By Dan Shea

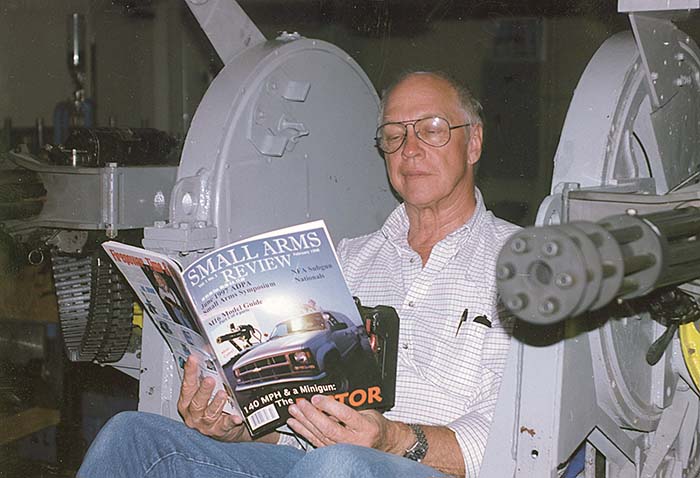

Most SAR readers will be familiar with Mike Dillon’s name- for many years he has been very high profile in the shooting world. Anecdotes abound, but SAR had the chance to sit down with Mike a little while ago, and the ensuing conversation stretches from the shop, to the office, to the hangar, to the Huey, out over the Arizona desert, following rivers and valleys, then back to a nice Italian restaurant in Scottsdale. Over the course of the conversation we covered many subjects, but in this first part of the interview we will stick to some history of Dillon Precision, Miniguns, Philosophy, Helicopters, Airplanes, Ballistics, Physics, and the learning process that started Dillon on the road to where he is today. In Part II, in SAR Volume 2 Number 3, Mike gets into the dynamics of reloading, specifically for machine guns, and we have his private recipes for Thompsons, 1911’s, M-16 / AR-15’s, Brownings, and a few more… Herewith we begin at the beginning…

SAR: What was your first gun Mike? What’s the first firearm you had?

Mike: The first one? I had a .22 Mossberg semi-automatic rifle. The first machinegun is easier to remember, it was a Tommy Gun; a Model 1921 Thompson. Still have it. I got it back around 1978. A good friend of mine died in an airplane crash. He had introduced me to machine gunning- the crash killed him and another friend of mine and we spent a considerable amount of time settling and locking up his machine shop and settling his estate for his widow. She wanted me to have something from the estate, and she gave me the Tommy Gun and a Star reloader. I guess this was the moment that launched me into the right path in life.

SAR: Was the Star reloader your first reloading machine?

Mike: My first reloading machine was a Lyman Tong tool, that I used to load .45 Long Colt for my Single Action 45 Colt. That was the first centerfire gun I ever owned. No, in retrospect it was probably the second, I think my first centerfire gun was a Winchester 30/30. I really liked that Single Action Colt, but I never learned how to shoot it! My buddy Jimmy Cavenor went out and bought a Smith and Wesson K38 with a four inch barrel. At that time he couldn’t afford a Single Action Colt, (even in those days a Single Action cost more than a K38 did), and I was really mortified that I had this beautiful Single Action Colt that I couldn’t hit the broad side of a barn with, and he could take this K38 out of the box and nail targets immediately. I could really fan that Single Action at an alarming rate of fire, though.

SAR: What was the target effect?

Mike: All the rounds hitting about 3 or 4 feet in front of my toes- but hitting the target really wasn’t the point- it was fun!

SAR: You’re well known around machinegun circles as being focused on machineguns, belt feds in particular. How did you start into the belt fed guns?

Mike: When I started making loading tools, well, more like messing around with loading tools, I modified that Star tool to .223. We put out a little kit that we called a SUPER STAR KIT. The SUPER STAR name came from Peter Kokalis, who was ridiculing me when he said it of course, but fairly quickly other people were asking me to make other modifications; make a machine to load 30/06 or whatever, and at that point I figured I needed a machine gun to test the results on. I bought a Hudac water-cooled Browning.

SAR: So you were specifically reloading for machineguns- what calibers?

Mike: Basically 30.06, .308, .223 and .45. People would call me up and ask me about their 257 Roberts or something of the sort and they have this problem or that problem, and “Mike, I know you’re an expert so I’d like you to help me with it…” I’d say wait a minute, you have to understand I do consider myself an expert in loading .223, .308, 30.06, .45 but that’s about it . Outside of that I didn’t know a damn thing about reloading.

SAR: When you were first reloading were you using other commercial tools to load for machineguns?

Mike: I never did. I mean I used that modified STAR to load 223 and 45, but I never reloaded any other calibers on anybody’s machine except for the ones that I made.

SAR: Were you driven strictly by a desire for more ammunition to shoot?

Mike: Truthfully, probably not. That is an element of it. I was driven by a desire, no, compulsion is probably a better word than desire, just to build things. I mean I LOVE to build things. I’ve been that way since my earliest memory of sitting on the apartment floor in Brooklyn, New York, pre-school age, building things with an erector set. I adore building things.

SAR: So this passion for building things translated itself into problem solving, and eventually Dillon Precision.

Mike: When I first started the company, I was a full-time pilot for TWA. I didn’t have as much time as I would have liked to. First off, I’ve never been a morning person, I don’t start real early. But I worked until I dropped. When I would start working I’d have no trouble with inspiration or adrenaline but the body can’t always keep up with that. I would work often until the sun was coming up, and I would go home after daylight having worked all night long. I had to set a rule for myself in that I would not work in the machine shop once I started stumbling. When I start missing steps I realized I was too tired to be working around machinery. I would keep working around the loading machine and one night I was in about that state, it was probably around 3 o’clock in the morning and I was loading 223 on the RO1000 and I was amazing myself with how fast I could go. I’d go a little faster, a little faster, a little faster until I finally I didn’t get my hand out of the way and my index finger on my left hand was speared by a cartridge case. I actually drove the cartridge case right up inside my finger. It was painful and very irritating, so I took a wrench and took the die out of the tool head. I put the die in the lathe and put a big 45 degree chamfer on the bottom of it so that if I did that again, it would sort of push my finger off. We used this chamfer in many of the dies. The next morning it looked like a major catastrophe had happened in the shop- you could track my blood from the reloader to the lathe and back again. I got so consumed in fixing things that I wasn’t paying attention to the pain.

SAR: Were the Browning guns of particular interest? I notice that you have a lot of variants, and used several different types in Machine Gun Magic.

Mike: Miniguns were the stars of that of course, but the Brownings are a very reliable gun. Probably the most interesting thing to me about the 1919 Browning, was the fact that when I first started reloading you could by H335 powder for about 25 cents per pound. Maybe it was $1.50, but it was still almost free the stuff was so cheap. I bought huge quantities of H335 and used that to load everything. It’s a great 223 powder and it’s an acceptable 308 powder, but it is NOT a 30.06 powder, which I discovered the hard way. I blew up my Browning about 3 or 4 times with it. Burst the case and bowed the top cover and you know how it is with a Browning; the cure is a 3 pound hammer. You drive the top cover back down where it was and you keep on shooting. It’s a good gun. I tried everything I could think of, I mean it said right there in that old reloading manual that the damn powder works for 30.06! I’d load this stuff and I’d get erratic ignition to the powder. I’d get muzzle blast that was enough to knock you off your feet, huge flames out the front for one round and the next round would burn clean. Then you’d get hang fires and the result of the hang fire was it would blow the back out of the case and bulge the top cover. We had some of that ammo tested- I took about ten rounds from right next to the shredded piece of the belt, and the parts of the destroyed cases, and sent them away. Results came back that pressures were erratic, but not all that high. It was one of those educational experiences in ballistics. There are certain combinations of powder and volume of case that you can’t combine. I mean the damn thing just blows up.

SAR: Too much volume?

Mike: To much volume for that powder. So I quit using H335. A748 will produce similar results in a 30.06. You’ll get short cycles because the powder is burning outside the barrel and yet people say it’s a quick burning powder, I can’t tell you what the formula is, but I can tell you that there are certain powders that in large capacity cases DON’T work properly.

SAR: When you say “explodes” it has a certain implication. Do you consider the mechanics of that, the physics of that, to be that the burning propellant gases are expanding and there is too much space for them to expand?

Mike: I think that and there was one other instance which made me decide that there were certain mysteries about powder burning inside the cartridge case that no one understands. Bob Ferris was there one day when I had a hang fire in the Browning. It went ZIP – BOOOOOOOM and ruptured the back of the case, broke the tee slot on the bolt that bolts the top cover, and I said “OK I am not touching this Bob, you come over and tell me what happened”. So he came over and put his hand underneath the ejection port and the case came right out. It looked like a prune. The case was completed collapsed. The hang fire had been just enough to push the bullet out of the case and into the rifling. The pressure in the case wasn’t sufficient to seal the case against the chamber wall. So now when the powder exploded, it was all down the barrel, and it went back alongside the case and crushed the case in the chamber, and blew the back off the case. Once again, the convenient thing with the Browning- you throw another bolt in it, take your three pound hammer and straighten the top cover and keep right on shooting. You haven’t even slowed down for the day. Brownings sure are a wonderful gun.

SAR: As far as belt feds go, it that your personal favorite?

Mike: Well, if it’s going to be mounted on something, probably yes. It’s hard to pass up the Minimi though, a gun that’s a lot of fun, because you can comfortably carry it around.

SAR: So in .223, did you load more for the Minimi or the M16?

Mike: I bought a huge load of linked .223 for the Minimi, so most of my experience would be with the M16 / AR-15 series.

SAR: In loading for the M16 series, have you done any accuracy testing personally or worked with people who were working for accuracy?

Mike: Yes, there were a couple of surprising incidents that led to our present reloading philosophies. We can cover specific recipes later. We went out shooting one morning, and Kokalis had an M16 carbine he had just gotten that little 3 power Colt scope on. I had an M16 and another guy had a Mini 14 and we went up to the range and set up. Pete was shooting his reloads using Hogsden H322. That has a DuPont number. It’s an extruded powder, an IMR powder where the grains are cut so short that it meters just like ball powder. It is the best powder for a small capacity high-pressure cartridge that there is. The silhouette shooters have taken to it. I mean it’s a beautiful powder, it’s great. He shot off a sand bag rest on the bench at 100 yards, getting sub-minute groups with an M16- a machinegun- right out of the box. He then took my H335 reloads and shot those, and they opened up to about 11/2 inches. It wouldn’t have surprised me if my loads didn’t shoot as tight as his just for psychological reasons. What did surprise me is that the group moved about 2 1/2 “ up and about an 1 1/2” to the left. The group was in an entirely different place on the paper, not just higher or lower.

SAR: Same rifle?

Mike: Same rifle. He then shot GI loads in it, which were bloody hot, 3150 feet per second or so. The group opened up to almost 3” and moved to an entirely different spot on the paper. I am thinking, what in the HELL is going on here. As far as throwing a 55 grain projectile, it can’t change where it’s going to go that much just because of a few feet difference in velocity. Why is it moving around the damn page?

SAR: Did you ever get an answer for that?

Mike: Yes. I saw it on television. There was a series on the Discovery Channel or something like it, we called it the education channel at that time. The show was on high-speed photography and one of their examples was photographing a cannon shell being fired out of the barrel of a tank. As this cannon projectile exited the barrel, it was tracked by a high-speed camera. It was painted alternatively black and white so you could clearly see it turning. The camera tracked it from the barrel at right angles all the way down range to the target. This projectile, which had to be 20” long, exits the barrel and as soon as the base of projectile clears the barrel it pitched up, must have been 15 degrees, and then as it tracked it, it pitched down about 14 degrees, up about 13 and down about 12. It kept wobbling its way down range, and you would have thought “Damn, that’s not going to hit anything”. The camera tracked it down range right through the bulls-eye. Right through the center of the target. Now, I understand something about ballistics, that the round comes out of the barrel twirling at 3000 feet per second, which means 3000 rotations per second, in a one in twelve twist. So you take 3000 x 60 to get the RPM and were talking about 180,000 RPM. That why it’s stable- it’s a Gyro. Seeing it made it clear.

OK, but what happens when you put pressure on a spinning object? You get gyroscopic perception, gravity is pushing the bullet down, the instant it clears the barrel, gravity acts on the bullet and upsets the Gyro. The Gyro then, as it’s spinning, returns its path to stability. At what rate it returns it to stability dictates where the bullet is going to go. So in short, any time you change the minutest characteristic of the velocity, pressure, weight, balance, anything at all, the bullet is going to go some place else, because it’s only through this miracle of mathematics that it ever goes straight to begin with and it does not come out of the gun stable.

SAR: Any variable at all can change point of impact, even if the group is tight…

Mike: And there is no way to predict where it will go. That round leaves the barrel in an unstable manner. We learned a lot more than just seeing the theory in action as I just mentioned. Combined with this business of the gun blowing up, and we still couldn’t figure out why these cartridges were blowing up, then I was told that there were experiments where they had transparent chambers where they could high-speed photograph the charge inside the cartridge that was being fired. It never looks the same twice. They said the primer will throw the fire into the propellant, and it will light at the back and burn forward one time, next time it will flash underneath the whole thing, light from the front and burn backwards. The photography showed that every time it is different.

SAR: And that would effect the turbulence of the propellant gasses. So we’re really lucky that we can hit any target.

Mike: That’s right. It’s really about consistency in the firearm and sighting, as well as the ammunition.

SAR: How consistent in the ammunition? I mean, you have the combined input from all the bench rest shooters, the military competitors, plus your own experiences- how close does the powder have to be?

Mike: I’ve always been a pragmatist. If I had to pick a philosopher it would be William James, what works is right, screw the theory. Just go try it and see what happens. We have done a lot of work with the 223. We had results that are so clearly supportive of our position, that I am almost embarrassed to try to pass them on. Let me tell you about our testing. We ran a test with .223 were we had a bench rest shooter who worked for us for years, who was always concerned about the “Ultimate accuracy”. We had him run an experiment one time where he loaded four different batches of .223 ammunition. The first batch using new brass which he neck trimmed, neck turned, trimmed and uniformed all the primer pockets- did everything a bench rest shooter does. He trickled charged the powder into the cases, used all the fancy bench rest in-line dies to load the stuff with. That was at one end of the spectrum and in the decreasing steps the fourth batch of ammunition was mixed brass that had been fired, some had been fired once, some had been fired three times, we made no effort to determine what they were. We ran this mongrel batch through our electric size trimmer, that sizes and trims simultaneously, and stuck the brass into a 550 and reloaded progressively for the whole batch.

He then shot the batches of ammunition with other people loading his rifle for him, so he couldn’t see which round he was shooting. We sent a fairly substantial sample of the four batches of ammunition to a major scope manufacturer who shot it in their tunnel. The results were consistent between the stuff that Darryl shot here and the stuff the other company shot.

SAR: So you had four control groups , and you had two testing facilities duplicating the test. When he was firing he didn’t know what he was firing, but he did each control group on paper for record.

Mike: Right

SAR: He had no idea which one he was shooting….

Mike: And that was the same way with the people in the tunnel, they didn’t know what each group was, only that they were in groups. Clearly the best accuracy came from the stuff that was slam-banged together. Size, trim, stuck on the progresser and loaded.

SAR: The mongrel group was the most accurate? I used to trickle every grain in my hunting ammo- it took hours. What theory do we apply to this in reverse? Have you come up with one?

Mike: No, I mean that there are a lot of things that people are concerned about that have no effect. There have been numerous tests were you could maul the front of the bullet and it has virtually no effect, but you touch the back of the bullet and it just goes to HELL. There are things that appear to be important, but aren’t. Powder charges being to the absolute last grain, or piece of a grain of powder has very little effect on accuracy. A half grain variation on a powder charge, like a 50 grain charge or even a 1/2 grain variation in a 25 grain charge. I am sorry, you can’t find it on a target, it isn’t there.

Darryl’s explanation was that probably one of the most important things is that the brass has been fired before. That he was actually handicapping the bench rest loads by using new brass.

SAR: Did you put this information out to the shooters?

Mike: On numerous occasions he took presses to the range during the bench rest rifle competitions, and demonstrated for people that progressive ammunition shot just as good or better as their tweaked ammunition. A friend of mine named Don Carper, who was associated with our company for awhile, had a distributorship over in California where he distributed our product back in the early days. He has retired from the shop he had, now he’s just a shooter and he goes out with this 5 gallon pail of 223 and shoots prairie dogs. Don told me that at first everyone said “Oh, we can’t have that much accurate ammunition because it takes too long to load. He’s converted virtually everybody to the fact that he hits just as many prairie dogs as anybody else does. Ammunition off of a progressive press.

SAR: You realize that for the next three months Mike, that everyone that has a re-loader is going be doing this test.

Mike: (With a big smile) Great!

SAR: I know I am going to be testing this.

Mike: The powder charges need to be accurate, they need to be pretty close. The first press we made was the AR1000, everything was automatic then. Powder measure was extremely accurate, I had the Army Marksmanship Unit come in and they wanted to know how accurate our powder measure was. I told them there is no sense in me BS’ing you , I am not a accuracy shooter. Here is the press, here is a whole variety of powders, here’s a scale- knock yourself out. You determine how accurate it is. So they worked with it for about 3 hours and they came out and said we’re getting 3/10th of a grain variation on 55 grain charge of extruded stick powder. I was impressed. Then he asked me if we couldn’t do any better than that.

That floored me! I said what in the HELL are you talking about? You’re going to tell me you can find 3/10th of a grain out at a 500 yard target? He laughed and said “No, of course not, but if the Son of a Bitch shooting the ammo knows there’s any variation in powder, then every “flyer” he has on the target is going to be my fault”. They bought two units, and used them.

SAR: Other than the reloading products, Dillon Precision is known for the Miniguns. When did you put your first one put together?

Mike: 6 or 7 years ago

SAR: There are a number of changes that you have made to the design- evident at the NDIA shows among others.

Mike: The only real “changes” that we are responsible for are in the feeder de-linker. We have incorporated what you call “SLAP round guides” in all of our feeder de-linkers. It’s an integral part of the feeder de-linker rather than a bolt-on accessory that goes inside it. It gives us a lot of advantages- any length cartridge will feed in it- it positions the cartridge to feed into the gun off of the shoulder of the case rather an off the point of the bullet. This means we can use short blanks. The military designed the system so they could use SABO penetrator rounds, sometimes referred to as “SLAP” rounds. The system they came up with was a bolt-on snail guide. It had to be positioned inside the feeder de-linker, which was a real pain in the neck to do. We’ve incorporated it as part of the casting of the endplate. Actually, we have changed much of the design of the internal part of the feeder de-linker, while retaining a few of them as standard. A few of them can be modified rather than replaced. Probably the most interesting change we made is evident from the outside. We are replacing the entire mid-section of the housing with a unit that has a hatch in it. The Minigun that has this modification can be loaded much like a Browning A4. Rather than having to twist the barrels and disassemble the unit if you get a jam, now you just open the hatch and clear the jam.

SAR: There was a clutch system on the back of the Miniguns that I saw downstairs.

Mike: GE designed a clutch for the gun a number of years ago that really changes the way the gun operates. I remember reading in Clancy’s Clear and Present Danger where he was talking about the guys going in a helicopter to do a jungle extraction, and as they were firing the Miniguns, and after the barrels were spinning you would press firing switch and fire the gun. I don’t where he got that weird piece of information, because that’s not the way the clutch operates. When you pull the trigger it engages the clutch, which is clutching the feeder de-linker. When the gun is turning and firing the feeder de-linker is clutched to the gun, and therefore it’s turning and feeding ammunition into the gun. When you let go of the trigger it de-clutches the feeder de-linker but continues to put power to the drive motor for another one to two revolutions of the Minigun, so that everything in the gun fires out. The barrels are always empty. In the past the feeder de-linker performed the same service but it did it by throwing 6 – 12 rounds of loaded overboard at the end of the burst. You don’t like to do that because you are throwing away a lot of ammunition- especially if you’re shooting a series of short bursts. The other problem is that without the clutch you might throw only 6-7 rounds overboard, which meant if you had a little drag you might still have a loaded barrel in the gun. With the clutch system, when you let off the trigger, there will be no rounds in the gun and the feeder de-linker is fully loaded and ready to feed into the gun. No cook off, no vibration of the gun turning it another degree and firing it. So the gun is always clear.

SAR: Is this clutch something that can go on any Minigun?

Mike: It’s a straight add-on. You just pull the drive gear off the back of the rotor and slide the clutch in. As long as the rear of the gun is accessible, you can do it without even taking the gun apart. I tried to buy clutches from General Electric, and they wanted an enormous amount of money for them and so I finally got a set of drawings and we made our own castings and now we’re making the clutches ourselves.

SAR: You could fire a two round burst from a Minigun?

Mike: You can sit there and fire a two-round burst out of the gun now. Before if you fired a two round burst you’d throw 8,9, or 10 rounds overboard in the unloading after you let off the trigger. I wanted my guns to be equipped exactly the way the military guns are equipped, because we are developing some products for them.

SAR: Was the military clutch installed to save ammunition or for safety?

Mike: I think their prime motivation for the clutch had to do with the SLAP round. Once you put the SLAP round guide in the gun you no longer have the option of throwing loaded rounds overboard, it shuts off that gate where you threw the loaded rounds out. Actually they have found you can cut the slap round guide off a little short and still throw loaded rounds overboard, but in the initial approach to it they figured that putting the SLAP round guide in required the installation of the clutch

SAR: At SAR we’re hearing of a resurgence of the Minigun being used in special operations units in various countries around the world. Is that something you are seeing as well?

Mike: There does seem to be that, I do believe the gun has been used more than anybody realized because it was by the special operation groups that don’t want or get a lot of publicity. The Minigun has been used all along as a “STAY THE HELL OFF MY HELICOPER” gun. It is an excellent defensive weapon and it gives you a lot of fire power- which translates into time. Miniguns allow you to send a lot of lead at your enemy, and to keep it up for a very long period of time. It’s not unusual in these installations to have magazines that hold 5,000 rounds, and to have multiple magazines. Many of these rescue helicopters carry 20,000 rounds of ammunition for the guns.

SAR: Is there a recommended burst rate that should or should not be exceeded?

Mike: Well, it’s a common misunderstanding that the gun fires 6,000 rounds per minute. It doesn’t. There were a few rare installations that with a linkless feed system would fire 6,000 rounds per minute, but the most common rates of fire are 2,000 rounds or 4,000 rounds. Some of the services are beginning to think that the multiple fire rates are not desirable, that a single fire rate of about 3,000 rounds per minute probably makes more sense. Now that the clutches are there, the low rate of fire doesn’t make much sense because you can fire a short burst out of the gun.

SAR: Is there an amount of ammunition that you shouldn’t exceed in firing a Minigun?

Mike: The GE engineers tell me that if you fire 3,000 rounds in a single burst of 3,000 rounds that you maybe flirting with structural problems in the barrel assembly, over heating and what not. With 6 barrels that’s only 500 rounds per barrel. As of yet I haven’t had a big enough magazine to fire mine with 3,000 rounds, but we soon will and will find out what it does.

SAR: Dillon Precision is now manufacturing the Minigun as a complete system.

Mike: Correct. We are manufacturing for military contracts only, for liability reasons. One of my customers contacted me after the last Knob Creek shoot, sending a fairly hostile letter. He said that I wasn’t supporting the Second Amendment because I wasn’t willing to sell these guns to the general public, and that two different people had told me that they needed parts and that I wouldn’t service them. I was a little irate because the two people that needed parts I had given the parts to, and the issue was that they were complaining that I said a bolt head was a $300.00 item. I am sorry, it IS a $300.00 item and if someone is willing to make them for less than that, please call me I’ll buy them from them.

SAR: There is a different between buying surplus equipment that was bought at scrap prices and manufacturing new, quality equipment in modern facility. That definitely would show a difference in price. We don’t need in-fighting on this.

Mike: Indeed. The company that called me, I won’t tell you who it was, had allegedly damaged somebody’s Minigun with bad ammunition and they wanted to fix it. They were asking to get these parts, and I said I am really not comfortable selling this stuff domestically because of the liability problem. I suggested that they call Neil Smith. That is his business, and I am sure he wouldn’t mind selling the parts. He’s very knowledgeable on Miniguns. I said if he can’t supply you, come back to me, be aware that this is probably a $300.00 part. Then I get the story back from Knob Creek that I am trying to hold this guy up for $300.00! I called this guy back and said I was a little incensed by this. I gave him the parts – free – stuck them in an envelope and sent them to him with no bill. What more do you think I could have done to have been a “Good guy”?

SAR: Flown out there and put them in

Mike: (Laughs) Right…..

SAR: The Minigun is a little bit more complex than most firearms are.

Mike: I consider it the most dangerous gun I have ever laid my hands on. Not because it can throw a lot of bullets fast, but because it has 6 barrels and not until you become fully acquainted with the gun, and fully acquainted by making mistakes with it, do you gain the respect for the gun that you should have. We go to enormous lengths for safety when we shoot the gun. Our guns are spiked until we are on the range, facing down range, away from everybody and there is no chance that the gun is pointing at anybody, and that everybody is clear. We literally spike our guns, passing 5/16 steel rods down between the barrels so they can’t turn, and while they are spiked the safing sector and firing cover are removed, and we don’t put them on. We go step by step by step by step, so the gun becomes less safe, less safe, less safe and the very last thing we do is reach round and pull the spikes out of the gun, so the barrels can turn.

SAR: Is your preferred method of shooting the Miniguns as duals in the Quad mount?

Mike: First, the Minigun has to be mounted to something heavy. It’s got up to 600 lbs of thrust when it is firing and I prefer to have it mounted to something that weights 2500 lbs. The quad-mount is a delightful way to shoot the gun, because you have total control over it and you can sit there in comfort and electrically power the guns around where you want them to go.

SAR: This was in that world famous video that you made “Fire Storm In the Desert”.

Mike: That setup was the star of the show. We don’t really want to reveal all of our secrets in the magic of making the movie.

SAR: We at SAR don’t mind the occasional “Patented Shameless Plug” Mike. Do you still have that available?

Mike: Of course! We’ve also had a sequel in planning ever since we made the first one. The mistake I made was that I should have gone out 6 months later and just made another one. I’ve been trying to make it so big and so grandiose, that we’ve been 6 or 7 years now in preparation and we’ve still haven’t gotten started on it yet. We have all sorts of props ready, but the main filming hasn’t been started.

SAR: I take it that means you don’t have a release date yet in mind

Mike: That would be a fair evaluation.

SAR: You’ve been doing some other theatrical work with the Miniguns recently.

Mike: We had a real interesting one that came in from England. Stembridge Gun Rentals from Hollywood had been working over in Ireland on a show and these guys were talking about a fellow named Jeremy Clarkson who writes a column and has a TV show on the BBC. It’s about cars and he is a humorous evaluator of different cars, and they had done a video last year that they had sold very successfully where he evaluated several cars and then destroyed the ones that he didn’t like. They wanted to make a better one this year. Jeremy called us up and asked us if we could shoot a sports car for them. We said of course! (Mike now has a huge grin) One thing led to another, then led to another, then led to another as the project escalated and we ended up using the Hughes 500 with dual Miniguns on it, with all sorts of special ammunition loaded for them. We used a Corvette which we radio controlled, then we put a radio controlled crash dummy in the Corvette that could shake his head and look in different directions. Jeremy came over and we put the corvette on a dry lakebed that was 5 miles in diameter and then shot the hell out of it with the helicopter mounted Miniguns.

SAR: And that was on British television?

Mike: Yes, and it’s become a British video that’s been distributed over there and called “Apocalypse Clarkson”. The working title was “Jeremy Clarkson Out of Control” but after they got back and viewed the helicopter footage and what not, they decided to call it “Apocalypse Clarkson”. It’s a good video. It probably will never be distributed over here, but it’s a fun video.

SAR continues the interview with Mike Dillon in next month’s issue- wherein we get to divulge Mike’s private recipes for machine gun ammunition- don’t miss it!

| This article first appeared in Small Arms Review V2N2 (November 1998) |