By Jason M. Wong

It’s said that Abraham Lincoln may have freed all men, but Sam Colt made them equal. Founded in 1836, the Colt name has long been associated with innovative and advance firearm designs. Colt Manufacturing (and later Colt Defense) first started producing the Stoner and Sullivan designed AR-15 in 1960. The basic foundation continues today as the M4 Carbine. Recently, individuals within the industry and in the press have been critical of the M4 Carbine as a legacy weapon, in need of modernization and improvement. Several representatives of Small Arms Review recently had an opportunity to discuss innovations and improvements to the AR-15 and M4 design with MG Jim Battaglini, (USMC, Retired), Chief Operating Officer; Mr. Jeff MacLeod, General Manager, and Mr. Kevin Brown, Vice President of Military Programs.

At the outset, MG Battaglini explained that despite recent tests conduced at the request of Congress, the U.S. military remains satisfied with the M4 carbine, and has not requested any major changes to the basic design. The M4 carbine performs as requested and meets current military needs. Nevertheless, Colt decided to take a proactive position and recently displayed nine new variants of the M4 carbine, demonstrating a mix of new designs and prior technology. Not all variants that were displayed will be produced. Rather, the variants are intended to demonstrate what features are available, should the U.S. military seek to upgrade the M4 carbine at a future date. Although the following upgrades have been built into specific models, MG Battaglini pointed out that all of the developments can be built into a complete system in response to the needs of the military.

The APC: Advanced Piston Carbine

Recently, it seems as though nearly every AR-15 manufacturer has introduced a piston-based recoil system to their catalog. While the benefits of a piston upper are numerous, not all manufacturers have executed a successful design. Is the APC just another piston carbine? Not at all. Outfitted with a 14.5 inch barrel, the APC weighs 6.2 pounds (empty), measures 33.5 inches in length with the stock collapsed, and features a piston recoil operating system.

Built with a monolithic upper receiver, the barrel is free floating for increased accuracy, despite the short barrel length. With nothing restraining the barrel, the barrel is free to flex during the firing sequence. Viewed under high speed photography, the barrel can be observed flexing in a wave pattern. When constrained by a gas tube or piston operating rod, the natural harmonics of the barrel are interrupted, resulting in decreased accuracy.

How did Colt respond to the issue? The APC features an articulating operating rod that flexes with the barrel during firing, rather than impeding the barrel or disturbing the rifle’s accuracy. The result: increased accuracy from a shortened weapon platform, with a stable rate of fire. Kevin Brown, Colt’s vice-president of Military Programs, pointed out that even after firing 18,000 rounds through the weapon, there was no significant increase in the rate of fire. With a traditional gas recoil system, barrel wear would result in an increased rate of fire, rapidly exceeding the original rate of fire specifications. As a testament to the effectiveness of the piston system, the rate of fire for the Advanced Piston Carbine was within 50 rounds per minute of the original specification after firing 18,000 rounds.

The AHC: Alternative Hybrid Carbine

Similar to the APC, the AHC is outfitted with a 14.5 inch barrel, weighs 6.2 pounds (empty), measures 33.5 inches in length (with the stock collapsed,) and features a piston recoil operating system. Unlike the APC, the AHC utilizes a mid-length, direct impingement, gas operated piston. Why did Colt develop two outwardly similar rifles with differing types of recoil systems? Recall that the purpose of the recent developments was to showcase and highlight the available technologies available. There are multiple methods of making an AR-15 or M4 operate effectively in semi and fully automatic mode. Rather than focusing on a single type of piston recoil system, Colt presented an alternative that allows drop in retro fitting to existing M4 carbines.

Designed as a short-stroke system, the mid-length piston is designed to eliminate accuracy issues inherent in the traditional full length piston design discussed above. As a short-stroke system, the piston is still reliant upon a short gas tube. Unlike the traditional gas recoil system, the mid-length piston system does not release combustion gas into the upper receiver of the weapon. Rather, the gas is released under the hand guard, and directed forward and away from the shooter.

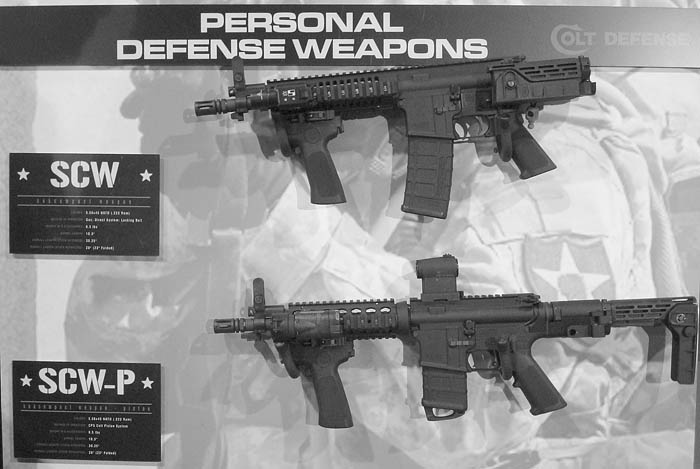

The SCW and SCW-P: Subcompact Weapon (Piston)

By outward appearances, the SCW harks back to the M231 Firing Port Weapon designed for use within the M2 Bradley Fighting Vehicle. Designed to be used from within the Bradley Fighting Vehicle, the M231 had a high rate of fire, was only capable of fully-automatic fire, was difficult to control, and was only intended for use from within the vehicle. Understandably, the M231 was not the most effective weapon, and added one more piece of equipment in the already confined space of an armored personnel carrier.

By all accounts, the SCW is a response to similar requirements. Designed as a personal defense weapon available as either a gas or piston operated system, the SCW can be used by soldiers to engage targets from within an armored vehicle. This is where the similarities between the SCW and M231 end. Outfitted with a 10.3-inch barrel and designed with a dual collapsible/folding stock, the weapon can be made extremely compact – just 23 inches in overall length with the stock fully collapsed.

In the event that the soldier is required to exit the vehicle to engage the enemy, the SCW stock can be extended to provide a stable firing platform that exceeds the capabilities of the M231 wire stock. Combined with a Lasermax front grip, the SCW is capable of engaging targets to 200 meters and beyond. Unlike the M231, the SCW is designed to be the soldier’s primary weapon – not a weapon to augment the M4 carbine. While the shortened maximum effective range may seem limiting when compared to the capabilities of an M4 carbine, bear in mind that the majority of military engagements take place within the 200 meter effective range of the SCW. Due to its small size, increased accuracy, and upgraded operating system, the SCW has potential to become a highly effective weapon for cavalry and mechanized infantry troops.

The ERC: Extended Range Carbines

Recent infantry doctrine has called for the inclusion of a designated marksman, allowing a designated infantry soldier the ability to engage targets beyond the limitations of the M4 carbine. Currently, the U.S. military trains soldiers and sailors to use the M4 at 300 meters. The M16 has a maximum effective range of 600 meters, while the M4 carbine is effective to 550 meters. Clearly, the platform is not being utilized to the fullest potential. Enter the ERC-16 and ERC-20. As an enhanced rifle system, the rifle uses either a 16-inch or 20-inch barrel that allows the designated marksman to engage targets to 600 meters. While outwardly similar to the legacy M4 systems, the EHC is a highly accurate platform that provides the user with the familiarity of the M-4 system.

Use of a .30 caliber rifle by the designated marksman presents several issues. Parts commonality and different ammunition can be problematic on the battle field. Engagement of targets is often within the 600 meters. More importantly, use of a different weapon immediately identifies the designated marksman as a valuable target. By using the same ammunition, using the same major parts, and using a similar weapon profile with the M4 system, the ERC is effectively integrated into an infantry platoon, while also providing the designated marksman a highly accurate weapon.

Relocation of the Charging Handle within the M4 System

The original AR-15 is an excellent design, as demonstrated by its longevity and ability to be modernized and updated as needed. One may recall that the original charging handle was located at the top of the upper receiver, and within the carrying handle of the weapon. In terms of marksmanship training, the original location of the charging handle allowed the shooter to maintain a good sight picture while reloading the weapon. The current AR-15 requires the shooter to break the sight picture and lift his head from the butt stock when operating the weapon’s charging handle. Recent developments and innovations may change the manner of operation for future iterations of the AR-15 design.

By utilizing a piston recoil system, the charging handle is no longer constrained to the traditional location on the upper receiver. By engaging the piston, the newly relocated charging handle is tasked with double duty. First, the handle is used to operate the bolt when charging and clearing the weapon. Designed with ambidextrous use in mind, the newly designed charging handle can be extended to the opposite side of the receiver, allowing for ambidextrous use of the charging handle. Second, the charging handle can now be used to engage the piston to push the bolt home into the chamber, augmenting or replacing the forward assist when trying to close the bolt.

By relocating the charging handle to the hand guard, the new design allows the ability to shoot with better technique, allows ambidextrous operation of the charging handle, and allows replacement (or elimination) of the traditional forward assist. In return, the shooter potentially loses the ability to use a small portion of the Picatinny rail. Is the exchange worthwhile? The exchange may be worthwhile, if the new design allows the shooter to more accurately engage the target. The U.S. military will ultimately decide whether the new system is worthwhile to implement. In the meantime, the new design is an excellent example of thinking outside of standard parameters to improve an otherwise proven product.

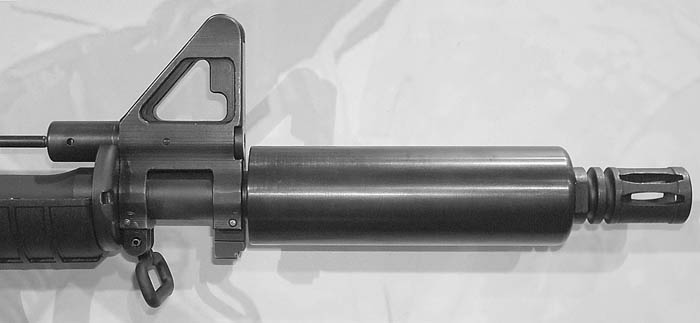

Other design innovations included the introduction of a built in suppressor, the elimination of the traditional dust cover, and self-lubricating internals. Only time will tell whether these innovations will prove effective, and whether they will be implemented into future designs of the M4 family.

As indicated earlier, the designs displayed by Colt were intended to demonstrate the combination of new designs and prior technology. Most of the variants will never be made as production models. MG Battaglini pointed out that the models were not designed for commercial, international, or law enforcement sales, nor are the models intended as a replacement for the M4. Rather, the models were built solely to demonstrate what technologies are available should the U.S. military decide to upgrade the existing specifications at a future date. Based upon the designs presented, it appears as though Colt is well equipped to modernize and update the M4 well into the 21st century.

| This article first appeared in Small Arms Review V12N9 (June 2009) |