodrow Wilson and Teddy Roosevelt. Woodrow Wilson: “If this country goes to war, our boys will immediately leap to arms.” Teddy Roosevelt: “Whose arms, their mothers’? We don’t have any guns!”

SAR: So, Jim, what inspired moving to Singapore?

Jim Sullivan: Again, it was Armalite. They had been over there trying to sell the AR-18, and the problems between Singapore and Colt on the M16 manufacture also involved the State Department. It was a huge mess. The US State Department wasn’t going to let Singapore sell any M16s they made, claiming US technology was involved. Singapore had contracted with Colt to build a factory to build M16s for their military. They also thought they were going to be able to sell them in the region. Their understanding of the deal with Colt was that they would have that part of the world and they could sell M16s to anybody the State Department agreed to. Once Singapore made their 100,000 M16s for their army, they wanted permission from the US State Department to sell to Malaysia. I don’t know how they found this out, but this is what I am told happened: Colt pressured the State Department to tell Singapore no, because they had a man in KL (Kuala Lumpur) that was going to sell the M16s to them. Singapore’s the one that did all the demonstrations that got Malaysia ready to buy. They wouldn’t have contracted on the M16 if they had known they wouldn’t be able to sell them regionally.

SAR: That’s a deal we’ve all seen before.

Jim Sullivan: Remember, this was when the Munitions Control Act and the new Arms Export Control Act of 1976 (AECA) was coming into play. The ramifications weren’t known yet, so it was hard to tell how things would be viewed by the US State Department regarding US made defense articles, let alone the quagmire of design and US based technology exports. Singapore wanted another gun to make that they could sell, that the AECA didn’t forbid. Armalite was all ready to sell them or license the AR-18 to Singapore so Singapore could make it and sell to, no longer Malaysia – they missed that opportunity – it was the Philippines that was the next customer in line. But again, the US State Department said no way. I wasn’t on the AR-18; that had been Art Miller’s project. I was working nights there at Armalite, so Armalite knew me, Armalite knew CIS and the problems they were having, and so Armalite said to me, “What would you think about going over to Singapore?” They hadn’t talked to Singapore yet. They said they saw one way around this technology transfer issue. The AECA didn’t forbid it at the time, although it does now, an American could go anywhere he wants to and design guns there. They said, “What would you think about going over there and designing a gun?” I jumped on that. They set up a meeting, and they talked to the Singapore people and we all agreed I would go. What they wanted was an assault rifle. I don’t know why they were doing both at the same time, they had bought the Sterling assault rifle, which was really an AR-18 knockoff.

SAR: So, it’s 1978, and you saddled up and headed to Singapore to design a new “Assault Rifle.”

Jim Sullivan: Correct. I took my whole family – wife and kids. It was supposed to be a two year project, but it ended up to be three years. I loved it, it’s a great place. It was a bit hard to get along with the people there at first. We did travel around Southeast Asia a lot. We’d take the train up to KL maybe three times a year. That is the most beautiful train ride around. Only problem was that at that time, people used to not want to go in first-class because the Communists that were in the jungle would shoot at the first-class coaches when the train crossed their areas. Some people, when they’d come to the bad areas along the track, would move back into the cheap seats, with the chickens and goats. Once they passed the Communist Guerilla areas, they’d move back up front. Singapore to KL up to Bangkok: all the way along there. That whole west coast of Malaysia is great. Penang is simply beautiful. Our son went over there first, but he couldn’t get a job, so he went back to the States. Our daughter went to high school there and graduated in Singapore. She just loved it. Every year at The American Singapore School, they’d go off on trips, and she ended up going to about 30 different countries when she was in high school.

SAR: Great way to grow up and learn the world. In those three years, your project was originally to just make something along the lines of an AR?

Jim Sullivan: Yes, an “assault rifle” was what they had said. They weren’t real specific, and I had a bunch of ideas I wanted to try out. One of them was how to make a controllable full automatic gun. If you can’t hit anything in full auto, the gun is worthless. It goes to my guideline rules of Rugged, Simple, Reliable, and Accurate. If the accurate part is missing, the rest of them don’t count.

SAR: I like that motto, it goes to the heart of things. How were the people to work with?

Jim Sullivan: I liked the people very much, but I didn’t like what they call “filial piety.” Your boss is god-like and Americans don’t accept that very well. I was kind of in the same position that Bob Fremont had been. I had argued with the Chairman of the Board and he was an officer in the government. He made a suggestion that I didn’t think would work and I argued with him about it. Everybody froze up solid, but I wasn’t going to give up on it. I was expected to stop talking because he was upset.

SAR: That’s not really an American trait.

Jim Sullivan: (Laughs) You got that right. Anyway, he ended up beating his hands together, and he couldn’t even talk he was so upset. (Laughs again) Two guys helped him out of the room. They said, “Don’t anybody leave,” and we just sat there absolutely silent, nobody could talk, and pretty soon they came in and said, “Okay, you can leave now.” Last I heard of that!

You know, they had good machinery, but the machinists were basically uneducated types that are just naturally gifted people. They did good work because they had this innate understanding of mechanisms and mechanics. I got along real good with them. Funny, because they didn’t speak English and I didn’t speak Mandarin. It was a difficult environment in some ways. I had designed this thing, and it was obvious how it was supposed to work, and the machinist was making the two or three parts that had to go together. The other engineer who kind of acted as the interpreter went out because of a fuss going on out in the machine shop. He came back in and the machinist was hanging his head, following along. These two parts didn’t fit together and they were ashamed. I said, “Oh, well, he gets 20 lashes.” (Laughs) They kind of brightened up because I was kidding, and pretty soon they went back and came back in again with the drawing, and they were both kind of smirking, and here it was because of my mistake on the drawing. I said, “Okay, now you only get 10 lashes.” They all laughed, and that story went all through the plant. It became real easy to work with everybody over there, there was no tension at all like there had been at first.

SAR: Let’s recap this. You had ideas, and you’d seen and designed different systems and studied all around. At this point you had 25 years of small arms design, and now you’ve got a country and a company that wants a rifle, and they’re not really quite sure where they’re going with it, and you’ve got full access to the machine shops and design. The end result is one of the most controllable machine guns ever made, the Ultimax 100.

Jim Sullivan: Yeah, it was great! I started in on making a machine gun that in fully automatic fire would be accurate. I had lots of ideas, plus some things I had seen elsewhere – you know Hugo Schmeisser’s work, I had seen the guns. In fact, they had some at Armalite, but I hadn’t paid much attention to the STG, although I recognized some kindred ideas. The Ultimax idea came from over there. It wasn’t until I was working on this thing as an assault rifle that it all clicked. One of the things about 5.56 being a small cartridge with low impulse is that you don’t need excessive length in the gun. I had already recognized that as a blowback submachine gun, the MP-18 in World War I was designed to get controllable full auto, but that was a blowback gun, and I got to thinking about that principle. How could you do it in a gas-operated gun? You can’t use blowback, of course, with a high-pressure cartridge like a rifle cartridge. The case walls seize in the chamber and it’ll just blow the back end right off the case. The pressure needs to come down enough so that you can get extraction. Pistol bullets that are used in a submachine gun are low pressure so no problem, but that higher pressure was a huge stumbling block. We had solved this in several weapons before, but not to my satisfaction for a controllable weapon. They gave me several guys to assist me, and I invited Bob Waterfield over there too. He came over a couple of months after I had started, and I’m glad he did. Bob did almost all the work on the 100-shot round magazine, and I concentrated on the gun, but there’s a lot of overlapping on that type of thing. He did an excellent job. Think of the requirements we faced. First, I had to design a gun that would fit the equipment they had at the factory; that they could build with what they had. The reason that factory could make the M16 is because Colt had come over there and gave them all the production equipment, tooling and everything else, a turnkey line. Now, I had to design a gun that could be built on what the factory had, or could use. The skills necessary to manufacture something are different from the skills needed to design something. My specialty is the product, not the production end of it and I now had to engineer for manufacturing capability, not what might have been my best choices.

SAR: Adding another dimension to the design phase. Any examples?

Jim Sullivan: I used sheet metal that was simple to form – not drawn, complex shapes. These were very simple shapes requiring very simple machining. And to also make use of some of the Colt machines and processes because by then they were familiar with them, so that they were similar type. Other than the magazine, there are no dimensions that are the same on the two guns. But some of the machining that’s done on the bolt and bolt carrier is similar in principle, so they could set up and do it.

SAR: Did you have any problems with the system you designed?

Jim Sullivan: There are always problems. I made a first prototype. Talk about a plumber’s delight. Except for the barrel coming out of this junk pile, you wouldn’t know it was a gun. (Laughs) I tackled that thing very early on and got the controllability I wanted but not the looks. Then I made the gun fire full auto only, and from the open bolt, and tried to interest them in working backwards towards the assault rifle idea. I was going for an open bolt, closed bolt trigger mechanism. You really can’t get accurate semiautomatic fire from an open bolt mechanism. You get too much lurch in the gun before it fires, throwing your aim off.

SAR: So you went off on a tangent to the goal of an assault rifle. Were they supportive of that?

Jim Sullivan: Yeah. What I was doing there for the first year, and what they were doing was in parallel, and they would only end up with one of these guns. What I suggested to them is why don’t we break off and go in this direction, and come back to the assault rifle? They liked that idea because they saw that of these two programs, one of them would just die a natural death. I knew that would happen too, and I didn’t want it to, because I really had something with that controllable full auto.

SAR:What’s the heart of the system?

Jim Sullivan: Everyone thinks they know the reason a gun kicks. A bullet goes this way…

SAR: …and Mr. Newton tells us that there will be an equal and opposite reaction….

Jim Sullivan: …and it’s true you can’t violate that principle, Dan, but recoil is a measure of force times time. Let’s take a simple bolt action rifle: The force of recoil is the same force that’s driving the bullet, and it’s for the same amount of time that it takes to drive that bullet. In other words, whatever amount of time it takes to accelerate that bullet from the back of the barrel to the front, and out through the front of the barrel, that amount of time is what that same force is pushing rearward against the gun and against the guy’s shoulder. Okay, of course it kicks, but here’s the thing: that time is very short, so the force is very high. Recoil is a function of force times time. In a machine gun, let’s say it’s firing 600 shots a minute, that’s ten shots a second or one shot every one-tenth of a second. You have one-tenth of a second to deliver that force. If you’re delivering it in the one-thousandth of a second that a bolt action rifle does, you’re screwed. But if you can find a way to stretch it out, instead of a thousandth of a second, stretch that time out to a tenth of a second, that’s 100 times longer. That means the force is one one-hundredth, and it’s the force that moves you, not the time. It not only means that you can reduce that force to one one-hundredth; that’s a hell of a reduction in force. It also means it becomes a constant force, because you time it so that it fires this shot and stretches all the recoil out until exactly the time it fires the next shot. So the force is not only a very small force, it is now constant. It doesn’t hit you as a bunch of sharp impacts.

SAR: OK, Jim, the mass of the bolt is traveling rearward after it unlocks. It travels rearward on the spring, and that spring applies pressure against the rear of the stock and the platform, the shooter’s shoulder. That bolt mass never has a jarring impact to the rear because you’ve got such a long recoil spring designed into this. It runs out of energy, and the spring energy forces it into return. So the spring is always constantly pushing backwards against the platform, which is your shoulder.

Jim Sullivan: That’s right. You don’t have two things going on in there: it’s constant over the stroke. You can’t do it perfectly because of friction and a lot of other things. If you take an assault rifle of the same weight as the Ultimax, the Ultimax out-hits them about eight-to-one, on light machine guns it out-hits them three-to-one, but they’re heavier. It’s finding the harmonic of a machine gun, and balancing it with a constant recoil system.

SAR: So, what was the response from CIS to this?

Jim Sullivan: Excellent. We went to the range, and they were impressed. It’s a shame it never made it to the SAW trials in the US. The Ultimax kicked the M249’s ass in all of our trials! But, the politics involved kept it out.

SAR: It’s 1978 and you’re with your family in Singapore, and you’ve designed the constant recoil system in the Ultimax 100.

Jim Sullivan: Singapore was 1978 to 1981, and the Ultimax was what I did first. We got the proof of concept done and we took it to one of their army bases to shoot. They did the firing against their M16s as I think that was all they had to compare it with. Later on, they got a hold of some of the Minimis. This is before the US adopted the Minimi. After they fired the Ultimax they were sold on it, and that was very early in the program. Bob hadn’t finished the 100-round drum yet and we just used a standard M16 magazine. The prototype gun looked really crude but it was the first step. This was about the time that I found out that they had been running a parallel program to make the Sterling rifle, what became the SAR80 in Singapore. The US military had come out and I suggested that we go in this new direction, do this machine gun first, partly because the US military already had come out with the Squad Automatic Weapon requirement.

SAR: So you saw this as a possible SAW candidate?

Jim Sullivan: They were so angry over the State Department screwing them over on the export of the M16 projects that they refused to enter it in the SAW trials. This was too bad because it would’ve beat that M249. By then we actually had tested it against the new M249. There was no way to really compare it because the guys in Singapore couldn’t hold an M249 on target at all. One guy fired the thing. It was kind of a gravely berm and he was laying at an angle to the gun. He started shooting and it was so wild that he froze on the trigger. It swung him around and rolled him over. He was firing straight up in the air, and we’re all steppin’ and fetchin’ all around there. Luckily, he ran out of ammo. There was a lot of nervous laughter after that. They couldn’t hit anything with it. They wanted to get into production on the Ultimax immediately. There were actually 16 patentable items, and they patented it in 19 countries: separate patents. That’s the most patents I’ve ever had at one time, but patents run out after 17 years. At any given point the most patents I had active was 200, so I’ve gotten a lot of patents, on a lot of guns.

SAR: How many of the Ultimax 100 were made?

Jim Sullivan: I never got a full count, but about 10,000 for their army. One guy out of ten had the Ultimax 100. They’ve got a system like Switzerland does where everybody has to go in and serve. They have a fairly big army, 100,000 men or so. I looked on Wikipedia on the internet and they said they’re up to 80,000 Ultimax 100s made now, so they’ve sold a lot of them. A lot of the users are Central and South American countries.

SAR: I understand that the Mark IV Ultimax, with the quick changeable barrel, has some interest in the US military. Vince Dinero is involved in that project.

Jim Sullivan: Yes. Bob Waterfield and I went back to Quantico and put on a demonstration with the Ultimax. This was a different group of people from the ones who had tested it a year before that. There were four guns they had tested at 29 Palms. Ultimax was one, and they had a Colt Light Machine Gun, HK’s MG36, and the M249. Somebody had taken off the elevation slide on the Ultimax. On the Ultimax, when the aperture drops down without the slide, all you see is a pivot pin and you can’t get a sight picture at all. Still, on one of the tests, it beat the M249, and yet nobody could get a sight picture. Out of all the four guns, the Ultimax was chosen by almost all the Marines that tested it.

SAR: Are you familiar with the Israeli Negev?

Jim Sullivan: Yeah, I am, I’ve fired it. I was over at IMI one time, and they were going through their paces with that thing. A lot of similarity in the Negev system to the Ultimax but it’s not controllable like the Ultimax and it’s no better than the M249 in my opinion. They shortened the travel, and didn’t really get the constant recoil thing although people say the Negev does. It doesn’t.

SAR: In 1981 you left Singapore?

Jim Sullivan: From there I went to Italy. I had a program where I did an assault rifle for Beretta. They had the AR-70, then the AR-70/90 later on. There was one gun I was supposed to do, and there was another they were doing with SIG or somebody in Switzerland. That had fallen apart on them and whatever that program was they weren’t able to sell it to their own military. Beretta wanted a new gun to offer. Again, the Armalite people kind of lined that up because they knew the people over there at Beretta. I spent a year and a half there and did a prototype of that.

SAR: They never completed it? Italy has some new offerings now.

Jim Sullivan: All they did was a prototype. My agreement with them was a royalty agreement. They couldn’t make it without my permission, and we hadn’t reached the point where they had signed yet; assignment hadn’t been made. What went wrong was, right about the time I got done with it, their Air Force went and bought 17,000 of the gun they thought they were never going to be able to sell to their military. They didn’t need my project anymore. Mine was a controllable full automatic weapon, somewhat different in principle from the Ultimax, and it would have an open bolt, closed bolt trigger mechanism, to fire accurate semi-auto. It had a precise quick barrel change. You need the barrel change for hot barrels for the machine gun role, but that traditionally has ruined your accuracy, it makes for a loose, sloppy fit for barrel, for heat expansion, and ruins it as a rifle. But this system didn’t do that. It was accurate hot or cold, you could change barrels and it stayed put on accuracy.

SAR: At the end of that project you came back to the US?

Jim Sullivan: Yes. I met a US submachine gun designer named Gordon Ingram. I had actually known him for a while and one day he and his “angel” who had funded one of his programs ended up there at Beretta. We all went out to dinner together. This was right about the time things were falling apart on the Beretta project, and it looked like there was going to be no completion on this thing, and his angel asked me to do the C-Mag for him – it was part of my Italian project ideas. Actually, he feigned interest in the C-Mag. What he wanted me to do, though, and this ended up kind of as a fight between myself and Gordon, was to take Gordon’s program over, where in this guy’s mind, Gordon had kind of messed up. There were problems with the gun. That’s what the guy wanted me to do. Gordon had been working on something similar to the Mini 14 idea in 5.56, but it was based more on the M1 Carbine.

SAR: He didn’t have a drum magazine for this…

Jim Sullivan: No, it was an assault rifle. The gun I did for Beretta had a double drum magazine. It was the predecessor of the C-Mag. I took the innards out of my Italian design and that eventually became the C-Mag, but that was my design, my invention. It didn’t belong to Beretta yet, because they hadn’t completed the program because our agreement was they had to fund the whole thing before I made assignment. They hadn’t done that. So, I was with Gordon and his financial backer, and I mentioned this C-Mag – it wasn’t called that at the time – and he got all excited about it. He wanted me to leave Beretta, and that was fine with me because it was all coming apart. I still had to complete some stuff, so I said, “Okay, in two months we’ll get on this C-Mag.” Before the two months was up, it became clear that what he really wanted me to work on was Gordon Ingram’s program. Well, I wouldn’t do that. The thing that Gordon and I had the fight over was that this guy that was funding all of this, he was setting up in Somalia, in Mogadishu. I had gone down there, still thinking the interest was in my magazine, and it wasn’t. Gordon, when he found out I was going down there, he thought I was stabbing him in the back. I wasn’t, but he thought that.

SAR: Did you ever get that squared away with Gordon?

Jim Sullivan: Yeah, but it took a while. He never did quite trust me after that, which is too bad. Anyway, I did make the deal on the magazine with the guy. He was kind of an entrepreneur. It wasn’t his money, he had a group of investors lined up, and one of them was the ex-governor of Georgia, Carl Sanders. Sanders was the real investor in this thing, and then he and this entrepreneur had a falling out, and neither one of them owned enough of it, and they got Sylvia involved, otherwise it would have fallen apart.

SAR: What was your inspiration on the beta C-Mag?

Jim Sullivan: I designed it there in Italy for the purpose of the gun I was designing, and I used a double drum magazine because it makes a lot of sense. You’re familiar with the old German saddle drum magazine?

SAR: Of course. The 75-round saddle drum fit on the MG15 and the MG34 with a special top cover.

Jim Sullivan: I was going to do that basic design, only the one I did for Singapore, the two drums were right up tight against each other. I had to spread it out again when I made it a C-Mag; when I wanted to make something that would fit the M16. But the thing about it is the M16 was designed for a 20 or 30-shot magazine. We really designed for a 25-shot at the start. The bolt comes back, it barely over-travels, 3/16ths of an inch, and that’s enough time for the cartridge to get up there before the bolt is bounced back forward and starts chambering it. The C-Mag, you couldn’t make 100 rounds work, because 100 rounds moves slower than 30 rounds. In theory you can just make the spring three times stronger and get it to move as fast, but in reality you can’t. It’s like putting the brakes on and the gun couldn’t cycle. This was all in 1983.

SAR: Where did the physical work get done for the C-Mag?

Jim Sullivan: In the US. The original idea was to make this an expendable package of ammo that the soldier would use once and toss. The ammunition was going to be low temp ammo. On the technical side, barrel heat doesn’t really come from the powder gases; it comes from the friction of shoving a bullet through the barrel with the brakes on. A Spitzer bullet, a lead core bullet, remember that we think of lead as a solid, but lead is real weak, and it’s nothing more than hydraulic fluid when it gets heated. Imagine a bullet copper skin has been filled with hydraulic fluid, and now you hit it with 50,000 psi behind it, driving it through the barrel. That’s where barrel heat comes from – resistance. The reason I know that is from the ammunition that we did: Delta ammo. It’s a steel bullet with a plastic sabot, and the rifling twist is transferred from the sabot into the bullet by fingers that reach through grooves on the steel bullet. You can get 19 grains of powder to give you as much energy in 5.56 using that as 26 grains in standard ammo. The difference between 19 and 26 isn’t really the barrel heat. Sure, the powder’s got something to do with it, but a bullet only takes one millisecond going down the barrel. The powder hangs on for a little while longer. It’s venting out the barrel. It’s about one and a half milliseconds at 5,000 degrees, which is hot as hell, but that’s 5,000 degrees for only one and a half seconds on a long burst. That won’t heat that barrel up enough to boil water; the real heat is coming from friction.

SAR: One and a half seconds, you mean…

Jim Sullivan: Yeah, a thousand-shot burst is the equivalent of a 5,000 degree torch put on the barrel – 5,000 degrees for one and a half seconds. You can take 5,000 degrees and go very quickly like that over the back of your hand and it doesn’t do anything. That’s about a half a second that you’re exposing it to. At one and a half seconds, an M16 barrel, just to use a well-known weight, is 1.7 pounds. It will not heat 1.7 pounds up more than 30 degrees. It won’t even boil water. There are all kinds of things that should have been done by now in small arms development. You don’t need water-cooled barrels or seven-pound barrels on .30-caliber machine guns. You can get by with rifle barrels if you design the ammunition correctly. Nobody’s doing this kind of work.

SAR: Reducing the friction? What about the chamber heat?

Jim Sullivan: Most of that just comes back from the pressure, from the heat that builds up in front of it. The hottest part of the barrel isn’t the chamber area, it’s well forward of that. That’s one thing you can do to fix the systems. You can get rid of barrel heat, not entirely, but you can sure reduce it with ammunition design. Since the barrel’s the heaviest single part in a machine gun, if you can cut two and a half pounds out of a machine gun barrel and get rid of a quick barrel change, you’ve done something for a machine gun. Although I developed the magazine in America, I had invented the ammunition in Mogadishu, so we chose England to develop that in. You could still do that back then. Americans could still develop things overseas. Today you can’t legally help a foreigner in designing munitions. That’s the AECA. All this was before that law changed, and I went and developed that ammunition in England. The name of the company was Delta.

SAR: What happened with the C-Mag?

Jim Sullivan: The C-Mag became a success; just not so much in this country. Remember, the C-Mag is a different type of drum. The Ultimax drum moves pretty slow. The C-Mag has an accelerator in it so it’ll work on an M16 because you don’t have much time to get that top cartridge lifted up and presented. The way they work, it’s like two rings of ammunition moving together, and you can squeeze them together. They make their full circle and they get to the end of their circle, and then they get squeezed. As they squeeze together, this doubles the speed of the cartridge. It’s changing it from a double column to a single column. That doubles the speed and cuts the force in half. Now you can have twice the spring force and twice the speed of the cartridges at the top. If you took the Ultimax drum, it wouldn’t be near fast enough. It was fine for the Ultimax because I sailed way on past the back end of the magazine and gave it just lots of room, lots of time before it starts ramming the cartridge forward. You can have a sluggish drum magazine. Before the C-Mag the only way you could get something like this to work was you had to design a gun for a drum, you couldn’t just put a drum on there. Some of the other high capacity designs, well, they’re not that reliable because they use way too strong a spring force. Spring force equals drag on the bolt. That limits the reliability of the gun. It’s all about getting that cartridge out there just as fast as if you had a 30-round magazine. The C-Mag system does it.

SAR: How long did you work on that project?

Jim Sullivan: Six months, I guess. It didn’t take very long. That’s been pretty successful, but not in the US military market. The US, they don’t seem to even know what’s out there, and for another thing, they don’t test anything in the US unless they have a big budget for testing. That means they don’t like to test anything that they haven’t written a requirement for. That means they don’t write requirements for stuff that’s already there. I don’t know what’s gone wrong here. When I say “they,” I mean Army Materiel Command and it’ll be one of their agencies. I don’t think they’re opening the market up to enough tests other than just specifically the things that they are writing a requirement for and not testing what’s out there to see if it suits. The other thing is they like program longevity; I mean to the point of the extreme. They never want a program to end. I think the last thing they want is the successful conclusion of a project.

SAR: You’re defining “bureaucracy.”

Jim Sullivan: I know, and the contractors know that, and cooperate because they want it that way too. That’s why they love stuff like caseless ammo, even if somebody in there knows that they’ll never get to the finish line with that idea, they love those programs. You can always make small incremental improvements.

SAR: Still, there have been a lot of successes and advancements out of these programs…I mean, research has its place, but admittedly not as many fielded projects as there have been programs.

Jim Sullivan: (Jim gestures emphatically) That’s the whole point! Look, after C-Mag, I had made some money, and I went back to my office in Armalite and did a lot of proposal work and stuff. I did a lot of consulting. I went over to Royal Ordnance, Nottingham; just short-term stuff. Looked at the British SA-80 program. It was at the time they were shutting down RSAF and Enfield. They had already switched all the manufacturing to Nottingham. There wasn’t all that much to my involvement. They asked me to go over there and take a look at it, I did and I told them my views on the gun, and they got angry and that was the end of it. From what I saw, everything about it was wrong. For instance, they were using an M16 type bolt and not making it right. In manufacturing it, first you drill a hole for the firing pin. Once that hole is there, everything centers on that hole. You turn the outside, you cut the slots and everything else. They didn’t do that. They cut all the outside first, then tried to drill the hole for the firing pin in the center. It wasn’t “true.” Then they found out you can’t drill a hole that way, holes go off this way and that way and aren’t centered. To solve that, what they did was mess with the firing pin tip. The firing pin has a nice, respectable diameter for most of its length until the front. Instead of a tapered firing pin so that it’s good and strong, they just narrowed it down, and they had the thing about a half-inch long, and just a sixteenth inch in diameter. Another thing was the magazine well. It’s a sheet metal receiver, and the magazine well is sheet metal, but it has to be welded on. That’s fine. But the sheet metal stamping for the magazine well, they stamp the slot, the little hole, the slot for the magazine latch, they stamped it in there, and then they weld it on. I mean, sure, you save an operation because you can stamp the hole instead of machining it, but no two latch positions on any guns are precisely the same. Their magazines on some of the guns were jammed up and the bolt couldn’t move ’cause the magazines were stuck in there on some guns. On other guns it was too low, wasn’t feeding properly. They didn’t fix this stuff, it just went on and on like that. They’d hold plus or minus one-thousandth, completely unrealistic tolerances, which nobody could make the parts to. The firing on that trip when I went over there was still done at the only range they had, which was still at RSAF Enfield. One of the things you do to test is you load up a mag, put it up in the rifle, you fire a shot and let the thing cycle and chamber the next round, and then instead of firing that next round, you hand extract it and look for scratches on it. When I did this test, it was just scratched all to hell. They weren’t up on that. The back end of the lugs, you’ve got to carefully smooth off that corner. These were just raw. It was just cutting the cartridges. I don’t know why they weren’t getting split cases from that. Maybe they were.

In part three of the interview with L. James Sullivan, we cover Uzi Gal, the Ruger SMG, Kalashnikovs, “Sacred cows”, his current design work and Jim takes a no-holds-barred look at the current USM4 issues. Don’t miss it!

| This article first appeared in Small Arms Review V11N7 (April 2008) |