By P. Lazarides and H. Montgomery

The German T-Gewehr

The Tank Abwehr Gewehr Mod 18 (usually abbreviated to T-Gewehr) was the world’s first anti-tank rifle and was developed by Mauser. Development of the rifle and its ammunition started in November 1917 in response to the British use of tanks in the autumn of 1916 at the Battle of the Somme. The first of these rifles rolled of the production line only 3 months later in January 1918. At this time the steel-cored armor-piercing ammunition was also ready (the ammunition was jointly developed by Mauser and Polte Werke and could penetrate 25mm of face-hardened steel at a range of 250m). It is claimed that around 15,800 T-Gewehr rifles were produced. The T-Gewehr itself has been described adequately in many previous articles and will not be repeated here. The purpose of this article is to describe how suitable “range ammunition” was fabricated at low cost for use in the T-Gewehr.

The Collector’s Dilemma

The authors are both collectors of firearms in South Africa, and each of them possesses an original T-Gewehr. They were faced with a dilemma that is quite common amongst collectors:

You have a very collectable firearm in your collection that you would like to shoot, but it is chambered for an obscure and obsolete cartridge.

This is exactly the case with these T-Gewehrs. They are both fully original and hence most collectable. However, the owners also wanted to shoot these rifles. Unfortunately original 13.2x92R ammunition is obsolete and unobtainable, in fact original ammunition is eagerly sought after by ammunition collectors.

In the past some T-Gewehr’s were converted to .50 BMG caliber by their owners to enable them to be fired, but this was considered too drastic a step as it would destroy the value of the firearm. So the logical next step was to manufacture suitable 13.2x92Rmm “range ammunition” on a small scale and at a cheap cost.

Making the bullets

Monolithic bullets can nowadays be easily turned on a lathe, using brass or copper. After finding an original 13.2x92Rmm round and measuring up the original bullet, we settled on a new lathe-turned solid copper bullet of boat-tail design, somewhat resembling the shape of the original bullet. Because of the differences in density of the materials, the new bullet is slightly shorter in length than the old bullet, but the weight is approximately equal. The original bullet weighs 803 grains and the newly made bullet weighs 795 grains. In order not to escalate pressures in these old barrels, the bullets were machined with a body diameter of 12.7mm, stepping up to 13.3mm for the base and three driving bands. On the computer-controlled lathe it was easy to turn out 200 bullets in no time.

Making the cases

The main problem with making ammunition for the 13.2x92R is how to fabricate the cartridge case and what to use as a starting “base” case. The first step was to obtain a set of full-length reloading dies from CH Tool & Die Co. in the USA. The initial attempt at making a cartridge case used a 700 Nitro Express case as a basis. A few rounds were successfully loaded and fired, but the following problems were experienced:

- The rim diameter of the 700 Nitro is about 1mm too small which results in insufficient extractor tension.

- The 700 Nitro case is about 3.5mm too short.

- The 700 Nitro case is very thin in the neck area leading to cracks in the neck after firing (see photo) and insufficient neck tension on the 13mm bullet.

- The diameter of the 700 Nitro case just in front of the web is about 1.3mm too small which results in a severely swollen case after firing (see photo)

- The main problem with the 700 Nitro case is its price!

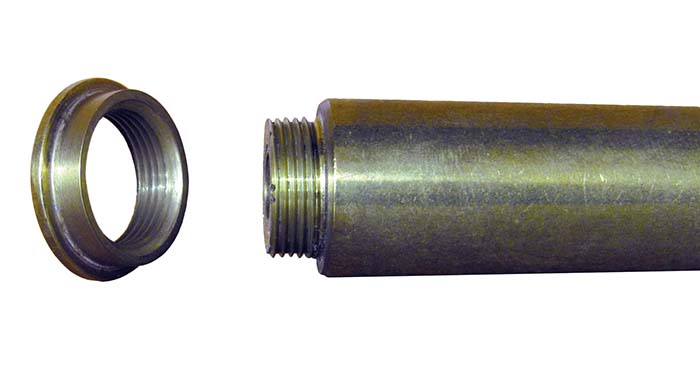

After looking at many other surplus cartridge cases, including various 20mm cannon types, the authors came to the conclusion that the .50 BMG case had the most potential. It was long enough and its body was roughly the correct size, and it was cheap and freely available. The main problem of course with the .50BMG case is the fact that it has no rim. The solution was simply to add a rim with the dimensions of the 13.2x92Rmm rim, to the .50BMG case body. This was achieved by machining off the .50BMG’s normal rim and extractor groove, threading the case head, and screwing on a separately machined brass threaded rim. The threaded rim was locked in place with high-grade Locktite and the resulting case was full-length sized, loaded and fired in the T-Gewehr.

Loading the ammunition

Loads were developed using the homemade bullets and cases as described above. Since the primer pocked of the original .50BMG case was intentionally left intact, we could use standard CCI No.35 50BMG primers. Propellant used was a South African local powder called “Somchem B12.7” which was originally developed specifically for the .50BMG. A load of approximately 210 grains gave a muzzle velocity of 2600fps over the chronograph. It was felt that this was close enough to the original ballistics. The original WW1 ammunition muzzle velocity is claimed to be 2500fps or 2575fps or 2650fps or 2700 fps, depending on the literature source. It is interesting to mention that the original powder charge, using some unknown flake powder, was 200.6 grains. To date approximately 50 rounds of this load have been fired without any problems and some cases have been fired and reloaded 3 times.

Shooting the beast

It was with some trepidation that the first rounds were fired through the T-Gewehr as it is historically reported to have fierce recoil. In the literature it states that “its powerful recoil broke the shoulders of some untrained troops” and “the 2-man crew alternated when shooting, since after 2 or 3 shots, they complained of headaches and dizziness”. It must be remembered that the T-Gewehr was built without the modern recoil-reducing muzzle brakes and other devices. In fact it does not even have a recoil pad!

We found the recoil to be substantial, but manageable. Provided of course one limits the number of shots fired. It seems that these historical reports are perhaps somewhat exaggerated. Under wartime conditions there should be no problem firing quite a number of rounds.

An interesting observation of both T-Gewehr’s used in this article is that the rear tangent sight is graduated from 100m to 500m only. The rifle and its 795grain boat-tail bullet with a high BC at 2600fps is certainly capable of shooting way beyond 500m! The rear sight looks as if it was designed for much longer range settings, but is only marked to 500m. This looks rather curious. It is suspected that the rear sight was purposefully limited to 500m as the bullet probably could not penetrate armor beyond 500m. Another theory is that the T-Gewehr team should not give their position away to the enemy tanks too early by firing at the tanks at ranges beyond 500m.

| This article first appeared in Small Arms Review V20N6 (July 2016) |