Packing

The Record of Army Ordnance Research and Development, Volume Two, Book Two, published by the Office of the Chief of Ordnance in January 1946, is a unique source of information providing thorough description of the numerous research and developments conducted all along the Second World War concerning, among many others, the containers for ammunition belts used with ground machine guns. The following descriptions of developments of ammunition boxes are based or excerpted from this Record of Army Ordnance.

Before World War II, .30 caliber ammunition was packaged in the M1917 wood box with steel metal liners. The majority of the cartridges were packed in bulk, in 20-round paperboard cartons, seventy-five cartons per M1917 metal lined wood box. Most of the belts were issued empty and the belting was to be accomplished by the troops using the crank operated M1918 Browning Belt Filling Machine. Merely for war reserve only, a comparatively small amount of .30 cal. ammunition was packed in 250-round Browning fabric belts, five belts per M1917 wood box.

The acceleration of the training program and defense preparations already indicated in 1940 that the separate issue of ammunition and empty machine gun belts, which required the belting be accomplished by troops using the M1918 crank operated belt filling machine, introduced a serious problem in field operation and made it difficult to keep machine guns in operation. Troops in the field had neither time nor facilities for repacking ammunition in functional assemblies. This reopened the question of supply of ammunition to the services in assemblies packaged for ready use.

In 1942 after the entry of the USA into World War II, the question of field belting of large quantities of ammunition for ground machine guns became an even more acute problem. The first result was to increase the procurement of pre-loaded belts packed by five in the M1917 wood box while still relying on manual belting in the field for a part of the requirements.

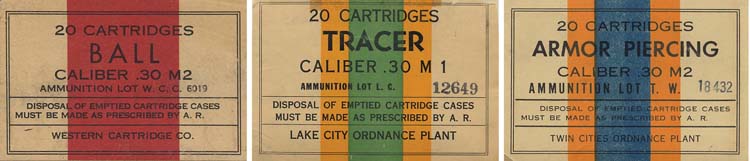

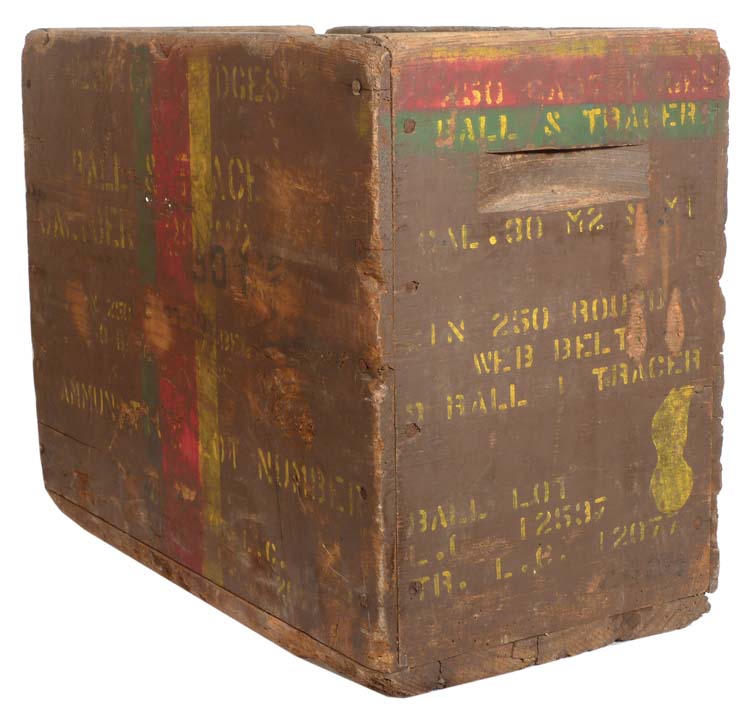

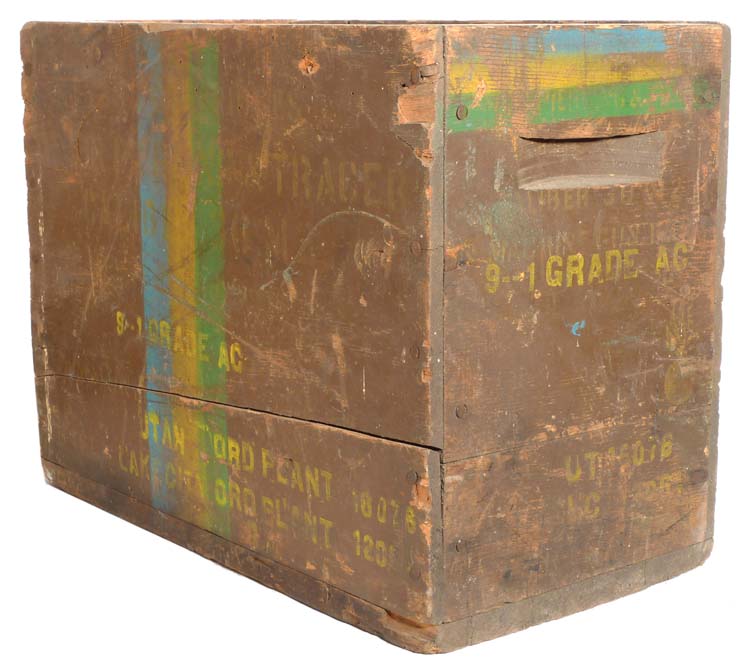

To assist in readily identifying types of ammunition, a system was devised that consists of painting different colored stripes: vertical stripes on the front and rear faces and horizontal stripes on the ends just above the handle cuts.

The colors used correspond to those found on the 20-round cardboard boxes: red = Ball, green & yellow = Tracer and blue & yellow = Armor-Piercing. Accordingly, M1917 crates filled with belts loaded with a mix of Ball and Tracer are painted with red-yellow-green stripes, whereas those with Armor-Piercing and Tracer are painted with blue-yellow-green stripes. For WW2 production, M1917 boxes containing belted ammunition are sometimes observed without the color stripes.

Early in 1942, the standard belt box to accommodate one 250-round belt for infantry weapons was the Chest, Ammunition Belt, Caliber 30, which was constructed of wood, was not expendable and was issued as an accessory to the weapon.

Both the WW1 design with the typical 45 degree angled cut in the bottom/side of the box and the 1930s square box (Ordnance Department Drawing 49-1-84) were in service. These wood boxes were to be repeatedly refilled with either pre-loaded belts or belts loaded in the field by the Troops. These wood boxes proved very durable and were still used as late as 1945 in Europe as many combat pictures show.

Because of the large quantities of ammunition required for use with ground machine guns, expendable small metal boxes were developed and adopted as containers for pre belted cartridges. Extensive development work was invested in this project of expendable containers and thorough description of the various prototypes and improvements are available in the relevant chapter in Dolf Goldsmith’s book. This type of box was suitable both as a shipping and storage container, and could be used as an ammunition ready box with the appropriate weapon. These boxes were packed initially at factory or depot and their content could be fed directly to the gun without the necessity of transferring the ammunition to special chests or feed boxes before firing.

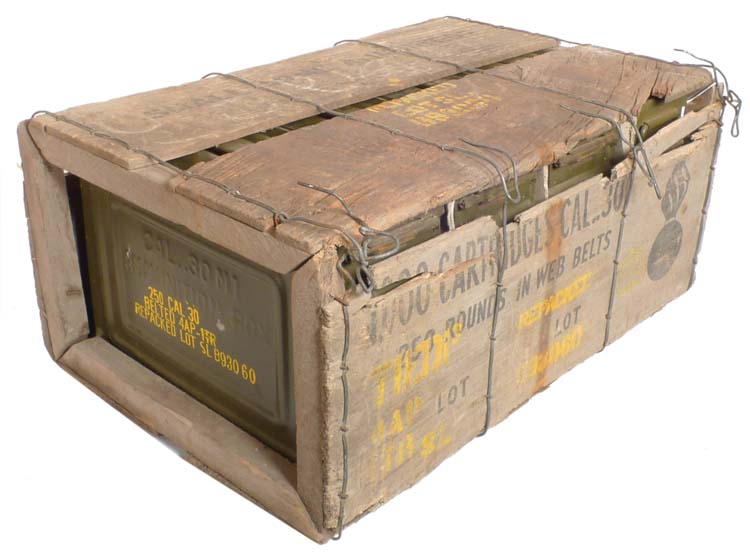

The expendable airtight container adopted as Box, Ammunition, Caliber .30, M1, became the standard packing container for all 250-round fabric belts of ammunition for caliber .30 ground Browning machine guns. This item was in quantity production in the early fall of 1942 and underwent various improvements during the entire duration of the War. M1 boxes usually bear on their outer surfaces markings painted in yellow. These markings indicate the type of content (caliber, quantity, type of belt), the sequence of the different types of cartridges, and a repacked lot number. Four of these M1 boxes are assembled in a wirebound box for shipping.

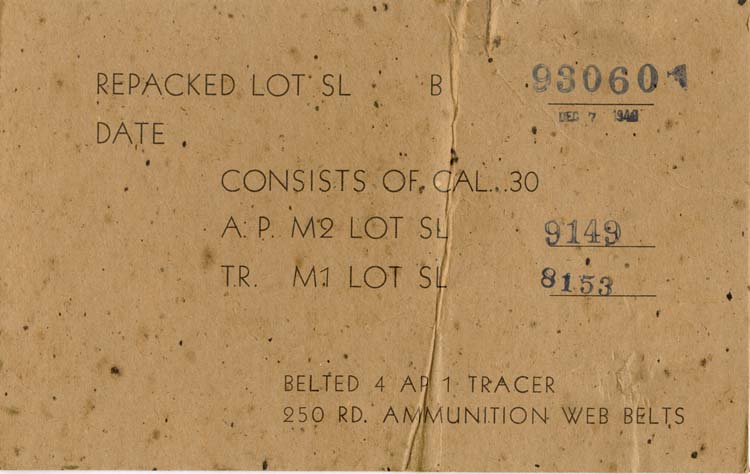

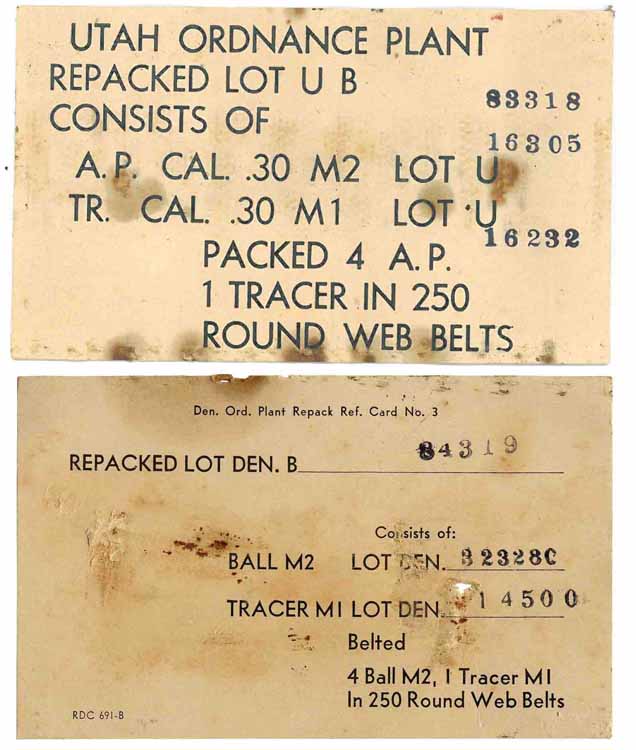

Early in the war (1941-43) the official belting for ground machine guns involved ordinary M2 Ball and M1 tracers with either (9 Ball + 1 Tracer) or (4 Ball + 1 Tracer); early Armor-Piercing belting ratio was 9 Armor-Piercing M2+1 Tracer M1.

Standard belting was then changed officially in July 1943 for a ratio of 4 Armor-Piercing M2 + 1 tracer M1. This change did not start to be packed out at the plants until later in 1943. This is the type of belting sequence that was the most widely produced during WW2.

Since ammunition packed in preloaded belts may consist of more than one type of cartridge and hence would require two or more lot numbers marked on packing boxes and entered in records, a single “repacked lot” number is assigned by the repacker in order to replace the original ammunition lot numbers. The “repacking” operation consists in assembling belts with the various types of cartridges, those being removed from the original bulk packing as issued from the munition factory. Repacking operation was conducted either directly within the munition factory or in separate Ordnance depots. The repacked lot number is painted on the outside of the packing box and on a repacked reference data card inserted in the box. The repacked lot number consists of the words “REPACKED LOT,” the repacker’s initials; the letter “B” or “L” indicating Belted (fabric) or Linked (metallic) cartridges respectively; and the serial number assigned by the repacker.

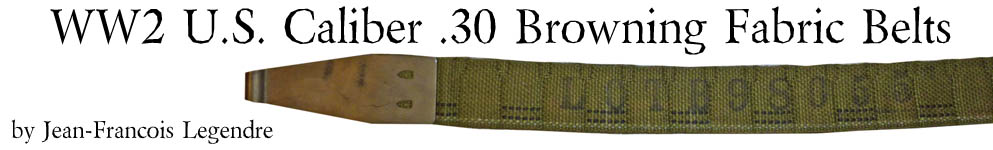

Early in 1945, the repacking lot number was inked directly on the belt thereby avoiding the use of the cardboard Reference Data Card inserted inside the box. The corresponding marking inked on the belt is “REPACKED LOT” immediately followed by the lot number.

By mid-1945, the term “Repacked Lot” was generally replaced by “Functional Lot,” these being assigned a whole new series of lot numbers which were assigned in blocks of numbers to each plant. After this change, the term “Repacked Lot” was still used but only applied to lots repacked by plants or depots to upgrade packing or replace unserviceable components. Functional Lot reference inked on the belt is just “LOT” immediately followed by the lot number.

(The author is deeply indebted to Frank Hackley, Anaheim, CA-USA for the sharing of his knowledge on U.S. Small Arms Ammunition management system and to H.E. Wanting, Bedburg-Hau, Germany for his constant help in improving the manuscript and pinpointing the smallest inaccurate detail.)

| This article first appeared in Small Arms Review V15N4 (January 2012) |