By Kevin Dockery

The M79 was not the final answer to using the new 40mm low velocity ammunition by the US military. Other avenues of research had been going forward since the first adoption of the M79 in 1960. The idea of an automatic weapon firing the 40mm family of grenades had been brought forward and examined by a number of civilian companies. The Honeywell Corporation first introduced the concept of a rapid fire grenade launcher to their designers in 1962. Honeywell had been heavily involved in the design of the fuzes for the 40mm grenades and the concept of a mechanical grenade launcher was proposed during an in-house meeting on fuzes.

Instead of developing a fully-automatic grenade launcher, the Honeywell engineers suggested that a mechanical repeater be done instead. Instead of trying to adapt a standard automatic weapons design to the characteristics of the 40mm grenade, a hand-cranked repeater would be much simpler to produce in a very short time. The idea was moved forward as an in-house development with no government contract pending. By 1965, the first launcher was ready for demonstration.

In place of a normal chamber, the new launcher had two rotors the length of the cartridge case. Each rotor had six semicircular grooves cut in its length, each half the circumference of a 40mm round. The two rotors were geared together so that a 40mm round would be held in a complete chamber made up from the two rotor halves. Since the chamber formed around the cartridge, the normal functions of chambering and extracting didn’t have to happen. This gave the Honeywell a very simple operating system with relatively few parts.

The two rotors were driven by a side-mounted crank handle, much the same as an old Gatling gun. The rotors were locked into place by a cam driven rod as the firing pin was cocked and dropped by another cam. Rotating the crank handle fired the Honeywell when the handle was at the top or bottom of a rotation, launching two grenades for each full revolution. Depending on how fast the operator turned the handle, the Honeywell would fire at rates of 1 to 250 rounds per minute.

Ammunition for the Honeywell was placed in a plastic belt, spaced out at proper intervals. The initial belts were nothing more than fiberglass-reinforced sticky tape, with the rounds stuck between two lengths of the tape. Spacing of the rounds in the tape belt was done with two tape clinching wheels (large gears) in a special loading machine. The tape belt gave a great deal of trouble when the weapon was introduced and were quickly replaced by a stronger system.

The new belts for the Honeywell were made of Mylar-backed Dacron fabric with pockets between heat-sealed sections of the belt. The fabric belts were supplied in 24 or 48 round lengths and could be reloaded about five times before they wouldn’t hold the 40mm round firmly enough. Old fabric belts sometimes were seen in Vietnamese and other hands being used as 40mm bandoleers.

The Honeywell was examined by the Navy in 1965 for possible adoption as a small boat weapon. Testing proved the system and the Honeywell received the nomenclature assignment of Gun, Rapid Fire, 40mm Mark 18 Mod 0 on 10 December 1965. Between 1965 and 1968, when production ceased, about 1,200 Mk 18 launchers were produced, almost all production going to the US Navy.

Though the Mk 18 could produce a good deal of firepower, it was considered a temporary, stopgap weapon until a self-powered design could be developed. There wasn’t a secure seal between the cartridge case and the barrel so propellant gases leaked out, limiting the muzzle velocity. Accuracy suffered as a result. Volume of fire was considered the Mark 18’s main advantage.

The Mk 18 was able to fire an entire belt of 48 rounds as fast as a man could turn the handle. By carefully sweeping the weapon back and forth, starting at the longest range (400 meters) and working back, a football-field sized area could be covered with one 48-round belt of ammunition. Properly done, all of the grenades would impact at roughly the same time due to the high lobbing arc of the 40mm grenade.

•SEAL TEAM ONE – COMMAND AND CONTROL HISTORY – 1967

The performance of the MK 18 Honeywell has proved unreliable. The quality control must have been lacking since the engineering of certain vital parts is sub-standard. At the present time the MK 18 is unsuitable for SEAL Team operations.

Further testing and development of the Mk 18 continued on a limited basis. The introduction of the Dacron fabric belts helped eliminate many of the earlier complaints about the weapon.

The SEALs used the Mk 18 primarily from PBRs and other river boats. The Mk 18 could be fitted to the standard .30 caliber machine gun tripod for ground use, but the weapon was difficult to operate in such a manner. The SEALs only used the ground mount tripod when introducing trainees to the Mk 18 for familiarization.

Probably one of the most unusual mounts for the Mk 18 was also its most common one. The Mark 46 Mod 0 gun mount would cradle an M2 HB .50 caliber machine gun on a tall, tripod-like Mk 16 stand. This mount was often seen at the stern of the Mk II PBRs as they patrolled the rivers of Southeast Asia. The Mk 46 mount would also hold a Mk 18, or later Mk 20, grenade launcher above the rear of the .50 caliber. A gunner could switch from the point fire of the .50 caliber to the area fire of the grenade launcher by simply changing which grips he held.

THE MARK 20

The Mk 18 grenade launcher was still a manually operated weapon and considered not completely satisfactory by the US Navy. In August 1966, the naval Ordnance Station in Louisville, Kentucky was ordered to develop a 40mm machine gun, capable of semi automatic and full automatic fire, as quickly as possible. Henry Watson, the Engineer in Charge, Colonel George Chinn, and William Schnatter attacked the problem of the new design vigorously. By May, 1967, only nine months later, the first three weapons of the new design were ready for testing.

On August 6, 1968, the new grenade launcher received the nomenclature assignment of Gun, Machine, 40MM (Grenade) Mark 20 Mod 0. The item description on the assignment request read;

This is a lightweight, automatic, low-velocity, reciprocating barrel-operated 40mm weapon. It is 31” long, 9” wide and 9” high and fires M381, M382, M387, M406, or M407 40mm grenades belted with the M16 metallic links, at a rate of 200 -250 rounds per minute in either full or semi-automatic modes. It was designed for pedestal mounting, however, because of its recoilless action, it is adaptable for multiple mounting systems such as tripods and bipods.

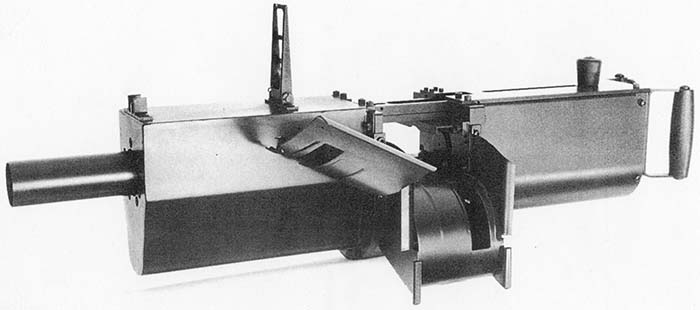

The Mk 20 has a sheet metal receiver over a framework that holds the operating parts, A set of twin spade grips are at the rear of the weapon with a push-button trigger that can be depressed with the thumb of the right hand. A sliding safety switch is to the left of the trigger button. The cycling of the weapon is so slow that the trigger button is just quickly released for semi-automatic fire.

The operation of the Mk 20 is a unique combination of blow-forward and recoil. To cock the weapon prior to firing or loading, the cocking knob at the top rear of the receiver is pushed forward. Pushing the cocking handle forward moves the barrel forward, extending it out from the front of the receiver, where it locks into place. When the trigger is pushed, the barrel slides back over the 40mm round in the feed tray. The rifling in the barrel presses back on the rotating band of the grenade, driving the round back onto the firing pin which sets off the propellant charge.

The force of the grenade going down the barrel drives the barrel forward against the barrel spring. A lug on the barrel engages a ratchet cam underneath the barrel that rotates the feed mechanism to move the ammunition belt forward one round. The bolt also recoils from the force of firing, moving against several springs. As the bolt reaches the end of its travel, it moves forward under the power of the bolt springs and a mechanical connections helps the barrel rotate the ratchet cam.

The balance of forces in firing the Mk 20 results in the weapon having very little felt recoil. Though designed to be fired from mounts, the Mk 20 can be hand-held and fired for short bursts with no real difficulty. Accepted by the Navy and in limited production by 1970, the Mk 20 replaced the Mk 18 grenade launchers still in service. The Mk 20 could be mounted on any standard pintle mount or piggyback above a .50 caliber machine gun on the Mk 46 mount. Some 1080 Mk 20 launchers were reported as being made before production was suspended in April 1971.

| This article first appeared in Small Arms Review V5N7 (April 2002) |