By Frank Iannamico

Introduced in 1935, the German MG 34 was the first lightweight multi-purpose machine gun to be produced in appreciable quantities. Patents from several German firms contributed to the design of the weapon, which was based on the Solothurn S 2-200 Swiss machine gun originally designed by Louis Stange of Rheinmetall.

One of the best features of the 7.92mm MG 34 was its quick-change barrel. There were a number of improvements implemented into the basic design since it was initially fielded, resulting in a number of variations of the weapon. One modification of the MG 34 served as a tank machine gun. Captured examples of the MG 34 had an active postwar service life, pressed into service by a number of nations. Even during the Vietnam War a new generation of American troops occasionally faced the menacing MG 34 machine gun.

The MG 42, being made principally of sheet metal stampings and could be made cheaper and in larger numbers, supplanted the MG 34 during World War II although the MG 34 still remained in service throughout the conflict. Modern variations of the MG 42 still serve as the general-purpose machine gun of a number of countries.

During World War II, the United States Ordnance Department routinely studied, tested and evaluated many captured enemy small arms. Reports were written that included all of the weapon’s characteristics, specifications and overall performance. Each individual component, to the smallest spring and pin was carefully measured, weighed and photographed.

Captured arms were usually subjected to the Ordnance Department’s standard test for the particular type of weapon being evaluated, to see how they compared to similar U.S. designs. In the case of the German MG 34, the light machine gun test was administered. The U.S. Ordnance reports seldom gave praise to foreign designs.

The U.S. Ordnance Department Tests the German MG 34 Light Machine Gun, 1942

The first test of the German MG 34 was initiated at the Aberdeen Proving Center on 8 March 1942, lasting until 5 May 1942. Due to the lack of sufficient 7.92mm ammunition (only 1,383 rounds of tracer, ball and AP were captured with the weapon), the endurance test was not performed.

The initial impression of the MG 34 as reported from the field was that it was a very effective machine gun, and accomplished its mission in an efficient manner. The weapon and ammunition being submitted for the test had been captured in the Middle East. Three additional breech bolts were received with the weapon, all bearing different numbers, which did not correspond with the arm’s primary serial number. This led Ordnance personnel to initially believe that the bolts were hand fitted to each particular weapon. However, all of the bolts fit and functioned in the subject piece.

Ordnance Department Description, 1942

The MG 34 is the standard machine gun of the German Army. It can be employed as a light machine gun on a bipod or light tripod, or as a heavy machine gun on a tripod or the Lafette 34 mount. The machine gun can be used for anti-aircraft purposes on either tripod. Other mounts have been reported including a twin A.A. mount, which mounts a pair of MG 34 LMG’s in a side-by-side configuration. In addition to mounts, there are a number of different sights to include; the standard sights, the rear sight is a U-shaped affair graduated from 200 to 2,000 meters with a blade type front sight; an anti-aircraft sight with an aperture rear sight and a “cartwheel” A.A. front sight, mounted approximately 8-inches to the rear of the standard front sight position. A dial-type sight is used for the heavy machine gun role; this sight has a 3x magnification with a field of view of about 240 yards wide with a range of 1,000 yards.

The MG 34 is a short recoil-operated, belt fed air-cooled design. It operates on the typical Solothurn action. It is similar to the MG 15 weapon, differing mainly in that the bolt incorporates a firing pin spring and a tripped firing pin. This principal allows the bolt head to be completely locked before the force of the driving spring pushes the bolt body forward another 1/2-inch, releasing the firing pin by means of a trip.

The MG 34 is normally fed by a metallic ammunition belt, although the German hand book for the MG 34 also refers to a 50 and a 75-round cartridge drum. Each belt contains 50 rounds, although troops often join together as many as 5 belts for a 250-round capacity.

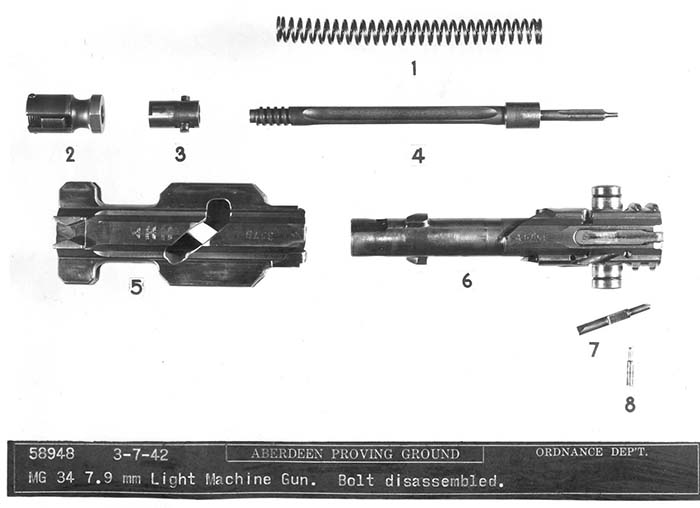

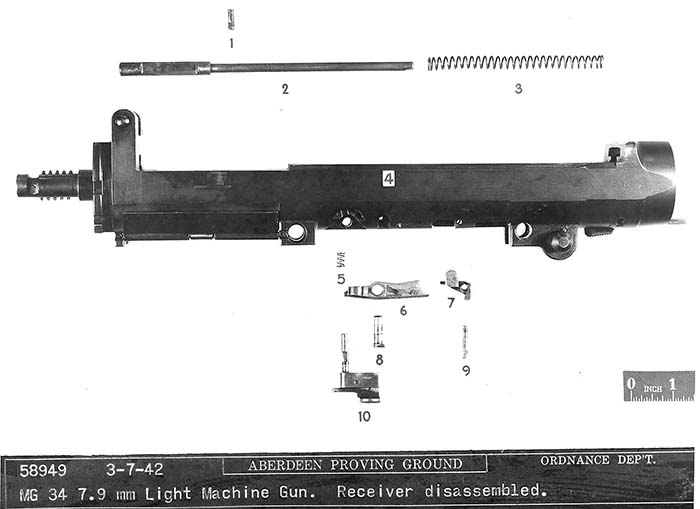

This weapon was originally reported to be easily manufactured; at first glance this appears to be true because of its circular configuration. However a closer study reveals that there are many intricate milling cuts on the breech-bolt alone. The bolt of this weapon has been shown to numerous American manufacturers, all of who estimated a high cost of manufacture for the part. Other parts of the MG 34 that require difficult machining procedures are the receiver, rear of the barrel jacket, the trigger mechanism and the feed cam. The reminder of the parts appear to be simple to produce, but not enough to off-set the cost of the complex pieces.

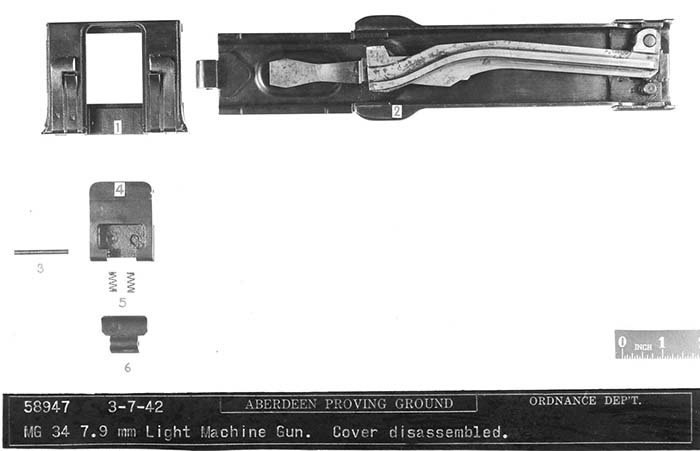

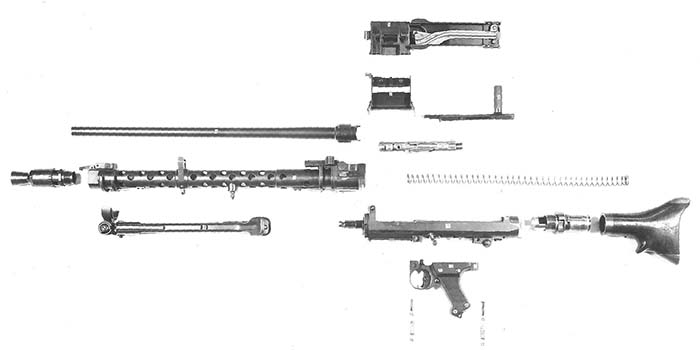

Field Stripping

The time required to field strip the MG 34 was 15-seconds, reassembly time 25-seconds. A complete strip requires approximately 2 minutes, reassembly time requires about 3 minutes. Time required for a barrel change was 6 seconds.

Firing Test

Accuracy of the MG 34 was found to be rather poor. Fired from the prone position, at a range of 300 yards an experienced gunner engaged five paper targets that measured 6 feet by 9 feet. Twenty rounds were fired using the semiautomatic mode. Only two of the targets had twenty hits with an extreme spread from 53 to 65.5 inches. The remaining targets showed 13, 15 and 19 hits on target.

Using full-automatic fire at 300 yards the weapon could not be held on the 6 foot by 9 foot targets, firing twenty-round bursts. Results on three separate targets were; two of the targets had 13 hits one had only 9 hits.

The average muzzle velocity was 2,380 feet per second. The cyclic rate of fire was measured at 750 rounds per minute with the booster plug closed and 830 rounds per minute with the booster plug set at 15-notches out from the closed position.

The MG 34 was capable of lifting 75 rounds of belted ammunition during firing.

Noted during the test was that most of the motion of the weapon during firing was in a horizontal plane. The jarring of the gunner’s head during firing made aiming difficult. Motion in the vertical plane was small, due to the point of support being in a direct line with the bore. The moment of forces acting on the muzzle are close to zero with little tendency to rise. This characteristic has been recently investigated at the Proving Ground with a Thompson submachine gun, using an improvised straight-line buttstock. The results of this testing bear out that the most efficient position of the stock is directly in line with the bore.

Problems encountered during the test.

During the early phases of the test a lack of sufficient power was noted due to 41 short recoils in the first 60 rounds fired. The short cycling resulted in failures to feed and eject. After several attempts at replacing various parts, it was necessary to disassemble the ammunition from the belts and remove all of the fine sand and debris from the ammunition and belts. After cleaning the weapon functioned in a satisfactory manner. An interesting note was during testing at Aberdeen, the MG 34 was subjected to Ordnance’s standard artificial sand test with no major problems encountered. Further investigation revealed that the sand present on the weapon and ammunition was from the Middle East and had a very fine consistency and was nearly invisible to the naked eye.

The general functioning is excellent, but the weapon is critical to proper adjustment, lubrication and foreign matter. The weapon was originally fitted with a booster having a .420-inch diameter. A new muzzle booster was made with a .350 and .380-inch diameters. With the clean ammunition and the .350-inch booster the weapon functioned well. The semiautomatic trigger would not function correctly, double and triple shots were common when attempting to fire the machine gun semi-automatically.

The accuracy of the German MG 34 during automatic fire is poor, this is due in part to the recoil and shock to the gunner’s shoulder. Its rate of automatic fire is far to high for a weapon of this type. The stability is good due to the point of support being a direct prolongation of the bore.

The weapon’s resistance to heat is very good.

The ability to rapidly change the barrel was excellent. German manuals state that a maximum of 250 rounds of continuous fire requires a barrel change. However, German prisoners of war have stated that up to 400 rounds could be fired during an emergency situation before changing out the barrel.

Conclusions of the U.S. Ordnance Department Testing

Results of the testing concluded that the MG 34 is simple, easy to disassemble in the field, however it would be difficult to manufacture on a mass production basis.

The general functioning is quite good, but is extremely critical to adjustment, lubrication and foreign matter.

The performance of the MG 34 during the dust test was considered poor; functioning in extreme cold was poor. Full-automatic performance is poor due to the recoil and shock to the gunner’s shoulder. Its rate of fire is too high for a light machine gun. The ease of changing out a hot barrel is excellent. The belt lift is good.

In general the German MG 34 is neither adaptable to American manufacturing methods due to the critical tolerance of its parts, or to the American soldier due to its inaccuracy.

MG 34 Dual Purpose Machine Gun

Caliber………………………..7.92 mm (.312 in.)

Overall length……………..48 1/4 – inches

Barrel length………………..24 9/16 – inch, 4- groove R.H. twist

Weight with bipod………..26 3/4 pounds

Weight without bipod……24 1/4 pounds

Command height

Low bipod position…..11 1/4 – inches

High bipod position…..13 1/2 – inches

Cyclic rate…………………..800 to 900 rounds per minute

Cartridge feed………………flexible metallic belt containing 50-rounds

Cooling………………………air

Operation……………………short recoil assisted by muzzle blast

| This article first appeared in Small Arms Review V9N9 (June 2006) |