By Jim Schatz

PEO Soldier (www.peosoldier.army.mil)

The “Program Executive Office (PEO) Soldier” is the over arching US Army organization responsible for the development, procurement, fielding and sustainment of nearly everything the soldier wears or carries. PEO Soldier at each AUSA event shows off its accomplishments in small arms, accessories and related individual and crew served weaponry within its expansive and well-staffed booth. The 2007 AUSA Annual Meeting exhibit was no exception. The PM for Soldier Weapons, Colonel Carl Lipsit, was there again and ready to discuss programs and US Army initiatives and objectives, and to provide this snapshot of ongoing efforts.

XM320 Grenade

Launcher Module (GLM)

The planned one-to-one replacement for the aging M203, the XM320 GLM, is in final testing to address numerous Army requested changes deemed advantageous before fielding. The contract for this more or less Commercial Off-The-Shelf (COTS) item was awarded to Heckler & Koch in 2005. First fielding is planned for late fiscal year 2008 and will begin with the Army’s Brigade Combat Teams (BCTs). The US Army plans to procure upwards of 60,000 M320s over the next 5 years. Final operational testing includes evaluation of the day/night sight (DNS) mounting bracket and remote activation switch. A commercial hand-held miniature laser range finder will also be procured and issued with the GLM to allow for range determination to the target, the most common reason for grenadiers missing targets with low velocity 40x46mm ordnance at ranges beyond 150 meters. The M320 will provide the war fighter with new capabilities to include modular on or off the weapon use, night fire capability and first round on target accuracy within 5 meters.

M110 SASS

The 7.62x51mm NATO Semi-Automatic Sniper System (SASS), developed for the US Army from the COTS Knight’s Armament SR-25/MK11 sniper rifle systems, has completed all testing, is in production, and by the time this article is published will have been fielded with various US Army units to include US Army National Guard units from New York. The M110 SASS brings back to the regular Army the availability of aimed and accurate .30 caliber semi-automatic rifle fire that was lost when the bolt-action US M24 Sniper Rifle fully replaced the semi-automatic Vietnam era M21. Old lessons relearned again. When you find an auto-loading sniper rifle like the M110 SASS that can deliver accuracy on par or better than a bolt-action rifle, and with that it brings the ability for rapid multiple shot/target engagement capability, a capability always appreciated in the fast moving urban combat environment, keep a place for such a “tool’ in your infantry tool box.

XM26 MASS

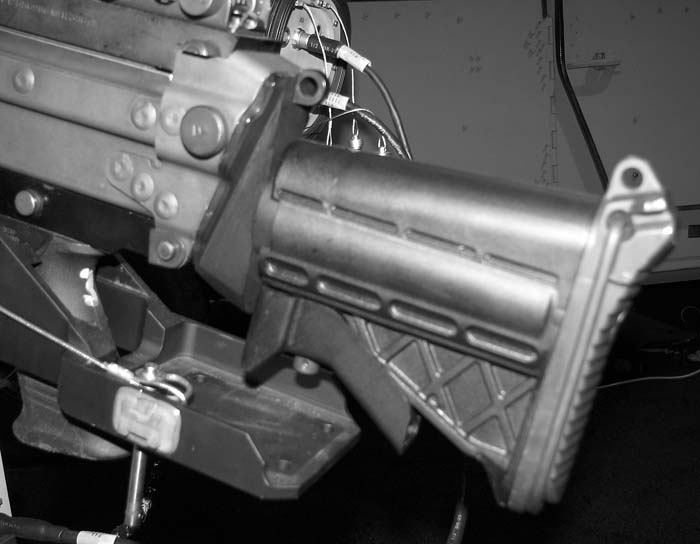

As has been reported in detail in a recent SAR issue, the XM26 Modular Accessory Shotgun System (MASS) has been in development for nearly 10 years. The US Army is now close to fully fielding the final weapon and has been working on various improvements to the design. This includes a new liquid (oil) hydraulic M4-style butt stock to reduce felt recoil from the relatively light weight shotgun in the stand-alone mode. 3-round and 5-round box magazines will be available for the M26 to suit the needs of both weapon mounted and stand-alone use.

M2HB QCB

PM Soldier Weapons will have released a solicitation for a Quick Change Barrel (QCB) version of the venerable M2HB heavy machine gun before this article is in print. The requirement will be for upgrades to existing guns to be installed at Anniston Army depot and then to purchase these upgrades on new guns at a later time. This requested package, available for some years from various vendors as COTS items, includes the quick-change barrel, fixed headspace and timing, new safety and an improved blank firing adapter and flash hider.

Breaking News in US Weapons Procurement: Information that Shook Up the Small Arms Community

The last several years have been “interesting” in the small arms community, as various companies jockeyed to present replacements for our legacy system; the venerable M16/M4 rifle. At this AUSA meeting, information was available that rocked the community.

Colonel Lipsit provided some insight into the then ongoing Extreme Dust Environment testing that was being conducted at Aberdeen Proving Ground in 2007. The test included the standard issue M4 Carbine (from US Army stock), the new SCAR-L Standard Carbine (prototype – LRIP design status), the HK416 Carbine (new production) and the XM8 Baseline Carbine (Spiral 3 prototypes from US Army stores). The M4 was tested with standard USGI aluminum magazines, the HK416 and SCAR-L with the vendor provided magazines and the XM8 with the polymer XM8/G36 magazine that is unique to that system. This test was intended to ascertain the performance of the US M4 Carbine in a severe dust/sand environment with various lubrication and cleaning methods/intervals applied. This is the third such test conducted on the M4 since 2006.

During the test, the weapons and test ammunition loaded in magazines and placed in magazine pouches, were “conditioned” in the dynamic dust chamber for 30 minutes. If ejection port covers were present on the weapons (M4 and HK416 only), they were closed and the bores sealed with shoot-through dust caps, SOP for soldiers in such environments. 120 rounds were then fired through each sample. The weapons were then re-exposed in the chamber again and another 120 rounds fired. At 600 round intervals the weapons were field stripped and wiped down. Lubrication was applied as per the manufacturers established guidelines for this test. At 1,200 rounds, the weapons were thoroughly cleaned. Testing continued to 6,000 rounds on each sample, the 6,000 round figure based upon the expected barrel and bolt service life as listed in the US military M4 specification document.

This testing, started in September 2007, was conducted after pressure was applied by Congress, primarily from the office of US Senator Tom Coburn, a hard charging Republican from Oklahoma and a long-time supporter of the US ground-pounder. Senator Coburn, and his equally engaged staff, orchestrated a delay in the confirmation of the then pending and now current Secretary of the Army, the Honorable Peter Geren, during the summer months of 2007. The purpose of this delay was to force the Army to evaluate the reliability of the US M4 Carbine against select op-rod 5.56mm carbines in a harsh dust/sand environment replicating as close as possible conditions in Iraq and Afghanistan. Even special fine silicon based sand of the light powdery nature found in the Arabian Gulf was obtained for this assessment. An earlier and similar test at Aberdeen in January 2007 of new M4s, M16A2s and M249s in this dust/sand environment, conducted without lubrication in hopes that reliability would increase, ended with poor results for the M4; far below what had been expected, with a stoppage occurring on average once in every six rounds fired. A second similar test conducted by the Army in May 2007 ended with an average stoppage rate of one in 88 rounds fired. This latest 2007 dust/sand test was conducted using heavy lubrication, and as a result of Congressional involvement and pressure, included three modern carbine systems each of which employs an operating rod-style gas system.

Colonel Lipsit was quick to remind this writer that there was no requirement from the User Proponent, that being the US Army Infantry Center at Fort Benning, for a replacement to the M4 at this time. Therefore this test was for data collection only for review by the US Army in its current planning for what might one day replace the current M4 Carbine when the sole source contract to Colt Defense ends in June 2009.

First Formal US Army Test of Op Rod Carbines

With the help of experts in the community, Congress mandated that in addition to testing the baseline US M4 Carbine that this assessment would also include three other systems that stand out from the ever increasing field of more than 15 commercially available op rod ARs. These three carbines were picked because they are or were recently being considered for US fielding, or are actually blooding bad guys in combat by an elite assortment of US Government organizations as is the case with the highly regarded HK416. Already fielded with select US Special Operations Forces, the HK416 Enhanced Carbine has exceeded expectations of the elite user community that have adopted it to replace M4s and MK18 CQBRs. As has been reported in the “Army Times” over the last 16 months every tier one (classified) unit within the US Special Operations Command (USSOCOM) has tested, fielded and continues to employ the HK416 today.

Even the US Army’s own relatively new and mostly unknown Asymmetric Warfare Group (AWG) selected and fielded the HK416 in 2005 but ironically has been recently told by US Army leadership that its use of the HK416, a “non-standard” carbine, creates too many questions and requests from conventional units as to why the rest of the US Army cannot benefit from the availability of superior commercial off-the-shelf op rod carbines. They were then directed to turn them in. The removal of the 416s from the AWG began in November 2007 and will likely have been completed by the time this article goes to print. AWG sources reported that even after more than 2 years of hard training and combat use, not a single part was replaced in any HK416. Because M4s are hard to come by at the moment, the AWG received FN M16 lowers (with the M16 engraving milled off and M4 over stamped) with M4 upper receivers fitted to them. The 416s were sent to the depot; their fate unclear. Superior carbines as proven by other units, paid for by the US taxpayer, cherished by highly experienced and decorated AWG unit members, removed from a highly regarded operational unit and replaced by the very weapon they elected not to field to begin with.

SCAR Lights Up the Field

The second entry within this dust test is the new SCAR (Special Operations Forces Combat Assault Rifle) being developed under contract for the USSOCOM by FNH USA, a regular and proud exhibitor at the AUSA Annual Meeting. Like the HK416, the SCAR family of rifles and carbines was developed as a result of user dissatisfaction with the documented poor performance and limitations of the 40+ year old M16/M4 platform when used hard in torturous SOF environments and on SOCOM missions. Like HK416, SCAR was developed from day one with first-hand user input and has been jointly and exhaustively tested by the expected end users, to include US Army, Navy, Marine and Air Force Special Operators in environments that closely replicate those in which the system will actually be deployed. The SCAR also uses an operating rod-style gas system and thus does away with the hollow gas tube and associated carbon fouling and heat transfer issues that have plagued the M16 and M4 with their direct gas system arrangements. It also boasts barrel life expectations of 35,000 rounds or greater and 100,000 round weapon service life, according to company and USSOCOM sources.

Dust off your XM8s

The third candidate (the word candidate may be misleading as the US Army is careful to point out this extreme dust/sand test was for data collection only. The final results will be reported to the US Army Infantry Center and be included in their ongoing Capabilities Based Assessment (CBA) intended to clarify and chart the US Army’s future path or plan for future small arms, due sometime before 2010) was the now defunct, and once US Army sweetheart, polymer based XM8. Once again operating with a piston rod, or operating rod gas system, the XM8 in its final official Spiral 3 configuration set a high water mark during reliability and environmental testing by the US Army in 2005 by achieving an impressive 18,000 round MRBEFF (Mean Rounds Between Essential Function Failure) performance rating (in layman’s terms, zero stoppages or parts failures in 18,000 rounds fired). No other official developmental carbine/rifle in the reported recent history of US Army testing has fared that well, according to sources within the test agencies.

Historical Significance

Four very different weapons in the first direct comparison test by the US Army in decades. The US M4; a combat proven and highly regarded variant of the original 1960s-era ArmaLite AR-15, first officially fielded with US forces in 1964, with its aluminum two part upper and lower receiver, add-on rail system and direct gas tube-style operating system. The HK416; a highly product improved hybrid of the famous ArmaLite platform, also sporting the two-piece forged aircraft-grade aluminum receiver design and using the proven pusher rod gas system first employed by its maker in the polymer G36 rifle in 1995, and with many of the same advantages and disadvantages of the Stoner design from which the weapon was reverse engineered. Then, the shinning star of the Tampa-based US Special Operations Command; the all business SCAR-L (L for “Light” for those versions chambered for the 5.56x45mm NATO cartridge). With its one-piece extruded aluminum upper receiver with polymer lower receiver and user exchangeable barrels, the SCAR represents a unique departure for a US military rifle in that is shares up to 82% parts commonality with its big brother SCAR-H (H for “Heavy” or caliber 7.62x51mm NATO), and the many modular variants in the SCAR family, to include the short-barreled “CQC” (Close Quarters Combat), “S” (Standard Carbine) and “SV” (Sniper Variant) models. All basically the same caliber-specific platform, but with different interchangeable parts available for the user to configure the weapon he or she needs for today’s mission. Finally, the son of G36: the XM8. Arguably the most controversial rifle since the original AR-15 was introduced into the US military in the 1960s due to the unconventional way in which it was developed by the US Army and the fierce resistance from within the US Army itself, and the small arms industry, to its possible procurement from a foreign vendor without a US production plant and one that is not part of the existing US Small Arms Industrial Base. The mere thought of the US fielding a replacement to the US M4 and M16 without full and open competition, and direct comparative testing with other available systems, doomed the XM8 from the very start. An all polymer rifle save the barrel, bolt and select internal parts with a separate upper and lower receiver arrangement, using a polymer magazine and offering the user a multitude of possible variants mostly configurable in the field, the XM8 offers some notable advancements in ergonomics, user exchangeable stock options galore and a very innovative multi-function sighting device combining all of the needed “aimers” (red dot reflex sight and IR laser aimer and illuminator), and all zeroed in one single and simple operation.

Early Results

While the US Army’s Carbine Severe Dust Tests had just been completed and the final report still being written at the time of writing, early intel indicates that all three op rod carbines finished far ahead of the M4 for reliability in this environment. Sources report that the XM8 performed best amongst this pack with one stoppage every 472 rounds. The XM8 was followed by the SCAR-L with one stoppage every 265 rounds and then HK416 with one stoppage every 257 rounds. The M4’s performance was one stoppage every 68 rounds, just barely 2 magazines fired without incident, and a reliability rate almost 7 times worse than that of the XM8 under identical test conditions and protocol, almost 4 times worse than the SCAR-L and HK416. Reliable sources within the community reported that an adjustment to the lubrication schedule for the SCAR-L was required early on in the test, that one of the ten HK416 test samples performed poorly having most of the recorded stoppages and thus lowering the overall score of the weapon system (had this one sample performed like the others it would have finished at the top of the pack) and numerous barrels were replaced on the M4s to complete the 6,000 round test. When presented with these reliability numbers the Army was quick to down play the significance of the results, stating that these tests were conducted in extreme conditions that did not address “reliability in typical operational conditions” and that “everybody in the Army has high confidence in their weapon.” However, this is not what knowledgeable users are saying to this author and SAR.

Easy Answer? Not So.

From all of this modern carbine/rifle technology to choose from, developed at a cost to the US taxpayer of reportedly $70M or more ($20M SCAR, $50M XM8, zero dollars for HK416), surely the US Army could select the best available carbine for our troops and get that to the field before the shooting is over. They could but one problem remains: there is no requirement for a new carbine, or even meaningful incremental carbine enhancements. The term incremental can be defined as the 75% or “90% solution” versus the fanciful so-called “leap ahead” or “100% solution” we in this country too often pursue while all but ignoring available and affordable incremental upgrades and enhancements offered off-the-shelf by industry. This writer is not talking about accessorizing existing platforms, such as the addition of different butt stocks, rail systems, sights and the like. We have done that with some success over the years with flat top receivers and modular rail systems. While this enhances the use of the weapon for the operator, it does nothing to address the basic function or performance of the operating system, weapon integrity, function, safety and/or operator upkeep.

While the users on the ground surely would welcome a new carbine with the enhanced capabilities now and very soon to be in use in US Special Operations units, the official procurement process starts with a properly formulated and approved Requirements Document. In the US Army this begins within the lead proponent for small arms, the US Army Infantry Center at Fort Benning, Georgia. The USAIC, as mentioned earlier, is in the throngs of their CBA to determine where they want to be in 5-10 years with US Army small arms. Shall they field a new conventional carbine in 5.56mm? Should they leverage the polymer or caseless technology being explored in the current JSSAP LSAT program? Should the new suite of US Army small arms include air-bursting, or counter defilade technology, a technology that the US Army has invested deeply in over the past years to the tune of more than $377 million for the OICW/XM25 and XM307 Advanced Crew Served Weapon programs?

Strategic Pause?

Thus, without a formal requirement for anything new, the US Army continues to procure M4 Carbines and plans to do so up until at least June 2009 when the current M4 contract expires, at the tune of up to $375 million on a sole source basis without evaluating other current COTS weapons. The US Army states clearly that the M4 meets current US Army carbine specifications; and it does. There is no argument to that point. Colt is building for the US Army the carbine they have asked for and has on multiple occasions proffered to the Army various enhancements to the weapon, most of which were not accepted as they were not required in the weapon specs. However those specifications were written more than two decades ago based on the then current performance of the M16A1/A2, long before the advent of the modern op rod AR, the unibody extruded aluminum receiver of the SCAR, or the highly modular and user configurable design of a modern weapon like the XM8.

The Smoking Gun: Soldier Perspectives on Small Arms in Combat

One has to question the wisdom of not leveraging the incremental improvements that the current modern crop of assault rifles offers the end user. This point is especially driven home when one reads the US Army sponsored, Center for Naval Analysis conducted survey of 2,600 soldiers that had returned within the previous 12 months from Afghanistan and Iraq and had engaged in a firefight using the M9, M4, M16 (A2 or A4), or M249 during their last deployment. While the majority (75%) expressed overall satisfaction with their current rifle or carbine, few had ever seen and literally none have used a SCAR-L, XM8 or the HK416 or anything of a more recent design. Their frame of reference is thus limited to only what they know and have seen first hand. Given a shorter and lighter carbine with adjustable length butt stock versus the longer, heavier M16 with fixed stock; who would not welcome that, especially when fighting from vehicles and in the urban environment? Surely then the M4 would get high marks when that question is asked; which do you like better? The real test would be to offer the soldier a look at and chance to handle the more modern COTS carbines developed in the past 10 years like those described above. Surely the results of such a survey would be far different. Why not field one or more of these proven, modern carbines in a combat unit, say to a company or battalion as we have done with the Land Warrior ensemble, and then let them tell Army leadership where to spend our precious small arms procurement dollars?

What has not been widely reported from this US Army sponsored study is that, quoting from page 17 of this report, the “Percentage of soldiers who report experiencing a stoppage while engaging the enemy” was 19% for both the M16 and M4 (26% and 30% for the M9 and M249 respectively). The report goes on to state that, “A large impact means the soldier was unable to engage the target with that weapon during a significant portion of or the entire firefight after performing immediate or remedial action to clear the stoppage” (author’s emphasis added). 18% of these same soldiers stated that they were unable to clear that stoppage and get the weapon running again during the course of that engagement with the M4, 20% with the M16, 38% with the M9 and an astonishing 41% with the M249. Nearly one fifth to almost one half of the unit was “out of the fight” due to serious malfunctions in their basic weapon. These are the statistics taken right from the US Army’s own report. When questioned, US Army officials were quick to blame poor soldier maintenance for the stoppages. Sadly, we have seen this tactic used before with early AR-15s in Vietnam and more recently with the British Marines and their SA80A2’s in Operation Iraqi Freedom; blaming the war fighter for the inherent shortcomings of the weapon system.

One can then see a direct correlation between operational reports from these 494 combat soldiers surveyed who reported poor reliability to the extent of complete failure to operate during the heat of battle and the recent poor results of the same weapons in the Extreme Sand/Dust Tests described above, results that some in the Army are saying are acceptable. It is certain that those 494 brave men and women were not so satisfied with the weapon when it was useless in their hands with the enemy all around.

One then must ask why our most elite units are not using the same standard issue rifles or carbines as used by our conventional forces and instead have sought out, tested, and have fielded with great success weapons like HK416, and soon SCAR, the USSOCOM MK46 and MK48 machine guns, the MK43, and every type of handgun imaginable except the US M9?

Not the Last Word

As reported last year by this writer, this subject is far from over. Congress is involved and is drafting new legislation to persuade the US Army to consider incremental and commercially available small arms, and ammunition enhancements, both of which can and would make a big difference on the battlefield for the solider, every solider, not just our most elite warriors. In fact, on page 29 of the CNA survey referenced above, and I quote, “Twenty-six percent of M9 users requested higher caliber ammunition and increased stopping power. M4 and M16 users echoed this recommendation. When speaking to experts and soldiers on site, many commented on the limited ability to effectively stop targets, saying that those personnel targets who were shot multiple times were still able to continue pursuit” (author’s emphasis added). Soldiers are asking for more reliable weapons and more capable, more lethal bullets and ammunition yet we continue to buy thousands more of the same small arms and millions more of the same cartridges to feed them. Is it a matter of money? Is it simply too expensive to field enhanced small arms and ammunition?

The Flawed Cost Argument

The current unit costs on the current contract for carbines, and the wealth of defense spending on programs like the Joint Strike Fighter ($4.2 billion) for R&D alone, or the Army Future Combat System (FCS) which in the current defense budget received $3.2 billion for R&D, places the modern and advantageous weapons like HK416 and SCAR, and enhanced ammunition types like improved “blind to barrier” bullets and medium caliber rifle cartridges, well within reach for all US military personnel. For the $430 million dollars spent since 1980 on so-called “leap ahead” small arms programs, from which no single weapon or new round of ammunition has been fielded, we could have fielded more than a quarter million new 5.56mm or 7.62mm SCAR rifles at $1,800 each, or 358,000 new XM8s or HK416s in the more lethal 6.8x43mm SPC caliber at around $1,200 a pop. (For comparison, the 2005 contract price for an M4 was $980, $836 in 2007). However the internal bureaucracy and strong institutional resistance to field something new in the way of a modern carbine and/or rifle, anything new that is available today not in 2010 or beyond, and has been proven by other users (and in the Army’s own tests) to be incrementally better and easily integrated into the forward deployed units, is both hugely perplexing and mind numbing to this writer and many others in the community.

The Bottom Line

There should not be a single day that any US serviceman or servicewoman steps off a truck, aircraft or ship without the very best small arms technology America can provide. That technology exists today. The funds for its purchase, fielding and sustainment are obviously available and are being spent, but on decades old technology. This issue is critically important as we lose personnel in combat every single day and any advantage, even one that is ever so minor, may improve the odds of both user survival and ultimately mission success. Our weapons should be the most reliable, hard hitting and user friendly weapons on the face of this round globe yet they are not, and we should be ashamed as a result. Our fleet of small arms is old and showing their age.

Aging Fleet of Old Warriors

The average age of our eight top “work horse” weapons from the M9 to the MK19 is 33 years, 25 years if you remove the oldest- the M2HB- 23 years without the M2HB and M203 and still 21 years old with the oldest three removed from the average. If our computers, vehicles, night fighting capability, body armor, rations or medical equipment were from the same era as that of our most recently adopted small arms (mid-1980s), our forces would be hard pressed to perform on today’s modern battlefield as they have so stunningly performed during OEF/OIF. With a few exceptions, such as the new M110 SASS or M107 sniper systems, we have not fielded any new small arms designs since the mid 1980s. Again, not just for our most elite warriors in units that we do not discuss in print, but for every Soldier, Airman, Marine, Seaman, Coastguardsman and Special Operator. Anything less is a sad compromise – a compromise that we are making today and a compromise that costs lives.

The German Success Story

Even the German military, who’s annual defense budget spending figure of EUR 29.31 billion (GDP 1.3%) is far below that of the US ($42.8 billion) and below many neighboring countries in Europe (GDP 2.0%) have since 1995 replaced nearly every one of their small arms, have added numerous new calibers and capabilities they had not possessed previously. Because of this successful incremental fielding approach, the German military has the most capable set of military small arms in the free world today. In new improved small arms they have fielded no less that six since 1995 to include handguns, rifles/carbines and sniper rifles, and are working on at least three more that this writer is aware of, a new 4.6mm handgun, lightweight 7.62mm machine gun and improved .50 caliber heavy machine gun. Nine new capabilities have been added to the German small arms arsenal also since 1995 and include the first general-issue Personal Defense Weapon within NATO, a 5.56mm LMG, .300 Win Mag and .50 BMG sniper rifles and two 40mm grenade launchers, both under barrel and 40x53mm belt-fed versions. No less than six new calibers have also been fielded within the German military in the last 10 years to include brand new high performance cartridges like the 4.6x30mm PDW round. While the Germans continue to investigate advanced technology with R&D funding, they have not forgotten their soldiers fighting on today’s battlefields and have applied the “90% solution” by fielding incrementally superior small arms and capabilities. The same can be said to a lesser degree for other NATO countries like Britain, Spain, Norway, Canada and others. Let us also not forget the substantial efforts of potential threat countries as well in their development and fielding of incrementally superior small arms.

Officially, the conventional side of the US Army has not tested a single one of these COTS German weapons for possible US adoption, not one, yet many (no less than four) are in use by select US Special Operations units over those standard US issue weapons available from US military stores and which are in fact comparable in cost or less expensive than the US equivalent.

The Consequences of Failing to Act

A highly decorated US Army Special Forces senior NCO recently stated as part of this debate, “Most of the boots on the ground in OEF/OIF will be the first to tell you that the enemy has no respect for our war fighters in a head-to-head confrontation while maneuvering with his individual weapon (M16/M4). An enemy who does not respect a Soldier’s ability to deliver pain or death will always bring the fight directly to the Soldier, at belt buckle distance.”

We would like to urge everyone to get involved in this, and help our service members to get the best weapons possible. They deserve our united support. Write your elected officials on Capitol Hill. Write the US Army and Defense Department leadership. Demand that we first test then field the best commercially available weapons and ammunition that industry offers today to all of our war fighters and that we do it now, not 5-10 years down the road.

| This article first appeared in Small Arms Review V11N9 (June 2008) |