At SHOT Show 2004, a new black rifle was introduced that was not just a copy of the standard design that most of the industry produce. This black rifle would move the family of weapons into new uncharted territory. Karl Lewis, president of Lewis Machine & Tool (LMT) introduced the MRP, the monolithic rail platform.

The MRP is the first monolithic upper receiver. The upper receiver is machined from a single 7075 T6 aircraft aluminum forging. There are four solid Mil-Std 1913 rails and permit complete zero retention for optics or any other accessory placed on the rails. The upper receiver is equipped with a forward assist, fired cartridge case deflector as well as an ejection port dust cover. All rails are numbered for easy replacement of optics to insure they are placed back in the same position from which they were removed. Removable sling swivel mounts are placed on the end of the MRP at the 3, 6 and 12 o’clock positions. Additionally, mounting points are located on the right and left side at the rear of the handguard area by the ejection port. This permits any type of sling or desired location for the operator’s discretion.

The innovation does not stop with the development of the first one piece monolithic rail platform. The barrel, held in by two bolts, is removable by the user. When the bolts are removed the barrel/gas tube assembly is pulled straight out of the receiver. This enables the 5.56mm caliber weapon to be configured for whatever mission it will be used. If a close quarter combat environment is the mission, a 10.5 inch barrel may be used. If the mission is urban or normal combat ranges, a 14.5 or 16 inch barrel may be used. If longer range is required, an 18 or 20 inch barrel may be used. It should be noted the 16 inch 5.56mm barrel uses a mid-length gas system and all others use a standard carbine gas system. All is accomplished at the user level; no armorer is needed to change out the barrels. The barrels are manufactured from machine gun barrel steel and button cut rifling. They are cut with the Mil-Spec 1 turn in 7 inch twist allowing up to 80 grain projectiles to be stabilized. The barrels have chrome plated bore and chambers and are equipped with an A2-style compensator. With Lewis Machine & Tool being a U.S. government contractor for many different parts, they are familiar with what Mil-Spec means and what it takes to achieve it. All barrels manufactured by Lewis Machine & Tool are proof tested with a 70,000 psi proof cartridge and then magnetic particle inspected to insure the barrels are free of stress fractures. When the barrel is installed in the MRP, the barrel is completely free floating. This increases accuracy as well as the air holes in the MRP circulate air to aid in cooling. The removable barrels also enable another innovation: the MRP is a multi-caliber weapon as different caliber barrels can be used. Complete changing of the barrel is accomplished in less than 5 minutes.

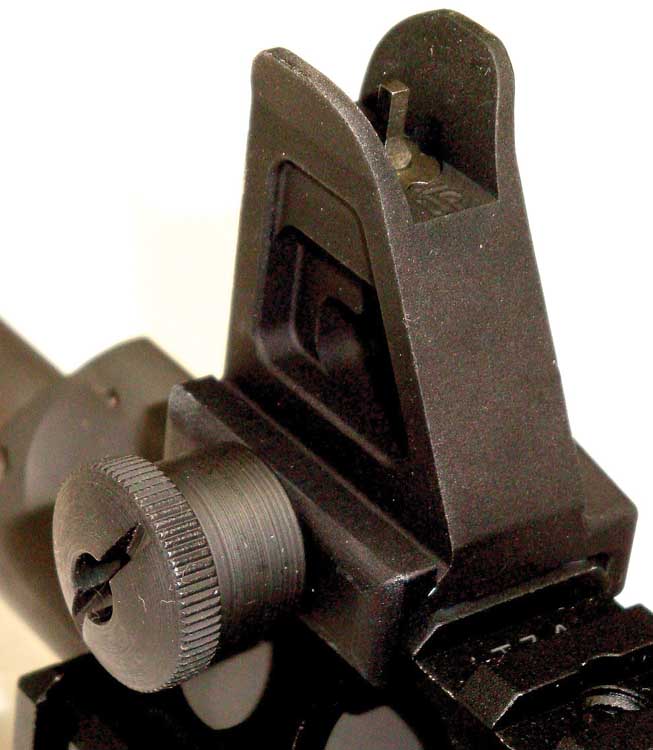

The MRP provided for this evaluation came with many enhancements that are all Karl Lewis. Starting with the sights, the rifle was provided with the LMT BUIS (Back Up Iron Sight). This is a fully adjustable rear sight that has been provided to the U.S. Navy and SOCCOM for the MK18 CQB 10.3 inch carbines. The sight is identical to that of the standard M16A2 or M4. The front sight is removable and held on by a nut. It has the traditional triangular shape and square front sight post. Of course, being a Mil-Std 1913 rail, any BUIS can be mounted.

The charging handle has an improved latch that is easier for one to grasp as it is made wider so it is easier to actuate.

The bolt and carrier are also a significant departure from the norm. When Lewis looked at the new design, he looked at the specific operating dynamics of the carbine and how different it is from the rifle. Given the different dynamics, Lewis designed the bolt and carrier to function with that in mind. To begin with, the bolt carrier has had several modifications. Due to the dynamics of the carbine, the bolt unlocks at a faster rate on a carbine length gas system than a full length rifle. Owing to this quicker action, there is still residual pressure in the cartridge case and it is still somewhat expanded when the rifle starts to extract making the extractor and extractor spring work that much harder to extract that cartridge case. It also causes extractor springs to wear quicker than that of the rifle. SOCOM has added rubber O-rings to increase the extractor force to cope with the wear issue. The standard GI M4 has a new and improved extractor spring (copper in color) that is designed specifically for the carbine to increase extractor force. Lewis also redesigned the geometry of the cam track by increasing the dwell time upon unlocking and thus permitting additional time for the residual pressure to drop allowing much easier cartridge extraction. He also added an additional gas relief port to get rid of unneeded gas.

The bolt was also redesigned with durability on mind using proprietary material that is significantly stronger than standard bolt material. Due to its hardness it is more expensive to procure and more expensive to machine than standard bolt steel. The geometry of the locking lugs has been modified as well. There are stress relief cuts that allow more flexing of the lugs to prevent breakage. The extractor has been redesigned as well. The improved “lobster tail” extractor uses two extractor springs instead of one that significantly enhances the reliability of the extractor in adverse conditions. The extractor claw is considerably more aggressive and stronger as well. Like the barrels and as per Mil-Spec, all LMT bolts are proof tested and them magnetic particle inspected.

The lower receiver has many enhancements as well. The stock is the LMT SOPMOD stock and is the stock assembly purchased by USSOCOM and the U.S. Navy for the M4A1 carbines and the MK18 CQB weapons. The stock is triangular in shape and very smooth. There are two removable sling mounting points on the stock as well as a cut-out for a standard GI silent sling. There are two battery compartments that are water resistant tubes placed inside of the stock and there is a removable rubber butt plate as well. The receiver extension is also designed by LMT and has six positions as opposed to the standard M4 which has 4 positions. The provided pistol grip is the Ergo Grip that is extremely comfortable and with the finger grooves is comfortable and makes the rifle stable in the shooting hand in adverse conditions. Also provided on the lower receiver is the Ergo Grip Gapper. This little spacer covers the gap in-between the front of the pistol grip and the trigger guard. LMT’s proprietary ambidextrous selector lever is also provided. This is not just good for left handed shooters but can be just as useful to right handed shooters as well given the tactical situation. Tangodown rail covers were provided on the rails.

The rifle was outfitted with the new EOTech XPS2-2 two dot reticle holographic sight. Extremely compact, this sight uses a single 123 battery and has a battery life is 500 to 600 hours. This sight only requires 2.75 inches of rail space. Along with the sight is the EOTech Generation II 3X magnifier. This comes with a Samson Quickflip tilting mount attached to an A.R.M.S. throw lever mount. When disengaged, the magnifier sits to the right side of the rifle: when engaged for long range shooting it flips back.

Also attached to the rifle was the Insight Tech M3X tactical light with pressure pad activation that was mounted in a Tangodown vertical foregrip. By just removing a spacer, the pressure pad sits in the grip. The grip also is hollow allowing for additional storage.

The magazines chosen for the rifle are the Magpul PMag, one of the finest magazines available anywhere in the world for the Black Rifle. This magazine is a significant reliability enhancement to any member of this family of weapons. The constant curve design allows the shot column to sit in its natural shape and increase feed reliability.

The ammunition for this test was provided by Silver State Armory (SSA). SSA is known for manufacturing some of the highest quality duty and match ammunition in the industry at competitive pricing. Silver State Armory just moved to a state-of-the-art facility in Packwood, Washington where they have a 100 meter underground range and the facility meets United States Department of Defense requirements to manufacture military contract ammunition. They manufacture their own brass. All SSA ammunition is loaded with custom blends of powder geared towards the specific loading. They offer several loadings in 5.56mm, 7.62mm NATO, 6.8SPC and .499 LWRC. They are also one of the only ammunition manufacturers in the United States to manufacture armor piercing rifle ammunition in 5.56mm, 7.62mm NATO and 6.8SPC.

More than 300 rounds of SSA 5.56mm 55gr FMJ rounds were fired through the MRP for function testing and no malfunctions were encountered. There were 200 rounds of SSA 5.56mm 77 grain OTM cartridges fired as well. Groups at 100 yards kept around 1.75 inch groups consistently with the FMJ rounds. All in all, this barrel has had more than 500 rounds through it and as it has broken in the groups had tightened up. First groups fired with the SSA 5.56mm 77 grain OTM were consistent at 1.75 inches. The last groups fired with this ammunition were printing consistently at 1 MOA.

LMT Piston Operated MRP

The industry has gone through a piston craze over the last few years. Although there is no statistical data proving the superiority of piston operation over direct impingement, there has been a market for piston operated weapons in the AR-platform. When asked why LMT began producing piston operated rifles, Karl Lewis simply said “customer demand.” Good enough of an answer.

The versatility of the MRP made it the ideal platform for the piston operated LMT offering. The piston is part of the barrel assembly. The gas block on the barrel has been altered to accept the end cap, piston, operating rod and spring. It is held together as an assembly so the assembly is inserted into the MRP and locked down with the two bolts. The one-piece bolt carrier was modified too for use with the piston. The impact area (key area) of the carrier is machined into the bolt carrier giving strength and durability to the carrier. All the gas relief ports have been eliminated. Skis have been added to the bottom of the rear of the carrier to prevent carrier tilt caused by the off-center movement caused by the impact of the operating rod on the bolt carrier. To remove the piston assembly from the barrel, depress the detent and rotate the end cap and pull outward. Now the operating rod and spring can be removed for maintenance. The piston operated system requires the use of the heavier H2 buffer (two tungsten weights and one steel weight). The MRP piston barrels are offered in both 5.56mm as well as 6.8mm Rem SPC.

Provided for testing was both the 16 inch as well as the 12 inch CQB barrel. More than 300 rounds of Silver State Armory 5.56mm 55gr FMJ ammunition was fired with no malfunctions. More than half of that was fired on fully automatic utilizing a Colt M4 lower receiver. Slightly more recoil and muzzle flip was noticed with the piston operated system

Converting the MRP to Fire 6.8mm Rem SPC

The absolute finest innovation of the MRP is its easy ability to convert to fire a different cartridge. LMT currently makes barrels in 5.56mm and 6.8mm Rem SPC. LMT has also tested calibers in 6.5 Grendal, 5.54x39mm and 7.62x39mm. Provided with the MRP test rifle was the barrel and bolt to convert the rifle to fire the 6.8mm Rem SPC cartridge. The 5.56mm barrel was unbolted and pulled out of the MRP and the 6.8mm barrel put in its place and the bolts torqued down to 140 inch pounds. The bolt was removed from the bolt carrier and replaced with an enhanced bolt chambered for the 6.8mm Rem SPC cartridge. LMT provided four Precision Reflex, Inc. 25-round magazines. Also provided by C Products were five of their steel 25-round magazines.

The first 300 rounds fired were SSA 110 grain Nosler Accu Bond cartridges. No malfunctions were encountered. With this ammunition, the groups at 100 yards remained at 1.25 inches off of a bench. For accuracy, the SSA 115 grain Sierra OTM Match rounds were used. Groups measured at a consistent 1 MOA. Recoil was noticeably more than the 5.56mm but not enough to mention firing on semiautomatic. SSA also manufactures an armor piercing round in 6.8mm Rem SPC. It consists of a pointed carbide core with a machined brass sabot offering an incredible barrier penetration. It penetrates with ease a 1/2-inch thick Mil-A-12560 class 1 armor plate out of a 16 inch barrel at 100 meters at a velocity of 2,800 feet per second.

In research into weapons chambered for the 6.8mm Rem SPC it was noticed there are two different chambers. They are referred to as the spec 1 and type 2 chambers. The spec 1 chamber is the one which has a SAAMI specification and has a .050 freebore. The spec 2 chamber has .100 freebore, which permits longer projectiles (better ballistic coefficient). Additionally, the longer freebore decreases pressure 4-5,000 psi. With a 115 grain projectile, a spec 1 chamber will give 2,425 feet per second and a spec 2 chamber will give a higher 2,575 feet per second. As of this writing a significant number of manufacturers are making their 6.8mm Rem SPC barrels with the spec 2 chamber; however, some remain with the SAAMI spec chamber. This is due to the standardization in chamber drawings. There is a rumor going around that a new chamber specification, which is the spec 2 chamber will be introduced to SAAMI as the 6.8x43mm. As of this writing, only Silver State Armory and one loading in Hornady TAP line is loaded to the spec 2 pressures. Silver State Armory loads both commercial and spec 2 loads. Before shooting spec 2 ammunition in your rifle, consult the rifle manufacturer to determine which chamber your rifle has.

The Lewis Machine and Tool MRP is truly in a category of its own and is the benchmark for the modularity of the M16/M4 weapon system: one receiver, multi-caliber barrels and available in both direct gas as well as piston operated. More caliber offerings are most certainly on the horizon. With all the barrel lengths and calibers offered, the MRP will do just about any job required of it. Whether it is a CQB environment with the 10.5 inch barrel or hunting medium game with the 6.8mm Rem SPC, this one size does fit all. Selective fire versions of the MRP are available to both law enforcement as well as military customers. With the proper tax stamp and compatible state laws, short barreled versions of the MRP can be had by the general shooting community. LMT has been a forerunner in new developments and innovation, which will bring the M16/M4 well into the new decade and beyond.

| This article first appeared in Small Arms Review V14N3 (December 2010) |