On a cold, snow-covered day in January, 2010 we had the opportunity to go to the area of Liege in Belgium, to visit FN Herstal.

Our day started with an inspection of the workshops where we could observe the various operations of machining, cold hammering of barrels, surface treatment of and assembly of the various weapons produced by FN. The frames, breech and other major pieces of the elements entering in the composition of the various models are carried out on ultramodern machine tools with rigorous quality control throughout manufacture.

Barrels are produced by cold hammering except those for 12.7mm machine guns of and 40mm grenade launchers. Surface treatment is conducted in a shop on the ground floor to apply electrolysis, anodization, parkerizing and painting while the chemicals are stored in the basement in order to eliminate any risk of cross contamination from certain components. The routing of parts in the course of manufacture are in the same building and is carried out by means of robots, which simplifies handling. Final assembly and tests are performed by highly trained and skilled employees.

In Belgium, FN employs approximately 1,400 people. The Herstal group maintains privileged relations with its subsidiary companies and its partners that include:

- Browning Viana in Portugal (handguns, hunting rifles),

- FNM in South Carolina, small arms for the American market and Winchester guns),

- ATI in Salt Lake City (Utah), Browning Buck Mark pistols and rifles

- Miroku in Japan, hunting weapons

Ballistic testing and the production of the ammunition are carried out in Zutendaal, approximately 25 miles from Liege. After our morning tour of the factories in Liege we then travelled to Zutendaal, where after a lunch, we were able to test on the shooting range some weapons which are the best of the FN production.

F2000

Conceived in 1995, the F2000 project was presented in 2001. It is a modular Bull Pup compact rifle and is completely ambidextrous. The interchangeability of parts such as sights, various types of hand guards and a stock with a housing designed to hold batteries used to feed an optoelectronic device makes it a general-purpose gun.

The internal mechanical units are contained in a polymer frame. The pistol grip is located at the centre of gravity. The cocking handle is located on the left side and ejection of the empty cases is carried out forward. There is a flash hider at the end of the barrel. In front of the trigger guard is a neutral or specialized hand guard that can receive various accessories. The upper portion of the frame receives a sight or various optic sights. A folding door flap makes it possible for the user to inspect the chamber or bolt head. The frame is made of composite material while the barrel and the bolt are made of steel. This model is available in a black or sand finish.

The safety is part of the selector switch. This is presented, as on the P90, in the shape of an ambidextrous rotary button placed just below the trigger and turns from right t left as safety (S), single shot (1), or burst (A).

On the initial version, sighting is ensured by a 1.6x optic, installed on a Picatinny rail made out of polymer and has a cover to protect it. Other models are fitted with a Picatinny rail made of light alloy, being able to receive a reflex sight, night sight, laser, or a Fire Control Unit (FCU) combining an optic sighting, rangefinder and a device for programming the grenade trajectories.

The rifle uses a standardized STANAG 4179 magazine (M16 improved steel magazine). The gun works with a gas port with a two-position regulator. The bolt is locked by a rotating head.

The F2000 receives a bayonet with a simple edge Bowie blade with no ring nor cross piece and has a prismatic khaki polymer material handle. The F2000 can be fitted with many accessories:

- standard hand guard with light,

- hand guard with three Picatinny rails,

- hand guard with 40mm grenade launcher

Several countries have purchased the F2000 to equip whole or part of their armed forces that include: Saudi Arabia, Belgium, Cyprus, Mexico, Peru, Slovenia and Eastern Timor.

While we have had on many occasions the opportunity to handle the F2000 at many international exhibitions, the handling of this Bull Pup designed weapon does not surprise the French who have handled a similar design with the FAMAS though the Belgian weapon is lighter while being bulkier, in particular in thickness.

The selector, similar to that of the P 90, surprises a little, but its control remains quite visible and a simple touch makes it possible to judge its position. Low pressure on the trigger allows single shots even when the selector is in the burst position. Recoil is light and without vibrations. The weapon is particularly stable, with a rate of fire about 800 to 900 rpm and the ejection of cases is carried out forwards.

FN SCAR

The FN SCAR (Special Forces Combat Assault Rifle) project was developed at the request of the U.S. Army for the realization of a modular system of weapons. The result is two families of weapons (SCAR L in 5.56mm and SCAR H in 7.62mm). Work on the project began in 2001 and the first models were delivered during the second half of 2007 for an evaluation by troops (Special Forces, Rangers, Navy Seals, etc).

The organization of the rifle is conventional with a folding telescopic stock that can be adjusted in length with a 6-position telescopic device. The cheek rest is adjustable in height. The stock, lower frame and pistol grip are of polymer and the frame is of light alloy. The barrel and bolt are made of steel. The cocking handle is reversible and the ejection port is located on the right. The front part of the upper frame is equipped with four Picatinny rails. This model is available in a black or sand finish.

The safety is combined with the selector switch (safe, single shot and burst) and is ambidextrous with a rotation limited to 90 degrees. The weapon is equipped with a six position rear sight (100-600 m) and a protected front sight. Both are adjustable for elevations and windage and can be folded. Various optic or sighting devices can be installed on the upper Picatinny rail.

FN SCAR is gas operated with a short stroke piston. The gas port has two positions and one is used with a sound suppressor. The bolt is locked by a rotating head.

The gun can receive a 40mm FN 40 GL (U.S. MK 13 Mod. O) grenade launcher locked on the lower the Picatinny rail, without any contact with the barrel. Export versions developed by FN can receive a bayonet.

The FN SCAR was developed in two initial versions, each one of them is available with two barrels of various lengths that are easily interchangeable:

* FN SCAR L (light) or MK 16, 5.56x45mm, with 10 or 14.5 inch barrels,

* FN SCAR H (heavy) or MK 17, 7.62mm NATO, with 13, 16 or 20 inch barrels.

Several thousand were provided to the U.S. Army (USSOCOM). In France, 20 units were delivered to the Army Special Forces and the police. It has also been delivered to several other countries for evaluation.

The FN SCAR is light, well balanced and its collapsible stock is unlocked and locked easily to adjust the length according to needs. The weapon is also usable with the stock folded back. While the position of the ambidextrous selector is similar to that of the M16, it has a more reduced rotation. Barrels can be change by the user without it being necessary to call upon a gunsmith. The barrel is free-floating and the Picatinny rails are machined in the frame. Recoil is very light in the 5.56mm version. With the SCAR 7.62mm (which weighs only 300 grams (0.7 pound) more than the 5.56mm version), the recoil remains very moderate. The rate of fire is close to 600 rpm for both rifles. Additionally, there are no vibrations in the stock when the bolt recoils and there is little friction with moving parts.

MINIMI

The development of this machine gun began in the early 1970s in order to meet a new need created by the appearance of small bore assault rifles. After the adoption of 5.56×45 ammunition with bullet S 109 from FN (5.56mm NATO), the Minimi is a success with its performances being notably increased because of its ammunition.

Its manufacture, initially undertaken in Belgium, extended to other countries that include Australia, United States, Canada, South Korea, Italy, Greece, Taiwan and Japan.

The stock is fitted with a shoulder rest. The frame is of rectangular shape with the cocking lever on the right. The barrel can be easily replaced and is finished with a flash hider. The gas cylinder is located below. The moving parts are the piston, the bolt and its head. A folding bipod with telescopic legs is installed just behind the gas block. The stock, pistol grip and forend are made out of polymer. The frame and the heat shield are of sheet metal. The barrel, piston, bolt and its head, are of machined steel. The weapon receives a black finish.

The safety is ensured by a transverse push-button placed in top of the pistol grip, pushed from right to left, it allows shooting. It acts by blocking the trigger. There is no selector. The front sight, adjustable in height, is protected by a cover and the rear sight permits shooting from 200 1,200 meters. On the most recent versions, a Picatinny rail allows the assembly of an optic sight or any other device.

Feeding is possible by two means:

* Belt with metallic detachable links introduced of the left side. Their advance is ensured by a lever which moves a feeder. The belt can be placed in a box or bag.

* FNC or M16 magazines. No change is needed to use one or the other feeding methods because the bolt has two lugs to push the cartridges.

Since its appearance, this weapon has had many improvements. Now a Minimi MK 2 is manufactured, which has an ergonomic stock, a folding carrying handle, an optional hydraulic buffer installed, a stop for the cocking handle and the removal of the loading indicator.

Several models are available:

- MK 2, standard version without buffer

- MK 2 H, standard version with buffer (used in the United States as the MK 46)

- MK 2 Para, with short barrel, telescopic stock, without buffer

- MK 2 H Para, with short barrel, telescopic stock with buffer

Both models can receive a standard handguard or one with three rails.

Since 1980, the Minimi has been the subject of an adaptation in 7.62mm NATO. Initially received with little interest, the Minimi 7.62mm was adopted by U.S. SOCOM under the name of MK 48. This weapon takes the characteristics of Minimi MK 2 H and it is intended to bring to the soldier an increased firepower of short duration. Its practical range is approximately 800 m.

Other 7.62mm Minimi: variations are

- Standard version with fixed stock

- Para version with telescopic stock

- Three rail hand guard with fixed stock

- Three rails handguard with telescopic stock

- Both are fitted with a hydraulic buffer

The Minimi 5.56mm is light:, approximately 7 kg (approx. 15 lbs) with a 250-round cartridge bag. Although not having a selector, the flexibility of its trigger allows single shot shooting. Recoil is moderate and the shooting remains stable, even in standing position.

The Minimi 7.62mm is a little heavier, + 1 kg (2 lbs more) with a 100-round cartridge bag. The recoil, too, remains very reasonable regardless the position of the gunner.

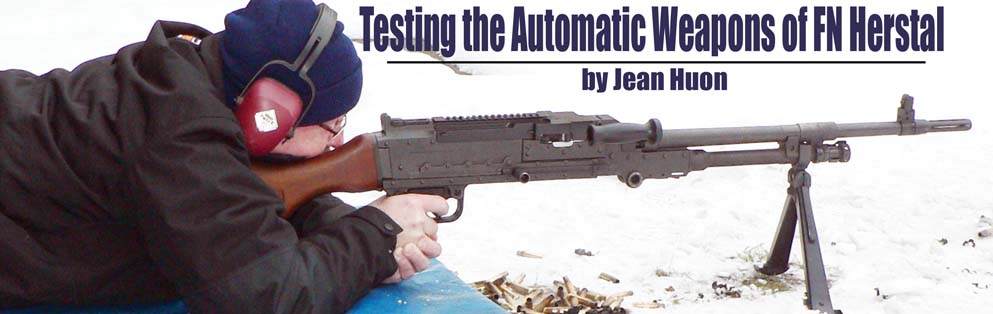

MAG 58

MAG = Mitrailleuse à Gaz (Gas Machine Gun) ou Mitrailleuse d’Appui Général (General Purpose Machinegun).

At the request of Sweden, the research department of FN, under the direction of Ernest Vervier (1908-1986), developed in 1957 a general-purpose, simple and robust weapon. This particularly powerful model machine gun is a world success with more than 230,000 guns beings manufactured. It is built in Belgium, but also made in Sweden, United Kingdom, Israel, Brazil, India, United States, Argentina, Canada, Australia and Egypt. In 1977, it replaced several machine guns in service in the American Army where it is designated as the M240.

The fixed stock contains a buffer. The frame is made of two steel plates riveted on spacers and contains the piston, bolt, lock and the recoil spring. Above the receiver is the feeding device and under it the pistol grip with trigger and sear. The cocking lever is on the right. The gas cylinder is under the barrel, its gas block has an adjustable valve making it possible to vary the rate of fire (3 positions + 1 maxi). The barrel can be easily replaced and it is fitted with a handle to carry the gun or replace the barrel.

The safety is ensured by a transverse push-button placed in top of the pistol grip, pushed from right to left, it allows shooting. It acts by blocking of the trigger. There is no selector.

Sights are:

- Front sight with ears, adjustable; rear eyepiece tangent sight with cursor on steps (200-800 m) U notch and leaf

(900-1,800 m) - Most recent models have a Picatinny rail on the cover of the feed mechanism

This gun works with gas action, locked bolt and the bolt is opened before shooting. Locking is ensured by a mobile lock that drops under the action of the piston and takes support on a central hardened steel locking point. The striker is interdependent of the piston.

The weapon uses a collapsible bipod. It can also be fitted on a tripod or various other devices on vehicles, tanks, boats or aircraft.

The MAG undoubtedly represents one of the best of the universal machine guns since World War II: not too heavy, accurate, handy and easy to use. The regulator ensures its good performance under the worst of conditions. In spite of its power, the recoil remains very moderate. The firing device does not have a selector but short bursts of two rounds are possible. Its stability when shooting is remarkable.

40mm Grenade Launcher

We tested the 40mm grenade launcher as installed on the 5.56mm FN SCAR. The assembly of this accessory is carried out quickly and without tools. The locking points are conceived in such manner that no stress is imposed on the barrel. Loading is carried out by spiral rotation, then by advance of the barrel. Moreover, it can swivel to the right or left side for easy loading of extra long ammunition.

The trigger, in the shape of a ring, is located beneath the rifle’s trigger guard. Its opening is sufficiently broad to allow the firing with gloves.

The recoil impulse is slightly higher than that of shooting a ball cartridge. Shooting is very accurate with a probable hit in a one meter square target at 100 meters. The model that we tested was equipped with lateral left sights as chosen by the Americans. We find it is not very practical because the head position does not permit comfortable and quick shooting. FN has developed for its other customers another sighting system and proposes their Fire System Control (FCS) combining an optic sight, rangefinder and a device for programming of the explosion of grenades according to their trajectory.

| This article first appeared in Small Arms Review V14N3 (December 2010) |