The Scorpion offers a lot of 9mm firepower in a small, lightweight package. With the removable receiver cap it would be a natural to turn into an SBR. It would then be as close to an original Scorpion EVO submachine as most shooters would be able to own.

By Chris A. Choat

The Czech Scorpion submachine gun started development in 1959. The first prototypes were built, minor changes made and then the little gun went into full production in 1961. It was designated the Samopal Vzor 1961 (submachine gun model 1961). The name was then shortened to simply the SA Vz.61 or Vz 61 or simply the Scorpion. The Vz 61 was originally chambered in 7.65×17 Browning, which is also known as the .32 ACP. This caliber was chosen as it was very popular in Europe at the time. The gun was intended for use by Czech special forces or non-infantry units and proved to be very popular with them because the diminutive .32 ACP cartridge was easy to silence. The gun uses a stamped steel receiver and fires from a closed bolt. The lower receiver is made from machined steel. It is magazine fed from either 10- or 20-round double stack, double feed magazines and ejects its empty brass straight up, out of an ejection port located in the top of the upper receiver. The Scorpion is select-fire and features a wire-steel, top-folding shoulder stock. With the stock folded the gun is a very compact 10.5 inches. The gun uses a telescoping bolt that keeps the overall length to a minimum. It also uses a rate reducing mechanism that slows the rate of fire to a very manageable 850 rounds per minute. In 1982 the Czech Army adopted the 9×18 Makarov cartridge and the Scorpion was redesigned to accept the more powerful, larger cartridge. It became the model SA Vz.82 and was also made in export models that were chambered in 9×17 Browning or .380 ACP. There were also some guns produced in 9×19 Luger or 9mm Parabellum. These last versions of the gun were produced starting in the early 1990s. The Scorpion submachine gun didn’t change much from the late 1950s until recently.

The Scorpion EVO III A1 submachine gun started production by the Czech gun manufacturer Ceska Zbrojovka Uhershy Brod (CZ-UB) in 2009. Prior to that, it was built in Slovakia and was called the Laugo submachine gun. In 2002 the gun rights were sold to CZ-UB and then was later re-designated the Scorpion EVO III. The gun was completely redesigned with a larger form factor and was made with the use of modern polymers and design technics. Being larger than the original gun the new Scorpion uses a simple straight blowback firing system. It still offers select-fire but now has a 3-round burst setting as well as semi and full-auto. The pistol grip/trigger mechanism, receiver and forearm are all made from polymer as is the side-folding, collapsible stock. The gun has a full-length top Picatinny rail with fully adjustable front and rear iron sights. With the full length rail any optic or combination of optic and night vision can be added. There are also side rails and a bottom rail mounted on the fore end. It is still fed from box magazines but now the mags are made from semi-translucent polymer and come in 10-, 20- and 30-round capacities. All fire controls are ambidextrous as is the charging handle that can be mounted on either the right or left hand side. Naturally where the Scorpion EVO III A1 is select-fire it’s available only to military, law enforcement and Class III dealers as a post-sample machine gun… until now.

CZ-USA is a subsidiary of CZ-UB and has been importing the CZ line of guns since 1998 to their facility in Kansas City, KS. There are several uniquely American CZ-USA products, notably their line of Safari Classic rifles as well as the 550 Tactical Rifles. These are built here in the USA at their Warsaw, Missouri plant. At the SHOT Show this year one of the new guns that drew the most interest was a semiautomatic pistol version of the CZ Scorpion subgun which is called the Scorpion EVO III S1; the “S” meaning semiautomatic. With the new gun being introduced in a pistol variant it still has the 7.8 inch barrel that the submachine gun uses. That’s the good news. The bad news is that to have a gun that looks just like the submachine gun you will have to register the pistol as an SBR (short barrel rifle) before you can add the stock. Now for more good news. CZ-USA has an arm brace adapter that allows the user to add a SIG type arm brace to the pistol giving it the look of the submachine gun. At the time that this article is being written AFT has just made a new ruling on arm braces. It basically says that you can own an arm brace, you can install an arm brace and you can even shoot a pistol with an arm brace installed; but if you shoot the pistol equipped with an arm brace, with the arm brace shouldered, then the whole unit becomes an SBR. If it is not registered as an SBR then you cannot shoulder it! Bureaucracy at its best. Just to be on the safe side you might want to register the Scorpion as an SBR then put on the adapter and install a collapsible buffer tube and stock and be done with it. CZ-USA says that they might be offering the original side folding, collapsible submachine gun stocks for the pistol if they can get the 922r restrictions sorted out and get ATF approval. For now just be glad we can get this pistol because it is quite a gun.

The Scorpion pistol has all the features of the submachine gun except for the select-fire mechanism. The pistol has an upper receiver that is made from polymer and is actually two halves that are bolted together with Allen head bolts. It has a full length Picatinny rail that runs across its top surface that is molded in. It also has two side rails and a bottom fore end rail that are also molded in. There are molded in loops on each side for a quick attach sling snap as well as a slotted one on the left side for a regular sling. Added to those are two metal “hard point” sling mounts right above the magazine well. The gun doesn’t lack for places to mount a sling of either the single point or dual point variety. The pistol comes with a detachable hand stop mounted at the front of the bottom rail to keep the shooter’s hand back away from the muzzle. This can be adjusted along the rail for the shooter’s preference. The pistol grip, which houses all of the fire control components, is also made from the same polymer. This grip assembly features a large pistol grip that should fit most shooter’s hands. The magazine well, which is also part of the grip assembly, features a large flare that guides the magazines into position very fast, every time. The magazines made for the Scorpion are first rate and are made from translucent polymer so that the shooter can tell at a glance how many rounds are remaining in them. They are available in 10-, 20- and 30-round capacities. They are the double column, double feed style and load fairly easily without the use of a magazine loading tool. The magazines have a removable baseplate and can be taken apart for cleaning.

The magazine release is located just in front of the trigger guard and releases the magazines with just a forward push. The release is ambidextrous and the empty magazines drop free when empty. The safety selector naturally has two positions, safe and fire, and the receiver has white and red pointer dots respectively. The bolt release is made from steel and is the only fire control that is not ambidextrous. It is released only on the left side of the gun but can easily be reached by either right or left handers. The charging handle on the test gun was set up on the left hand side of the upper receiver but can easily be changed to the right hand side as desired by the shooter.

At the rear of the receiver is a cap that covers the back dovetailed mount for a buttstock. It also has a sling attachment point and is made from machined steel. It can be easily removed by using a punch to depress a spring loaded button at the rear of the receiver – then it just slides up and off. The rear dovetail is where the SIG type arm brace is installed or maybe, at a future date, a stock assembly. The author was sent an arm brace adapter with the test gun and installing the arm brace was quick and easy and stabilized the gun dramatically. If you decide that you don’t want to have to wait for a ruling on the original side-folding collapsible stock, the arm brace adapter accepts any AR style buffer tube that will then accept any AR type stock after you get your approved SBR paperwork.

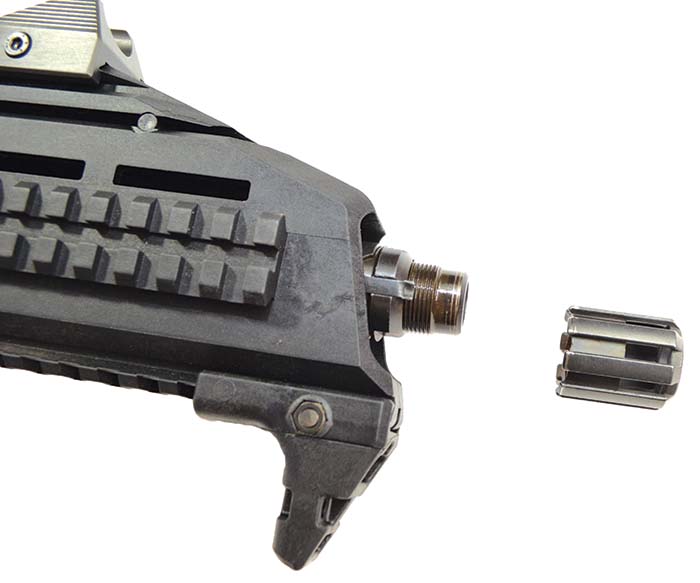

Even though the pistol is made mostly of a fiber-reinforced polymer it has a very robust feel to it. It weighs in at 5 pounds and is 16 inches overall. The 7.8 inch barrel is cold hammer forged and is threaded. The threads are metric 18×1 right hand. The barrel is capped with a flash hider and has a spring loaded detent to keep it in place instead of a lock or crush washer.

While 18 X 1 is not a common American 9mm thread pattern, Thompson Machine is already offering thread adapters to fit so that you can install a suppressor on the new pistol. They sent this author one of their adapters and it was installed in one of their ISIS 2 suppressors and installed on the gun. The Scorpion is a natural for use with a suppressor. The sheer mass and weight of the bolt combine to hold the bolt closed slightly longer than normal 9mm firearms. Using subsonic 9mm ammunition the Scorpion is extremely quiet.

At the range the new pistol was test fired using a two handed conventional style hold (two hands on the pistol grip), then with a two handed carbine style hold (one hand on the pistol grip and one hand on the forearm) and then two handed with an arm brace installed. As each style of hold was used the pistol’s accuracy increased. By far the most accurate way to hold this gun is with an arm brace installed. The shooters also incorporated a single point sling attached to the rear of the receiver and pushed the pistol forward, putting tension against the sling. With this shooting style the pistol shot like a mini carbine making hits on an 8 inch steel plate at 100 yards a matter of routine. So if you don’t want the hassles of an arm brace this is the next best thing. The pistol comes with a very nice set of steel sights already mounted on the Picatinny rail. The front sight is the standard AR platform style round post that is adjustable for elevation. The rear sight is also made like an AR-15 style sight but is only adjustable for windage. Like the AR style sight the rear has round peep type apertures but instead of only 2 it has 4 and they can be rotated either forward or rearward to the size or distance the shooters prefers. Both front and rear sights can be adjusted with the sight adjustment key that comes with the gun. The sights as they came set from the factory proved to be dead on.

Shooting the gun was a pleasure with recoil being almost non-existent. The trigger is just what you would expect in this type of gun. It has about 1/4 inch of take-up before hitting resistance but then broke cleanly. The trigger pull was right at 7 pounds measured with a Lyman Digital Trigger Pull Gauge but feels lighter when actually shooting it. The trigger has a grooved face for positive finger placement.

300 rounds were used the first time out with absolutely no issues with full metal jacketed loads with bullet weights from 115 grains to 147 grain subsonic. Several defense hollow point loads were also fired and, again, with no feed, function or ejection problems. The gun just ran magazine after magazine shooting any ammunition that it was fed. We fired the gun with the original iron sights first then an Aimpoint Micro T-1 was installed. The T-1 co-witnesses with the iron sights in its bottom 1/3rd. With the Aimpoint installed and the gun fired from a rest at 50 feet, the Scorpion would cut half dollar sized holes with entire 30-round magazines.

The polymer magazines proved to be well made and highly reliable and though very lightweight, they were very robust. They were ejected both empty as well as fully loaded out of the gun onto the dirt with no sign of breakage or rounds popping out. The magazine release on the pistol is ambidextrous with release grooved pads on both sides of the front of the trigger guard. They can be easily and quickly released by either the shooter’s trigger finger or with the thumb of your off hand. We never had to pull a magazine out – they always dropped free. The bolt release is located on the gun’s left hand side just above the rear of the magazine release where it can be quickly hit by the shooter’s off-hand thumb putting the gun back into action after a magazine change.

The safety on the pistol can be easily reached with the grip hand’s thumb or even with the trigger finger. It rotates about 45 degrees downward from safe to fire. The end of the safety switch protrudes out a fair amount from the gun. While it is rounded and doesn’t catch on your gear, one thing that all the shooters noticed was that it tends to bite into the hand if you shoot with your grip hand situated up at the top of the grip. It doesn’t sound like a big thing but, nevertheless, CZ is saying that they will probably be offering a non-ambidextrous safety/selector for it in the future.

The gun ships from the factory with two 20-round magazines. We were able to get 2 of the new 30-round magazines to try out as well. The forecasted retail on the 30-round magazines is supposed to be under $20. They work every bit as well as the 20-rounders though they get too hard to load after about 25 rounds. Here a loader, like the one from Maglula, would make the chore much easier. For people who live in high capacity magazine restrictive states the guns will ship with two 10-round magazines instead. At the time of this writing the only other accessories that are available for the gun is a shoulder sling, a double magazine pouch and a backpack style carrying case. As time goes on this author expects there will be a great many factory and third party accessories available for the new Scorpion as this should become a very popular gun. Not only is the gun totally reliable it is good looking, very accurate and with a retail price of just $849 it is one of the best buys in the firearms world today.

CZ-USA

P.O. Box 171073

Kansas City, KS 66117-0037

(913) 321-1811

www.cz-usa.com

Thompson Machine

172 Center Street

Panacea, FL 32346

(850) 408-5161

www.thompsonmachine.net

| This article first appeared in Small Arms Review V19N6 (July 2015) |