By Christopher R. Bartocci

The 9mm AR carbine has gone through many improvements over the years. The original design was made by Colt’s engineer Henry Tatro in the late 1980’s. At the time this was in the model shop, Colt was going through bankruptcy and few resources were available in both financial and human resources to complete the project. The gun was introduced to the market and sold in both full auto LE/Military models as well as commercial semi-auto only variations. The submachine gun never really was exploited to its full potential. Heckler & Koch owned the subgun market with their MP5 series. Colt was more concerned with their new M4 carbine and they really did not want to compete anything with the sale of that. The Colt SMG/Carbine had its issues and it would be safe to say that Hanks prototype was never actually finished over these years. Not by Colt anyway.

JP Rifles is known throughout the industry for producing match grade AR-based rifles as well as many innovative accessories and updates for the AR-platform. These include their own versions of highly modified triggers, handguards, bolt, bolt carrier, recoil systems, heat sinks and upper and lower receivers to name a few. However John Paul really was famous for what he did with the 5.56mm and 7.62x51mm caliber rifles.

Owner John Paul owned a Rock River Arms 9mm carbine and he thought it was very fun to shoot. He decided he wanted build his own with the first priority being ditching the Colt-pattern magazine and using the more popular Glock 17 magazine. He felt he could do better in getting controllability in line with this blowback design as well as improving other facets of the gun with other innovative designs. He did just that and he took that carbine prototype to a Magpul Dynamics Advanced Carbine course and he was amazed with the results even out to 100 yards.

The rifle received by SAR had several interesting advanced features. It is not just another reproduction of the Colt design. Starting from the rear, the rifle was equipped with an Ark Defense stock which has a similar feel to the LMT SOPMOD stock with a smooth triangular shape where the cheek weld is. The receiver extension is standard with six positions for the stock. The first refinement is located in the receiver extension. The standard 9mm steel buffer and spring are replaced with a JP designed silent captured recoil spring. John Paul was never fond of the noise made by the friction of the recoil spring on the inside of the receiver extension. He felt it was annoying and distracting. He went to develop the Silent Captured Spring (patent pending). In appearance it looks like an oversized pistol spring guide. The rear of the unit has a large neoprene-type bumper and the front has two circular shaped weights. The spring at no point comes in contact with the receiver extension. The lower receiver does not have a buffer retainer pin or spring. This Silent Captured Spring unit just drops into the receiver extension. The unit is set up to drop into the receiver extension. On the T&E rifle, the buffer retainer pin and spring were removed to facilitate easy installation and removal. You can leave the retainer pin installed, it is just more difficult to remove the Silent Captured Spring unit. Along with this is a modified 9mm bolt. Unlike the traditional 9mm bolt there is no steel slug in the inside rear of the bolt for additional weight to delay opening. The guide rod protrudes up the carrier body which prevents usage of the slug in the bolt. The mass is rather transferred to the Silent Capture Spring buffer and the JP 9mm bolt. The JP bolt is heavier than the standard even with the use of the slug. This also limits the stroke and provides a faster sight recovery. According to John Paul the bottom line is more controllable in either rapid semi as well as selective fire modes than the traditional AR based blowback.

The lower receiver is a dedicated 9mm and made by JP Rifles. It is manufactured from a solid billet of 7075 T6 aircraft grade aluminum. The receiver is designed for the Glock 17 magazine. During testing 9mm Glock magazines with 10, 15, 17 and 33 round capacity were used. The magazine release button is large on the right hand side of the receiver. The magazine well is beveled for easy insertion of the magazine. The fact that the magazine is double column with single feed also helps quickly reloading. The ejector is fixed to the inside of the receiver. The receiver does have a bolt catch but it is not activated by the magazine. According to John Paul, “Activating the bolt catch off a pistol mag follower in an AR type lower is an engineering problem in itself which we chose to put on the back burner so we could get to market ASAP with what we had as it was such an improvement over what was out there. Most of these types of lowers do not have a last round lock back feature. Note the MP5 does not have a last round lock back either. The next gen receiver will have a last round lock back”.

The trigger group installed in the lower receiver is the JP Enterprises E-Z trigger. This is a JP designed single stage trigger with a low mass hammer. The trigger itself has adjustment screws for the trigger hammer sear as well as the safety overtravel. Loctite needs to be used on the screws so they do not vibrate loose. Due to the dynamics of the blow back operated design, hammer pins take a beating and are prone to breakage. Colt’s answer to this issue was the use of a stainless steel hammer/trigger pin. The use of the low mass hammer in the JP 9mm carbine affects the torque effect transmitted to the pivot pins. The more mass on the top of the hammer, the more stress on the hammer pin in the blowback system. To date, JP Rifles has yet to break any hammer pins. However, JP Rifles next generation lower receiver will use larger.172 inch oversized pins to ensure against hammer pin breakage. Once adjusted, the creep was gone from this trigger. The trigger broke on the T&E rifle at 3 1/2 pounds. The grip on the T&E rifle is a Hogue OverMolded rubber grip with finger grooves.

As previously stated the JP rifle is designed for the Glock magazine only. SAR asked John Paul if he intended to introduce a lower receiver which would fire the Colt pattern magazine. His response “No need for that as the mag inserts sold by Rock River Arms solve that application nicely. If we make another lower, it will be a Smith & Wesson M&P mag based lower as we are mainly after sidearm magazine cross compatibility. In other words, our uppers and 9mm bolts are compatible with either double or single feed magazines and the uppers can be used in either format.”

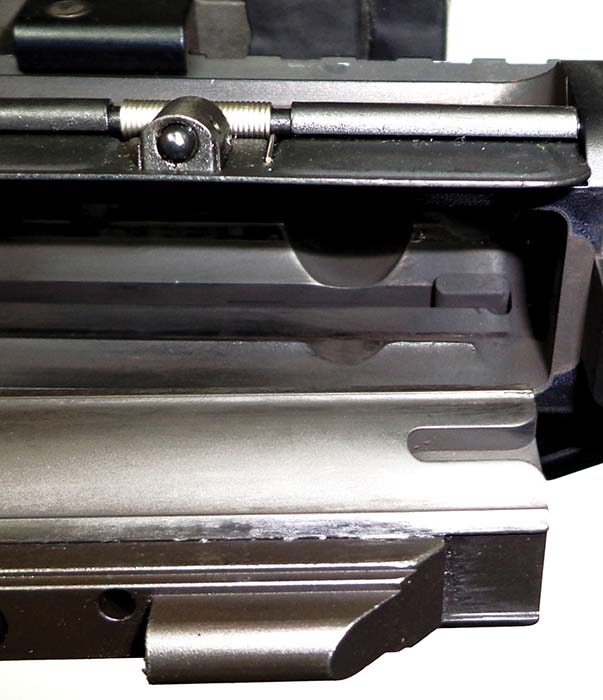

The upper receiver was also cut from a solid billet of 7075 T6 aircraft aluminum. The upper on this rifle was a standard 5.56mm upper receiver which included a forward assist assembly as well as a fired cartridge case deflector. There is an ejection port cover as well. There is no Gas block such as those found on the Colt rifles which prevents burning powder from hitting the shooter in the face. The charging handle is located in the same location as usual. However, there is a second charging handle. This is located on the left side of the upper receiver. Without having a bolt catch on the rifle, the side location allows for faster reloading due to the rifle not having to be fully removed from the shooter’s shoulder. This is an option which can be had. The upper receiver can also be a standard forged receiver. If the customer chooses the billet upper receiver the cost increases by $500.

The barrel is a JP Supermatch™ barrel. The barrels are manufactured to JP Rifles’ highly exacting specifications for superior performance and optimal fit with JP components. These barrels are turned from the finest 416R stainless steel and then lead-lapped, button rifled using state-of-the-art equipment and air-gauged to ensure minimal bore diameter run out for peak accuracy. JP Rifles also make a point of cryogenically treating all Supermatch™ barrels for cold bore shot predictability, minimum thermal drift, outstanding accuracy and extended barrel life. The barrel on the T&E rifle was manganese phosphate finished. The muzzle of the rifle was equipped with the JP compact compensator for 9mm AR type carbines threaded in the standard 1/2-36 TPI. It includes pin and pre-drilled barrel shroud features for pin & weld installation on 14.5” barrels to create a legal 16” configuration. Unique porting takes advantage of low residual muzzle pressure to maximize recoil reduction and muzzle rise on 9mm carbines. This also includes a crush washer for easy timed installation. There are sharp points on the end of the compensator which can be used for breaking glass or for “compliance”.

Another very unique JP Rifles feature is the JP Thermal Dissipator™. When it comes to transferring heat from the barrel, the JP Thermal Dissipator™ far exceeds traditional fluting and is intended for applications where sustained fire with excessive heat buildup is a problem, such as varmint rifles under hours of constant use. JP testing show that most heat resulting from sustained fire is developed in a 2- to 3-inch area in front of the chamber causing throat erosion and reduced accuracy over time, not to mention the problem of heat buildup in the hand guard itself that makes handling of the rifle difficult or impossible. Attaching this heat sink between the gas block and receiver will yield unparalleled heat dissipation by increasing the surface area under the hand guard by over 700% and providing more uniform barrel temperature under sustained fire. The JP Thermal Dissipator™ is an anodized, deep-finned 6061 extruded 2-piece sleeve available in black, silver, red or blue, giving a dynamic appearance when installed under a JP high-grade hand guard.

The rail on the T&E rifle is the JP MKIII hand guard system. Pooling the strengths of the Gen. 2 modular and more recent Rapid Configuration system in particular, the MK III combines the ever popular aesthetics of the tapered nut and beveled, fluted tubes with the patented attachment method of the RC system. This patented receiver attachment method is especially quick to install or strip for easy barrel replacement with an internal barrel nut that is a lifetime part that will not distort like other one-piece aluminum retention nuts that sometimes can’t even be used more than once. This accommodates unlimited rapid change-out of barrels as needed. This attachment method also eliminates the six attachment screws of the previous generation to increase the structural integrity and perfection of alignment to bore axis of the attachment system to ensure that any accessory devices can be easily sighted to point-of-impact. The precision of the system rises to a level comparable to monolithic one-piece systems. In fact, the JP top rail system is the only system other than true monolithic upper assemblies that offers rail continuity, meaning that the optional top rails pieces adjust to the upper receiver for rail slot timing as if they were one continuous piece of 1913 rail. This makes it possible to bridge the receiver and hand guard system with any optical mounting solution if so desired. The MK III system also supports several other platforms outside the typical AR-15 specification range such as Armalite, Knights and DPMS clones, making it the most versatile, all-encompassing system currently on the market. Finally, the MK III system unifies its predecessors by accepting both the fluted JP Signature and the newer Rapid Configuration tubes to accommodate those preferring classic design with those who’ve come to appreciate the elimination of backer plates on the rail attach points. In either case, reconfiguring the accessory systems takes only minutes and requires only basic tools. What’s more, unlike the competitor systems such as the Keymod, the MK III requires no proprietary hardware—just standard 10-32 screws available at any hardware store. With the compliment of accessories rails and mounting solutions that they currently offer, any sensible configuration in either tube design is possible.

Provided with the T&E carbines were two Glock 32 round magazines. Also the rifle was tested with Glock 10, 15 and 17 round magazines. The ammunition tested was Black Hills Ammunition 9mm 115gr full metal jacket as well as 115gr Tac-XP +P. Additionally Federal 9mm HST 124gr. There were 500 rounds of the Black Hills full metal jacket fired with no malfunctions. The carbine was never lubricated or cleaned during testing. One box of 25 of the Black Hills 115gr TAX-XP and 50 rounds of Federal HST. There were no malfunctions with the hollow point ammunition. The rifle was fired at 25 yards off hand. The biggest thing that stood out about firing the JP carbine was the recoil. It was noticeably less with the captured recoils spring. There was no spring noise in the receiver extension at all. The shot impulse felt less as well. The bolt held back on all empty magazines accept one. That was an old Glock Gen 1 magazine with a +2 extension plate. God only knows how many rounds had been through that magazine. Accuracy off hand was easily about 2 inches with all types of ammunition tested. The stock was comfortable to use, a little on the bulky side but comfortable. The testing was all done within an hour or so, the rifle did get hot but no cook offs. This was hardly enough ammo to truly test the heat sink on the barrel. Perhaps a selective fire carbine would be much better to test the merits of that excellent accessory. The optic chosen was the Trijicon ACOG Reflex Sight (RX01). This amber dot reflex sight was excellent for the short range this carbine was designed for. Shooting was done in a lower level light indoor range. The sight lit up without issue.

The JP GMR-13 is definitely in a league of its own. It is not the typical AR 9mm carbine. John Paul has made advancements to about every component. The Silent Captured Recoil Spring is an excellent development. The rifle was of excellent quality which one would expect from a company known for match grade rifles and innovative components. Reliable and accurate, the carbine is not cheap with an MSRP of $1999. This is a whole new level compared to the legacy 9mm carbine. JP builds these rifles custom for their customers with various barrel lengths, selective fire for LE customers as well as pistol models. You can have the expensive version with all these enhancements or a more basic rifle with a forged upper for $1499. They are built per order. Due to the cost and quality, do not expect the masses to have it. One who understands the quality and innovation of this carbine would have no problem spending the money to get the highest quality 9mm carbine in the industry.

| This article first appeared in Small Arms Review V20N10 (December 2016) |