By Christopher R. Bartocci

In this vast sea of black rifle manufacturers there has been a consistent island of innovation, Lewis Machine and Tool. Since the release of the MRP or Monolithic Rail Platform (2004), LMT has distinguished themselves as the next generation of the M16. Perhaps the most significant development in the weapon system since the release of the M4 carbine in 1995.

What was so ground breaking about the MRP system was it redefined the modular assault rifle. The M16/M4 series of weapons has always topped the industry in “modularity”. This was mostly based on changing the configuration to suit a particular need by swapping out upper receivers. You could alter barrel length as well as caliber by swapping upper receivers. LMT took this to another level. What if instead of changing uppers, you changed out just barrels?

MRP is a patented receiver manufactured from a solid forging of 7075 T6 aircraft aluminum. Monolithic means 1 piece. There are several manufacturers in the industry who claim to be monolithic but they have removable lower handguards. That is not one piece, that is two pieces. The barrel is held in place by two locking bolts; Torx head bolts tightened down to 140 inch pounds. The barrel when installed is completely free floated within the receiver. Thus, the operator cold hang multiple accessories on the rails and they would not affect the harmonics of the barrel. This increases accuracy of the rifle. There are six quick-detach sling swivel attachment points. The rifle also has the standard ejection port dust cover, fired cartridge case deflector as well as forward bolt assist. LMT has an additional MRP called the LM8 slick side upper. It has all the same features of the MRP but the rails on the sides and bottom have been removed. The user now has the ability to install detachable rail segments so rail is only where needed. The benefit of this is it is slightly lighter and the user will not have to worry about damaging unused rails on the receiver.

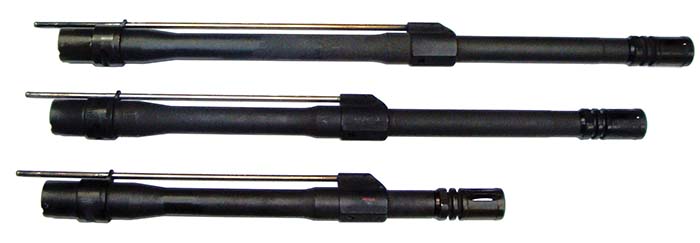

The barrels are the heart and soul of this design. The barrels are machinegun grade Chromoly vanadium barrels which are chrome plated. They come chambered in 5.56x45mm in lengths of 10.5, 14.5, 16 and 20 inches. This means the rifle can be configured in a Close Quarter Battle variation to an urban and then to a long range rifle by swapping out barrels. The 16 inch barrel sports a midlength gas system which assists and improved extraction by increasing time under pressure over the standard carbine length gas system. All barrels use a straight gas tube rather than the standard one which has several bends. This eliminates the hot spots in the bend areas, increasing the durability of the gas tube. Another innovation is that the gas port is drilled at an angle rather than straight. By having it drilled on an angle the cycle rate is far less affected by gas port erosion, thus maintaining the cyclic rate for the duration of the barrel life. Not only will the MRP system offer different barrel lengths but also different calibers. By just swapping barrels the user can have 300 Whisper/Blackout or .204 Ruger. By swapping out the barrel, bolt and magazine the user can have his rifle chambered in 6.8mm SPC. The barrel has the SAMMI spec (Spec 1) chamber.

Over the last decade or so there has been a section of the industry who wanted to get away from the Stoner direct gas system in favor of the external piston design. They claimed it shot cleaner and cooler thus was more reliable. Not necessarily saying Karl Lewis agreed with them but he was willing to give the customer what they wanted. The MRP can also change operating systems. By swapping out the bolt carrier and barrel assembly the rifle is now a short stroke piston operated rifle. The barrel has the gas block, piston and operating rod attached as an assembly. The standard buffer is replaced with an H2. LMT offers a 12.5 and a 16 inch 5.56mm barrel assembly as well as the same chambered in the 6.8mm SPC cartridge.

This is without a doubt the most modular configuration in the industry. One upper that can be configured to do several missions. For the soldier, he can swap out configurations to fit his battlefield condition. For the hunter, he can swap from shooting long range varmints (.204 Ruger and 5.56mm) to deer or hogs (.300 Blackout and 6.8mm SPC).

In 2014, LMT began working on their ambidextrous lower receiver. This would put the most advanced upper on a just as advanced lower receiver. At the same time this began, the New Zealand Army put out a requirement for a new infantry rifle that would replace the aging (28 years) Steyr AUG rifles. In May of 2014 the request was made public to the industry. The New Zealand Army felt the AUG lacked accuracy beyond 200 yards and wanted something better. Between March and June of 2015 trials were conducted. Rifle entries were made by Beretta, CZ, FN Herstal, Steyr, Colt Canada, Sig Sauer, Heckler & Koch and LMT. Also tested were grenade launchers with the listed manufacturers as well. At the time of testing, LMT had used their standard Guardian lower but the requirements were for ambidextrous so this requirement drove manufacturing and engineering to design, develop, manufacture and field their ambi lower quickly.

When the last shots were fired and the results came in the clear winner was Lewis Machine and Tool. New Zealand placed an order for 9000 weapon at a cost of $59,000,000. According to New Zealand Defense Minister Gerry Brownlee the LMT weapons are “combat-Proven” and “It gives our personnel a weapon they can rely on in any situation.” Mr. Brownlee also stated “Perhaps the strongest endorsement is that our own Special Forces will also use the LMT. Previously, they have used different rifles to the Army. They observed the trials carefully, and liked what they saw.” The Minister of Defense expects integration and replacement of the aging rifles to begin with the new LMT MARS-L in late 2016 and 2017. This is a significant contract for Lewis Machine and Tool. Not that they are new to military contracts by a long shot. They have supplied the L129A1 Sharpshooter rifle to the British MoD and have equipped numerous Special Forces throughout the world. This is their first order for a standard infantry rifle for a foreign country. This lets the industry know that LMT is now capable of producing large volumes of military grade rifles which up until now there were only a few companies set up to do.

The rifle chosen has been called the MARS-L. MARS stands for Modular Ambidextrous Rifle System-Light. The changes are so defining that LMT has designed and manufactured an entirely new forging for this lower receiver. The ambidextrous magazine release is identical to that of the .308 MWS weapon system. There is a lever on the left side that when the button is pushed inward the lever lifts up on the mag catch and releases the magazine. Very simple and very reliable. On the opposite side is the ambidextrous bolt catch. This is a standard sized bolt catch that has an arm that interlocks with a notch on the side of the bolt catch, a simple and robust design. The ambidextrous bolt catch lever assembly is held in place by two charging handle latch pins for parts commonality. The channel on the outside of the receiver is covered by a polymer cap. The lower receiver is equipped with the LMT ambidextrous selector lever which has been an option from LMT for well over a decade. The trigger guard has been redesigned as well on this lower receiver. It is oversized to accept heavy winter gloves. The last improvement was to the magazine well itself. It has a very nice beveling to it which will make magazine insertion easier, especially in low level to no light.

The trigger group in the rifle is also new. This is a selective fire trigger group but the trigger group is available in semi automatic only as well. This is a two-stage trigger in both semi and auto position. What makes this trigger new is that it is made by LMT’s new wire EDM machining capability. They are now cutting these triggers in house. It has a crisp break. The first stage of the test and evaluation rifle broke at 4 1/2 pounds and the second at 1 1/4 pounds for a total of a 5 3/4 pound trigger.

The rest of the lower is standard LMT. This model comes with the SOPMOD stock. The New Zealand rifle has two options, the Rogers Superstock or the SOPMOD). The receiver extension is hard coat anodized and then coated with dry film lubricant. This tightens the stock to extension finish to keep it from rattling and making noise. A standard rifle buffer is used. The pistol grip is the Ergo grip that is part of every LMT rifle. The selector markings are pictograms instead of words.

The rifle shipped to SAR is very similar to the New Zealand issue rifle but with several differences. The test and evaluation upper receiver is the CQB MRP. The rifle is produced for New Zealand in both the shorter CQBMRP (16 inches of top rail space) as well as the longer MRP (20 inches of top rail space). The submitted rifle has the standard 16” midlength gas system barrel with A2 compensator. The New Zealand rifle also has a 16” mid-length gas system (1/7 right had twist) but the barrel is specially contoured to accept a pinned on bayonet lug. The lug is on the right side of the barrel which means when the bayonet is mounted it is mounted at a 90° angle. It is the opinion of this author the 16 inch barrel is ideal, better than the 14.5 inch for military use. Granted that extra 1.5 inch may be slightly better for mounted personnel, the 16 inch barrel offers a good increase in accuracy. The average soldier would not see any accuracy benefit from a 16 to 20 inch barrel. The midlength gas system will offer a reliability and durability edge over the carbine length gas system. Like all LMT barrels they are test fired with a 70,000 psi proof round and magnetic particle inspected to guard against stress fractures. The muzzle is equipped with either a Surefire Warcomp flash hider or muzzle brake. All rifles are set up to accept the Surefire SOCOM 556 suppressor. Both 16 inch and 10.5 inch barrels will be part of the New Zealand Tender.

Another new product on this rifle is the LMT produced ambidextrous charging handle. Both latches appear to be slightly larger than the original LMT Tactical charging handle latch. Both sides are easy to grasp.

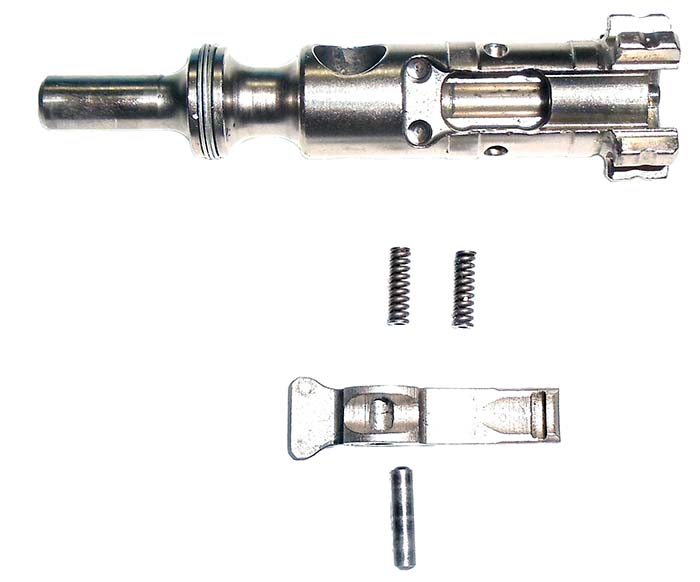

The rifle provided was using the LMT Enhanced Carrier Group. This is an improved bolt carrier assembly that was designed by Karl Lewis at the request of SOCOM. In the early 2000’s, SOCOM was experiencing a rash of broken bolts in their M4A1 rifles. This was not an army wide issue but confined mostly to Special Forces. These guys ran their rifles much differently than regular army. The M4A1 was also a fully automatic rifle versus the 3-shot burst of the common soldier’s M4. Due to the extremely heavy firing schedules SOCOM wanted something better. Karl Lewis gave it to them. The bolt was redesigned to address many issues. First, the material itself. LMT chose a material that was much stronger than Carpenter 150. This is a proprietary material to LMT. The bolt was finished with a proprietary nickel based finish. This dealt with the bolts breaking at the cam pin hole. To increase durability of the lugs was a combination of bolt lug stress relief cuts on the lugs as well as the geometry change. For over the beach requirements, the bolt face was changed so that the entire cartridge case base is supported. Extraction issues were dealt with from several different angles. On the bolt itself, the extractor was changed. It has the “Lobster Tail” appearance in that in the rear of the extractor there are two longer extractor springs rather than a single shorter spring. This gave more extraction spring force and lasted significantly longer. Next was the actual extractor claw itself. This was made to engage more of the extractor rip surface on the cartridge case with a more aggressive claw. The other changes were made to the bolt carrier itself to deal with extraction. The cam track was changed on the bolt carrier to allow more dwell time which meant the cartridge case had more time to contract prior to removal during the extraction phase of the cycle of operations. This permitted easier extraction and less wear on the extractor and springs. Also the way the gas was introduced into the expansion chamber inside the carrier was changed. Normally the gas is all introduced 180° directly into the chamber. LMT altered this so the gas would be split into a right and left side, more evenly distributing the gas which assisted in dwell time as well. Also the carrier face was changed, a rib was made around the front to fully support the bolt. There was an additional gas relief port added to help egress unneeded gas faster. The location of the rear gas relief port was moved further forward to help more gas eject out of the ejection port and less inside the receiver. The only negative thing about this enhanced bolt carrier group is that it would not cycle a full auto 20 inch bbl. The dwell time change is too excessive between the 14.5 and 20 inch barrels with the modified carrier. Keep in mind the port pressure is double that of a 20 inch barrel in the carbine. All LMT bolts, regardless if standard or enhanced are test fired with a 70,000 psi proof cartridge and then magnetic particle inspected to guard against stress cracks. Even though the Enhanced Bolt Carrier Group did its job and well it was never selected due to the interchangeability issue. The test and evaluation rifle was equipped with this enhanced bolt carrier group. New Zealand will be procuring both bolt carrier groups. They will not have any interchangeability issues due to them never procuring any 20 inch barrels. This carrier will work perfectly in the 10.5 and 16 inch rifles.

Both the test and evaluation rifle and the New Zealand rifles had been equipped with the LMT folding back up sights. The rear sight is adjustable for windage as well as elevation. It also has a long and short range flip aperture. The front is adjustable for elevation only. Both are quite compact. According to LMT the commercial MARS rifles will be equipped with LMT standard detachable sights which are not folding. The rear sight they use on the rifle is the same one they supply to the Navy for their Mk18 CQB rifles.

The magazines chosen for the New Zealand contract are the popular and at this point legendary Magpul Gen 3 PMag with Maglevel window. This is perhaps the most reliable magazine in the industry. This author has used them heavily since they were introduced and watched them evolve and improve over the years.

The test rifle was tested with several magazines for compatibility. This included the X-Products 50 round drum, Magpul D-60, Magpul PMag, Lancer AWM, Ultimag, Hera Arms, D&H Tactical, Hexmag, Mission First Tactical and Promag Rollermag to name a few. Testing ammunition was provided by Black Hills Ammunition who is a great supporter of SAR. Approximately 500 rounds of Black Hills 223 Rem new manufactured 55gr full metal jacket was fired for reliability. No malfunctions were found of any sort. The rifle was compatible with all of the magazines that were used. The Black Hills Ammunition Mk262 Mod1 ammunition, which is a 77gr open tip match projectile, produced consistent 1 MOA groups at 100 yards. The 55gr full metal jacket ammunition produced groups in the 1.4 MOA at 100 yards.

The new MARS rifle is significant to LMT in several ways. Not to mention with the introduction of the ambidextrous lower they complete their rifle as the most advanced AR-platform in the industry. Both top and bottom end. It marks the beginning of a new era of having the manufacturing capability to do major military contracts in large numbers. Not only with they have the capability to serve Special Forces and sharpshooters but the needs of a regular army infantry rifle as well. Cost of the MARS is going to be around $100 or so above the comparable Defender lower. Looking at the cost to equip a standard lower with this type of ambi features would bring you over that $100. The Norgon ambi-catch, which is military proven in both Canadian and US military, will run around $90 alone. Ambidextrous bolt catches can cost $20+ and some require modification of the receiver. With commercial and law enforcement looking for ambi features as well as military customers looking for something better than the mil-spec standards, here’s a good solution. Foreign customers are becoming more aware of other companies making rifles that exceed Mil-Specs and offer more features including modularity and increased reliability. The LMT MARS rifles are exceeding Mil-Specs and are what this author calls the 4th generation M16. First was the introduction of the Model 01, second the M16A2, third is the M4 Carbine and 4th the LMT MRP family of weapons. All generations brought the combat proven Stoner designed rifle to its next evolution.

| This article first appeared in Small Arms Review V20N6 (July 2016) |