By Christopher R. Bartocci

Without a doubt, the .22 Long Rifle caliber ammunition is the most popular in the industry. Rifles and handguns are made in every configuration possible making it a universal caliber. For the occasional plinker there is a gun and ammo combination and for the competitive shooter there is a rifle and ammunition combination as well. Hunters love the caliber for small game. All of the major U.S. ammunition manufacturers make multiple loads in this popular caliber. Ammunition is broken down into 4 categories for the most part. First is subsonic, which is normally 1,050 fps or less. This is good for use with suppressors as well as when noise is desired to be reduced. The second is standard velocity, which is normally around 1,150 fps. This is often target and match ammunition. The third is high velocity, which is usually around 1,280 fps. This is often for target and hunting ammunition. Also, this is preferred in semiautomatic firearms to reliably cycle the action. The fourth is hyper velocity, which is around 1,500 fps. This is normally a hunting load. Projectiles for the .22 Long Rifle are basically lead round nose or hollow point. Often they will be copper plated to keep the bore from leading. Some are truncated cone shaped such as the Remington Viper and Yellow Jacket. These truncated cone shaped projectiles often encounter feeding problems in semiautomatic firearms. There are specialty bullets as well is various subsonic loads.

For instance, Federal Cartridge Company offers standard (Champion), subsonic (American Eagle), match (Gold Medal) and high velocity (Champion and Game Shok) hunting rounds. Remington offers a wide range of loads. In standard velocity they offer a .22 Target Load. In high velocity they offer the Cyclone, Thunderbolt and Game Load. In hyper velocity they offer the Viper and Yellow Jacket. CCI offer one of the largest selections of loads. In subsonic they offer the Subsonic HP and Quiet .22. CCI offers Standard Velocity with the STR VEL, Green Tag Match, Pistol Match and Select. High velocity offerings include SGB, Mini-Mag and AR Tactical. CCI offers hyper velocity rounds in the Stinger, Velocitor and SRG. Winchester offers a significant number of options as well with one in particular that is pertinent to this article. It is called their M22 load which is a 40 grain Black Copper Plated round nose projectile fired at 1,255 fps. This was specifically designed to burn cleaner in AR-type .22 Long Rifle rifles.

Black Dog Machine, LLC Magazines

In 2005, Black Dog Machine of Nampa, ID introduced their first polymer AR-22 Long Rifle magazine. The AR 15/22 magazine referred to as “the skinny body” magazine is now referred to the “Gen 1.” Black Dog Machine began their development with polymer because they wanted to supply the market with the first molded magazine for a reasonable price right when the 1994 Assault Weapon ban sunset. Black Dog Machine is without a doubt the leading manufacture of .22 Long Rifle magazines for the AR platform in the industry. They manufacture magazines for 14 different OEM’s. In fact, all but two of the conversion upper receivers tested for this article came shipped with Black Dog Machine magazines.

In 2011, the Black Dog Machine magazines got an upgrade to cast stainless steel feed lips. This is a big upgrade to this sensitive part of the magazine and was released on all of the XF line of magazines. The follower on the Black Dog Machine magazines holds the bolt open after the last shot. It does not actuate a bolt catch; as soon as the magazine is removed from the rifle the bolt slams forward. This is very important in the life of the firing pin. If the chamber is empty and the hammer falls, the firing pin will peen around the chamber on the face of the barrel – not only damaging the firing pin but the peening of the chamber can be enough to stop a round from chambering. Locking back on the follower prevents this damage from taking place.

Black Dog offers magazine capacity of 10, 25, 32 and 50 rounds. Straight stick magazines are offered in 10-round capacity in both black and translucent polymer. The 25-round magazines are curved like the standard 30-round 5.56mm magazine and are also offered in black and translucent polymer. The most interesting magazine tested was their billet black 25-round magazine. This was designed to mimic the exact weight of a full 30-round 5.56mm magazine at 1 pound. When this was placed in the Tac Sol and DPMS upper equipped rifles the weight/balance was identical to that of a standard M4 carbine. Also offered is a polymer 32-round magazine. The follower is thumb assisted to aid in loading. This is a very long magazine. Of the three lowers tested, both of the sample magazines fit in the well quite snug. When tested they did not malfunction but due to the extreme size the standard 25-round magazines were far more appropriate for shooting off a bench as they all dropped free from any mag well they were inserted into. The other magazine tested was Black Dog Machines’ 50-round drum magazine. Many attempts have been made to make 50 and 100-round capacity magazines in .22 Long Rifle. Most were a complete failure. This one, however, is quite well thought out and executed. The magazine is convertible by simply getting a conversion kit and changing out the feeding tower so it can be used in either a Ruger 10/22 or AR-type lower receiver. The magazine has ridges on the rear of the back of the drum to aid in loading. Slightly pushing down on the rear allows the follower to drop slightly so a round may be easily inserted. This magazine was loaded five times with CCI Mini-Mag and Stinger ammunition out of the Tac Sol upper and the Chiappa upper and there were no malfunctions at all. This magazine performed well with the high and hyper velocity ammunition. All of the mentioned magazines were tested throughout the research for this article. No malfunctions were encountered due to these magazines at all. All of the malfunctions encountered were ammunition related (low power standard ammo). The quality is excellent which is why 14 OEM’s trust these magazines to go out with their product.

Spikes Tactical .22 ST-22 Upper Receiver Conversion

In 2008, Spikes Tactical introduced their .22 Long Rifle conversion kit as well as complete rifles called the ST-22. These are amongst the highest quality of those tested. It should be noted that as of this time, Spikes Tactical has discontinued production of the ST-22 series due to the high demand of their 5.56mm and .300 Blackout rifles. There is a good chance once things calm down with the demand for the larger caliber, Spikes Tactical will bring back the ST-22 line. Spikes Tactical has offered nearly 50 variations of their ST-22. That is every combination of handguard, lower receiver, gas block, barrel length and muzzle device you can think of including some different markings on the receivers.

The receiver sent for test and evaluation came with a Mil-Spec 7075-T6 aircraft aluminum upper receiver. It has a forward assist although it serves no purpose other than cosmetic. The receiver also has the fired cartridge case deflector and ejection port dust cover. The top of the rail has a regular Mil-Std-1913 rail along with a beautifully engraved spider on the rear by the charging handle.

The barrels used by Spikes Tactical are both Lothar Walther and Green Mountain, both 1:16 twist. The barrel on the test and evaluation unit was a Lothar Walther. The Lothar also had a slightly tighter chamber and bore that improved accuracy and reliability due to the increased back pressure. The barrel lengths offered go from 5.5 up to 16 inches. The barrel on the T&E unit was 16 inches in length. The muzzle device attached was the Spikes Tactical Dyna Comp. The Dyna Comp is designed to reduce recoil impulse and muzzle climb to provide faster follow-up shots. This is accomplished by balancing the direction of the blast along the vertical and perpendicular planes of the muzzle to lower muzzle rise, while the end of the devise restricts forward energy to reduce parallel recoil. The ports are ball dimpled for smoother expansion of gases and rapid heat dissipation. The compensator is Melonite treated.

The rail provided on the upper receiver is the Spikes Tactical ST/S3. The rail is 13.2 inches in length with quad Mil-Std 1913 rails. The rail is attached to a proprietary barrel nut that leaves the barrel fully free floated. The rail is manufactured from an extrusion and Type III anodized hardcoat finished. All of the rails are scalloped for operator’s comfort. There are four QD sockets as well. The rail is very well made and very durable.

The bolt is a modified Atchisson design. This design has an interchangeable front that is held in place by the receiver frame. This particular one is equipped with a barrel collar assembly that contains the feed ramp; the barrel end slides into the barrel collar assembly. The bolt group is entirely finished in NP3 Nickel Teflon.

The upper receiver was placed on the Aero Precision lower receiver. All magazines used were Black Dog Machine 10, 25 and 50- round magazines. The upper was tested with CCI Mini-Mag, Remington Golden Bullet, Scorpion, Federal Match and CCI Stinger. The rifle would not reliably cycle with the Federal Match and justly so due to it being standard velocity but this was by far the most accurate load. All other ammunition fed reliably and accurately. More than 200 rounds were fired through this upper with only a few malfunctions due to ammunition. Every manufacturer of these conversion units recommended high velocity or hyper velocity ammunition to make the rifle fire reliably.

Although the ST-22 went out of production in January of 2013, there are still many upper conversions as well as complete rifles out there. This is a high quality conversion that has had a lot of time and thought gone into it to make it that much better than some of its competitors. Hopefully at some point Spikes Tactical will put them back into production. Tom Miller at Spikes Tactical told this author that they have everything they need to go right back into production when the time comes.

Core15 .22 Long Rifle Conversion

Core15 is one of the newest manufacturers in the AR-business out of Ocala, Florida. When they opened their doors they hired Israel Anzaldua, formerly a Bushmaster senior executive, to assist them in getting going. They have very quickly gained a reputation of being one of the higher tier AR manufacturers. They make rifles in 5.56mm, 7.62x51mm and .300 Blackout. They manufacture .22 Long Rifle conversion uppers only, not complete rifles. Core15 introduced their .22 Long Rifle line up in December of 2011. They offer 5 different variations: M4, MOE, TAC, TAC III with 12 inch rail and the TAC III with a 15 inch rail.

The upper receiver received for test and evaluation was the TAC III with the 15 inch rail. The MSRP on this particular upper is $629.99. The upper receiver is a standard 7075 T6 aircraft grade aluminum upper receiver with a forward assist (looks only), fired cartridge case deflector and ejection port dust cover. The charging handle is manufactured from a solid piece of 6061-T6 billet aluminum allowing it to be held to extremely consistent tolerances and maintain exceptional level of strength. The charging handle is equipped with the Core15 V2 tactical latch.

The 16 inch barrel is nitride coated and equipped with a standard A2-type compensator. Core15 currently out-sources their .22 Long Rifle barrels to Green Mountain but are in the process of manufacturing their own barrels. As of this writing, Core15 is manufacturing their own 5.56mm barrels. The barrel on the test and evaluation unit is manufactured from 4140 steel and has a twist rate of 1 turn 16 inches. The handguard provided on the test and evaluation unit is the Midwest Industries Gen 2 SS series handguard. The handguard has a 1.5 inch outer diameter and is very light. The rail is manufactured from 6061 aluminum and uses a proprietary barrel nut that must be installed by a gunsmith. The rail is set up so that there are removable rail segments that allow the user to only put on what is needed and not to worry about the others being damaged. The provided upper was equipped with two of the 2-inch rail panels mounted at 3 and 9 o’clock on the front of the handguard.

The bolt is a modified Atchisson design. This design has an interchangeable front that is held in place by the receiver frame. The bolt group is made from 4143 stainless steel. This particular one is equipped with a barrel collar assembly that contains the feed ramp. The barrel end slides into the barrel collar assembly. The bolt group is nickel boron coated.

The upper was tested solely with Black Dog Machine magazines and placed on the Aero Precision lower receiver. The upper was tested with CCI MiniMag, Remington Golden Bullet, Scorpion, Federal Match and CCI Stinger. Approximately 200 rounds were fired. Like all the rifles before it and after it, the upper would not cycle with the Federal Match ammo due to it being standard velocity. However, the best groups were shot with this ammo. Other than that, the rifle cycled reliability with all the ammunition it was fed. Core15 recommends CCI and Winchester ammunition and stated their uppers have zero issues with CCI Stingers.

Core15 offers 5 variations that cover any customer. They are very high quality but expensive. You do get what you pay for. Their most popular upper is their TAC III with the 12 or 15-inch Midwest Industries rail system. Core15 feels that it is the narrowest rail in the industry, providing comfort, lightweight and modularity.

DPMS

DPMS has been around for quite some time and they were probably one of the earliest to come out with a .22 Long Rifle conversion kit. DPMS introduced their line of conversion upper receivers in the fall of 2011. They offer two models: The AP4 and the Bull Barrel. The Bull barrel is a very heavy 16 inch barrel with a free float tubular handguard. The AP4 was sent for test and evaluation.

The upper receiver is rather unique compared to all the others tested. The receiver is manufactured from 7075 T6 aircraft aluminum and is machined to be dedicated solely to .22 Long Rifle caliber. First, the ejection opening is half the length of the standard M16/M4. Second, there is no cam slot machined into the receiver. Thirdly, the inside of the receiver is a different shape to accept a rectangular shaped bolt group. The forward assist is permanently attached into the receiver and stationary. You have the appearance but it is non-functioning. The rail is the typical Mil-Std 1913. Another totally unique feature of this upper receiver is that the ejector is screwed into the left side of the inside of the receiver.

The barrel on the AP4 tested is 16 inches in length with a 1 turn in 16 inch twist. The barrel is manufactured by DPMS and is manufactured from 4140 steel and Teflon coated. The barrel has the step-cut for mounting the M203 (not that you would) as well as a standard A2-style compensator. The front sight base was pinned to the barrel and has a bayonet lug. Standard large M4-type handguards came on it with a delta ring.

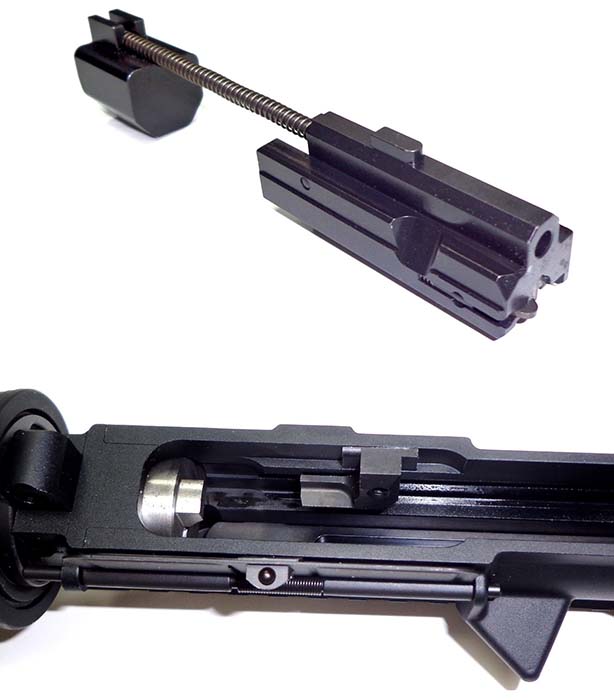

The charging handle is proprietary on this design. There is a raised portion of material on top of the bolt that rides in a track in the charging handle. The bolt is also very unique compared to the rest of the uppers tested. It consists of two pieces and the recoil/action spring. The front part of the bolt is not so out of the ordinary other than the shape. The piece of metal on the rear is out of the norm. It is a rather large chunk of metal. It appears the reason for the large chunk of metal is not just to take up space but, due to the mass, will assist on more energy to drive the bolt forward. Try to picture bolt carrier bounce on a M4 but reverse the direction of the bounce. When two pieces of metal collide and one is heavier than the other, there will be rebound due to the physics of the thing. This would appear to be the logic behind it – or it could just be a sheer benefit of the design.

The upper receiver was placed on the Aero Precision lower receiver. Only Black Dog Machine magazines were used. The upper was tested with CCI MiniMag, Remington Golden Bullet, Scorpion, Federal Match and CCI Stinger. This was the only rifle to cycle the standard velocity Federal match ammunition. The upper fired all 25 without a hitch. More than 200 rounds of the mentioned ammunition were fired without a single malfunction. The rifle grouped very well, although the range was 15 yards.

The DPMS is certainly an excellent option for one looking for a .22 Long Rifle conversion kit. The AP4 is a great all-round upper. The bull barrel version is great for a competitor or for one who likes to put every bullet in the same hole. The quality of this upper receiver is excellent and with an MSRP $399 it is hard to beat.

Chiappa M4-22, .22 Long Rifle Conversion

Chiappa has been known mostly for blank firing weapons as well as reproduction firearms from way back – opening their doors in Italy in 1958. They opened a facility in Dayton, Ohio in 2007 to expand their North American market. Chiappa introduced both their M4-22 upper receiver conversion and their M4-22 complete rifle. They offer three different upper receivers. First is the M4-22 (CF500-059) upper, which is a 16 inch government profile barrel. This upper has standard M4-type handguards and a polymer upper receiver. The receiver has a forward assist (nonfunctional), fired cartridge case deflector and ejection port cover. The average selling price is around $350. This upper comes with a 28-round magazine. The next is the M4-22 Gen II Pro (CF500-097), which differs from the standard by having a 7.8 inch free floating handguard. The third variation is the M4-22 Gen II Pro (CF500-095), which differs from the previous by having an 11.8 inch free floating barrel.

There were three different uppers tested during this research. All were the same but with different handguards. The barrel was equipped with a standard A2-style compensator. The bolt is a modified Atchisson. The feed ramp is on the end of the barrel itself. There is a spacer directly behind the bolt that seals up the ejection port protecting the inside of the rifle from debris. Both black and chrome plated carriers were seen.

The upper receiver was placed on an American Tactical Gen 2 Hybrid polymer lower receiver. This was the most finicky of the lot. Quite accurate at 25 yards with 28 rounds in just over an inch with Scorpion ammunition but the uppers experienced some failures for the bolt to fully close. This was pretty much the only type of malfunction. Probably 5% of the rounds failed to cycle properly. If the round fired, it extracted, ejected and fed. At this point is where the hiccups began. This rifle did not like Stingers; the longer case was a contributor to failure of the bolt to close. The best performance came with Scorpion and CCI MiniMag ammunition. The magazine is proprietary to Chiappa but the Black Dog Machine magazines worked perfect as well. The Chiappa magazine was a little more difficult to load and you had to get the technique down. If the back end of the rim of the cartridge did not all stagger, that would interrupt the shot column from rising and cause a stoppage. All three of the uppers tested experienced this failure for the bolt to close. One of the uppers only had it happen a few times. This could have well been a chamber issue. The chamber and bore were scrubbed and clean to insure there was no lead fouling.

The Chiappa receiver has the lowest MSRP and is not a bad unit to start off with. Chiappa has excellent customer service and were very helpful. Chiappa has some OEM contracts for these upper receivers. Finding the right ammunition is always the key to reliability. During testing, due to the sheer number of uppers tested there just was not enough time or ammunition to do any real ammo compatibility testing. Given more time and ammo this author is sure I could have found a winning ammo/rifle combination.

There are many options out there for the purchaser of a .22 conversion kit. Certainly some are better than others. Based on this testing, price is not always a determining factor for quality. Mostly yes, but not always. The DPMS is the perfect example, with a low $399 MSRP it outperformed some of the ones in the $600 range. Then again the top performer has an MSRP of $625. The testing showed clearly that the .22 Long Rifle caliber is just not as reliable as a center fire cartridge. When the rifle malfunctioned it took some time to determine if the problem was with the rifle or the ammunition. Mostly, it came down to the inconsistencies of the ammunition. Good magazines make a difference and for best reliability result leave a standard trigger group with a rounded hammer. During testing two match grade triggers were tested with the notched hammer and the rifle would malfunction. Also, you do not want to change out your hammer spring for a lighter one. This may cause issues with detonation on the hard rim of the cartridge case. Stay with high velocity ammunition. The best result from this testing showed CCI MiniMag, CCI Stinger, Scorpion, Federal American Eagle, Winchester M-22 and Remington Thunder Bolt. Every rifle can be a little different; you may find a round that works better in your particular rifle.

| This article first appeared in Small Arms Review V18N6 (December 2014) |