By James Ballou

Mention a mouse today and most will think of their computers. To my generation a mouse meant large ears and lecherous thoughts about Annette Funicello. What in the world does a “mouse” have to do with BAR’s? According to Maxwell G. Atchisson, a noted arms designer, “mouse” refers to the mechanical rate reducer developed for use on the 1918A2.

This mechanical delay appeared to be like a mouse racing back and forth in a cage. Early on, John M. Browning recognized that the cyclic rate of the BAR was too fast for a hand held machinegun. Remember, the bipod for the 1918 was not developed until 1922.

On September 12, 1924, Browning was granted patent Number 1,511,262. It reads in part, “The rate of firing may be so rapid that the shooter can not properly aim his gun or rifle, ammunition is wasted and the rapid succession of recoils is so severe, particularly in the case of a machine rifle being fired from the hip or shoulder, that the accuracy is much decreased.”

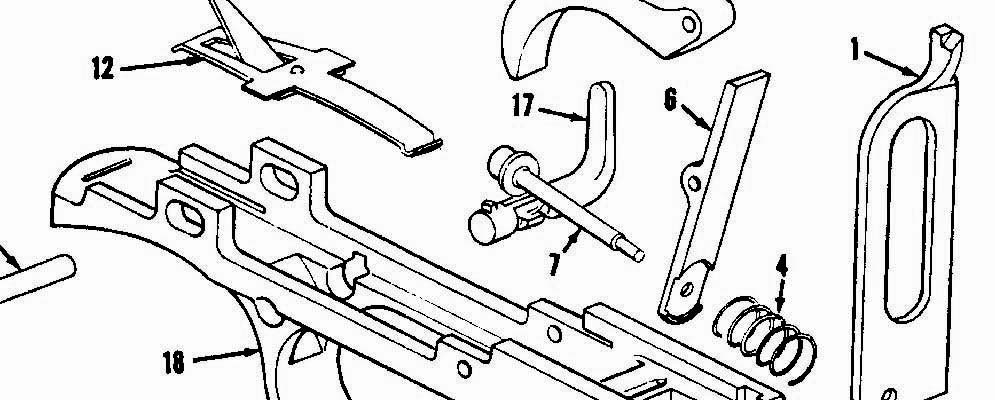

The essence of the mechanism is a clockwork spring that holds the bolt slide back until the ratchet engages the sear again to allow it to fire. In other words the retarding lever is pushed down to compress the spring and until it returns to the normal position the primary sear will not allow the bolt slide to go forward.

Interestingly enough, most people think the rate reducer was an FN design, but even a cursory examination of the two mechanisms will reveal its true origin.

Among the recommendations found in the ordnance committee’s memorandum. O.C.M. – 14553 – June 30, 1938 was section g. that called for a reduction of cyclic rate to reduce training problems and provide more accurate fire direction.

This led to the now familiar 1918A2. The rate reducer developed at Springfield Armory was a team effort. Among the members of the team were Maxwell B. Atchisson and William B. Ruger. Yes, that Ruger. They developed such things as the belt fed BAR and other classic innovations.

Atchisson is known for sub-machinegun designs, assault shotguns, and .22 conversion units. It was he who coined the term “mouse” for the rate reducing mechanism, that the team developed for the butt stock of the BAR. The heart of the mechanism was a weighted actuator that flitted back and forth in the butt stock like a mouse. It’s spring retarded movement provided a mechanical delay before it tripped a secondary sear release causing the rifle to continue firing at a cyclic rate of 350 -400 RPM. The Marine Corps, from early on, recognized the value of the BAR and geared tactics around the squad automatic weapon.

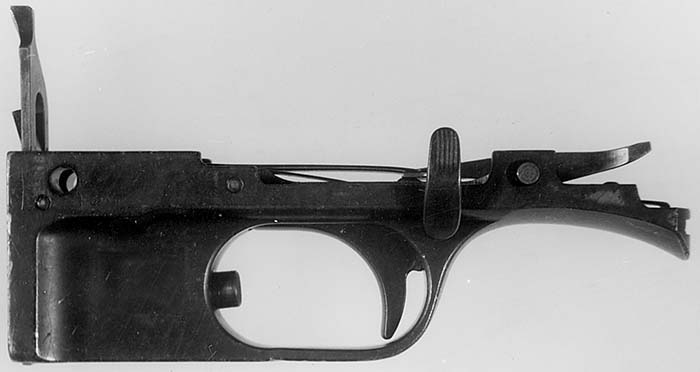

During WW II they wanted to restore its semi-automatic capabilities in order to maximized the accuracy. To accomplish this, a young Warrant Officer in the Corps developed the T-30 semi-automatic conversion. In January, 1946, the New England Small Arms Corporation began installing the T-30 field conversions. Obviously, from the number found they did not continue very diligently.

I would like to thank two individuals for their contributions to this article. Kent Lomont who sent me a box of a dozen different trigger housings and Bob Landies, who when asked for a semi-auto trigger housing sent me an entire cutaway Semi-Auto 1918A3.

Finally, Kent Lomont made the comment, “That the beautiful thing about the BAR is the case of interchangeability of parts from one maker to another. Even the Belgian, Swedish, and Polish BAR’s interchange to a degree”. This is not remarkable since Colt sent examples of their 1924 Commercial BAR’s to Belgium, Sweden and Poland as part of a franchise agreement. BAR’s are universal having been adopted by over 50 countries.

Kent A. Lomont

Lomont Precision Bullets

R P 1, Box 34

Salmon, ID 83467

Phone: 208-756-6819

Fax: 208-756-6824

Robert Landies

Ohio Ordnance Works, Inc.

PO Box 687

Chardon, OH 44024

Phone: 440-285-3481

Fax: 440-286-8571

| This article first appeared in Small Arms Review V3N11 (August 2000) |